An electrically heated planar cathode

A flat cathode, thermal expansion coefficient technology, applied in the direction of discharge tube solid thermionic cathode, discharge tube main electrode, X-ray tube electrode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

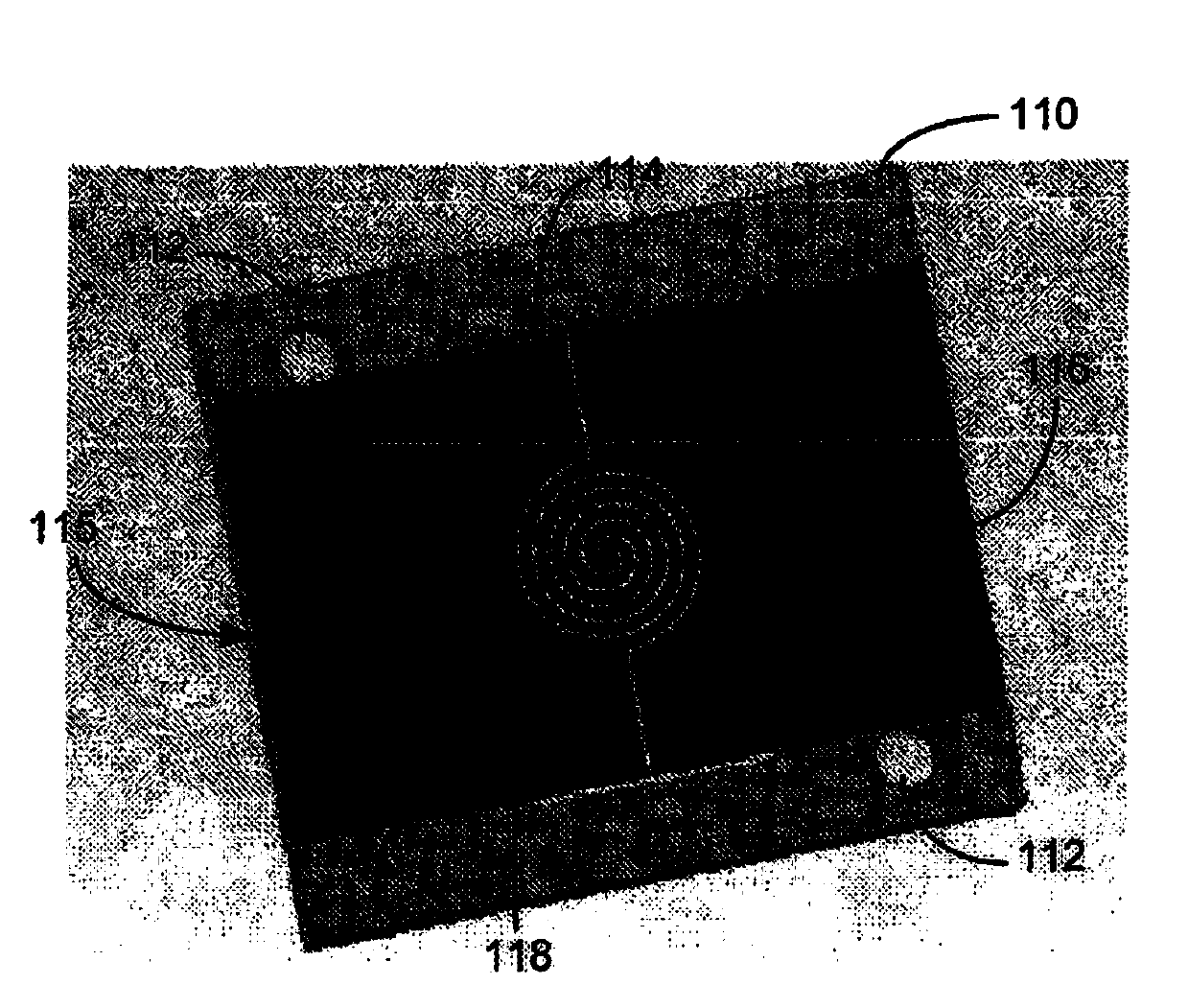

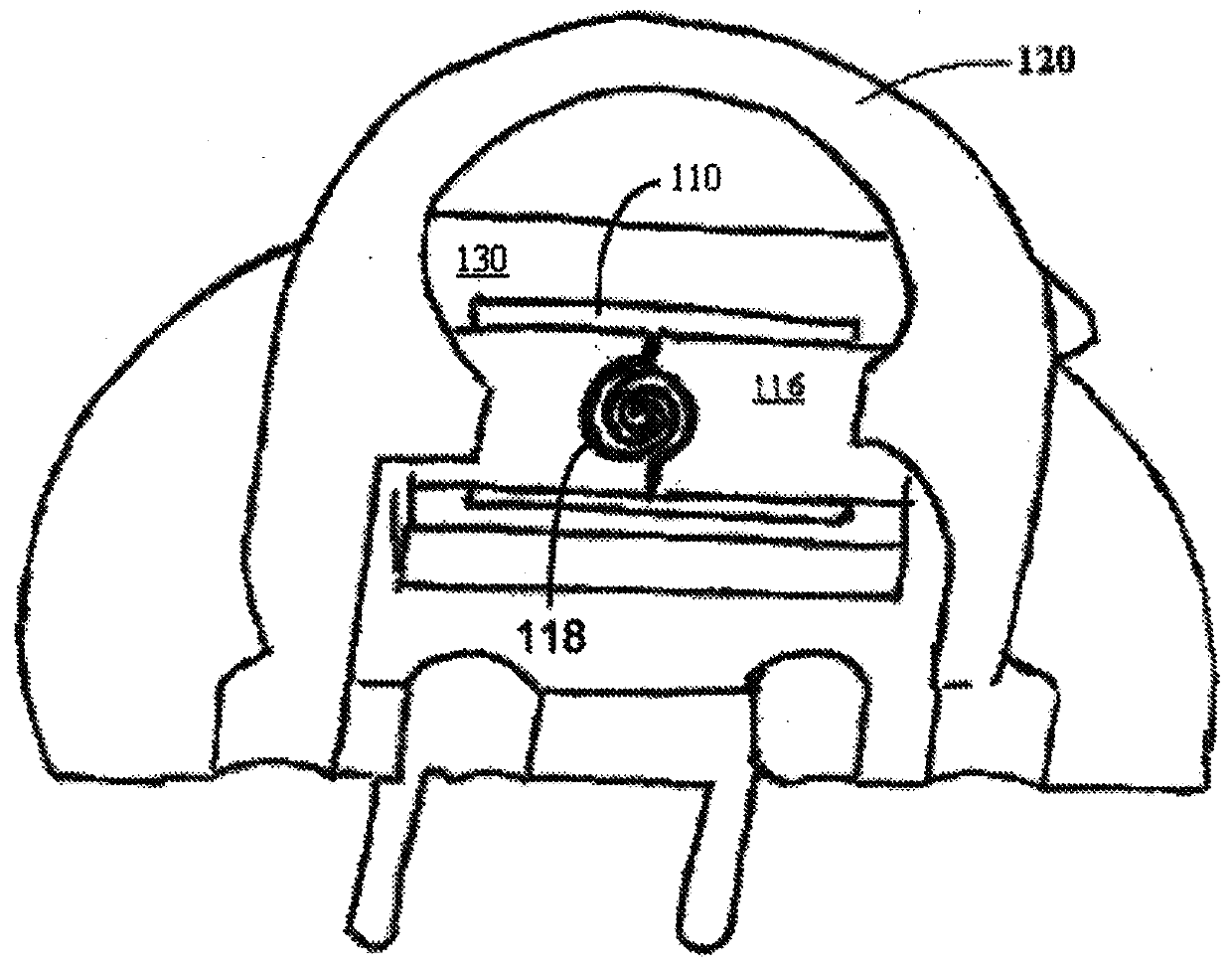

[0006] An electrically heated planar cathode for small X-ray tubes includes a spiral design laser-cut from a thin ribbon foil of tantalum alloy, which has particle-stabilizing properties. The bare ribbon is brazed to an aluminum nitride substrate in such a way that the ribbon is placed in minimal tension before being machined into a geometric pattern such as a helix. This prevents distortion of the planar figure by the cutting process or by handling and mounting. The spiral pattern can be optimized for electrical and thermal properties. The resulting cathode assembly is mounted to a header (sometimes referred to as a "first substrate") for mechanical and electrical connection to the rest of the X-ray tube assembly. The remainder of the tantalum ribbon on the outside of the cathode spiral forms an equipotential surface that contributes to a very collimated and easily focussable electron beam.

[0007] This particular implementation addresses the fragility of such a structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com