Saltless dyeing method for fabric modified by cationic polymer

A cationic polymer, salt-free dyeing technology, applied in the direction of dyeing, textile and paper making, etc., can solve the problems of fiber leveling, uncontrollable color light, large fiber damage, etc., and achieve level dyeing and color fastness. Simple and environmentally friendly, solve the effect of uneven dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Dye species: vinyl sulfone type reactive dyes

[0057] (1) Pre-treatment modification process: two dipping and two rolling of the fabric (dipping for 10 minutes, the excess rate of 80%) treatment liquid (2g / L cationic polymer modifier, the bath ratio is 1:10) → 100°C baking for 10 minutes →Wash in cold water and tumble dry.

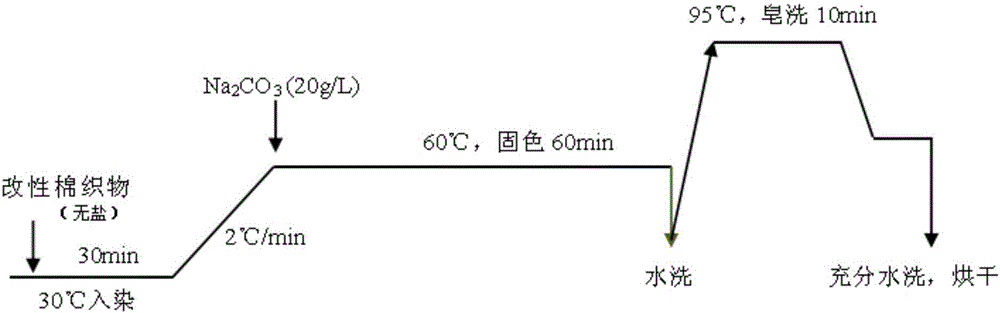

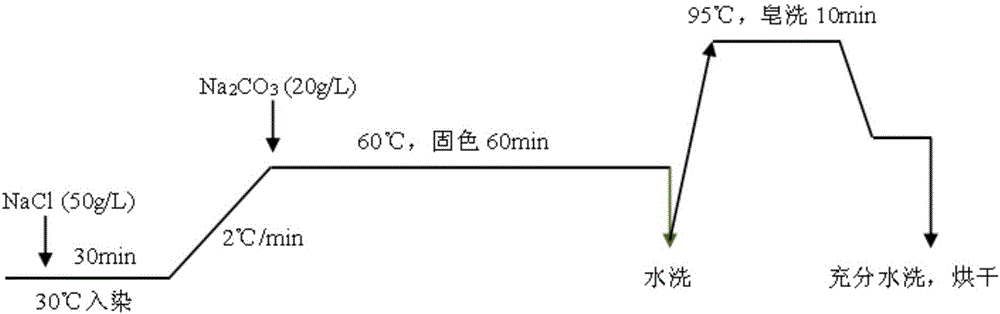

[0058] (2) Salt-free dyeing process: The modified and unmodified cotton fabrics were immersed in the dyeing bath of Remazol reactive brilliant blue dye 2% (o.w.f.), pH 6-7, liquor ratio 1:10. According to the dyeing temperature process curve ( figure 1 and image 3 ) was dyed, and the apparent depth K / S value, unevenness S and color fastness were measured, and the results are shown in Table 1.

[0059] Table 1

[0060]

Embodiment 2

[0062] Dye species: vinyl sulfone type reactive dyes

[0063] (1) Pre-treatment modification process: two dipping and two rolling of the fabric (dipping for 10 minutes, the scrapping rate is 80%) treatment solution (5g / L cationic polymer modifier, bath ratio is 1:10) → 100°C baking for 5 minutes →Wash in cold water and tumble dry.

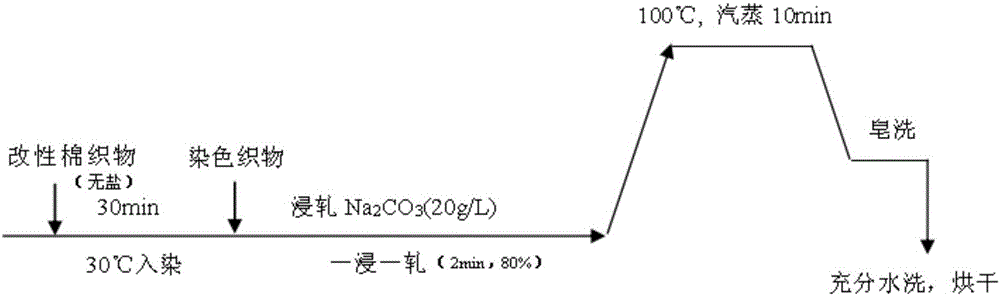

[0064] (2) Salt-free dyeing process: The modified and unmodified cotton fabrics were immersed in the dyeing bath of Remazol reactive brilliant blue dye 2% (o.w.f.), pH 6-7, liquor ratio 1:10. According to the dyeing temperature process curve ( figure 2 and image 3 ) was dyed, and the apparent depth K / S value, unevenness S and color fastness were measured, and the results are shown in Table 2.

[0065] Table 2

[0066]

Embodiment 3

[0068] Dye species: vinyl sulfone type reactive dyes

[0069] (1) Pre-treatment modification process: two dipping and two rolling of the fabric (dipping for 2 minutes, the scrapping rate is 80%) treatment solution (5g / L cationic polymer modifier, bath ratio is 1:10) → 120°C baking for 10 minutes →Wash in cold water and tumble dry.

[0070] (2) Salt-free dyeing process: The modified and unmodified cotton fabrics were immersed in the dyeing bath of Remazol reactive red dye 1% (o.w.f.), pH 6-7, liquor ratio 1:10. According to the dyeing temperature process curve ( figure 1 and image 3 ) was dyed, and the apparent depth K / S value, unevenness S and color fastness were measured, and the results are shown in Table 3.

[0071] table 3

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com