A casting core removal device

A technology for castings and components is applied in the field of sand core removal of castings, which can solve the problems of increasing the labor load of workers and reducing the efficiency of sand core removal of castings, and achieves the effect of reducing labor force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

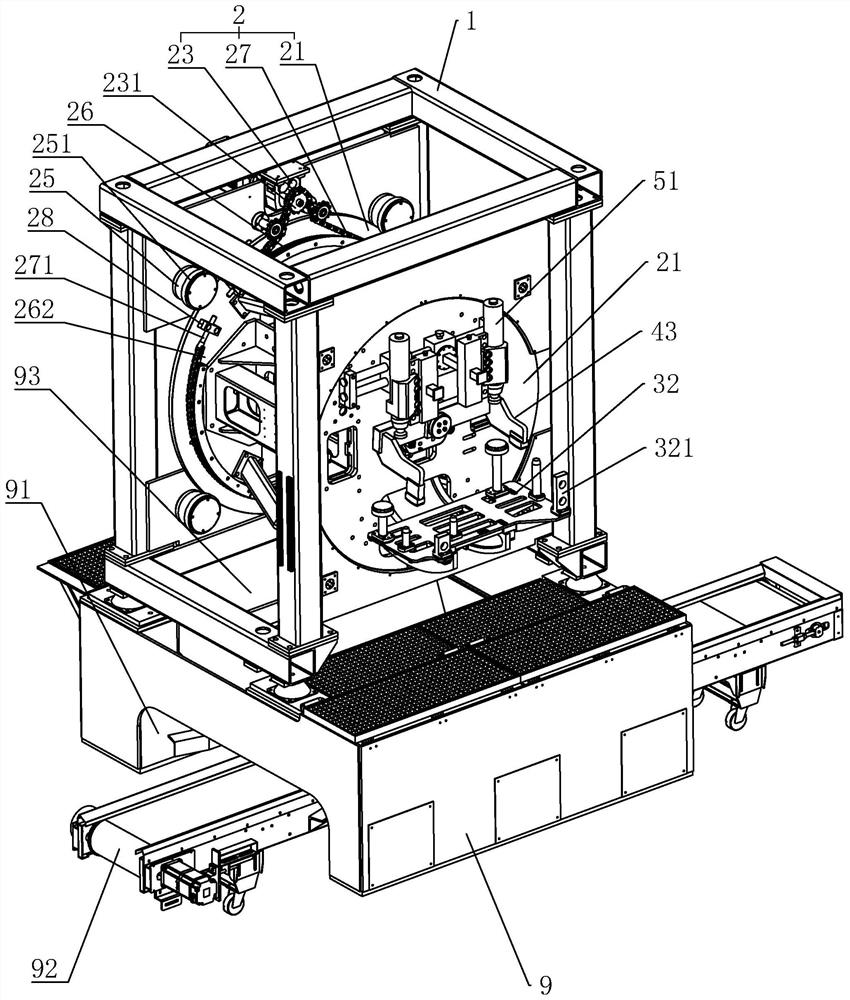

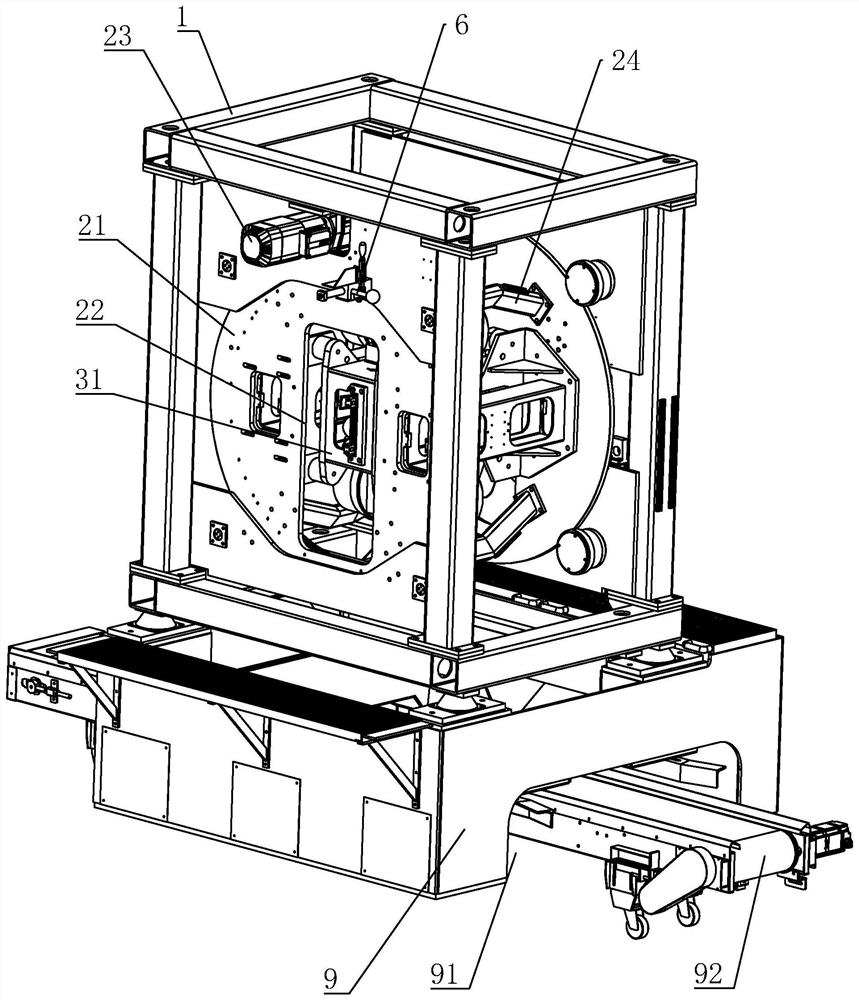

[0045] Embodiment: a kind of casting coring removal device, with reference to figure 1 , including fixed frame 1, rotating assembly 2, fixed assembly 3 (refer to Figure 6 ), pressing assembly 4 (refer to Figure 6 ) and hammer assembly 5 (refer to Figure 7 ). During the working process, the fixed frame 1 is used