Steel-based iron-nickel alloy diffused-type solid self-lubricating bearing and manufacturing method thereof

A solid self-lubricating, iron-nickel alloy technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of self-lubricating bearing bearing capacity and service life, low production efficiency, complex manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

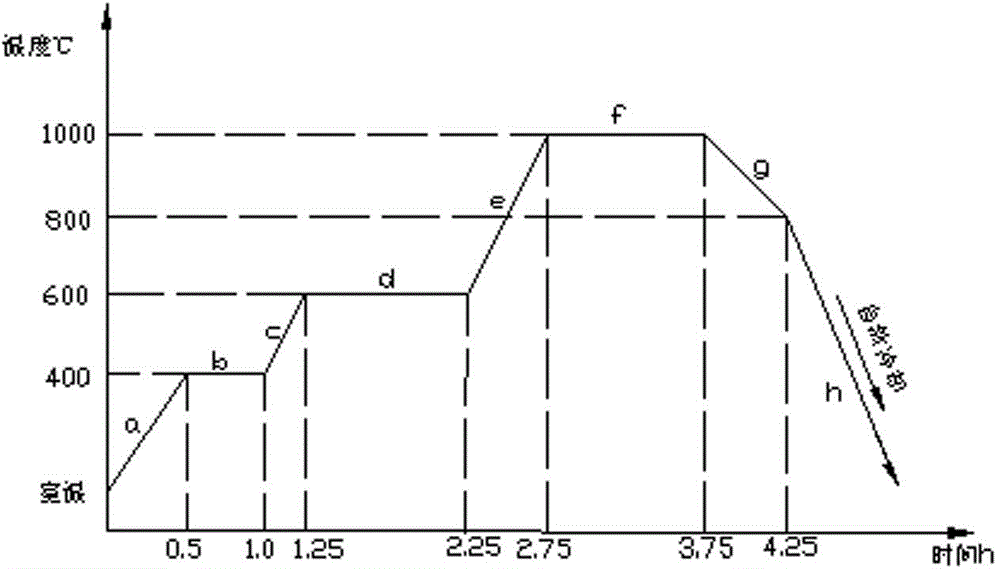

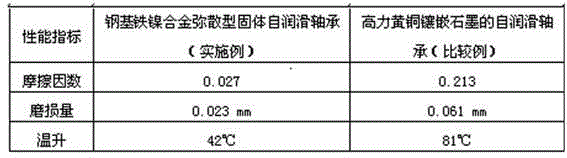

[0024] The following steps are required to manufacture the steel-based iron-nickel alloy dispersion type self-lubricating bearing with the size of φ50×φ40×30

[0025] A. Preparation of iron-nickel alloy dispersed solid self-lubricating bearing blank

[0026] (1) Ingredients: The weight percentage of raw materials is nickel 15-20%, iron 35-40%, tin 5-8%, titanium powder 0.5-1.0%, molybdenum disulfide 1-4%, aluminum oxide 1- 3%, graphite 1-4%, zinc stearate 1-2%, the balance is copper, the average particle diameter of nickel is 50 μm, the average particle diameter of iron is 50 μm, and the average particle diameter of tin is 100 μm, The average particle size of titanium is not greater than 50 μm, the average particle size of molybdenum disulfide is 1.5 μm, the average particle size of aluminum oxide is not greater than 5 μm, the average particle size of graphite is 4 μm, and the average particle size of copper is 61 μm;

[0027] (2) Mixing: Put the above ingredients into a ZX-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com