Foam apparatus for use with roll-over and/or automatic type car wash

a roll-over and/or automatic type technology, applied in the direction of cleaning using liquids, coatings, constructions, etc., can solve the problems of difficult to rinse off type foam waxes from the vehicle, and difficult to provide adequate wax coats, etc., to achieve the effect of maximum solution coverage over the vehicle and easy visual inspection of the solution coverag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

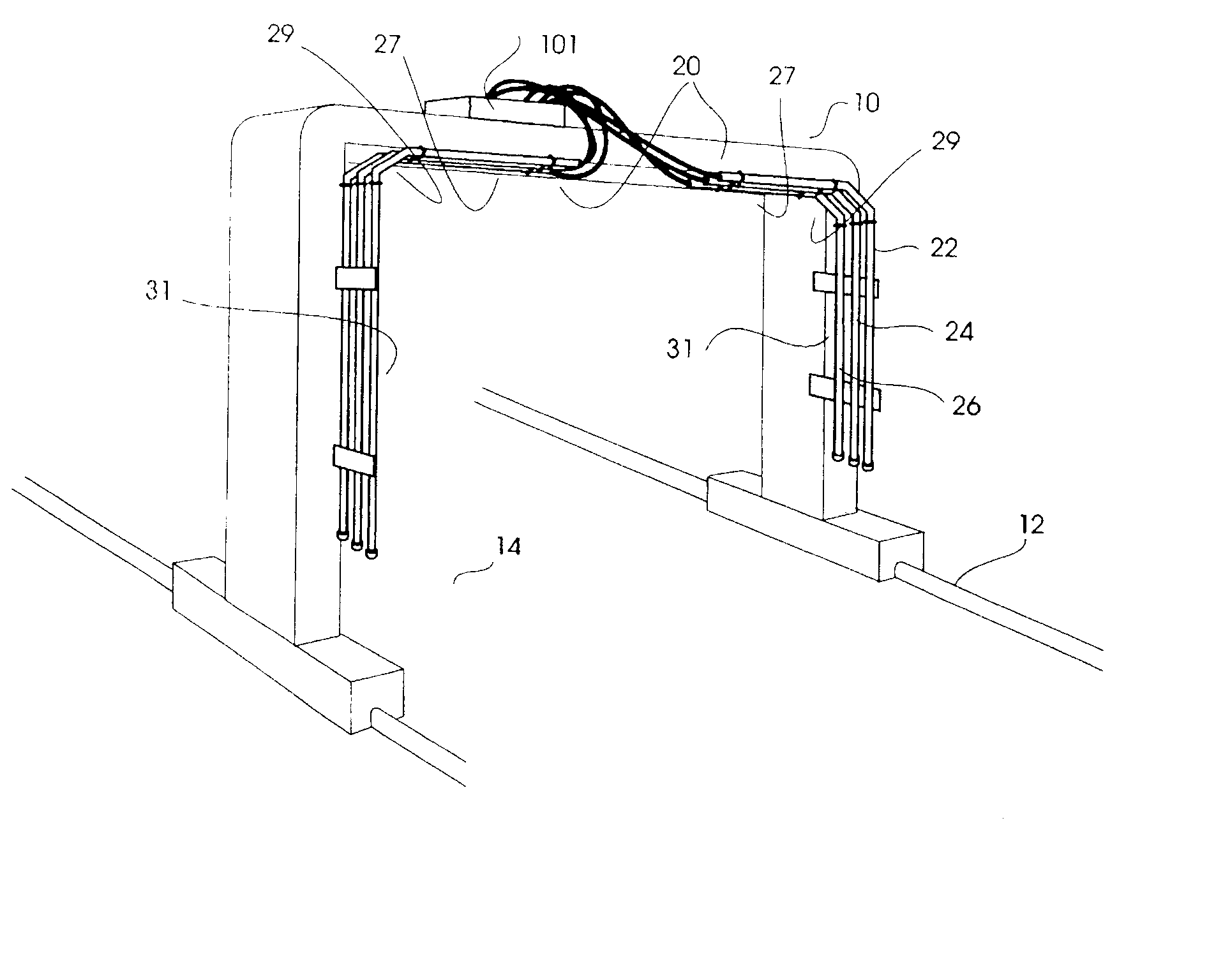

