Method for preparing solid particle emulsifier by compounding random copolymer with homopolymer

A technology of random copolymers and solid particles, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve the problems of uneven distribution, large particle size of micelles, unstable micelles, etc. The reaction conditions are easy to control, the preparation method is simple, and the conditions are mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

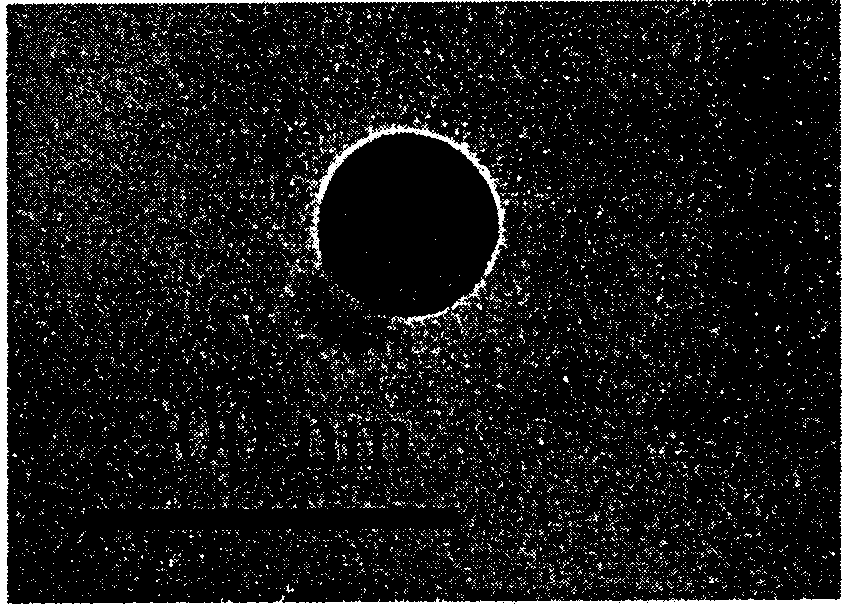

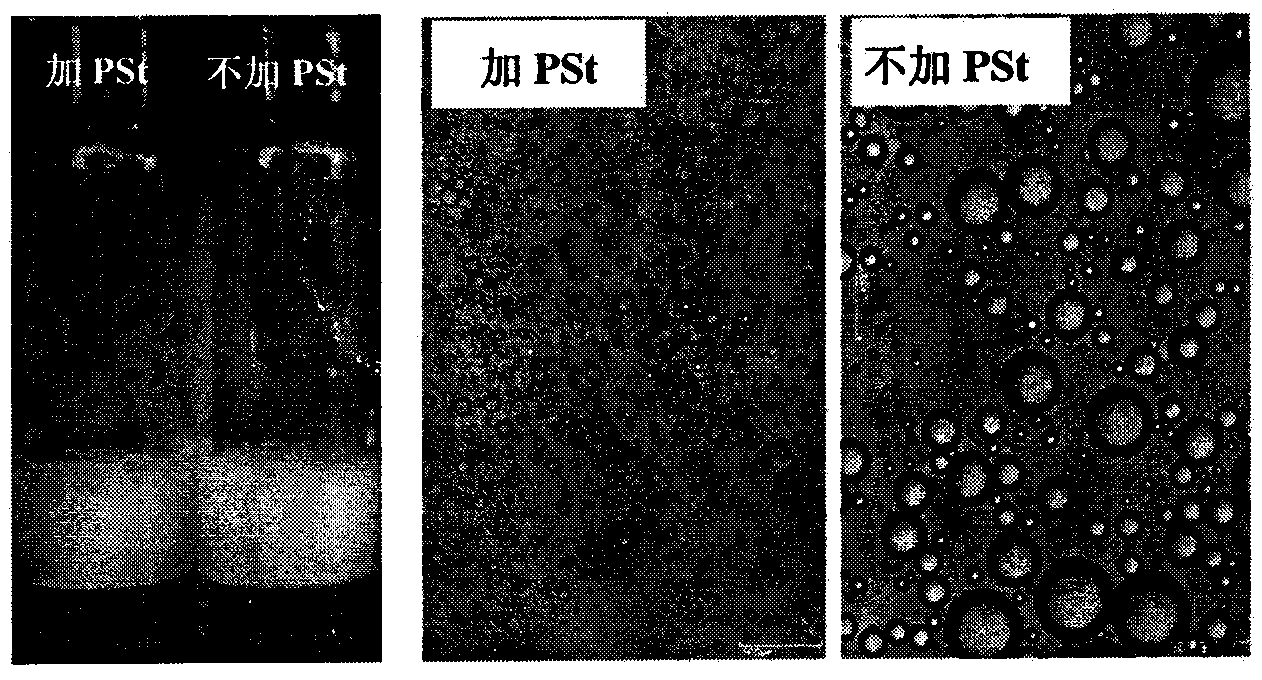

Image

Examples

Embodiment 1

[0018] (1) Preparation of amphiphilic random copolymer P(St-co-DM): Weigh 6.24g styrene (St) (30mmol) and 9.42g dimethylaminoethyl methacrylate (DM) (30mmol) respectively Add to a 50mL single-necked flask, add initiator AIBN (0.0783g, 0.5mmol), dissolve in 15mL of dioxane, fill with nitrogen, vacuumize, repeat 3 times to remove oxygen in the system, and react in an oil bath at 70°C 24h. After the reaction, use petroleum ether (30-60°C) as a precipitant, tetrahydrofuran (THF) as a solvent, dissolve and precipitate three times repeatedly, and finally dry in vacuum at 40°C to remove the solvent to obtain an amphiphilic random copolymer P (St-co-DM).

[0019] (2) Preparation of homopolymer PSt: Weigh 12.48g styrene and add it to a 100mL single-necked flask, add initiator AIBN (0.13g, 1mmol), dissolve in 30mL dioxane, fill with nitrogen, vacuumize, repeat 3 times Once, to remove the oxygen in the system, react in a 70°C oil bath for 24h. After the reaction, use petroleum ether (30...

Embodiment 2

[0023] (1) Prepare amphiphilic random copolymer P(St-co-AA) with 6.24g styrene and 4.32g acrylic acid, and prepare polystyrene with 12.48g styrene. Dissolve 100mg of amphiphilic random copolymer P(St-co-DM) and 25mg of homopolymer PSt in 10mL of co-solvent N,N-dimethylformamide self-assembly, and use self-assembly to obtain micellar particle emulsifier Make lotion.

[0024] (2) Refer to Example 1 for the specific preparation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com