High purity nano-scale magnesium-aluminum spinel synthesis method

A magnesia-aluminum spinel and a synthesis method technology are applied in the synthesis field of high-purity nano-magnesium-aluminum spinel to achieve the effects of huge specific surface area, huge surface activity and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The synthetic method of the high-purity nano-scale magnesium-aluminum spinel provided in this embodiment comprises the following steps:

[0020] 1) Lightly calcined magnesium hydroxide nanocrystals at 400°C for 20 minutes to obtain lightly calcined magnesium oxide;

[0021] 2) Dilute the light-burned magnesia and boehmite by MgO and Al 2 o 3 The amount of substance is 1:1 and the ingredients are mixed evenly;

[0022] 3) Put the prepared materials in the fast ball mill, the speed is 1000r / min, and the fast ball mill is 180min;

[0023] 4) Put the ball-milled mixture into the mold and pressurize it, dry press it into a disc of Ф10mm×5mm, the pressure is 20MPa, the pressure holding time is 1min, and the green body sample is obtained after unloading;

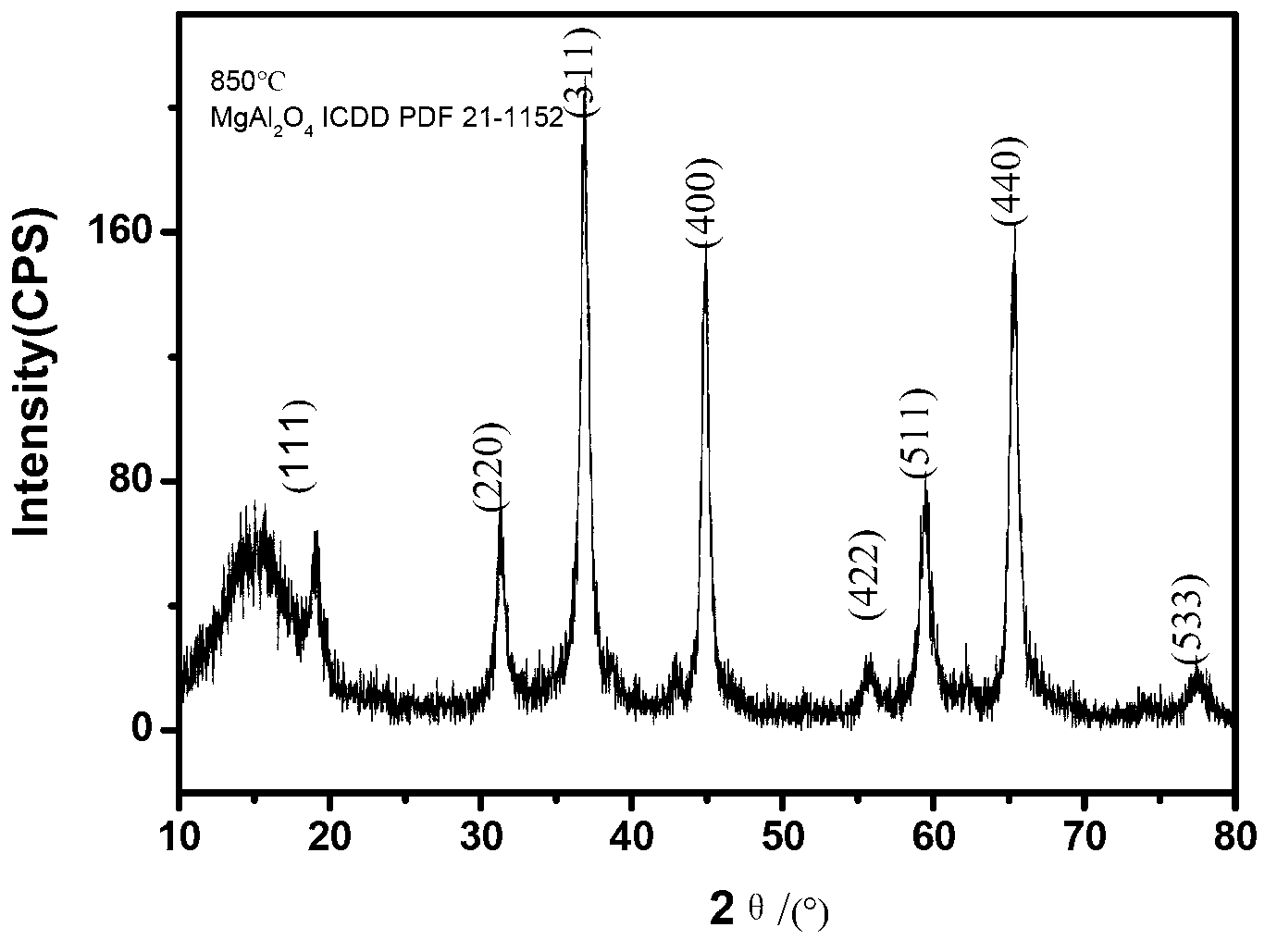

[0024] 5) Pre-fire the green body sample at 500°C for 1 hour, heat it up to 850°C for 3 hours, and then cool it to room temperature to obtain high-purity nano-scale magnesium-aluminum spinel.

