Hollow ceramic core by mold swing method and preparation method thereof

A technology of hollow ceramics and cores, which is applied to cores, casting molding equipment, casting molds, etc., can solve the problems of low cleaning efficiency and difficulty in cleaning and removing ceramic cores, so as to reduce the workload of core removal, Improved core removal efficiency and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

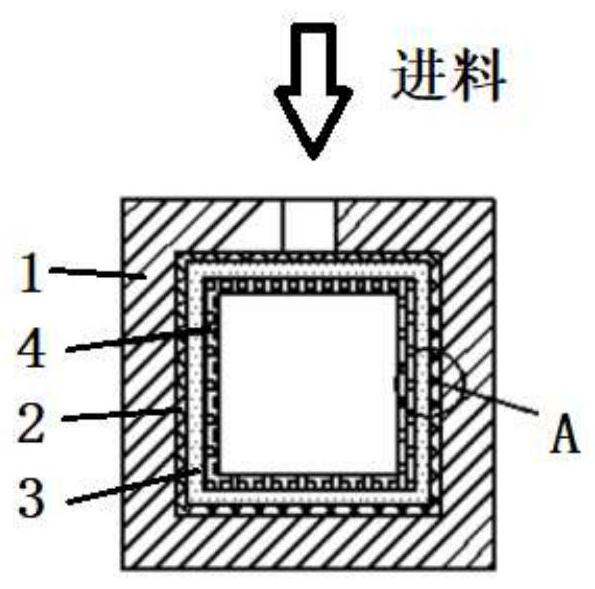

[0028] The preparation method of the above-mentioned hollow ceramic core of the present invention is implemented according to the following steps:

[0029] Step 1, preparing refractory beads adhered with binder,

[0030] Weigh 90%-96% of refractory matrix raw material, 1%-5% of binder, 0.25%-1% of catalytic curing agent, 0.05%-0.1% of lubricating and dispersing agent, 0.05%-0.5% of two-phase coupling agent according to mass percentage %, mix and stir evenly to obtain refractory beads of aluminum oxide adhered with binder.

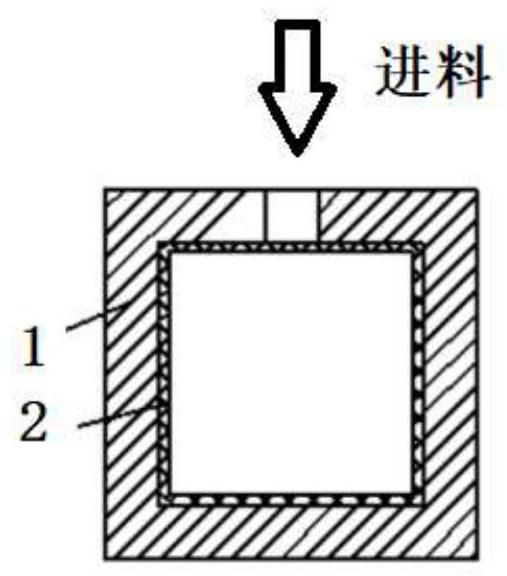

[0031] Step 2, blowing the refractory beads prepared in step 1 into a closed swing range of 30°-90° (heat-resistant steel) mold 1 to prepare the core body, the specific process is as follows:

[0032] Prepare surface layer 2 (surface layer 2 is close to the inner wall of mold 1): heat mold 1 to 150-300°C, blow in fused corundum beads or white corundum beads of 100-500 mesh, heating time 30-40s, and shake the mold 1. Make the refractory beads evenly form a...

Embodiment 1

[0038] Step 1, preparing refractory beads with binder,

[0039] The raw materials were weighed according to the following mass percentages: refractory matrix material fused corundum beads 96%, binder 3%, catalytic curing agent 0.45%, lubricating dispersant barium stearate 0.05%, two-phase coupling agent aluminum acid compound coupling 0.5% of the joint agent is mixed and stirred evenly to obtain the aluminum oxide refractory beads with the binder.

[0040] Step 2. Blow the refractory beads prepared in step 1 into a closed heat-resistant steel mold with a swing range of 30°-90° to prepare the core body. The specific process is as follows:

[0041] Preparation of surface layer 2: Heat the mold to 150°C, blow in 500-mesh refractory beads, heat for 30s, shake the mold so that the refractory beads evenly form a dense sintered layer of aluminum oxide with a thickness of 0.2mm on the inner wall of the mold, turn over the mold, Pour off excess refractory beads.

[0042] Preparation ...

Embodiment 2

[0047] Step 1. Preparation of refractory beads with binder

[0048] The raw materials were weighed according to the following mass percentages: refractory matrix material fused corundum beads 95%, binder 4%, catalytic curing agent 0.4%, lubricating dispersant barium stearate 0.545%, two-phase coupling agent aluminum acid compound coupling 0.055% of the joint agent is mixed and stirred evenly to obtain the aluminum oxide refractory beads with the binder.

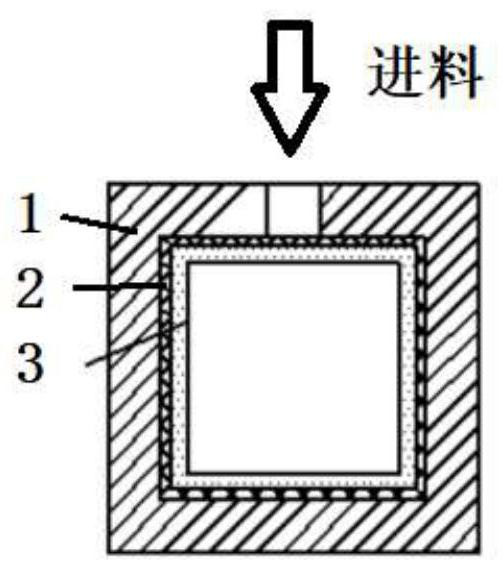

[0049]Step 2. Blow the refractory beads prepared in step 1 into a closed heat-resistant steel mold with a swing range of 30°-90° to prepare a hollow ceramic core. The specific process is:

[0050] Preparation of surface layer 2: Heat the mold to 170°C, blow in 300-mesh refractory beads, heat for 35s, shake the mold so that the refractory beads are evenly formed on the inner wall of mold 1 to form a dense sintered layer of 0.4mm aluminum oxide, turn over the mold, Pour off excess refractory beads.

[0051] Preparation of inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com