Chilled water direct supply system and method

A technology of chilled water and water pipes, applied in heating and ventilation control systems, heating and ventilation safety systems, air-conditioning systems, etc., can solve the problems of large occupied area and high energy loss rate, achieve convenient installation and transportation, reduce waste, improve The effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

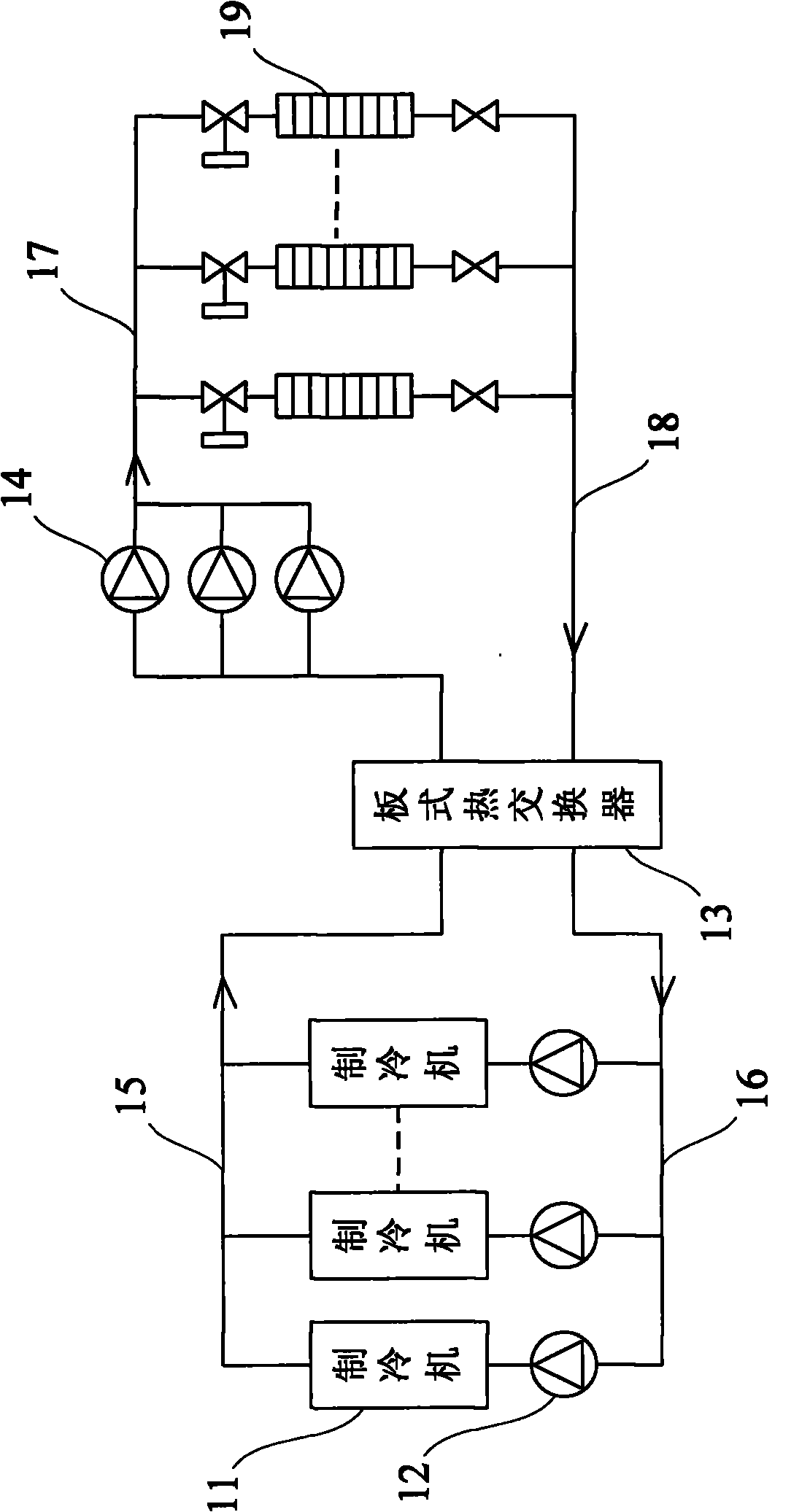

[0033] The main idea of the present invention is to make the chilled water directly enter the end fan coil for heat exchange without going through the plate heat exchanger, so that the construction cost and the operation cost can be greatly saved.