[0025] The product of this...

Embodiment 2

[0027] The synthetic method of the high-purity nano-scale magnesium-aluminum spinel provided in this embodiment comprises the following steps:

[0028] 1) Lightly calcined magnesium hydroxide nanocrystals at 400°C for 20 minutes to obtain lightly calcined magnesium oxide;

[0029] 2) Dilute the light-burned magnesia and boehmite by MgO and Al 2 o 3 The amount of substance is 1:1 and the ingredients are mixed evenly;

[0030] 3) Put the prepared materials in the fast ball mill, the speed is 1000r / min, and the fast ball mill is 180min;

[0031] 4) Put the ball-milled mixture into the mold and pressurize it, dry press it into a disc of Ф10mm×5mm, the pressure is 20MPa, the pressure holding time is 1min, and the green body sample is obtained after unloading;

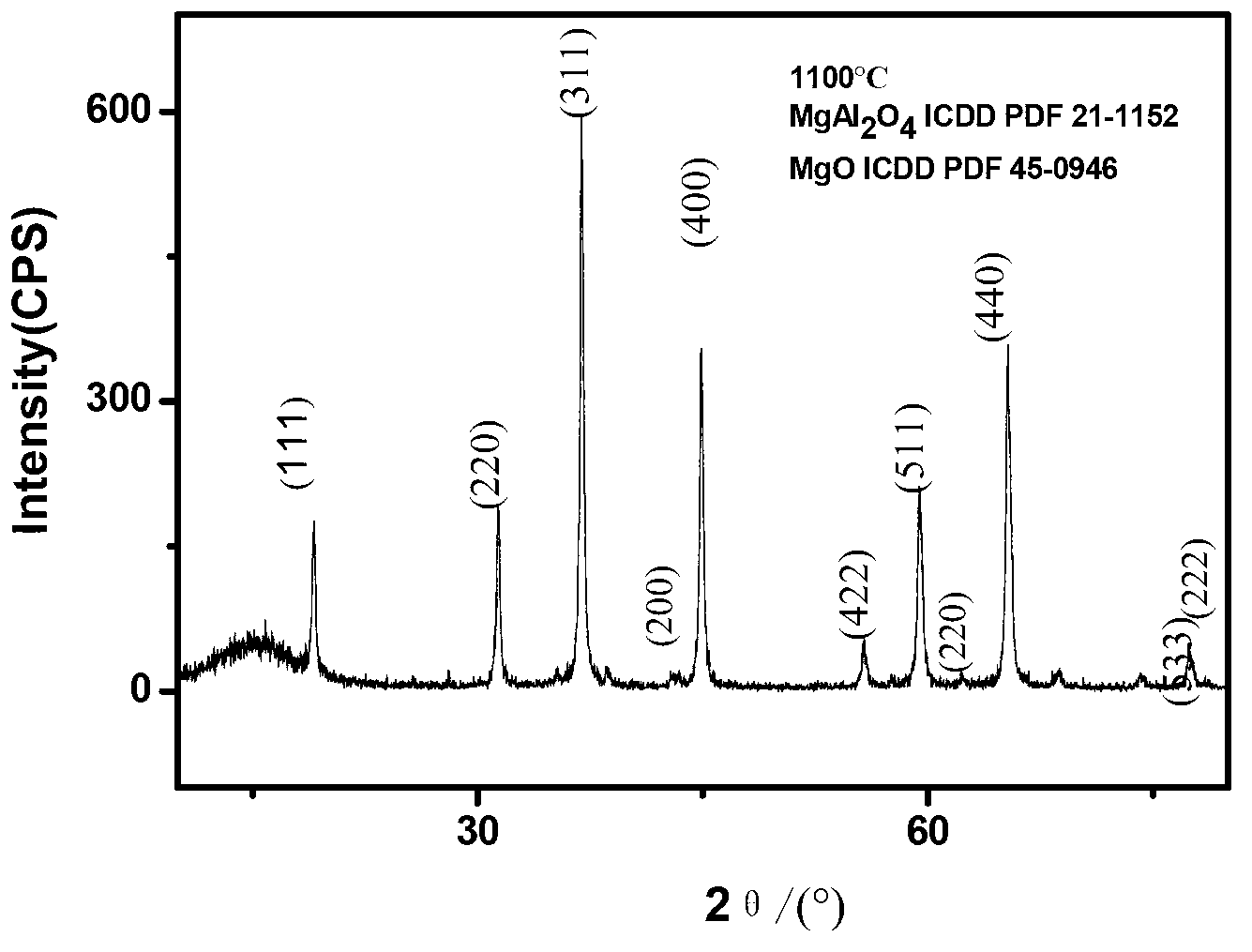

[0032] 5) Pre-fire the green body sample at 500°C for 1 hour, heat it up to 1100°C for 3 hours, and then cool it to room temperature to obtain high-purity nano-scale magnesium-aluminum spinel.

