Preparation method of high-temperature-rutting-resistant warm mix asphalt mixture

A warm-mix asphalt and mixture technology, applied in the direction of climate change adaptation, etc., can solve the problem of affecting the high-temperature stability and low-temperature cracking resistance of asphalt mixture, reducing the mixing temperature of asphalt mixture, and the bonding between binder and aggregate To avoid problems such as small force, to achieve the effect of enhanced high temperature rutting resistance, improved viscoelastic performance, and enhanced toughness

Inactive Publication Date: 2018-09-07

吕莉

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The technical problem mainly solved by the present invention is aimed at reducing the mixing temperature of the asphalt mixture for the current warm asphalt mixture, which will affect the high temperature stability and low temperature cracking resistance of the asphalt mixture.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

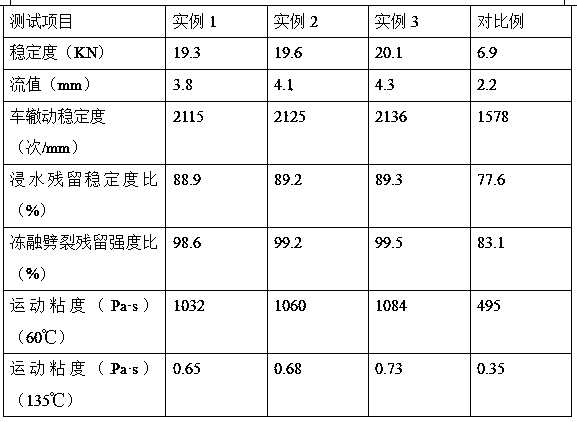

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of the preparation of road engineering materials, in particular to a preparation method of a high-temperature-rutting-resistant warm mix asphalt mixture. The preparation method comprises the following steps: dispersing SBS rubber powder in the mixed asphalt to obtain the asphalt with the dispersed SBS rubber powder, adding the asphalt with the dispersedSBS rubber powder into white mineral oil, performing high-speed cutting emulsification to obtain rubber powder modified asphalt, mixing filled aggregate rubber powder modified asphalt, a warm mix agent and quick lime to obtain the high-temperature-rutting-resistant warm mix asphalt mixture. The warm mix asphalt mixture is dispersed in the white mineral oil in a small particle form, the solubilitybetween the white mineral oil molecules and the SBS molecules is improved, the low-temperature fracturing resistance of the warm mix asphalt mixture and the adhesive force between binder and aggregates at the low temperature can be improved, and the molten fiber components and little un-molten components coat the surface of stone to form a bridging effect between the stone and the asphalt and between the stone and stone, so that a large adhesive force is produced, the viscosity elasticity of the white mineral oil is improved, and the application prospect is wide.

Description

technical field [0001] The invention relates to the technical field of preparation of road engineering materials, in particular to a method for preparing a high-temperature rutting-resistant warm-mix asphalt mixture. Background technique [0002] The pace of highway construction in my country is accelerating, and the maintenance and repair tasks of roads are intensified accordingly. my country has gradually changed from the construction stage to the maintenance stage. Due to the characteristics of the semi-rigid base pavement structure in my country, there are many reflection cracks in the early diseases of highways. In addition, there are many heavy-duty vehicles in my country's road vehicles, and the phenomenon of heavy traffic is common. Under heavy-duty traffic, the early damage of asphalt pavement is serious. The typical type of road damage under heavy traffic is high-temperature rutting. Therefore, how to effectively improve the deformation resistance of asphalt mixtu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B24/36C04B111/34

CPCC04B24/36C04B2111/0075C04B2111/343C04B14/06C04B24/045C04B22/0046C04B14/185C04B18/027C04B14/386C04B24/383C04B24/2676C04B22/064C04B24/00Y02A30/30

Inventor 吕莉何伟仁张建初

Owner 吕莉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com