High temperature deformation-resistant modified polypropylene random (PPR) copolymer tube and preparation method thereof

A polypropylene pipe, random copolymerization technology, used in rigid pipes, pipes, machinery and equipment, etc., can solve the problems of easy deformation of PPR pipes, and achieve the effects of easy processing, cost reduction, and high temperature deformation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

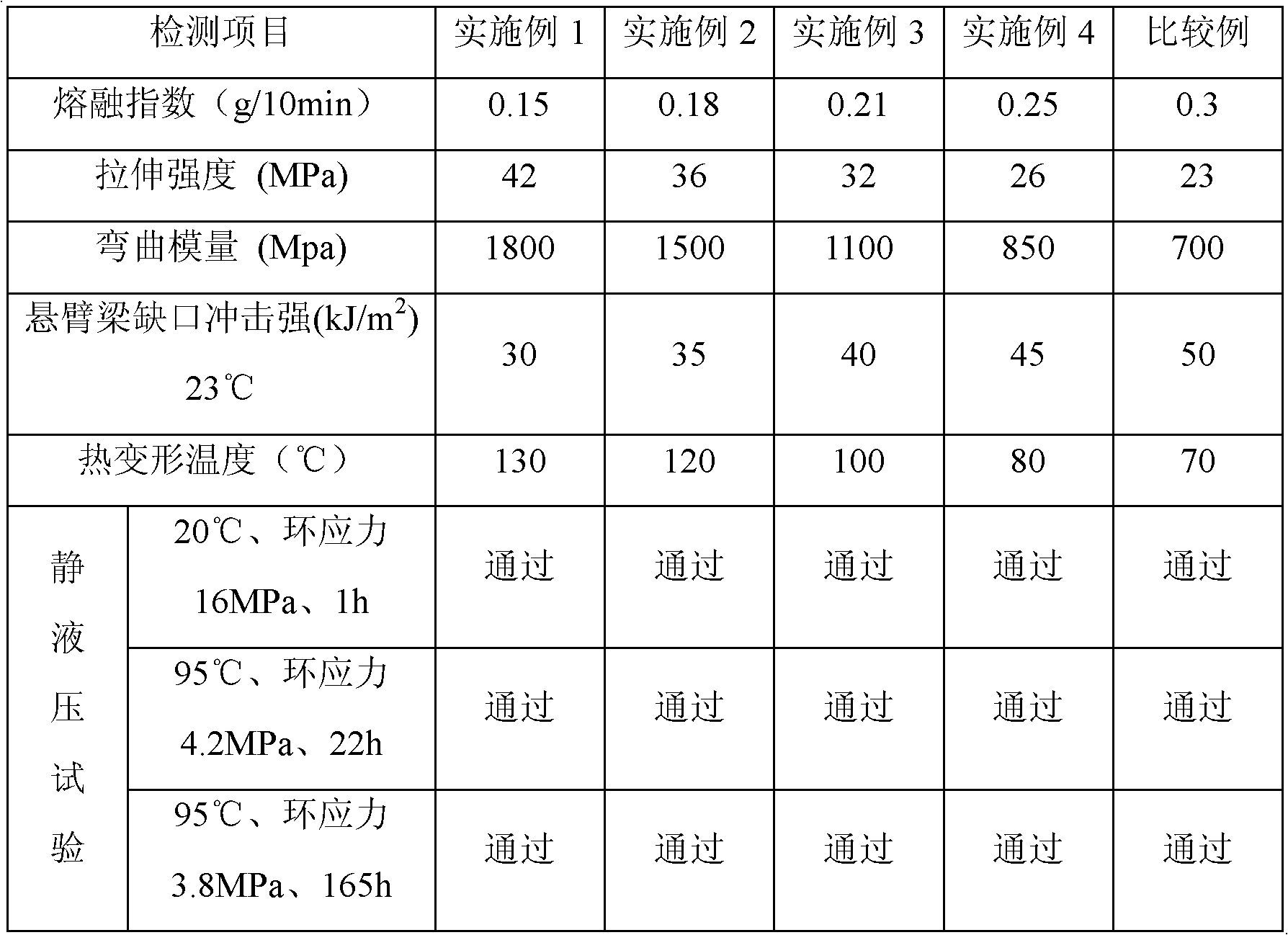

[0034] Table 1 has listed the formula of embodiment 1-4, and by the component listed in table 1 and weight part thereof, with PPR special material, talcum powder, α nucleating agent, antioxidant dry mix 3 minutes in high-speed mixer ;Then melt and extrude the mixed raw materials with a twin-screw extruder, and granulate; finally, extrude the granulated raw materials with a fully automatic integrated pipe, and process it into a pipe. The process is: feeding section 160-180°C, compression section 180-200°C, plasticizing section 180-210°C, homogenizing section 200-220°C, die opening temperature 190-210°C. The feed section is 170-180°C, the compression section is 190-210°C, the plasticizing section is 210-220°C, the homogenization section is 200-220°C, and the die temperature is 190-210°C.

Embodiment 5-8

[0048] The formula of embodiment 5-8 is as shown in table 3.

[0049] According to the components listed in Table 3 and their parts by weight, dry mix the PPR special material, talcum powder, NA-10, and antioxidant in a high-speed mixer for 3 minutes; then melt the mixed raw materials with a twin-screw extruder Extrusion and granulation; finally, the granulated raw materials are extruded with fully automatic integrated pipes and processed into pipes. The process is: feeding section 160-180°C, compression section 180-200°C, plasticizing section 180-210°C, homogenizing section 200-220°C, die opening temperature 190-210°C. The feed section is 170-180°C, the compression section is 190-210°C, the plasticizing section is 210-220°C, the homogenization section is 200-220°C, and the die temperature is 190-210°C.

[0050] The formula of table 3 embodiment 5-8

[0051] Components (parts by weight)

[0052] PPR4220

Embodiment 9-12

[0054] The formulations of Examples 9-12 are shown in Table 4.

[0055]According to the components listed in Table 4 and their parts by weight, dry mix the PPR special material, talcum powder, NA-10, and antioxidant in a high-speed mixer for 3 minutes; then melt the mixed raw materials with a twin-screw extruder Extrusion and granulation; finally, the granulated raw materials are extruded with fully automatic integrated pipes and processed into pipes. The process is: feeding section 160-180°C, compression section 180-200°C, plasticizing section 180-210°C, homogenizing section 200-220°C, die opening temperature 190-210°C. The feed section is 170-180°C, the compression section is 190-210°C, the plasticizing section is 210-220°C, the homogenization section is 200-220°C, and the die temperature is 190-210°C.

[0056] The formula of table 4 embodiment 9-12

[0057] Components (parts by weight)

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com