Preparation method of antibacterial and mildew-proof luminous decorative coating

A decorative coating, antibacterial and anti-mildew technology, applied in the field of coatings, can solve the problems of insufficient anti-bacterial and anti-mildew performance, and achieve good biocompatibility and degradability, no toxic side effects, good anti-bacterial and anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

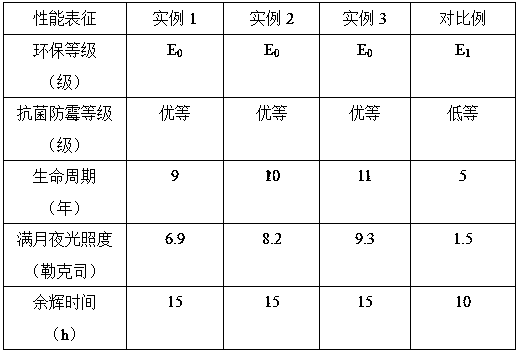

Examples

example 1

[0025]Take 0.1mol / L silver nitrate solution, mass fraction is 5% chitosan-acetic acid solution, 0.2mol / L sodium borohydride solution, KH-570, nanometer titanium dioxide, epichlorohydrin, mix 0.1mol / L silver nitrate solution Mix with a mass fraction of 5% chitosan-acetic acid solution, and magnetically stir to obtain the mixed solution A, add 0.2mol / L sodium borohydride solution to the mixed solution A, and continue stirring for 1h to obtain the mixed solution B; Add KH-570 to the mixed solution B, and ultrasonically disperse it to obtain the mixed solution C. Add nano-titanium dioxide and epichlorohydrin to the mixed solution C, and stir to obtain the mixed solution D; after soaking the zeolite molecular sieve, Filter to obtain the filter residue, wash the filter residue with deionized water until neutral, and then obtain the antibacterial and antifungal agent; take epoxy resin, acrylate resin, antibacterial and antifungal agent, luminous powder, No. 200 solvent oil, and mix ep...

example 2

[0027] Take 0.1mol / L silver nitrate solution, mass fraction is 5% chitosan-acetic acid solution, 0.2mol / L sodium borohydride solution, KH-570, nanometer titanium dioxide, epichlorohydrin, mix 0.1mol / L silver nitrate solution Mix with chitosan-acetic acid solution with a mass fraction of 5%, and magnetically stir to obtain mixed solution A, add 0.2mol / L sodium borohydride solution to mixed solution A, and continue stirring for 1.5h to obtain mixed solution B; Add KH-570 to the mixed solution B, and ultrasonically disperse to obtain the mixed solution C. Add nano-titanium dioxide and epichlorohydrin to the mixed solution C, and stir to obtain the mixed solution D; after soaking the zeolite molecular sieve , filter to obtain the filter residue, wash the filter residue with deionized water to neutrality, and obtain the antibacterial and antifungal agent; take epoxy resin, acrylic resin, antibacterial and antifungal agent, luminous powder, No. 200 solvent oil, and mix epoxy resin an...

example 3

[0029] Take 0.1mol / L silver nitrate solution, mass fraction is 5% chitosan-acetic acid solution, 0.2mol / L sodium borohydride solution, KH-570, nanometer titanium dioxide, epichlorohydrin, mix 0.1mol / L silver nitrate solution Mix with a mass fraction of 5% chitosan-acetic acid solution, and magnetically stir to obtain the mixed solution A, add 0.2mol / L sodium borohydride solution to the mixed solution A, and continue stirring for 2h to obtain the mixed solution B; Add KH-570 to the mixed solution B, and ultrasonically disperse it to obtain the mixed solution C. Add nano-titanium dioxide and epichlorohydrin to the mixed solution C, and stir to obtain the mixed solution D; after soaking the zeolite molecular sieve, Filter to obtain the filter residue, wash the filter residue with deionized water until neutral, and then obtain the antibacterial and antifungal agent; take epoxy resin, acrylate resin, antibacterial and antifungal agent, luminous powder, No. 200 solvent oil, and mix e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com