Multi-part cast turbine engine component having an internal cooling channel and method of forming a multi-part cast turbine engine component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

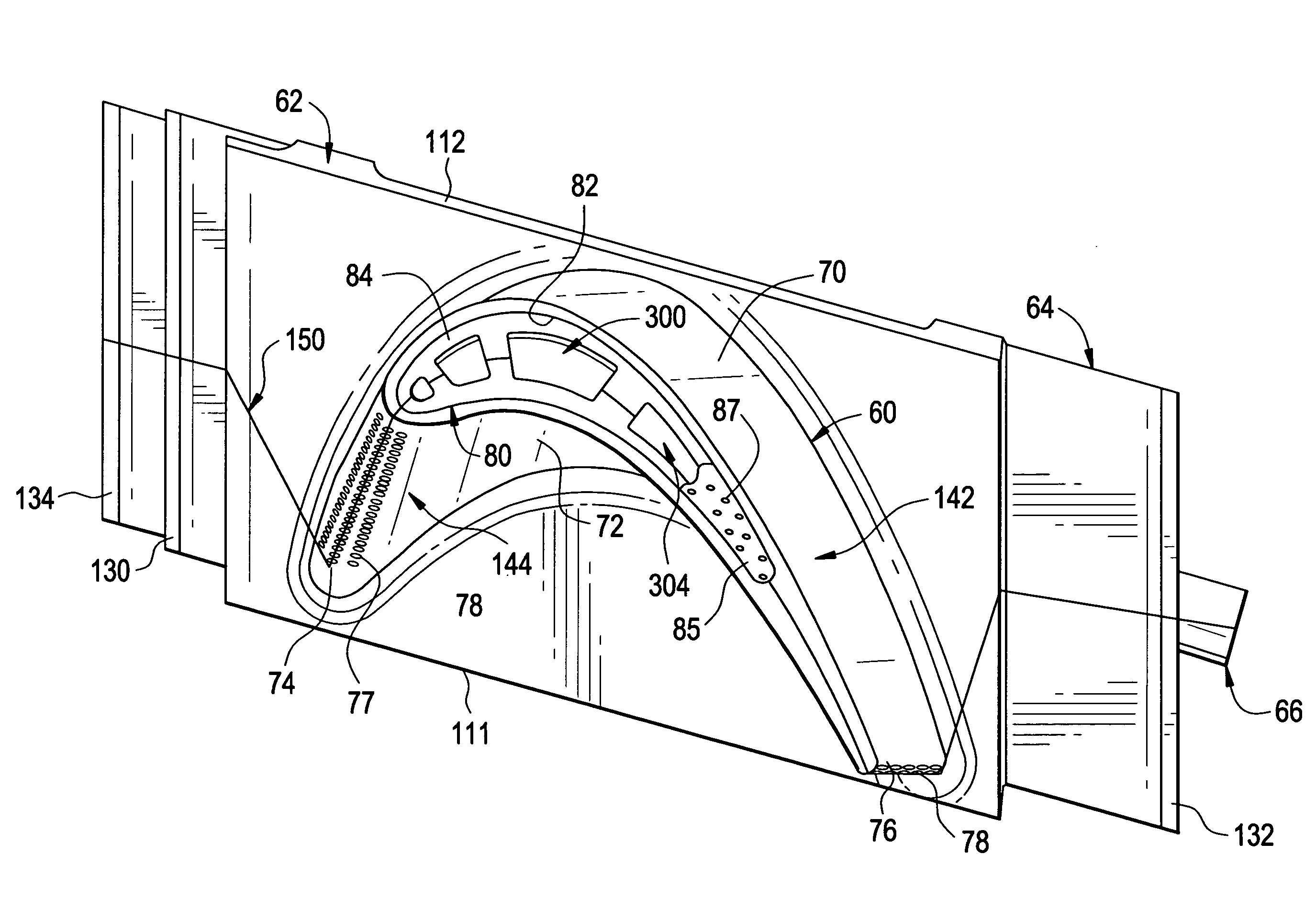

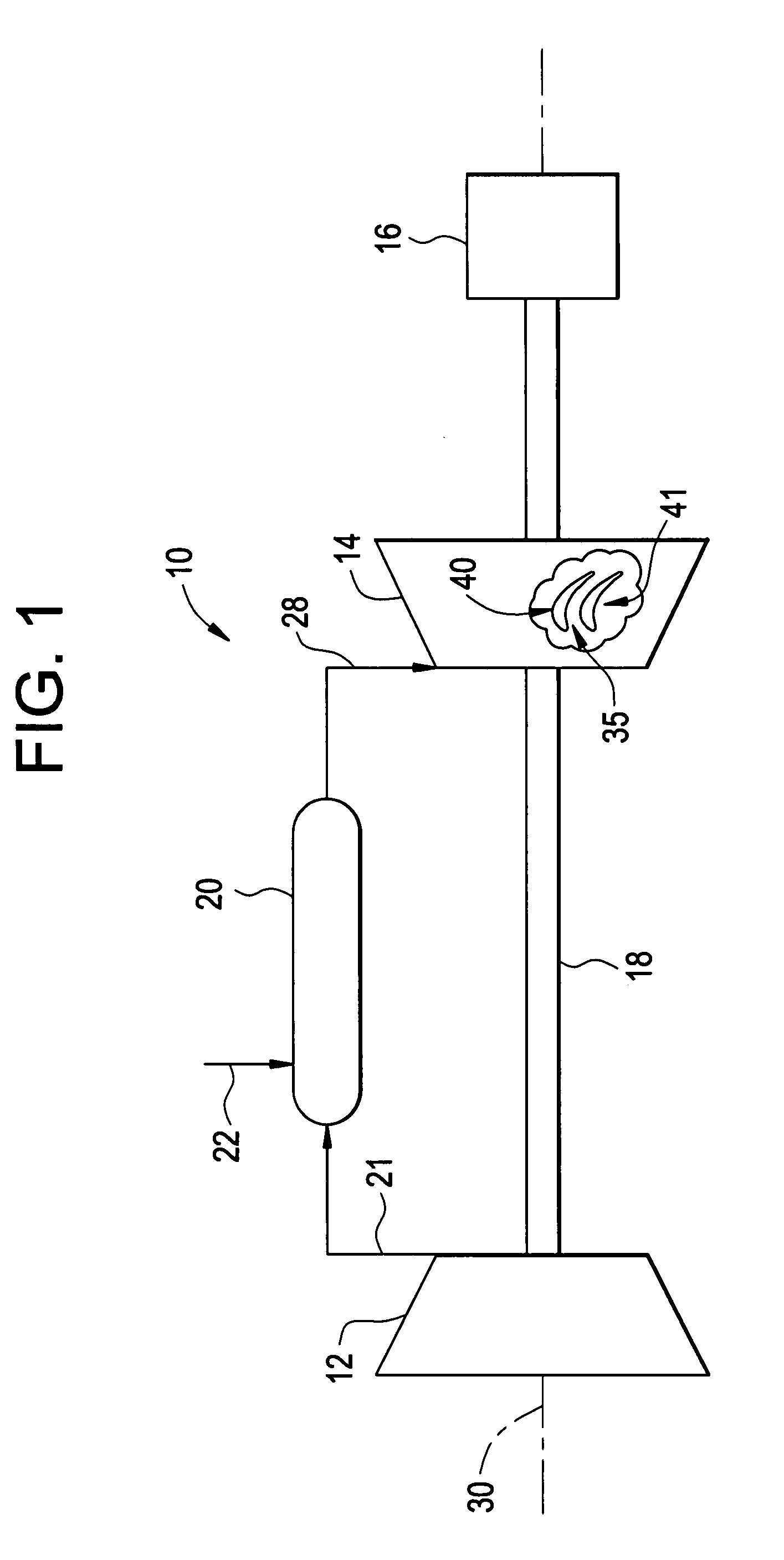

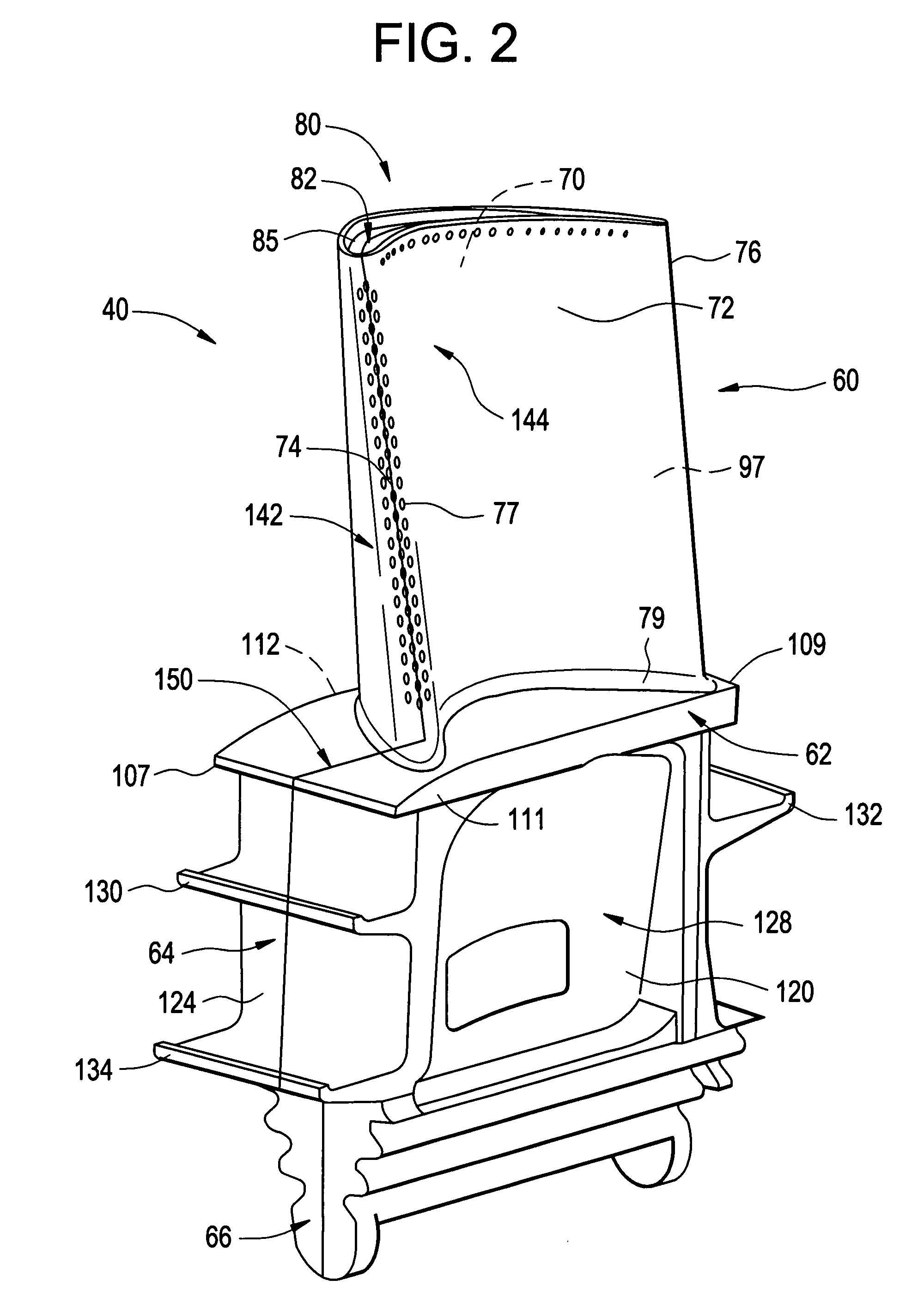

[0011]With initial reference to FIG. 1, a gas turbine engine constructed in accordance with the present invention is generally indicated at 10. Turbine engine 10 includes a compressor 12 operatively coupled to a turbine 14 and an electrical generator16 via a shaft 18. Shaft 18 is illustrated as a single, monolithic component, however, it should be readily understood that shaft 18 could also be formed in multiple segments with each segment being coupled to an adjacent engine component.

[0012]In any event, engine 10 is further shown to include a combustor 20 in which air 21 from compressor 12 and a fuel 22 are mixed to form a combustible mixture. The combustible mixture is ignited to form a high pressure, high temperature combustion product or gas 28 that is used to drive turbine 14. More specifically, high pressure, high temperature gas 28 enters into turbine 14 and impinges upon a rotor assembly 35 having a plurality of rotor blades, two of which are indicated at 40 and 41. Rotor ass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com