Anticorrosive coating composition

A technology for anti-corrosion coatings and compositions, applied in the directions of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of utilization limitation, difficulty in distinguishing the thickness of the coating film, lack of flexibility of the coating film, etc., and achieve excellent flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation method of coating composition and coating method

The anti-corrosion coating composition of the present invention can mix components such as described epoxy resin (A), amine curing agent (B), coumarone resin (C) containing hydroxyl group and other solvents by conventional methods while preparing. Generally, the form of a two-component coating is used. The two-component coating is composed of a main agent comprising an epoxy resin (A) and a hydroxyl-containing coumarone resin (C), and a curing agent comprising an amine curing agent (B). It is composed of different agents. After preparing the main agent and curing agent separately, they are mixed and used when used.

[0030] The anticorrosion coating composition of this invention contains 1-500 weight part of hydroxyl-containing coumarone resins (C) with respect to 100 weight part of epoxy resins (A), Preferably it contains 20-200 weight part. From the viewpoint of having excellent coating film strength, c...

Embodiment 1~2、 comparative example 1~5

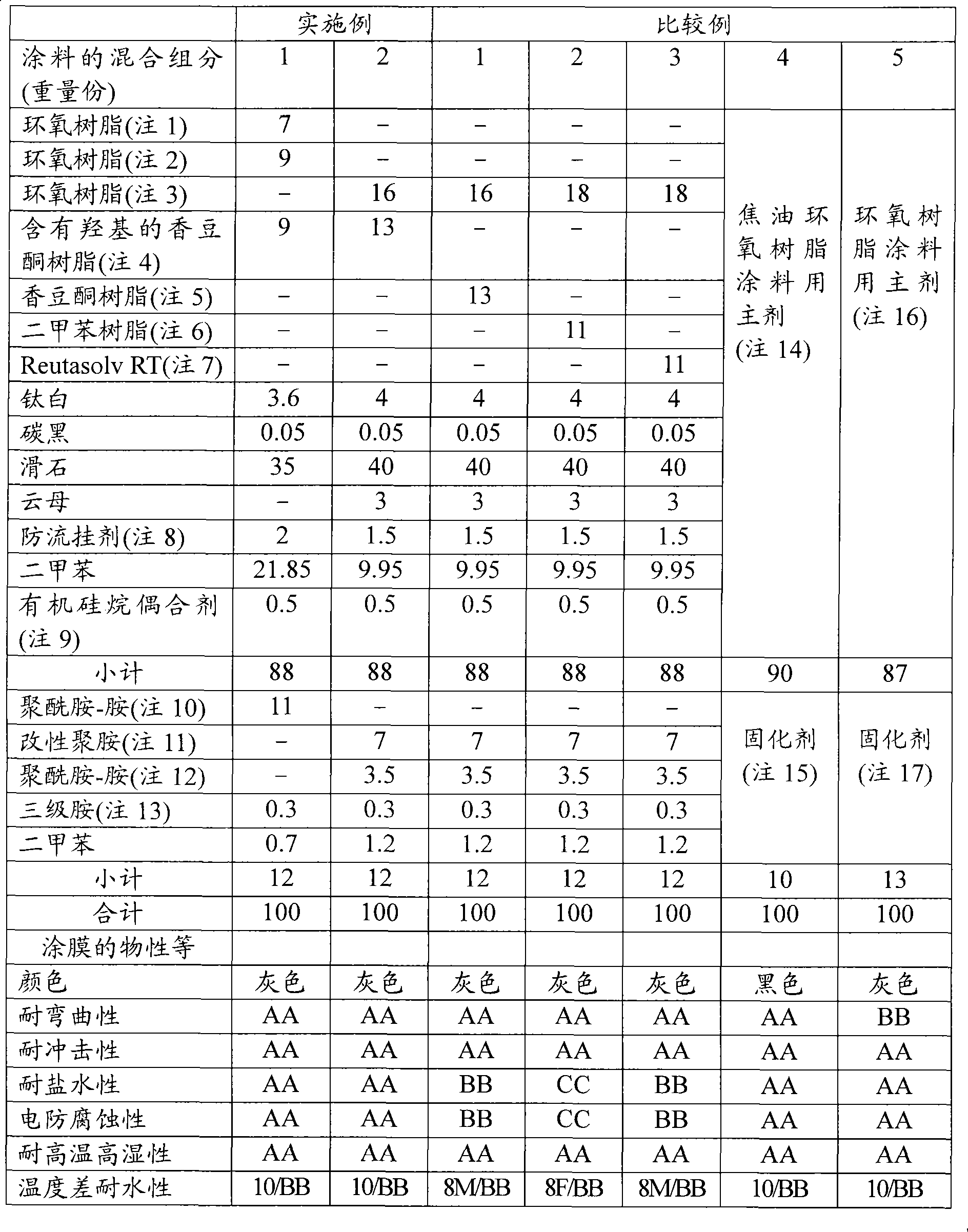

An anticorrosion coating composition having the mixing components shown in Table 1 below was prepared by mixing with a mixer or the like by a conventional method.

[0036] The test items shown in Table 1 were tested for each of the obtained anticorrosion coating compositions by the following test methods. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com