Improvements in and relating to pipe coupling

A technology for pipe joints and pipes, applied in the direction of pipe/pipe joint/pipe fitting, pipe element, sleeve/socket connection, etc., can solve the problems of health and safety, negative environmental impact, poor assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

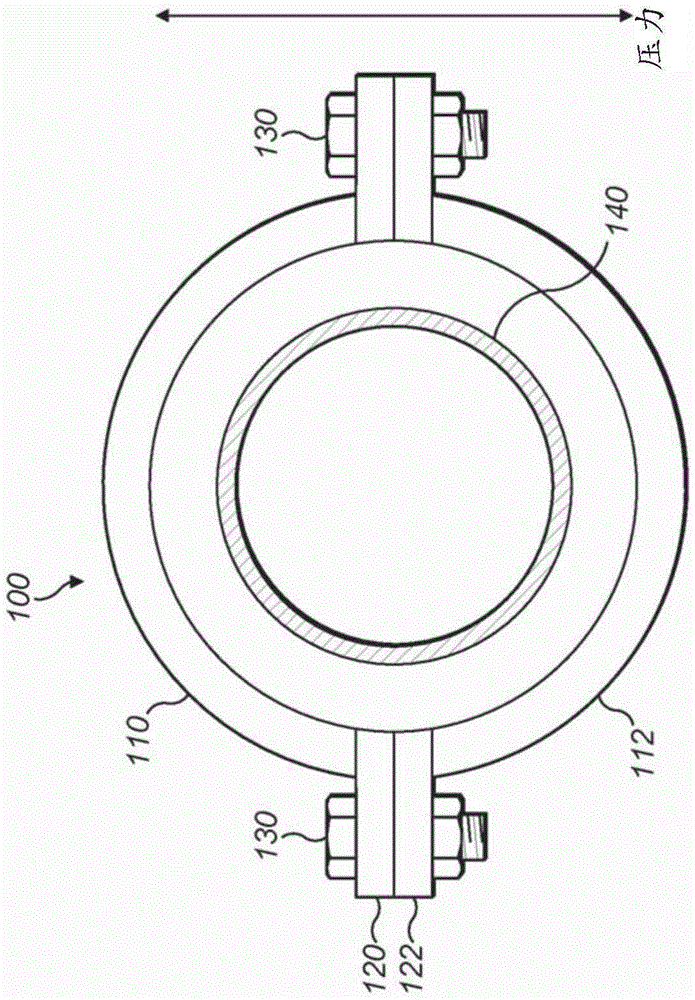

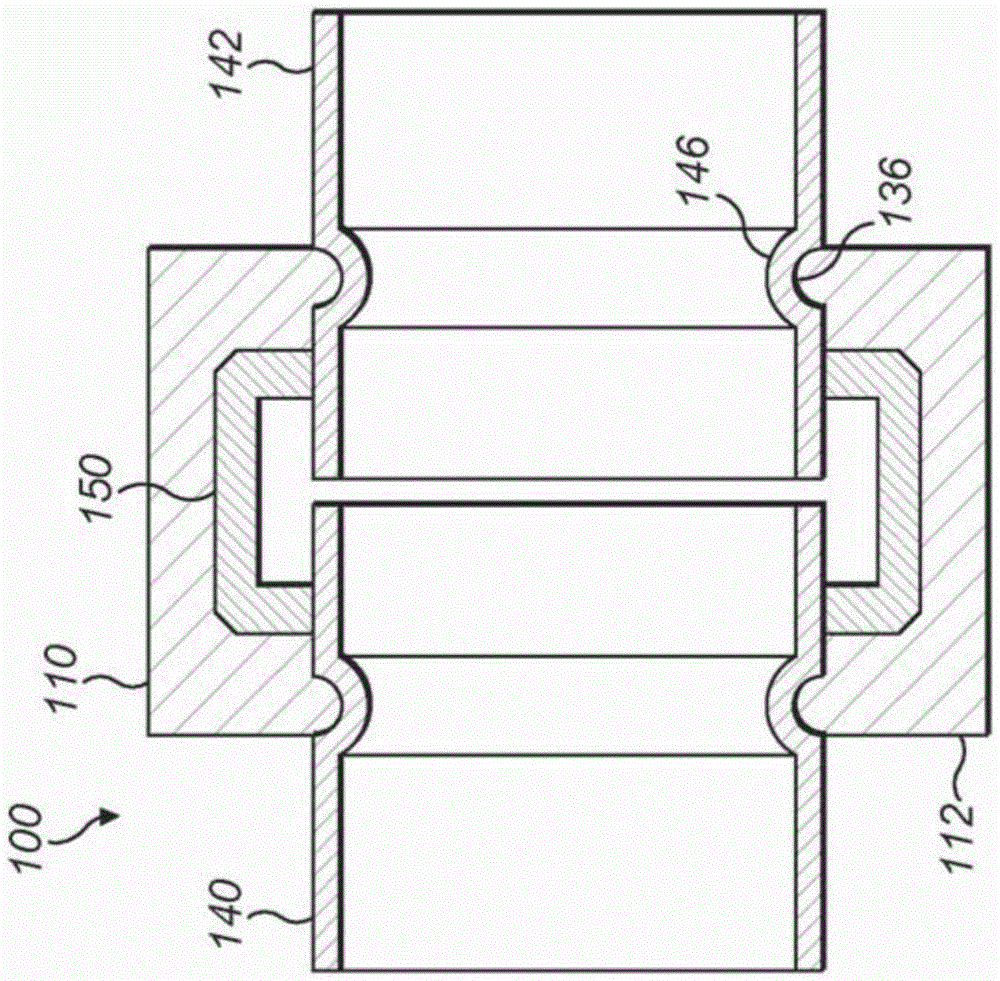

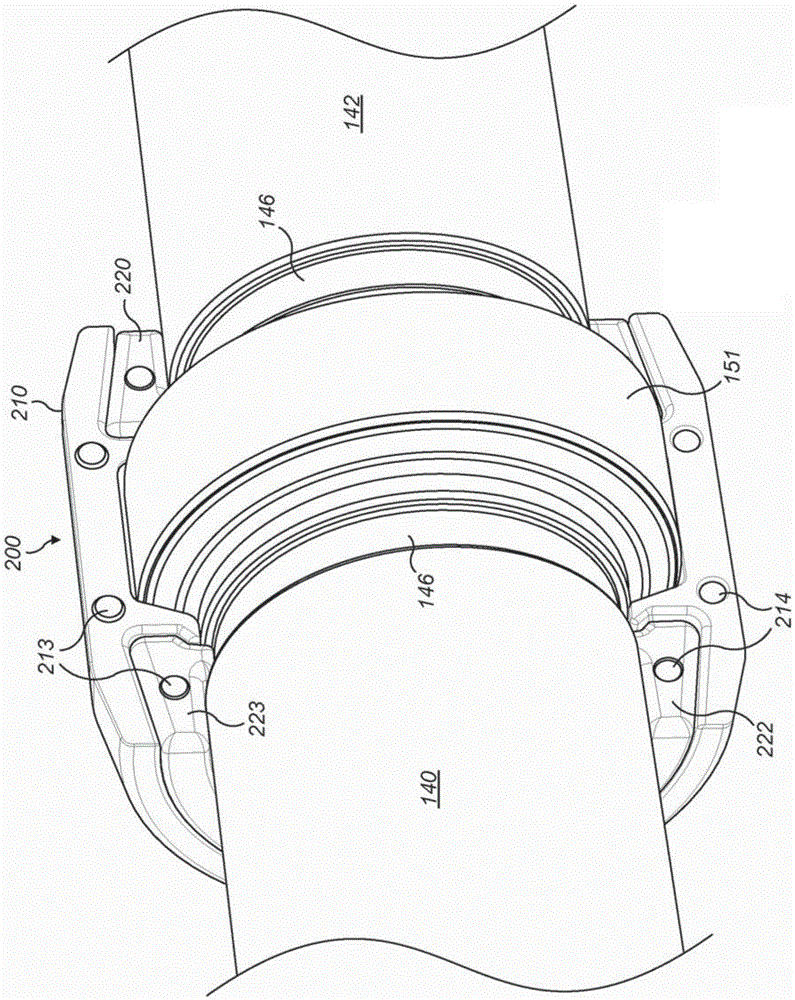

[0038] image 3 The first and second conduits 140, 142 are shown of the type having an annular groove 146 positioned in their outer surface near one end. An annular gasket 151 is provided which creates a fluid-tight seal between the respective ends of the tubes. exist Figure 4 The form of the gasket 151 is seen more clearly in , which shows a section through it. The gasket has a generally T-shaped cross-section, with a central 'upright' portion 152 arranged to be positioned between the ends of each duct 140,142. The 'horizontal' portions 153 of the T-shape terminate in sections arranged to contact the exterior of the pipe and provide a snug fit around the outer circumference of the end portion of the pipe.

[0039] The gasket is made of an elastic sealing material and may for example be molded from natural or synthetic rubber. Other materials from which this gasket can be manufactured include: Ethylene Propylene Diene Monomer (EPDM) (typically used when the fluid being con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com