[0034] The present invention will be specifically described below with reference to the accompanying drawings.

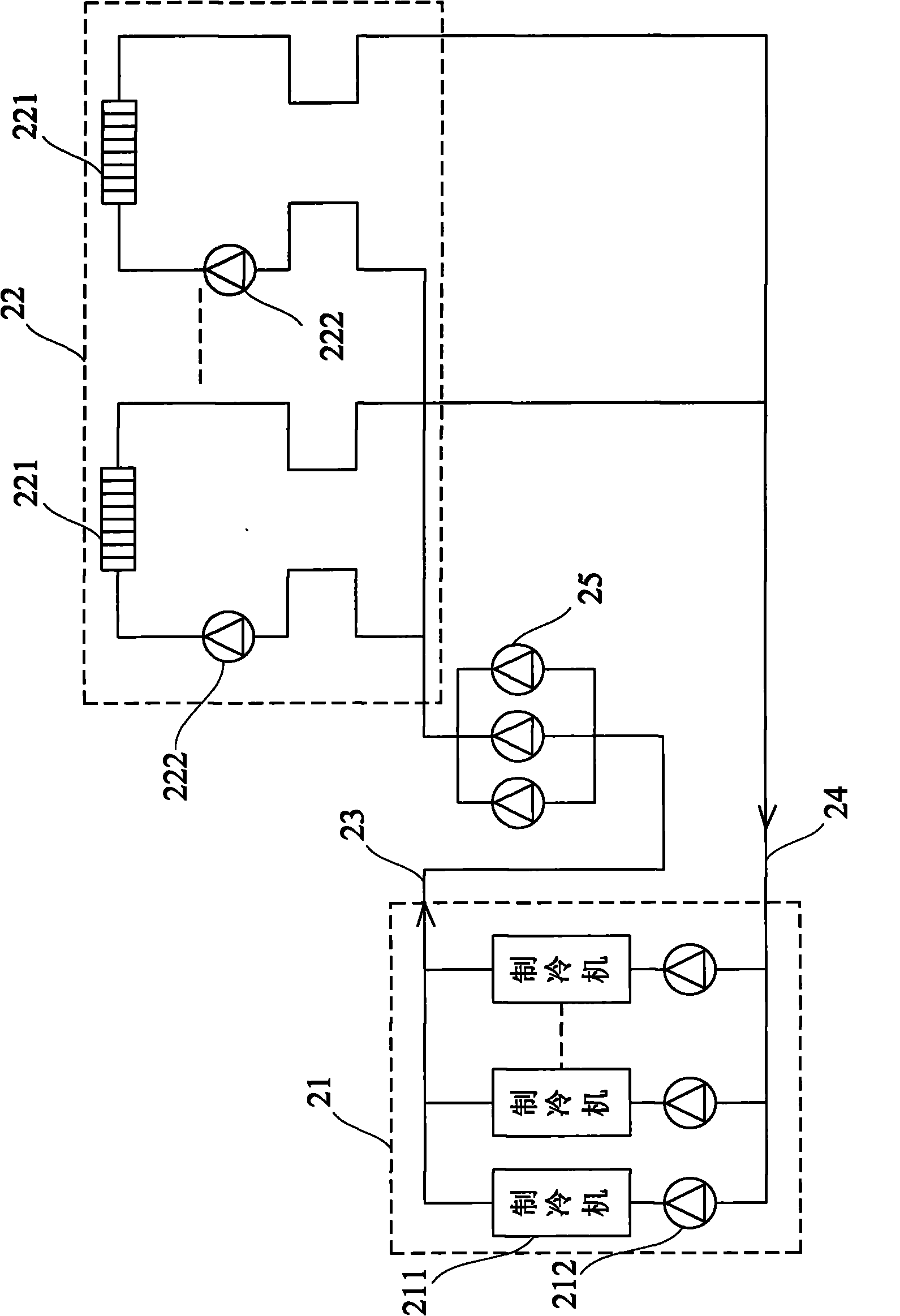

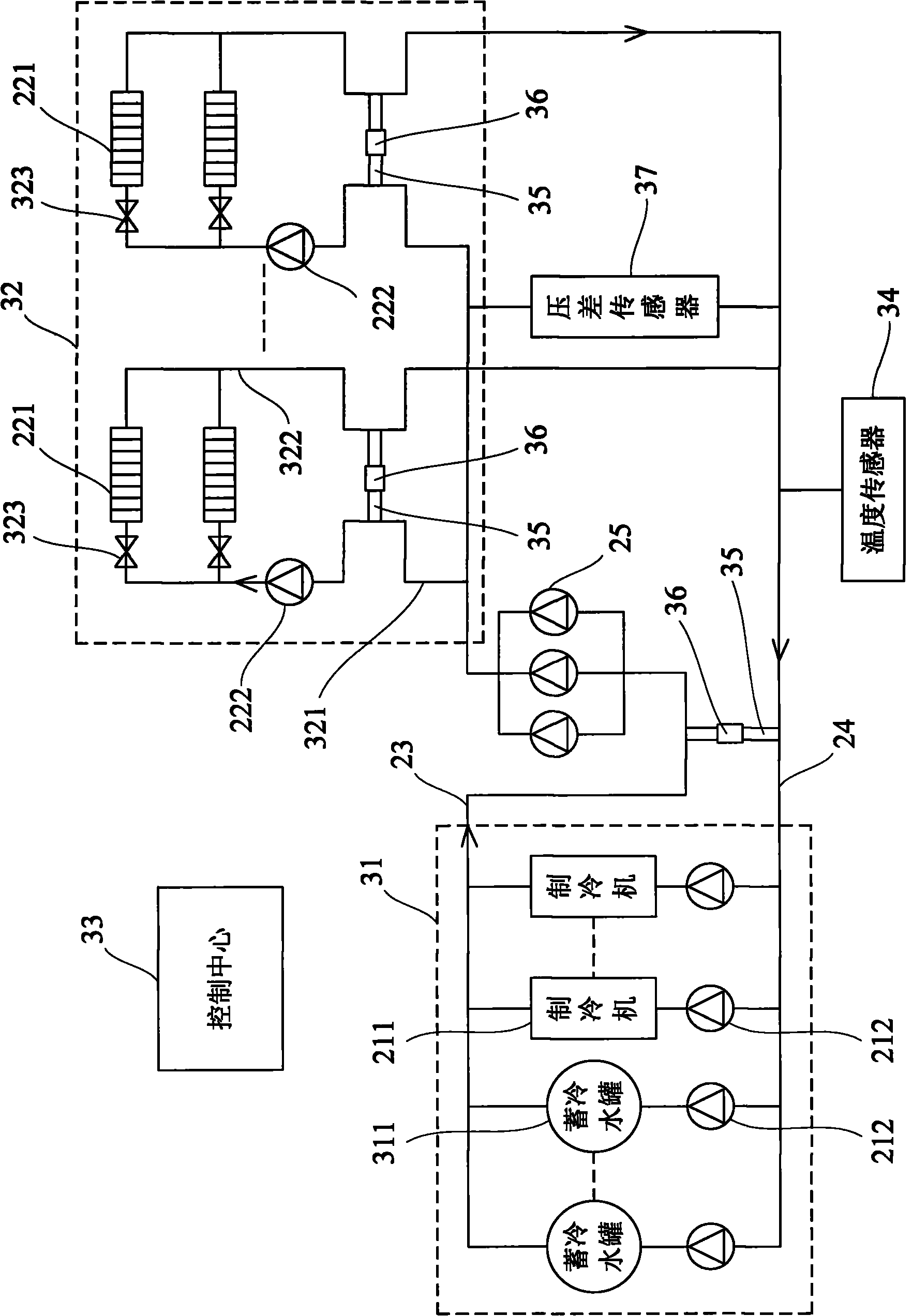

[0035] See figure 2 , which is a structural diagram of an embodiment of the chilled water direct supply system of the present invention. The system includes an energy center 21 and a heat exchange station 22 , and the energy center 21 and the heat exchange station 22 are connected through a main water supply pipe 23 and a main return water pipe 24 . A plurality of parallel secondary pumps 25 are arranged on the main water supply pipe 23, which are used to transport the chilled water output from the energy center 21 to the heat exchange station 22 to consume the cooling capacity.

[0036] Among them, the energy cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com