Soluble asphalt packing material

A packaging material, soluble technology, applied in the direction of packaging, transportation and packaging, building insulation materials, etc., can solve the problems of limited transportation distance, high transportation cost, difficult to peel off, etc., to improve high temperature resistance to deformation, reduce environmental pollution, formula design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

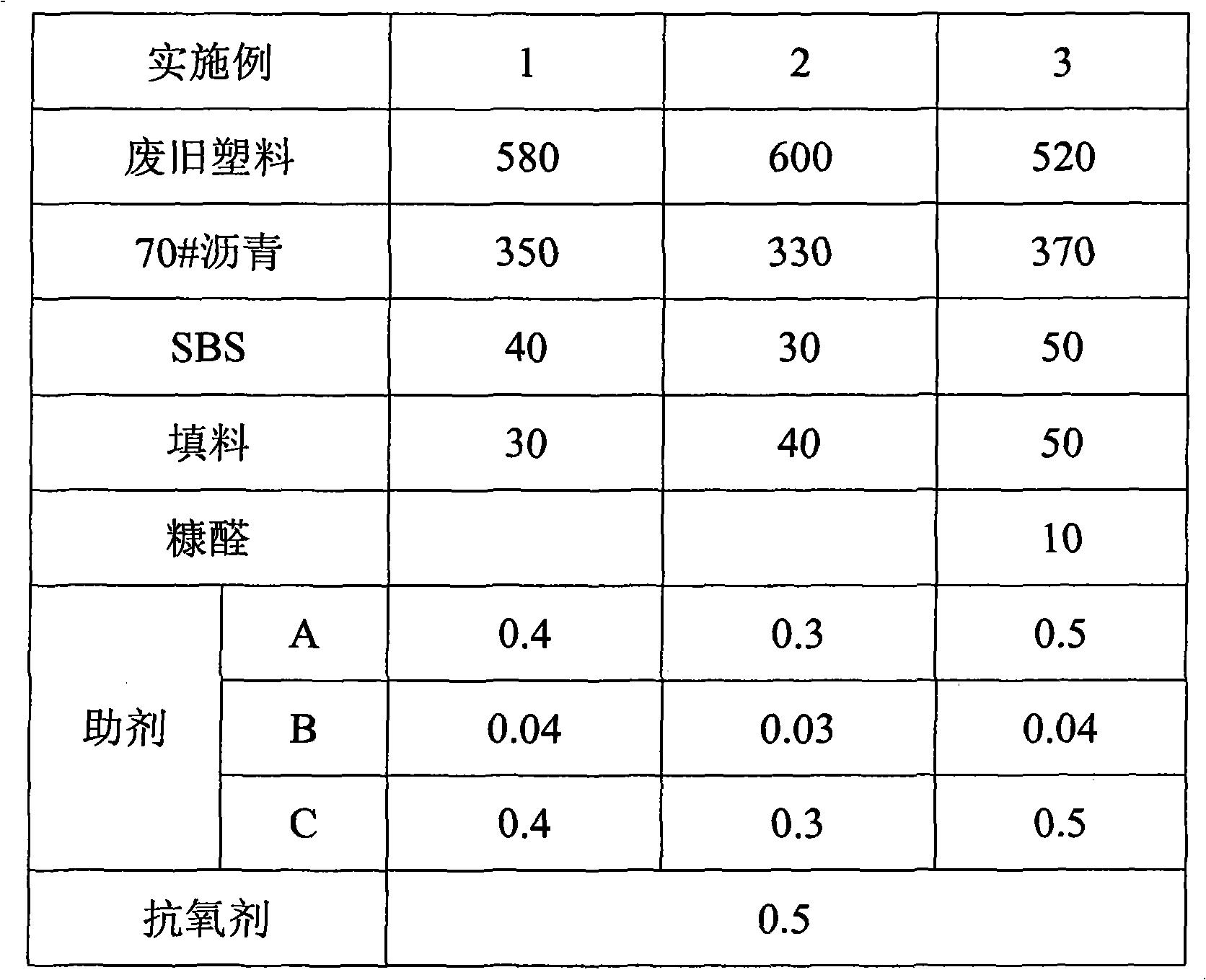

[0017] The following three embodiments of the present invention are listed as follows according to weight and share, but the present invention is not limited to the following embodiments. In actual application, different proportions in the following embodiments can be selected according to different performance requirements and usage occasions , or different proportions except the following examples, but all do not limit the scope of the present invention in any form.

[0018]

[0019] The preparation method of above-mentioned each embodiment is:

[0020] 1. Make a pair of rectangular box-type moulds, with a Φ80mm canning mouth with threaded buckles on the upper end, and equipped with a sealing cover. The mold is equipped with a hollow blow molding machine and has the ability to blow bag forming;

[0021] 2. Weigh the above-mentioned waste plastics, fillers, additives and antioxidants according to the proportion, put them into the mixer and stir them, and mix them evenly to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com