A method and equipment capable of improving the efficiency of ceramic core removal

A ceramic core and core removal technology, which is applied in the field of rapid removal of alumina-based ceramic cores for hollow turbine blades, can solve the problems of slow core removal rate and hinder the core removal reaction, so as to improve efficiency and eliminate reaction chambers Explosion, the effect of shortening the time of useless work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

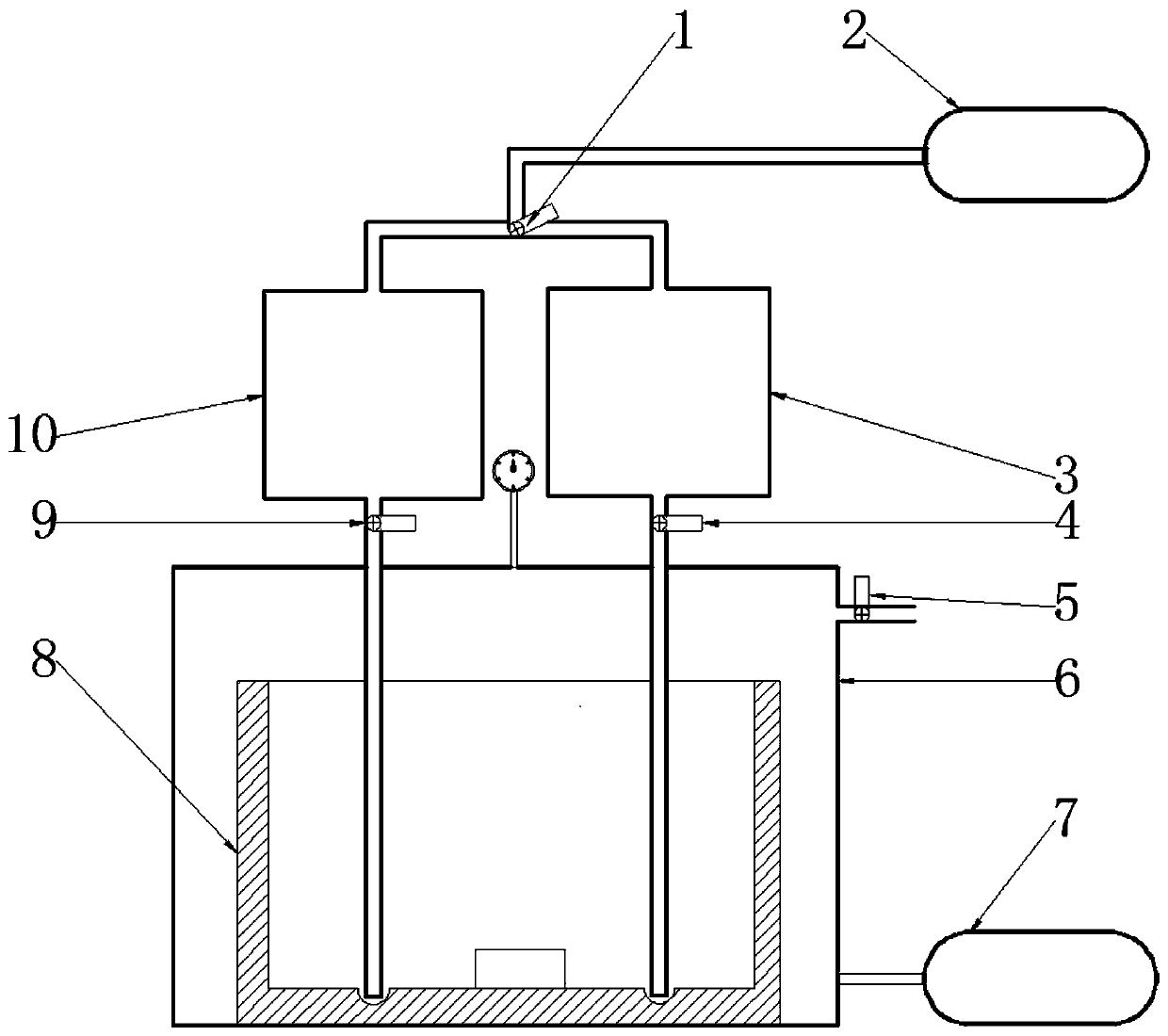

[0034] Such as figure 1 As shown, the present invention proposes a method and equipment that can improve the efficiency of ceramic core removal, wherein the equipment includes: electromagnetic reversing valve 1, vacuum pump 2, lye chamber 3, lye chamber solenoid valve 4, deflation Solenoid valve 5, pressure chamber 6, pressure stabilizing air pump 7, reaction chamber 8, clean water chamber solenoid valve 9 and clean water chamber 10, the specific structure is as follows:

[0035] 1) The pressure container is a pressure chamber 6, which is provided with an air release port and an air release solenoid valve 5, and the blades can be removed by opening the top cover; the pressure chamber 6 communicates with the pressure stabilizing air pump 7.

[0036] 2) The reaction chamber 8 is placed in the pressure chamber 6, and there are two grooves at the bottom of the reaction chamber 8 to match with the pipes under the clean water chamber 10 and the lye chamber 3 respectively, and are us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com