A kind of preparation method of gradient ceramic core material

A technology of ceramic core and ceramic powder, which is applied in the direction of core, casting molding equipment, casting mold, etc., can solve the problems of reducing the qualified rate, shrinkage or deformation, and long core removal time, so as to reduce the cost of raw materials and prevent shrinkage. Or deformation, improve the effect of core removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

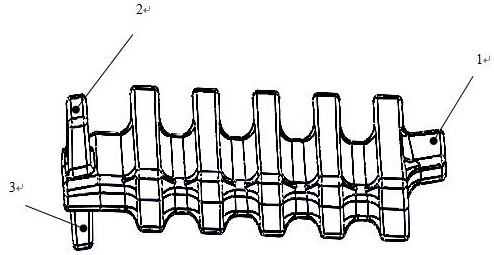

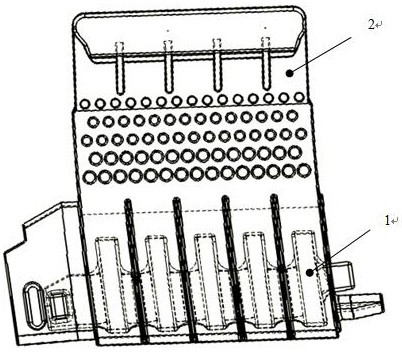

Image

Examples

Embodiment 1

[0028] A preparation method of a gradient ceramic core material, comprising the following steps:

[0029] (1) After drying 325 mesh, 150 mesh, and 70 mesh fused silica powder with a purity of 92.3% and 350 mesh alumina powder with a purity of 95.6% at 120°C for 90 minutes, the mass ratio is 40% :30%:20%:10% mix evenly.

[0030] (2) Heat the paraffin wax (No. 70) to 90°C to completely melt, add a small amount of oleic acid and mix evenly, slowly add the mixed powder prepared in step (1) to the wax liquid in batches, stir evenly and then vacuumize , to prepare 1# ceramic slurry. The mass ratio of paraffin wax, oleic acid and mixed powder is 19.6%: 0.4%: 80%.

[0031] (3) After drying the fused silica powder of 325 mesh, 150 mesh, and 70 mesh with a purity of 99.5% and 800 mesh alumina powder with a purity of 99.3% at 120°C for 90 minutes, the mass ratio is 45% : 25%: 20%: 10% mix evenly.

[0032] (4) After heating the paraffin wax (No. 58) to 80°C and completely melting, add...

Embodiment 2

[0038] A preparation method of a gradient ceramic core material, comprising the following steps:

[0039] (1) After drying the fused silica powder with a purity of 92.0% and 400 mesh alumina powder with a purity of 96.4% of 400 mesh, 200 mesh, and 100 mesh at 120°C for 90 minutes, the mass ratio is 35% : 30%: 20%: 15% mix evenly.

[0040] (2) After heating the paraffin (No. 64) to 85°C and completely melting, add a small amount of oleic acid, and then slowly add the mixed powder prepared in step (1) to the wax liquid in batches, paraffin, oleic acid and mixed powder The mass ratio of the material is 24.62%: 0.38%: 75%. After stirring evenly, vacuumize to prepare 1# ceramic slurry.

[0041] (3) After drying 400 mesh, 200 mesh, and 100 mesh fused silica powder with a purity of 98.9% and 1000 mesh alumina powder with a purity of 99.5% at 120°C for 90 minutes, the mass ratio is 40%: The ratio of 30%: 20%: 10% is evenly mixed.

[0042] (4) After heating the paraffin (No. 52) to ...

Embodiment 3

[0049] A preparation method of a gradient ceramic core material, comprising the following steps:

[0050] (1) After drying 325 mesh, 150 mesh, and 70 mesh fused silica powder with a purity of 92.3% and 350 mesh alumina powder with a purity of 95.6% at 120°C for 90 minutes, the mass ratio is 40% :30%:20%:10% mix evenly.

[0051] (2) Heat the paraffin wax (No. 70) to 90°C to completely melt, add a small amount of oleic acid and mix evenly, slowly add the mixed powder prepared in step (1) to the wax liquid in batches, stir evenly and then vacuumize , to prepare 1# ceramic slurry. The mass ratio of paraffin wax, oleic acid and mixed powder is 14.57%: 0.43%: 85%.

[0052] (3) After drying the fused silica powder of 325 mesh, 150 mesh, and 70 mesh with a purity of 99.5% and 800 mesh alumina powder with a purity of 99.3% at 120°C for 90 minutes, the mass ratio is 45% :25%:20%:10% mix evenly.

[0053] (4) After heating the paraffin wax (No. 58) to 80°C and completely melting, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com