Packaging for free-flowing products, consisting of a heat-sealed bag

a tubular bag and free-flowing technology, which is applied in the direction of flexible container closures, liquid handling, and closures using stoppers, etc., can solve the problems of uncontrollable rips, inability to open the packaging without utensils, and inherent danger of unwanted openings, so as to prevent damage to the sealing weld, improve transport and storage, and reduce the risk of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

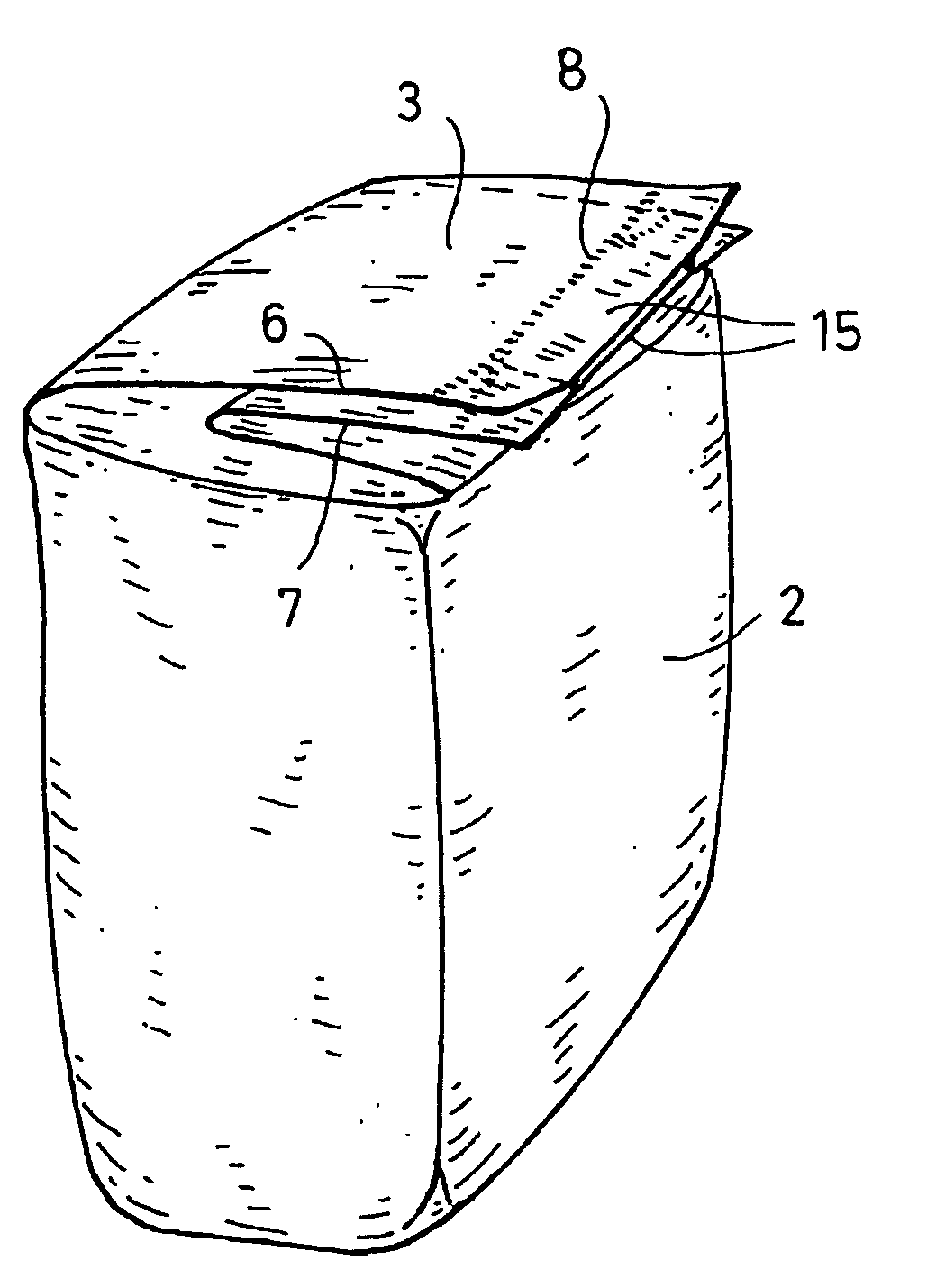

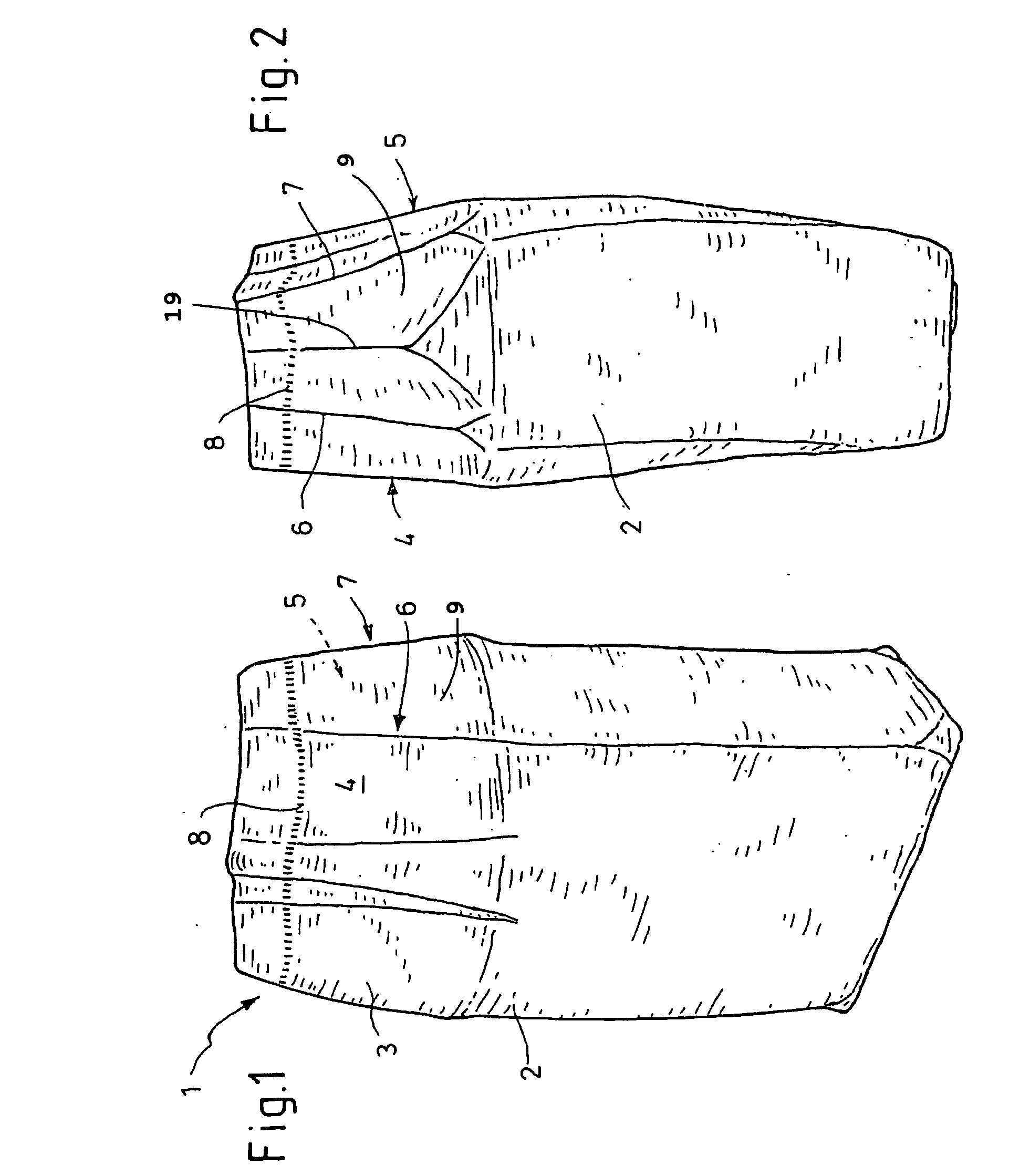

