Method and device for preparing carbon nanotubes

A technology of carbon nanotubes and nanotubes, which is applied in the field of preparing carbon nanotubes, can solve problems such as the general performance of carbon nanotubes, and achieve the effects of large coercivity, high magnetization, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

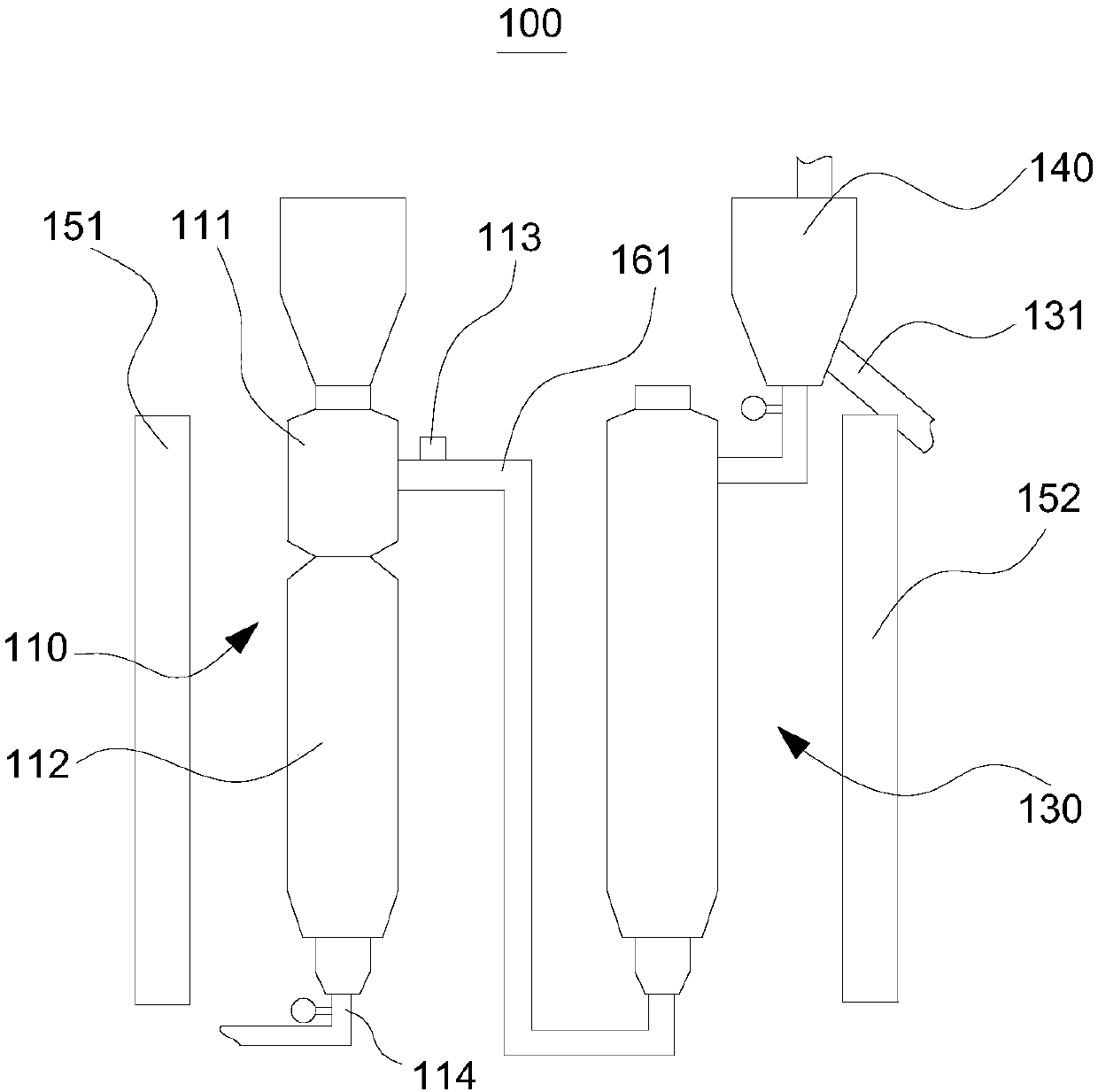

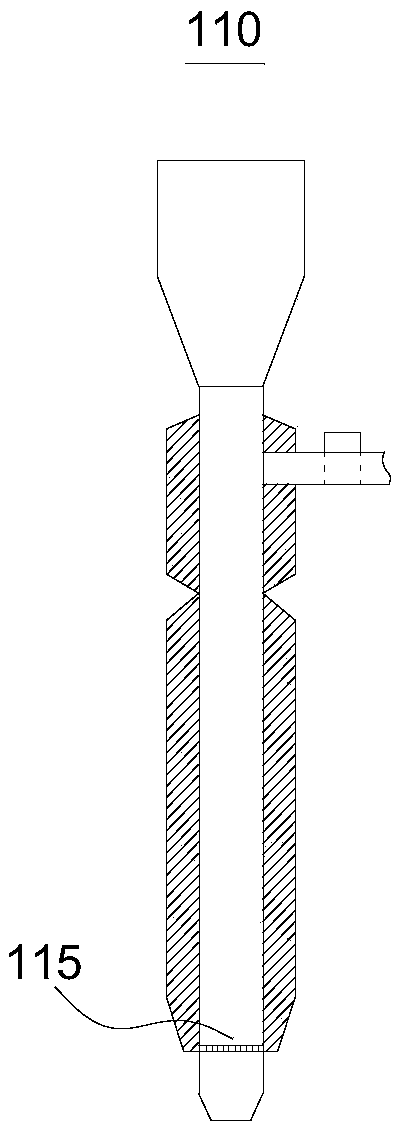

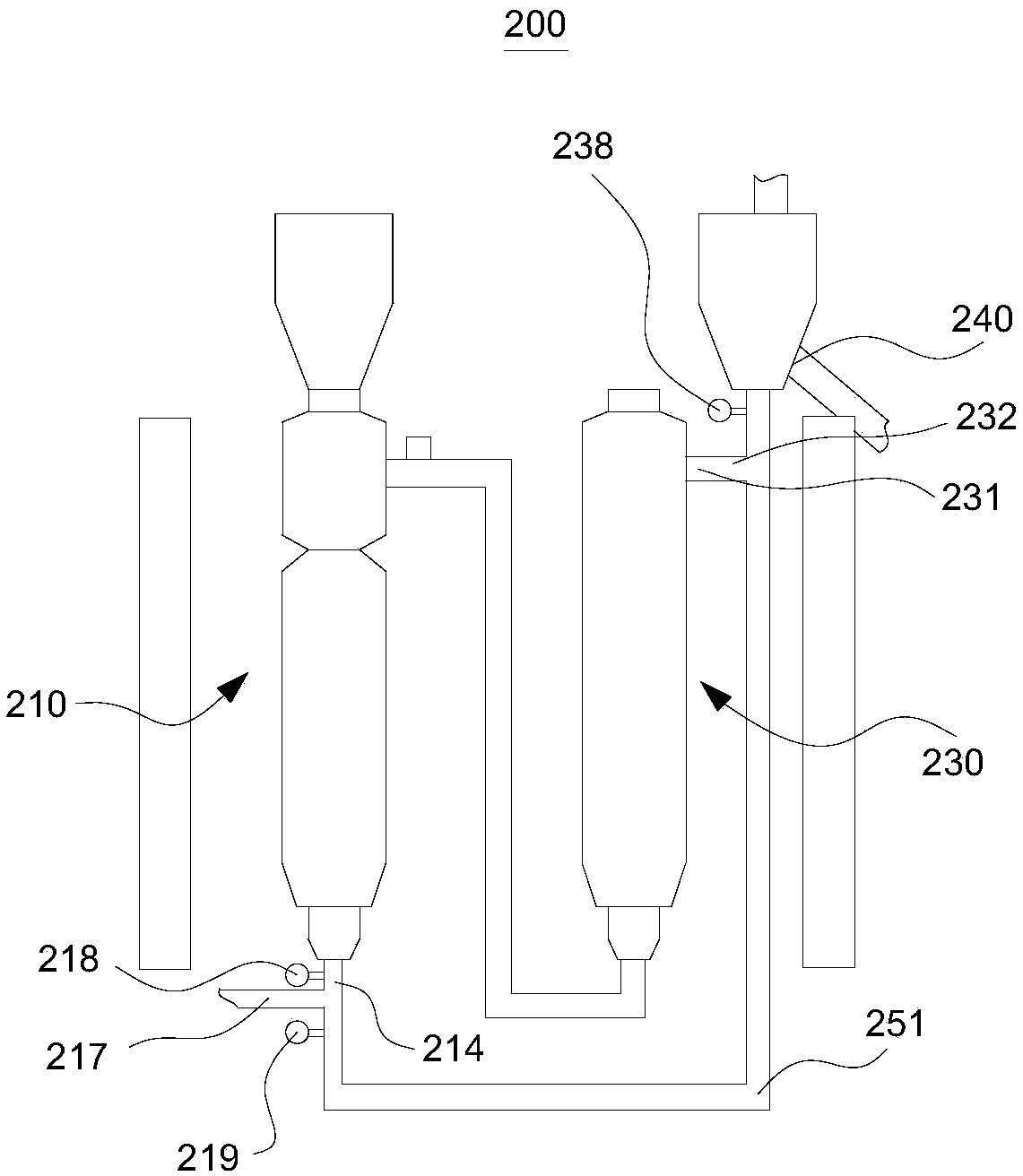

[0041] A method for preparing carbon nanotubes, the first choice is to weigh iron pentacarbonyl and nickel tetracarbonyl with a mass ratio of 370:163, and prepare the mass ratio of carbon contained to iron pentacarbonyl and nickel tetracarbonyl to be 5 to 7:3 Carbon source of ~5. Add the mixture of iron pentacarbonyl and nickel tetracarbonyl into the first-stage fluidized bed in the multi-stage serial fluidized bed, heat it at 225°C until it is decomposed to obtain the catalyst, and then remove the carbon monoxide, and then pass it into the multi-stage fluidized bed Inert gas, so that the catalyst is distributed to each fluidized bed, and the temperature of each fluidized bed is kept at 600 ° C