Polyester fiber or polyester fabric waste recycling method

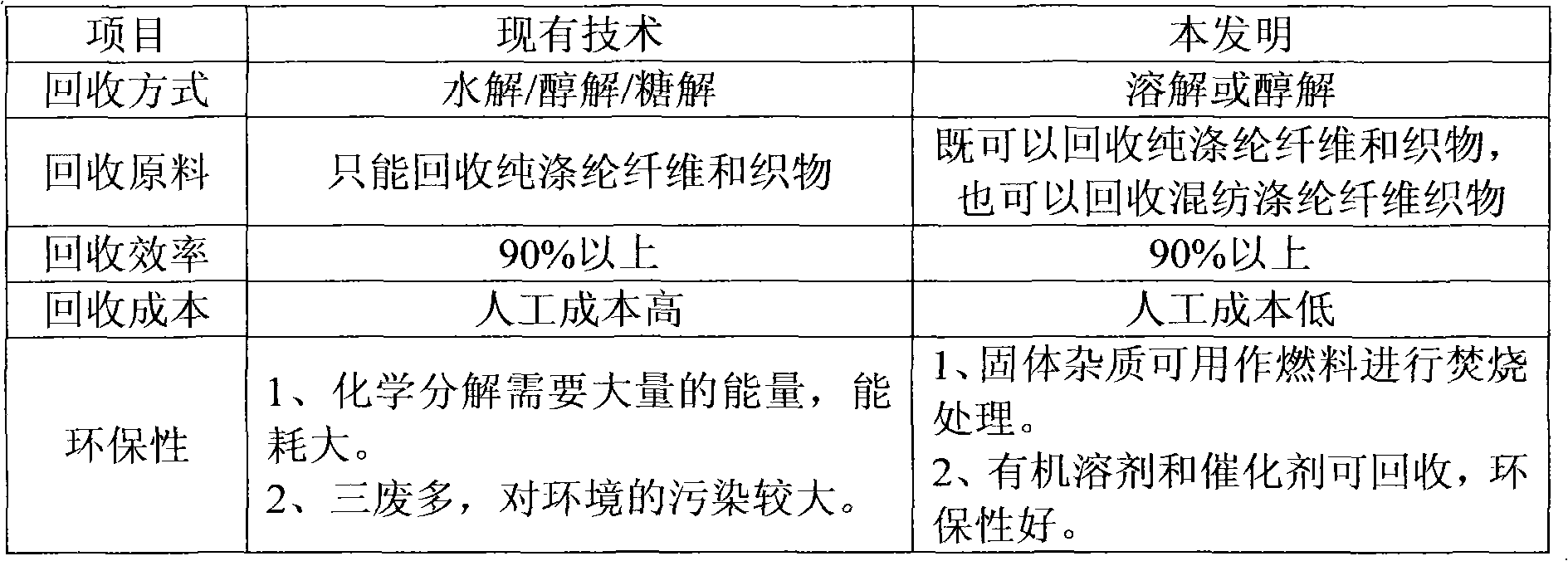

A polyester fabric and polyester fiber technology, which is applied in the field of recycling and reuse of ethylene terephthalate after dissolution or alcoholysis, can solve the problems of wasting energy and cost, high labor cost, cumbersome operation, etc., to save space, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Put polyester fibers with an intrinsic viscosity of 0.35, polyester fabrics and their blended fabric wastes directly into the reaction kettle without sorting, add a mixed solvent of phenol-tetrachloroethane, and dissolve them at about 80°C. After the dissolution is completed, Carry out centrifugation and filtration, distill the obtained solution, recover phenol and tetrachloroethane, and carry out liquid-phase viscosity-increasing polymerization and spinning on the remaining liquid, so as to realize the reuse of polyester fiber, polyester fabric and its blended fabric waste .

Embodiment 2

[0024] Put the polyester fiber, polyester fabric and its blended fabric waste with an intrinsic viscosity of 0.62 directly into the reaction kettle without sorting, add o-chlorophenol, and dissolve at 50°C. After the dissolution is complete, after the dissolution is completed, Carry out centrifugation and filtration, distill the obtained solution, recover o-chlorophenol, and carry out liquid-phase viscosity-increasing polymerization and spinning on the remaining liquid, so as to realize the reuse of polyester fiber, polyester fabric and its blended fabric waste.

Embodiment 3

[0026] Put polyester fibers with an intrinsic viscosity of 0.45, polyester fabrics and their blended fabric wastes directly into the reactor without sorting, add nitrobenzene, and dissolve them at 25°C. After the dissolution is completed, centrifuge and filter them. The obtained solution is distilled, nitrobenzene is recovered, and the remaining liquid is subjected to liquid-phase viscosity-increasing polymerization and spinning by other techniques, so as to realize the reuse of polyester fiber, polyester fabric and its blended fabric waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com