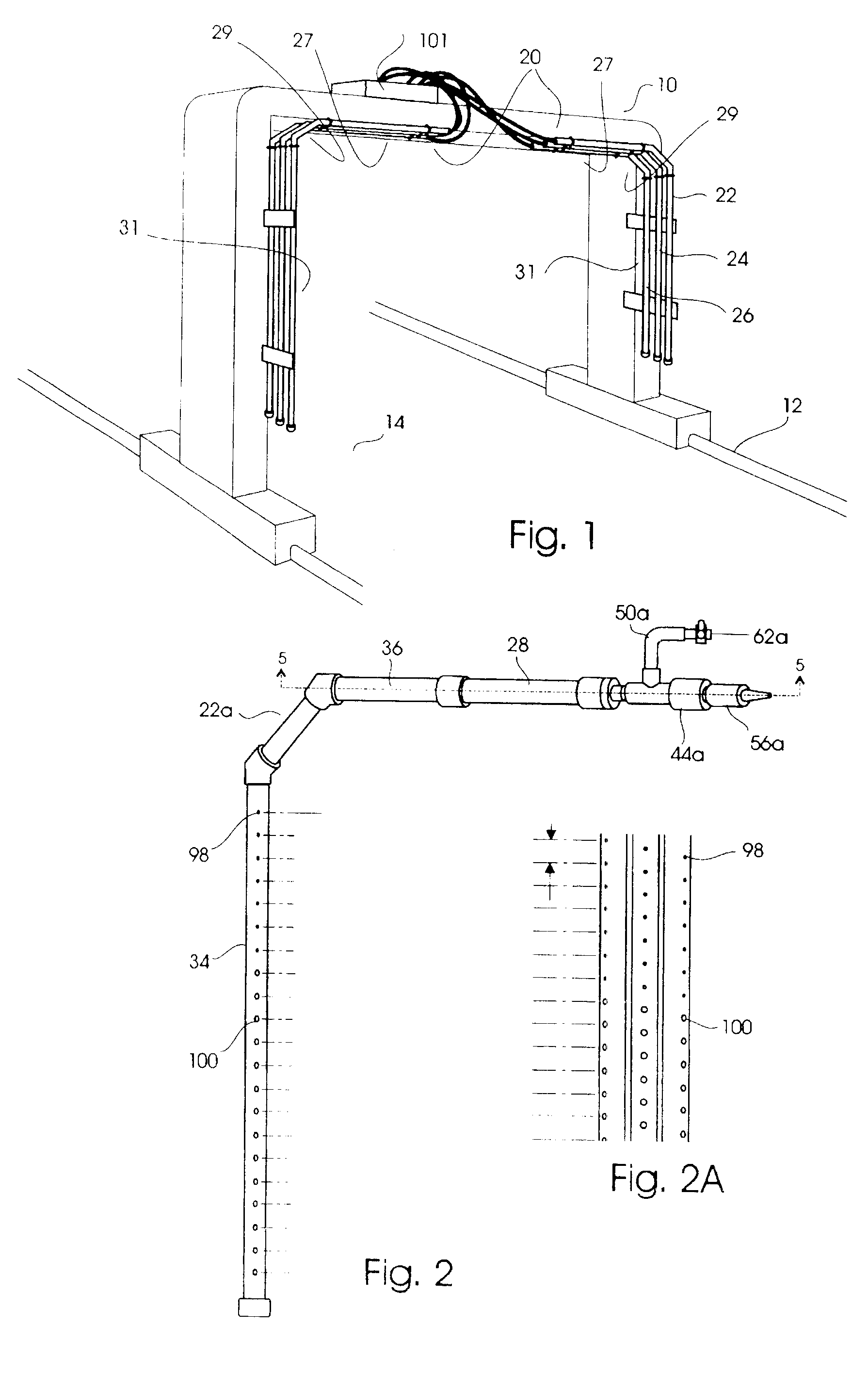

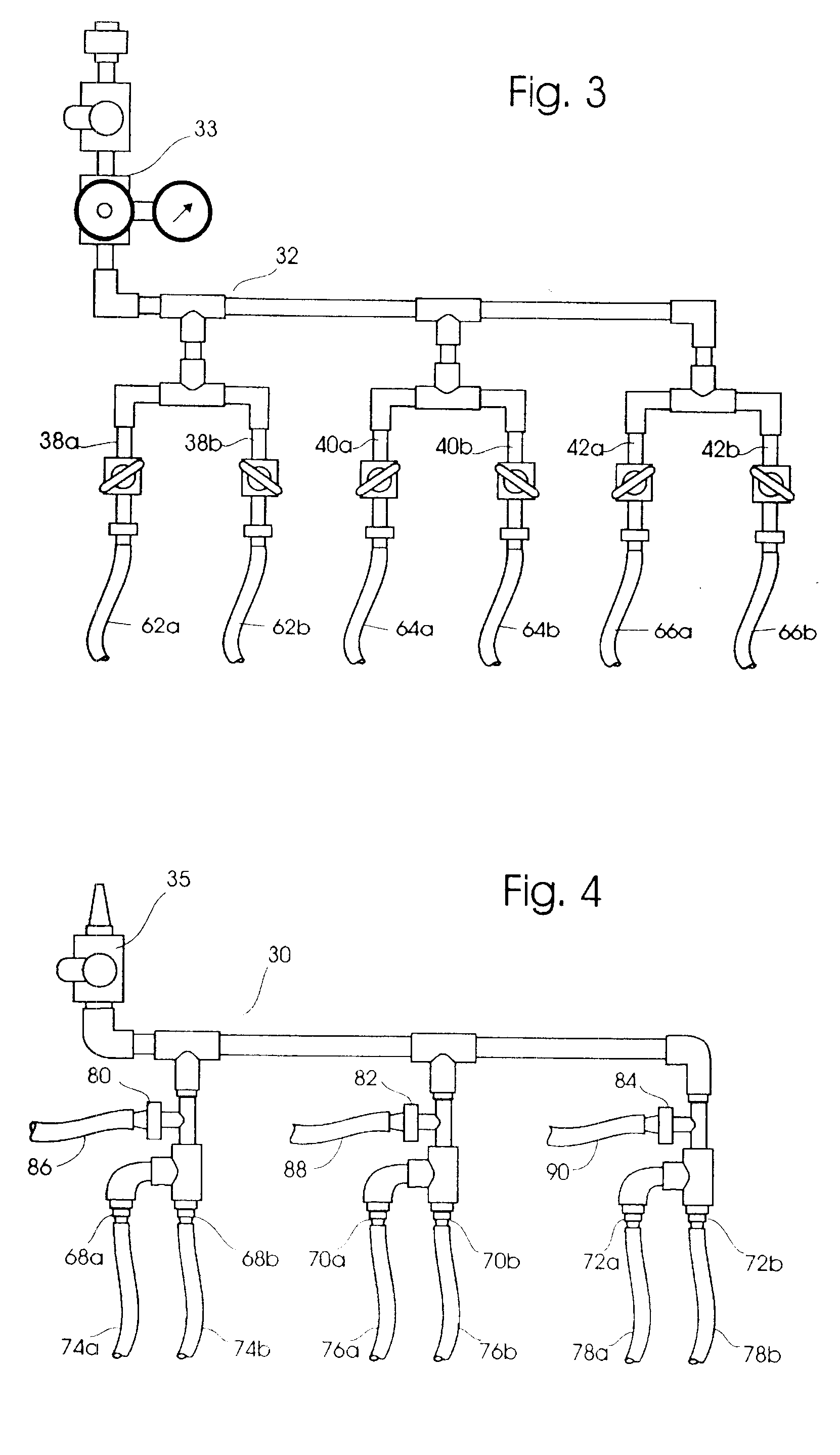

Referring to the drawings, a roll-over type car wash is generally designated by the numeral 10, having the manifold apparatus 20 of the present invention connected thereto. As can be seen, the manifold 20 is readily adaptable to the roll-over type car wash 10 which would include framework known in the art, as disclosed in U.S. Pat. No. 5,076,304, for example, such as a generally inverted U-shaped frame member having liquid dispensing means disposed on said U-shaped frame member and means pivotally mounting the liquid dispensing means for movement about the vehicle to permit dispensing liquid toward an exterior surface of the vehicle, motive means for reciprocally moving the U-shaped frame member along a path adjacent the vehicle along a pair of a parallel rails 12 mounted on the floor 14 of a vehicle wash location, and would include detection means for sensing the front end of the vehicle for measuring length of the vehicle, and sensing the rear end of the vehicle such that the moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com