Graphene reinforced alumina-based ceramic bearing for robot

A technology of alumina ceramic powder and graphene, which is applied in the field of precision casting, can solve problems such as the restriction of alumina ceramic cores, affecting the dimensional accuracy of blades and casting pass rate, and the decline in high temperature performance of alumina ceramic cores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

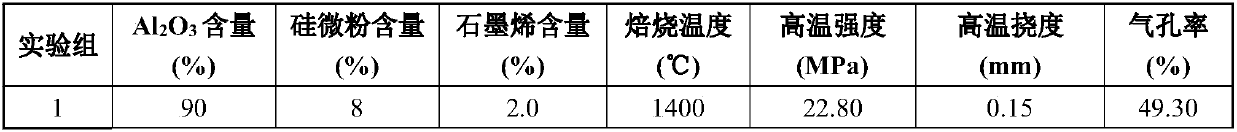

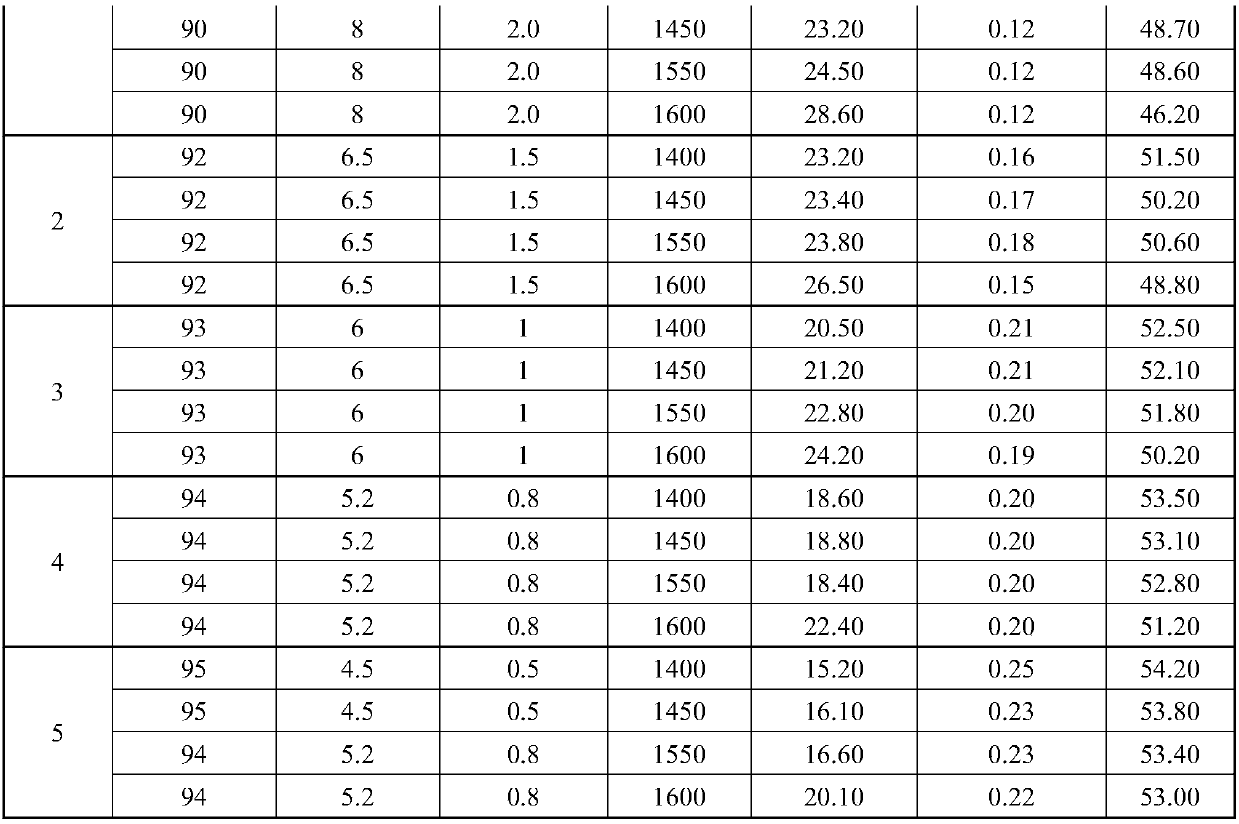

Examples

preparation example Construction

[0021] A method for preparing a graphene-enhanced alumina-based ceramic bearing for a robot, comprising the following steps:

[0022] (1) Alumina ceramic powder, silicon oxide powder, and graphene powder are mixed according to the weight percentage using a three-dimensional mixer to make a ceramic powder with uniform mixing and uniform composition.

[0023] (2) Add a plasticizer accounting for 15% to 24% of the mass of the ceramic powder, first dissolve the plasticizer, then gradually add the ceramic powder to the plasticizer, and continue stirring after all the ceramic powder is added 10h~20h to prepare ceramic core slurry.

[0024] (3) Adopt hot pressure injection molding method to prepare ceramic core, the ceramic core slurry that will obtain in step (2) is packed in injection equipment, obtain required wet state ceramic core in mold, injection pressure 2MPa ~ 4MPa, and keep the pressure for 10s ~ 30s;

[0025] (4) Sinter the wet ceramic core obtained in step (3) under th...

Embodiment 1

[0030] A graphene-enhanced alumina-based ceramic bearing for a robot is prepared from the following raw materials: 45% of 200-mesh alumina powder, 45% of 325-mesh alumina powder, 8% of nano-silica powder, and submicron graphene powder 2%. A plasticizer accounting for 15% of the mass of the ceramic powder is added.

[0031] The preparation method of ceramic core comprises:

[0032] (1) Alumina ceramic powder, silicon oxide powder and graphene powder are mixed using a three-dimensional mixer to make a ceramic powder that is evenly mixed and has a uniform composition.

[0033] (2) Add a plasticizer accounting for 15% of the mass of the ceramic powder. After the plasticizer is dissolved, the ceramic powder is gradually added to the plasticizer. After all the ceramic powder is added, continue stirring for 10 hours to obtain a ceramic core slurry.

[0034] (3) adopt hot pressure injection molding method to prepare ceramic core, the raw material that will obtain in step (1) is pac...

Embodiment 2

[0038]A graphene-enhanced alumina-based ceramic bearing for a robot is prepared from the following raw materials: 46% of 200-mesh alumina powder, 46% of 325-mesh alumina powder, 6.5% of nano-silica powder, and submicron graphene powder 1.5%. A plasticizer accounting for 18% of the mass of the ceramic powder is added.

[0039] The preparation method of ceramic core comprises:

[0040] (1) Alumina ceramic powder, silicon oxide powder and graphene powder are mixed using a three-dimensional mixer to make a ceramic powder that is evenly mixed and has a uniform composition.

[0041] (2) Add a plasticizer accounting for 18% of the mass of the ceramic powder. After the plasticizer is dissolved, the ceramic powder is gradually added to the plasticizer. After all the ceramic powder is added, continue stirring for 15 hours to obtain a ceramic core slurry.

[0042] (3) adopt hot pressure injection molding method to prepare ceramic core, the raw material that will obtain in step (1) is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature strength | aaaaa | aaaaa |

| High temperature strength | aaaaa | aaaaa |

| High temperature strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com