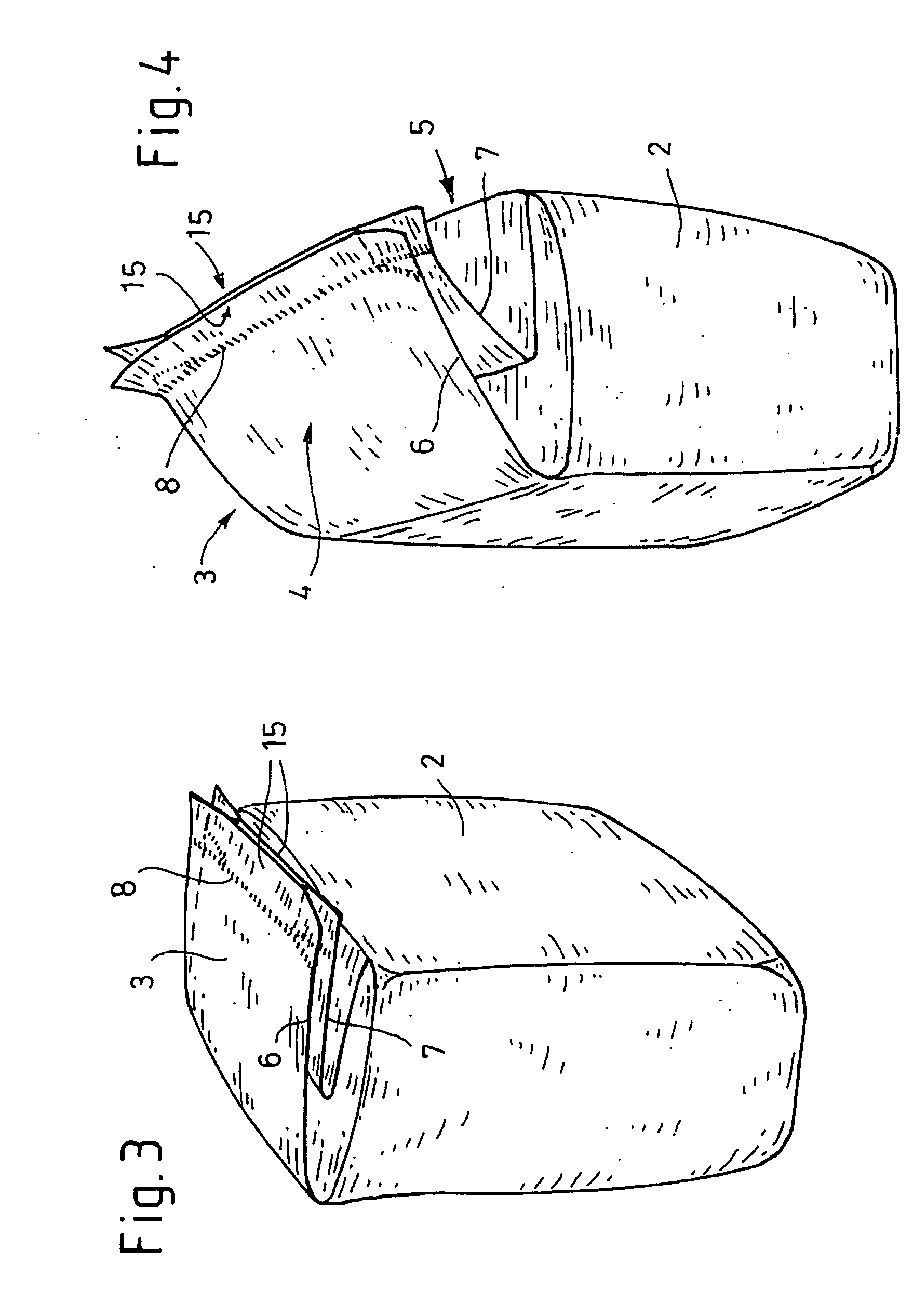

[0023] A packaging for free-flowing products, for example powdered detergent, is shown in FIG. 1 denoted in general by 1. This packaging consists of a tubular bag 2 that is closed at the bottom with a bottom seal (not shown). The bag may be formed with front, back and side panels which are tubulated by at least one lengthwise seam (not shown) extending substantially parallel to the longitudinal axis of the bag. At the top, the tubular bag 2 is first opened and is filled with powdered product only up to the point that, when full, a bag end 3 remains flat. This bag top end 3 is formed from two broad-face panels 4 and 5 lying flat against one another and two narrow-face panels, one of which is shown at 9, that are folded inwards at both edges of said panels and lie between the broad-face panels 4, and 5, wherein a side fold line 6 joins one broad-face panel 4 with the panel 9, and the other side fold line 7 joins the other broad-face panel 5 with the panel 9. The panel 9 is folded back...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| weld temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com