Modified polyurethane asphalt material

An asphalt material, polyurethane technology, applied in building insulation materials, building components, buildings, etc., can solve problems such as cracking and poor weather resistance, improve compatibility, improve high temperature deformation, improve weather resistance and tensile properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

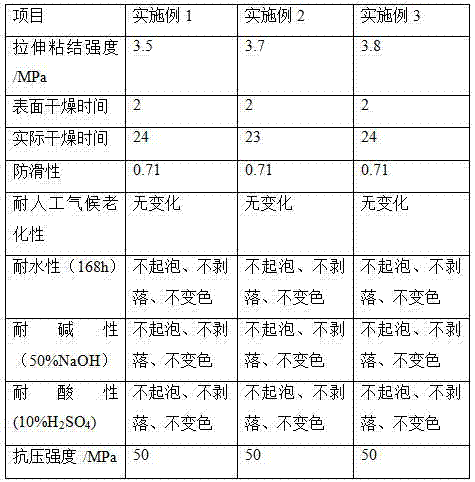

Examples

Embodiment 1

[0021] The modified polyurethane asphalt material consists of A component and B component:

[0022] Among them, component A is made of the following raw materials in parts by weight: 80 parts of modified polyurethane prepolymer, 8 parts of anhydrous butyl acetate, 15 parts of cyclohexanone, 60 parts of xylene, 8 parts of color paste, 40 parts of talcum powder, 11 parts of heavy calcium carbonate, 0.5 parts of N-methyldiethanolamine, 0.5 parts of monoethanolamine, 0.5 parts of BYK-320, 0.3 parts of BYK-052N, 0.3 parts of DISPERBYK-2163;

[0023] Component B is made of the following raw materials: 50 parts of coal tar pitch, 10 parts of polyester.

[0024] The mass ratio of A:B components is 3:1.

[0025] The modified polyurethane prepolymer is a siloxane modified polyurethane prepolymer. Specifically, polyoxypropylene diol and toluene diisocyanate TDI are mixed as raw materials according to a mass ratio of 54:43, heated to 90°C for 1 hour, and then added KH560, continue to re...

Embodiment 2

[0033] The modified polyurethane asphalt material is composed of component A and component B: wherein component A is made of the following raw materials in parts by weight: 85 parts of modified polyurethane prepolymer, 9 parts of anhydrous butyl acetate, cyclohexanone 18 parts, 62 parts of xylene, 9 parts of color paste, 45 parts of talcum powder, 12 parts of heavy calcium carbonate, 0.4 part of N-methyldiethanolamine, 0.4 part of monoethanolamine, 0.4 part of BYK-320, BYK-052N0.6 parts, DISPERBYK-2163 0.4 parts;

[0034] Component B is made of the following raw materials: 55 parts of coal tar pitch, 13 parts of polyester.

[0035] The mass ratio of A:B components is 3:1.

[0036] The modified polyurethane prepolymer is a siloxane modified polyurethane prepolymer. Specifically, polyoxypropylene diol and toluene diisocyanate TDI are mixed as raw materials according to a mass ratio of 54:43, heated to 90°C for 1 hour, and then added KH560, continue to react for 0.5h to obtain ...

Embodiment 3

[0044] The modified polyurethane asphalt material is composed of component A and component B: wherein component A is made of the following raw materials in parts by weight: 90 parts of modified polyurethane prepolymer, 10 parts of anhydrous butyl acetate, cyclohexanone 20 parts, 65 parts xylene, 10 parts color paste, 50 parts talcum powder, 15 parts heavy calcium carbonate, 0.5 parts N-methyldiethanolamine, 0.5 parts monoethanolamine, 0.5 parts BYK-320, BYK-052N0.6 parts, DISPERBYK-2163 0.5 parts;

[0045] Component B is made of the following raw materials: 60 parts of coal tar pitch, 15 parts of polyester.

[0046] The mass ratio of A:B components is 3:1.

[0047] The modified polyurethane prepolymer is a siloxane modified polyurethane prepolymer. Specifically, polyoxypropylene diol and toluene diisocyanate TDI are mixed as raw materials according to a mass ratio of 54:43, heated to 90°C for 1 hour, and then added KH560, continue to react for 0.5h to obtain a modified polyu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com