[0033] The product of thi...

Embodiment 3

[0035] The synthetic method of the high-purity nano-scale magnesium-aluminum spinel provided in this embodiment comprises the following steps:

[0036] 1) Lightly calcined magnesium hydroxide nanocrystals at 400°C for 20 minutes to obtain lightly calcined magnesium oxide;

[0037] 2) Dilute the light-burned magnesia and boehmite by MgO and Al 2 o 3 The amount of substance is 1:1 and the ingredients are mixed evenly;

[0038] 3) Put the prepared materials in the fast ball mill, the speed is 1000r / min, and the fast ball mill is 180min;

[0039] 4) Put the ball-milled mixture into the mold and pressurize it, dry press it into a disc of Ф10mm×5mm, the pressure is 20MPa, the pressure holding time is 1min, and the green body sample is obtained after unloading;

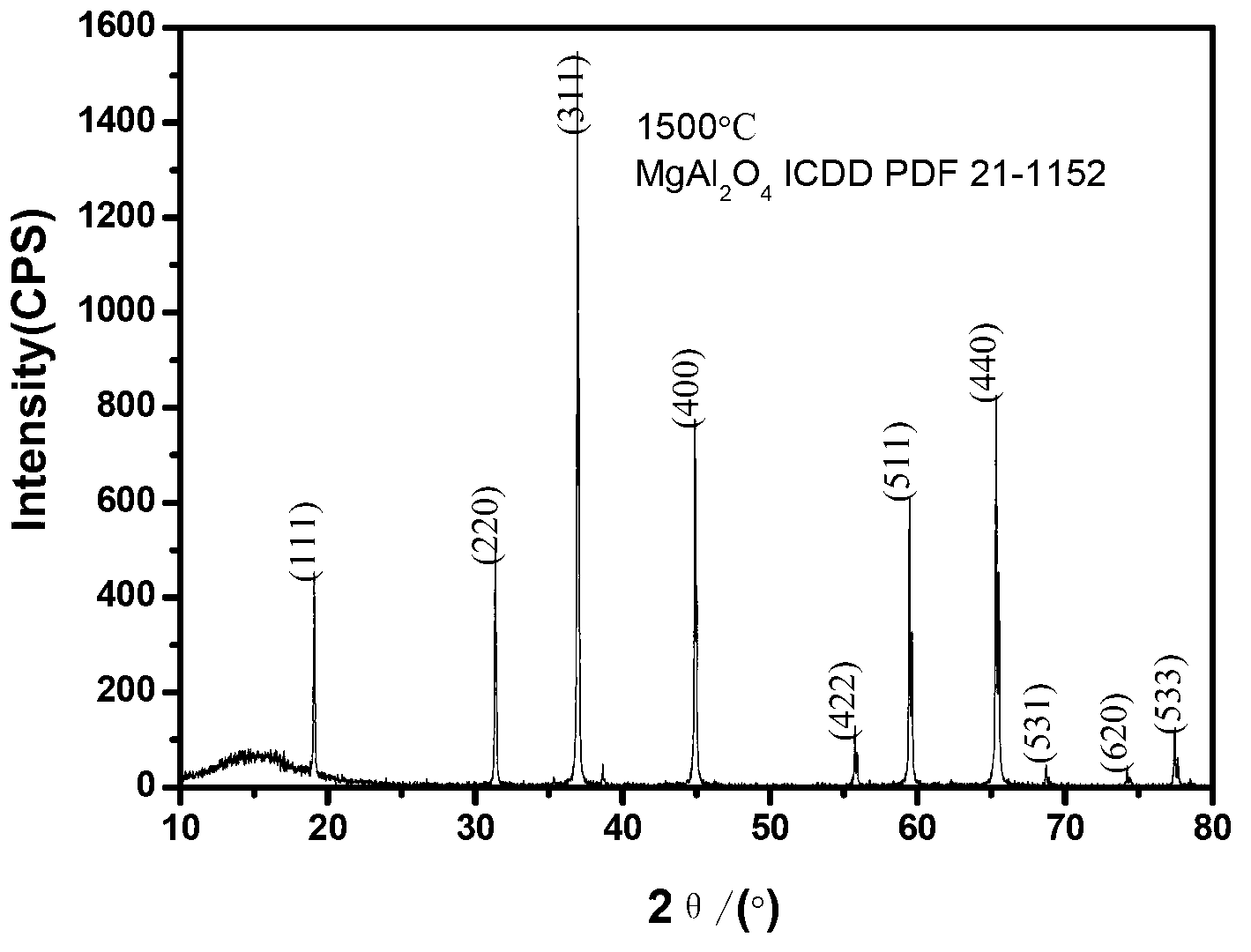

[0040] 5) Pre-fire the green body sample at 500°C for 1 hour, heat it up to 1500°C for 2 hours, and then cool it to room temperature to obtain high-purity nano-scale magnesium-aluminum spinel.

[0041] The product of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com