to support the cast parts of the structure of the present invention. The fixing assembly 3 is used to place the casting, and the pressing assembly 4 is used to compress the casting, so that the casting is fixed on the present invention. The hammer assembly 5 is used to shatter the sand core in the casting so that the sand core is separated from the inner cavity of the casting. The rotating assembly 2 can drive the casting to rotate, so that the sand core in the casting can fall out through each sand outlet.

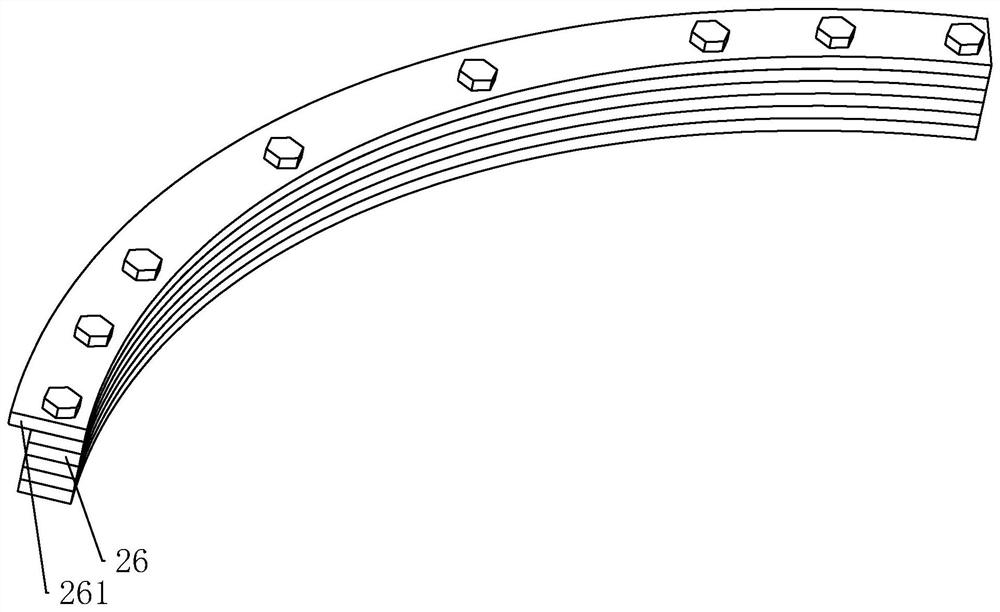

[0046] refer to figure 1 and figure 2 , The rotating assembly 2 includes a rotating disc 21 , a driving chain 27 and a driving motor 23 . There are two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com