Blast furnace spray-blow coal technology using semi-coke of iron works

A technology for blast furnace injection of coal and ironworks, applied in the field of metallurgical production, can solve the problems of semi-coke injection proportion, lack of research on performance, inability to be applied in industry, high transportation costs, etc., to achieve favorable application promotion and low cost price, the effect of accelerating industrial development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

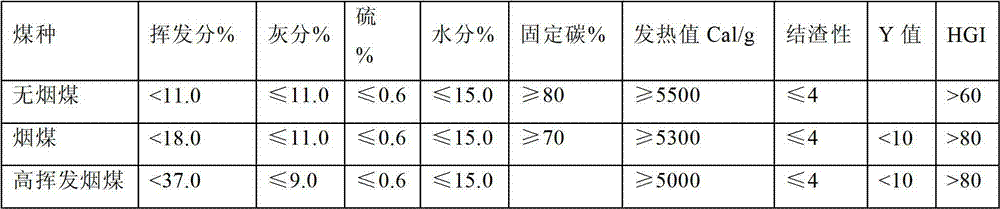

Method used

Image

Examples

Embodiment 1

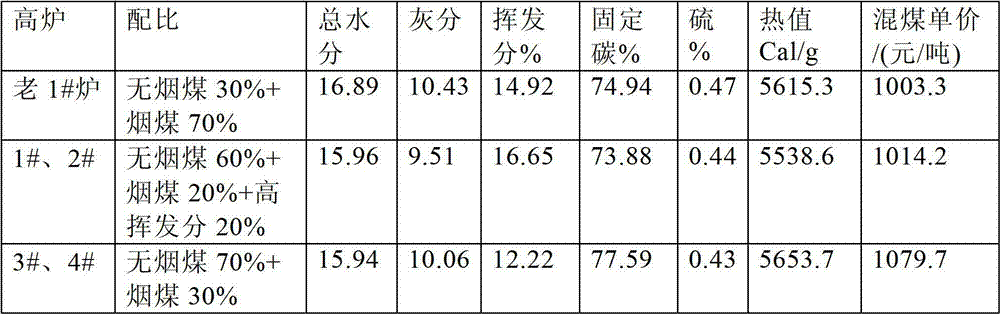

[0023] The iron-making plant uses the blast furnace coal injection process of blue charcoal to mix blue charcoal, anthracite and bituminous coal in a mass ratio of 20:10:70. After being pulverized in a mill, the blast furnace is used at a wind temperature of 1200℃. The coal injection system blows to the blast furnace.

Embodiment 2

[0025] The ironmaking plant uses the blast furnace coal injection process of blue charcoal to mix blue charcoal with anthracite and bituminous coal in a mass ratio of 30:10:60. After being pulverized in a mill, the blast furnace is used at a wind temperature of 1200℃. The coal injection system blows to the blast furnace.

Embodiment 3

[0027] The ironworks uses the blast furnace coal injection process of blue charcoal. The blue charcoal is ground into a powder with a particle size of less than 180 mesh, accounting for 85% in a medium-speed mill. Then the ground blue charcoal is mixed with anthracite and bituminous coal in a mass ratio of 20:10:70. After being ground in a mill, the blast furnace coal injection system is used for the first injection into the blast furnace at a wind temperature of 1200°C. ; Then blue charcoal is mixed with anthracite and bituminous coal in a mass ratio of 25:10:65, and then pulverized in a mill at a wind temperature of 1200°C. The blast furnace coal injection system is used for secondary injection to the blast furnace; Finally, the blue charcoal is mixed with anthracite and bituminous coal in a mass ratio of 30:10:60. After being pulverized in a mill, the blast furnace coal injection system is used for the final injection to the blast furnace at a wind temperature of 1200℃; The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com