Durable cement concrete bridge deck pavement structure with noise reduction and water drainage functions

A cement concrete and bridge deck pavement technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of bridge deck structure durability, anti-skid, drainage, noise reduction, and wear resistance. Requirements and other issues, to achieve the effect of reducing driving water mist, reducing road noise, and large macroscopic structural depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For a cement concrete bridge deck pavement project in Zhenjiang City, Jiangsu Province, the bridge deck is paved with asphalt concrete.

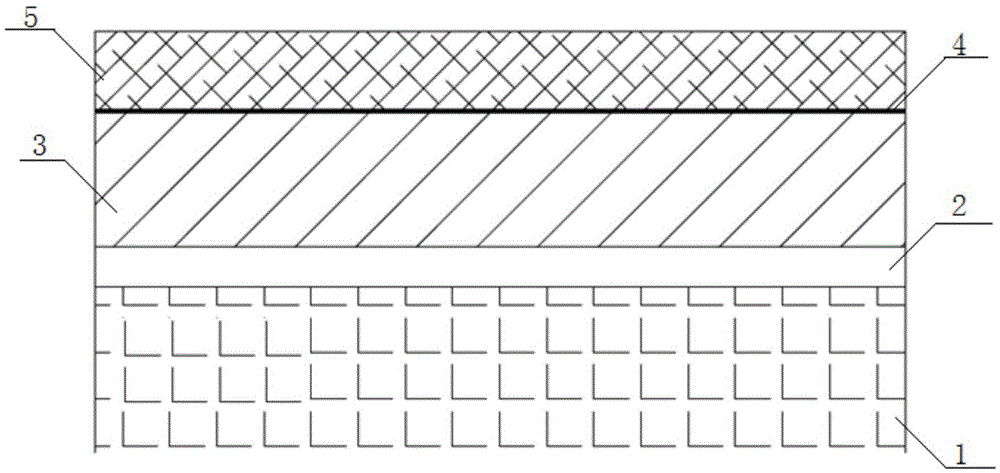

[0027] First of all, to process the cement concrete bridge deck, use a small cutting machine to carve grooves, the depth of the grooves is 3-5mm, the width is 3mm, and the distance between adjacent grooves is 20mm; The power of the machine is 15kw, the speed of shot blasting is 9m / min, and the sand laying method is used to test, the construction depth is 0.61mm, and the treated concrete bridge deck 1 is obtained.

[0028] A high-performance cold-laid waterproof adhesive layer 2 is set on the upper surface of the treated concrete bridge deck 1. The high-performance cold-laid waterproof adhesive layer 2 is prepared from water-based epoxy emulsified asphalt, and the spraying amount of water-based epoxy emulsified asphalt is 0.8kg / m 2 .

[0029] The durable high modulus asphalt concrete 3 has a thickness of 7 cm, and is arranged on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com