Method for detecting void of coarse aggregate

A measurement method and coarse aggregate technology, applied in the direction of measuring device, specific gravity measurement, analysis of materials, etc., can solve problems such as rutting phenomenon, different sample volumes, different calculation methods of sample surface voids, etc., to improve high temperature deformation resistance , Coarse aggregate particle stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

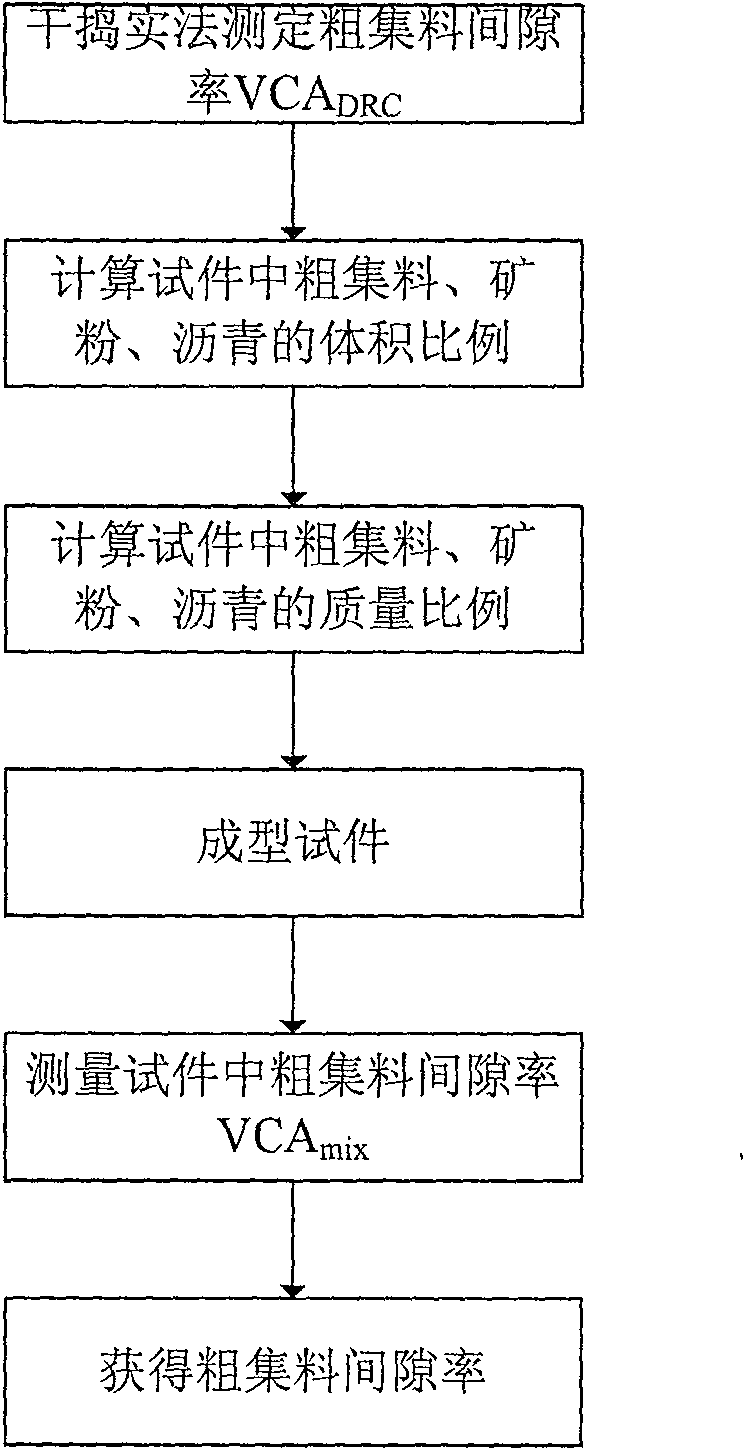

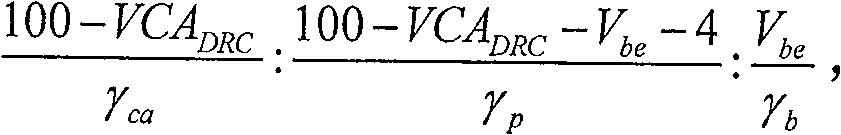

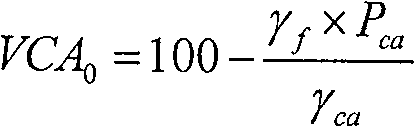

[0011] The present invention will be described in further detail below in conjunction with accompanying drawings and examples. The assay method of coarse aggregate void rate of the present invention comprises the following steps: one, measure the void rate VCA of coarse aggregate with dry compaction method DRC , %; Two, in the coarse aggregate, add an appropriate amount of mineral powder and asphalt, coarse aggregate: mineral powder: the mass ratio of asphalt is 100 - VCA DRC γ ca : 100 - VC A DRC - V be - 4 γ p : V be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com