Columnar coupling compound sucker rod centralizer

A sucker rod and composite technology, which is applied in the direction of drill pipe, drilling equipment, earthwork drilling and production, etc., can solve the problems of limited improvement of lubrication effect, difficulty in large-scale promotion, increase of surface cracks, etc., to achieve reasonable ratio and reduce cost , Lubrication performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

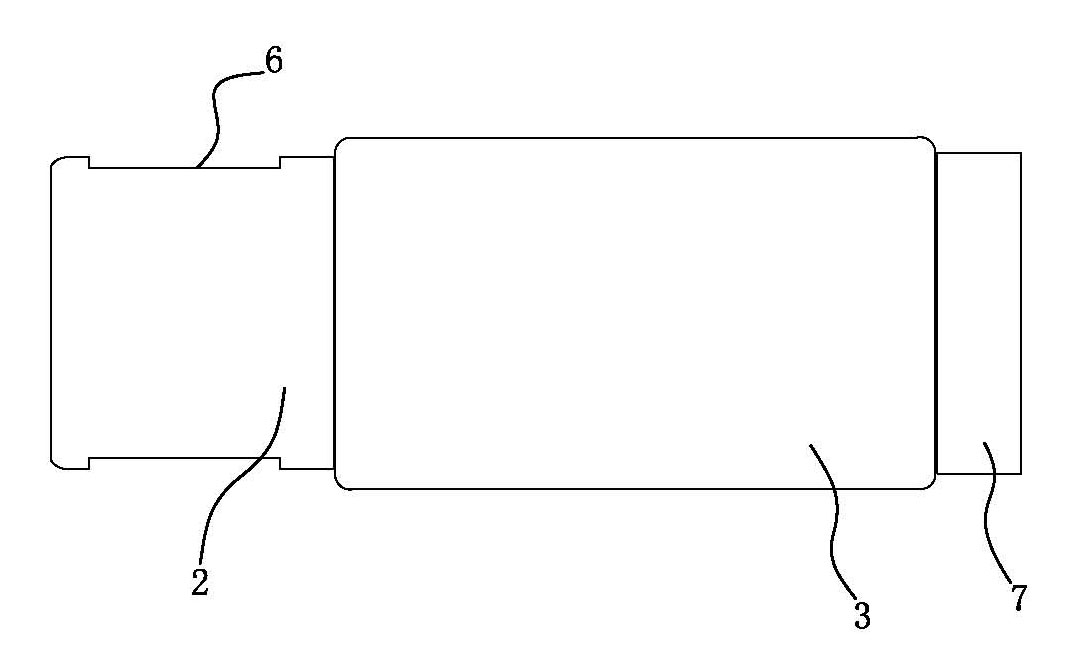

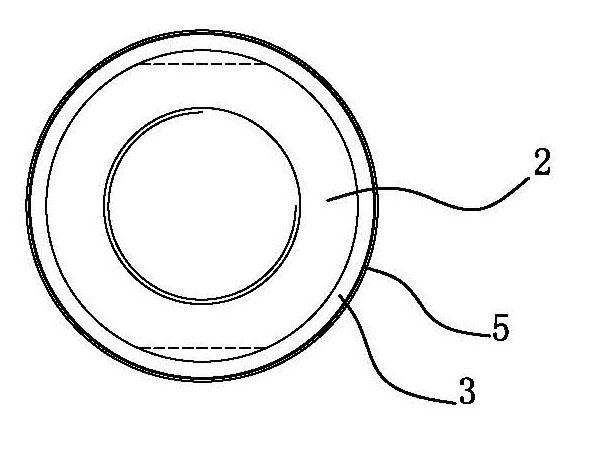

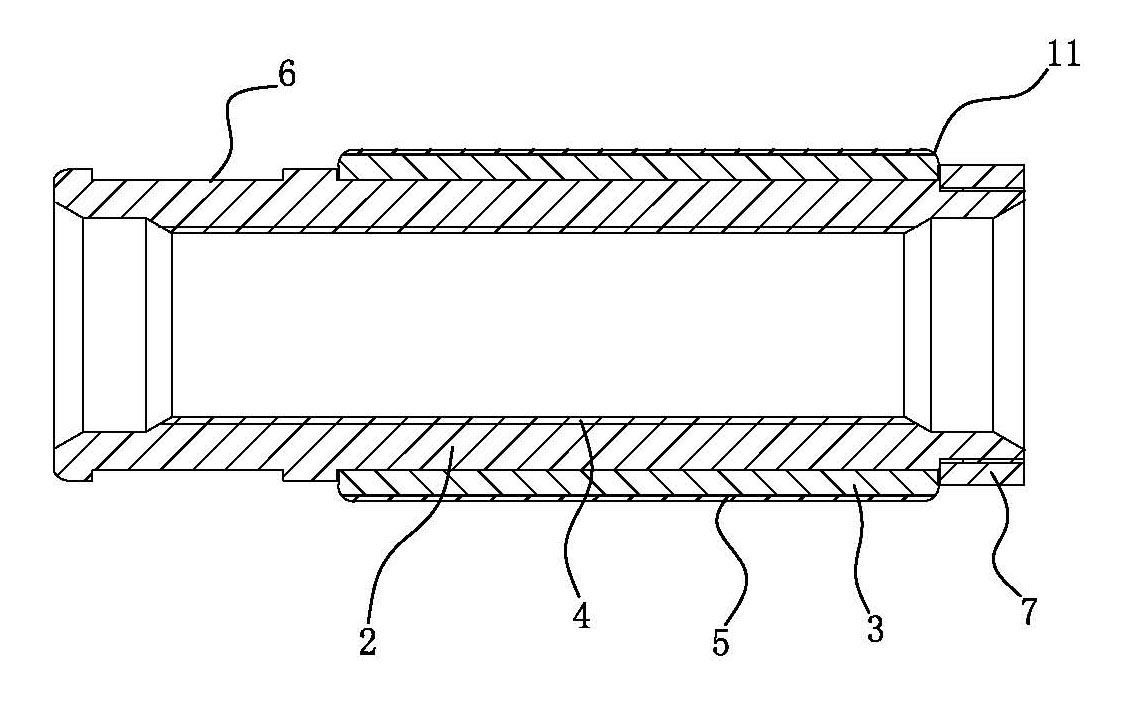

[0040] Embodiment one, see figure 1 , figure 2 , image 3 and Figure 4 , the length of the core rod 2 is 100mm, which is basically the same as that of a common coupling. The outer diameter of one end 8 of the wrench square neck 6 is basically the same as the outer diameter of the same specification coupling, and the outer diameter of the middle part 9 is less than that of the wrench square neck 6. The outer diameter of one end 8 is 2 mm, which is 1 mm higher than the outer diameter of the end 10 where the fixed collar 7 is located. The sliding sleeve 3 is a hollow cylinder, the outer diameter of which is about 4mm larger than that of the coupling with the same diameter specification, and there is a gap of 0.02mm between the inner hole and the center of the core rod, so that it can rotate freely. The surface of the sliding sleeve 3 A layer of wear-resistant and corrosion-resistant self-lubricating alloy coating 5 is prepared, with a thickness of 0.1 mm. The connection par...

Embodiment 2