for 90 minutes. The above operations are all carried out under the condition of a magnetic field, so that the carbon content of the final carbon nanotubes The ratio of the mass to the catalyst is 5-7:3-5, and then it is passed into a gas-solid separator for gas-solid separation, and the...

Embodiment 2

[0043] A method for preparing carbon nanotubes, the first choice is to weigh iron pentacarbonyl and nickel tetracarbonyl with a mass ratio of 390:178, and prepare the mass ratio of the contained carbon mass to iron pentacarbonyl and nickel tetracarbonyl to be 5 to 7:3 Carbon source of ~5. Add the mixture of iron pentacarbonyl and nickel tetracarbonyl into the first-stage fluidized bed in the multi-stage serial fluidized bed, heat it at 315°C until it is decomposed to obtain the catalyst, and then remove the carbon monoxide, and then pass it into the multi-stage fluidized bed Inert gas, so that the catalyst is distributed to each fluidized bed, and the temperature of each fluidized bed is kept at 800 ° C for 40 minutes. The above operations are all carried out under the condition of a magnetic field, so that the carbon content of the final carbon nanotubes The ratio of the mass to the catalyst is 5-7:3-5, and then it is passed into a gas-solid separator for gas-solid separation...

Embodiment 3

[0045] A method for preparing carbon nanotubes, the first choice is to weigh iron pentacarbonyl and nickel tetracarbonyl with a mass ratio of 390:178, and prepare the mass ratio of the contained carbon mass to iron pentacarbonyl and nickel tetracarbonyl to be 5 to 7:3 Carbon source of ~5. Add the mixture of iron pentacarbonyl and nickel tetracarbonyl into the first-stage fluidized bed in the multi-stage serial fluidized bed, heat it at 315°C until it is decomposed to obtain the catalyst, and then remove the carbon monoxide, and then pass it into the multi-stage fluidized bed Inert gas, so that the catalyst is distributed to each fluidized bed, and the temperature of each fluidized bed is kept at 700 ° C for 50 minutes. The above operations are all carried out under the condition of a magnetic field, so that the carbon content of the final carbon nanotubes The ratio of the mass to the catalyst is 5-7:3-5, and then it is passed into a gas-solid separator for gas-solid separation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com