Multifunctional permeable asphalt mixture and preparation method thereof

A technology of permeable asphalt and mixture, which is applied in the field of multifunctional permeable asphalt mixture and its preparation, can solve the problems of poor low-temperature stability and high cost of modified asphalt, improve viscosity and high-temperature deformation resistance, reduce preparation cost, and resist The effect of improved shear deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of modified asphalt:

[0026] Heat the finished 70# base asphalt to 180°C, add 2% SBS, 2% tackifier terpene resin, 8% waste rubber powder, stir for 30 minutes, then shear at 190°C for 1 hour at 6000rpm, and develop at 160°C 1h, add 0.2% MWCNT, shear at 5000rpm at 160°C for 30min, and develop at 160°C for 1h to obtain modified asphalt.

[0027] Preparation of multifunctional permeable asphalt mixture:

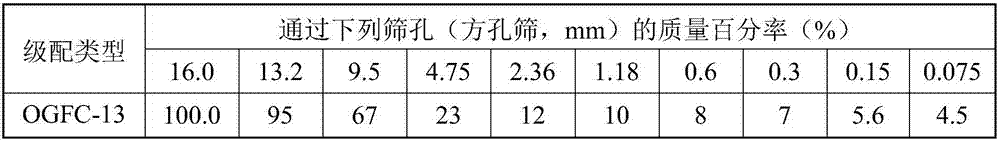

[0028] (1) The gradation is as follows, the oil-stone ratio is 4.8%, and the equal volume of percolation material replaces 50% of fine aggregate.

[0029]

[0030]

[0031] (2) Preparation process

[0032] Mineral material heating temperature 190~200℃ asphalt heating temperature 180℃ mixing temperature of asphalt mixture 185-190℃ Compaction temperature 170℃

Embodiment 2

[0034] Preparation of modified asphalt:

[0035] Heat the finished 70# base asphalt to 180°C, add 3% SBS, 1.5% tackifier terpene resin, 8% waste rubber powder, stir for 30min, then shear at 190°C for 1 hour at 6000rpm, and develop at 160°C 1h, add 0.3% MWCNT, shear at 5000rpm at 160°C for 30min, and develop at 160°C for 1h to obtain modified asphalt.

[0036] Preparation of multifunctional permeable asphalt mixture:

[0037] (1) The gradation is as follows, the oil-stone ratio is 4.8%, and the equal volume of percolation material replaces 30% of fine aggregate.

[0038]

[0039] (2) Preparation process

[0040] Mineral material heating temperature 190~200℃ asphalt heating temperature 180℃ mixing temperature of asphalt mixture 185-190℃ Compaction temperature 170℃

Embodiment 3

[0042] Preparation of modified asphalt:

[0043] Heat the finished 70# matrix asphalt to 180°C, add 3% SBS, 2% tackifier terpene resin, 8% waste rubber powder, stir for 30min, then shear at 190°C for 1h at 6000rpm, and develop at 160°C 1h, add 0.2% MWCNT, shear at 5000rpm at 160°C for 30min, and develop at 160°C for 1h to obtain modified asphalt.

[0044]Preparation of multifunctional permeable asphalt mixture:

[0045] (1) The gradation is as follows, the oil-stone ratio is 4.8%, and the equal volume of percolation material replaces 10% fine aggregate.

[0046]

[0047] (2) Preparation process

[0048] Mineral material heating temperature 190~200℃ asphalt heating temperature 180℃ mixing temperature of asphalt mixture 185-190℃ Compaction temperature 170℃

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com