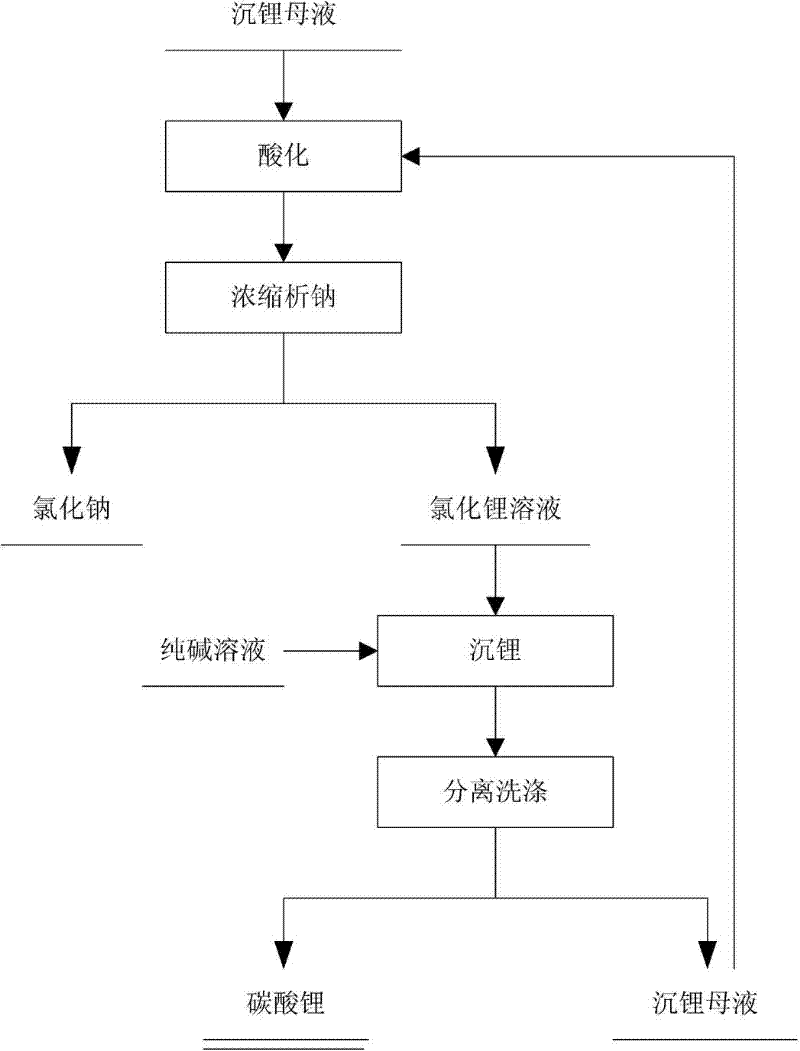

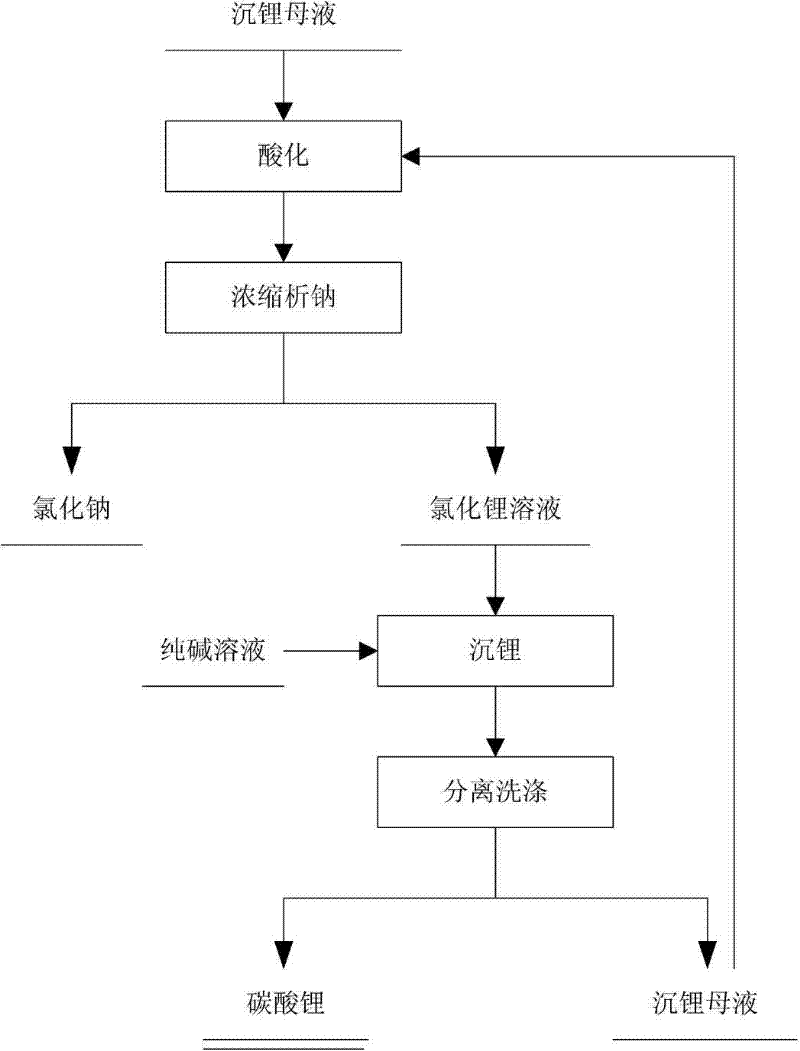

Method for processing battery-level lithium carbonate mother liquor

A treatment method and technology of lithium carbonate, applied in water/sewage multi-stage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of large steam consumption and increased lithium loss, and achieve improved recovery. efficiency, increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In 1000L mother liquor, use 35% hydrochloric acid to adjust the mother liquor to pH = 1, stir for 20 minutes, then use 1.25mol / L liquid caustic soda NaOH to make it neutral, stir for 20 minutes, and the acidification is completed. Pour the acidified mother liquor into the evaporator, continue to evaporate and feed continuously, when the solid-to-liquid ratio is about 25%, discharge the material, shake off the water, separate the sodium chloride and lithium chloride solutions, and remove the saturated sodium chloride solution Rinse once. Put lithium chloride solution into the reaction kettle, and then add 0.9mol / L soda ash solution according to the calculated amount (the calculation formula is: lithium chloride volume × lithium chloride concentration ÷ 85 × 106 ÷ 230 × 1.05 (unit: L) ), keep the temperature at 90-95°C during the feeding process, after the feeding is completed, keep the temperature constant for 30 minutes and then shake off the water. The obtained lithiu...

Embodiment 2

[0048] In 1000L mother liquor, use 35% hydrochloric acid to adjust the mother liquor to pH = 2, stir for 20 minutes, then use 1.25mol / L liquid caustic soda NaOH to make it neutral, stir for 20 minutes, and the acidification is completed. Pour the acidified mother liquor into the evaporator, continue