[0043] Embodiment two, see figure 1 , figure 2 , image 3 and Figure 4 , The structure of this embodiment is the same as that of Embodiment 1, the difference lies in the difference in size, the fixing method of the collar 7 and the composition of the coating. The specific structure of this embodiment is as follows: the length of the core rod 2 is 130 mm, which is basically the same as that of an ordinary coupling; The diameter is less than the outer diameter 4mm of an end 8 where the square neck of the wrench is located, and is 2mm higher than the outer diameter of an end 10 where the fixed collar 7 is located. The sliding sleeve 3 is a hollow cylinder, the outer diameter of which is about 10 mm larger than that of the coupling of the same diameter specification, and there is a gap of 0.10 mm between the inner hole and the center of the core rod 2, so that it can rotate freely. A layer of wear-resistant and corrosion-resistant self-lubricating alloy coating 5 is prepared...

Embodiment 3

[0046] Embodiment three, see Figure 4 and Figure 5 , the length of the core rod 2 is 110 mm, which is basically the same as that of a common coupling. The outer diameter of one end 8 where the wrench square neck 6 is located is basically the same as the outer diameter of the coupling of the same specification, and the outer diameter of the middle part 9 is less than that of the wrench square neck. One end 8 has an outer diameter of 3 mm, which is 1.6 mm higher than the outer diameter of one end 10 where the fixed collar is located. see Figure 5 , the sliding sleeve 3 is a multi-section structure, and each section is separated from each other. The design of the multi-section structure can ensure that the other sections of the sliding sleeve 3 can rotate freely even when a single-section sliding sleeve is sand-stuck. In this embodiment, there are 3 sections, of course, it can also be 2 sections, 4 sections, etc. The sections can be separated from each other by spacers 12 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com