Ferric oxide pellets and preparation method and application thereof

A technology of iron oxide and pellets, which is applied in the field of iron oxide pellets and its preparation, can solve the problems of reducing the gas permeability index in the sintering process, reducing the quality of sintered ore, and poor gas permeability, so as to reduce the amount of dust generated and reduce the cost , good drop strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

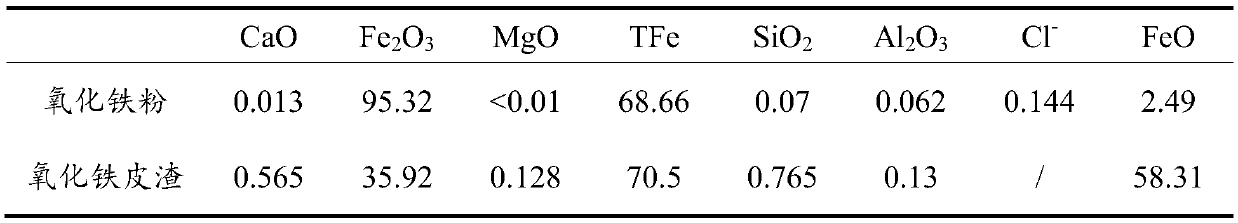

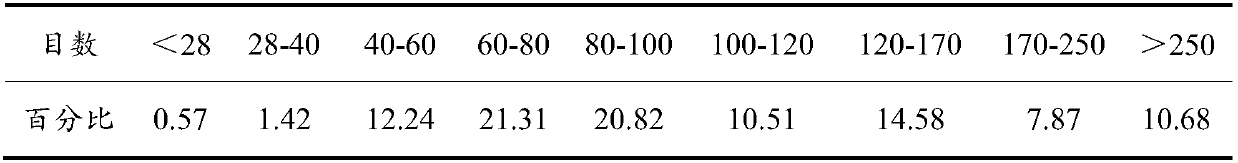

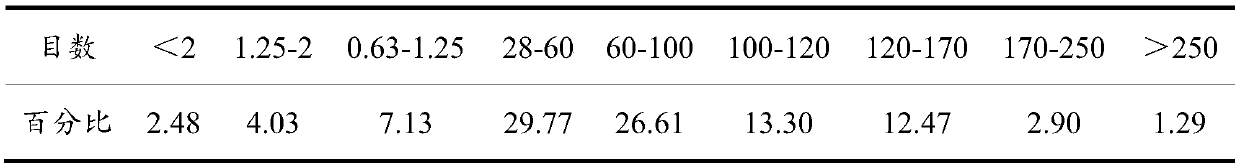

[0033] A preparation method of iron oxide pellets, comprising the following steps:

[0034] (a) drying iron oxide scale slag, and then mixing with iron oxide powder;

[0035] Preferably, the iron oxide scale slag is dried to a moisture content of less than 13%, more preferably less than 10%;

[0036] The iron oxide scales are dried to a typical but non-limiting moisture content of 1%, 2%, 3%, 4%, 5%, 6%, 7%, 8%, 9%, 10%, 11% or 12%.

[0037] Due to the relatively high moisture content of the initial iron oxide scale slag (9-25%), in order to ensure the normal development of dry mixing of ingredients in the subsequent process, it is necessary to reduce the moisture by airing or other drying methods until the binder can be evenly distributed after dry mixing of ingredients. In the present invention, the iron oxide scale dross is dried until the water content is less than 13%, which is beneficial to uniform mixing with the binder, and more preferably the iron oxide scale dregs a...

Embodiment 1

[0072] A preparation method of iron oxide pellets, comprising the following steps:

[0073] (a) Dry the iron oxide scale slag until the moisture is 10%, and then mix it with iron oxide powder for 4 minutes, and the mass ratio of iron oxide scale slag to iron oxide powder is 1:1;

[0074] (b) mix the mixed material in the step (a) with sodium carboxymethyl cellulose in a mixer in a mass ratio of 100:1.5, and the mixing time is 5min to obtain a dry mixed material;

[0075] (c) adding water to the dry-mixed mixture obtained in step (b) for wet mixing, the mass ratio of the dry-mixed mixture to water is 100:10, and the wet-mixed time is 5 minutes to obtain the wet-mixed mixture;

[0076] (d) the wet mixing mixture obtained in the step (c) is pressed by a universal testing machine into cylindrical pellets The pressure is 30MPa, and then through the pellet screening system, the pellets are transported to the drying process through a heat-resistant belt for high-temperature flue ga...

Embodiment 2

[0078] A preparation method of iron oxide pellets, comprising the following steps:

[0079] (a) Drying the iron oxide scale slag until the water content is less than 13%, and then mixing it with the iron oxide powder for 5 minutes, and the mass ratio of the iron oxide scale slag to the iron oxide powder is 4:1;

[0080] (b) Put the mixed material mixed in step (a) and polyacrylamide in a mixing mill (volume 2m) at a mass ratio of 100:0.8 3 , stirring capacity 1.2×10 3 kg / time) and mix uniformly, the mixing time is 8min, to obtain the dry blend mixture;

[0081] (c) adding water to the dry-mixed mixture obtained in step (b) for wet mixing, the mass ratio of the dry-mixed mixture to water is 100:12.5, and the wet-mixed time is 8 minutes to obtain the wet-mixed mixture;

[0082] (d) The wet mixed mixture obtained in step (c) is passed through a high-pressure ball press (oil cylinder pressure: 18Mpa, production capacity: 15×10 3 kg / h) to press round cake-shaped pellets (socket ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com