to evaporate and feed continuously, when the solid-to-liquid ratio is about 28%, discharge the material, shake off the water, separate the sodium chloride and lithium chloride solutions, and remove the saturated sodium chloride solution Rinse once. Pour lithium chloride solution into the reaction kettle, and then add 0.9mol / L soda ash solution according to the calculated amount. During the feeding process, keep the temperature at 90-95°C. After the addition, keep the temperature constant for 30 minutes and then shake off the water. After lithium precipitation, the mother liquor and washing liquid enter the stage of acidification, evaporation and lithium precipitation, and the cycle...

Embodiment 3

[0052] In 1000L mother liquor, use 35% hydrochloric acid to adjust the mother liquor to pH = 3, stir for 20 minutes, then use 1.25mol / L liquid caustic soda NaOH to make it neutral, stir for 20 minutes, and the acidification is completed. Pour the acidified mother liquor into the evaporator, continue to evaporate and feed continuously, and when the solid-to-liquid ratio is about 29%, discharge the material, shake off the water, separate the sodium chloride and lithium chloride solutions, and remove the saturated sodium chloride solution Rinse once. Pour lithium chloride solution into the reaction kettle, and then add 0.9mol / L soda ash solution according to the calculated amount. During the feeding process, keep the temperature at 90-95°C, keep the temperature for 30 minutes, and then shake off the water. The obtained lithium carbonate product is packaged after drying and pulverizing. After lithium precipitation, the mother liquor and washing liquid enter the stage of acidifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com