Iron-nickel alloy nanocluster-graphene composite material and preparation method and application thereof

A technology of iron-nickel alloys and composite materials, applied in nanotechnology, metal processing equipment, chemical instruments and methods, etc., can solve the problems of easy agglomeration and oxidation of iron-nickel alloy nanoclusters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

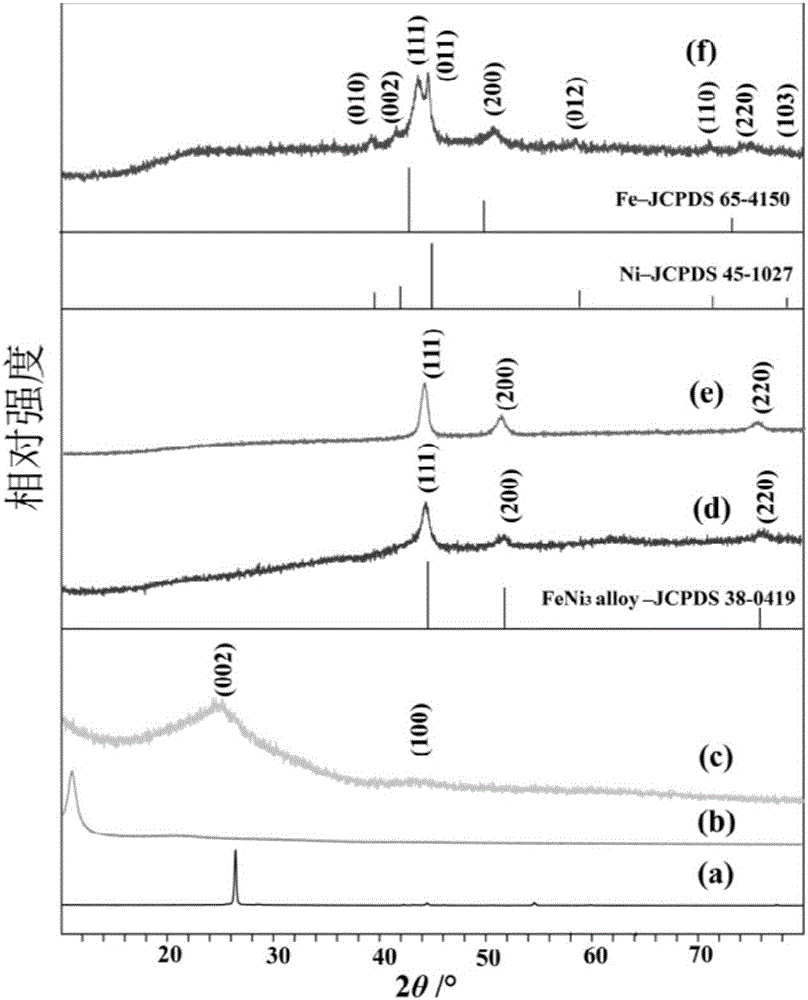

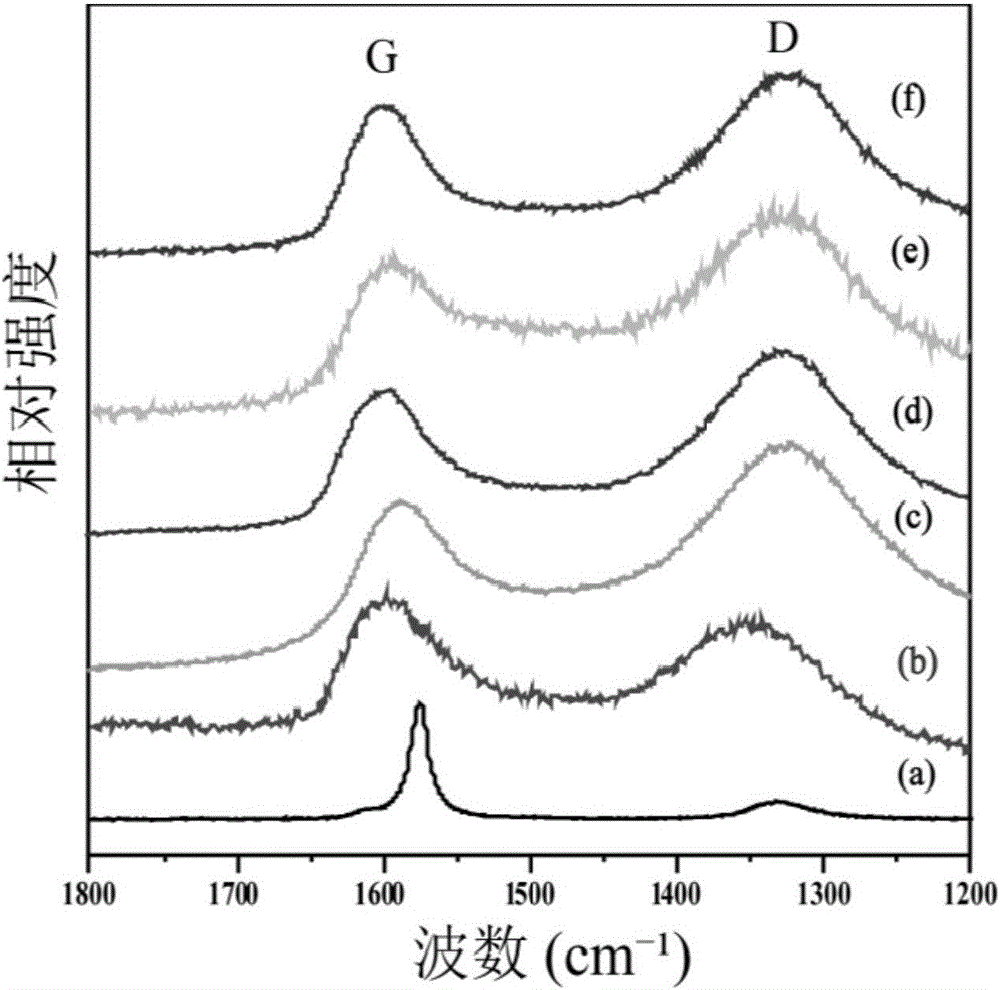

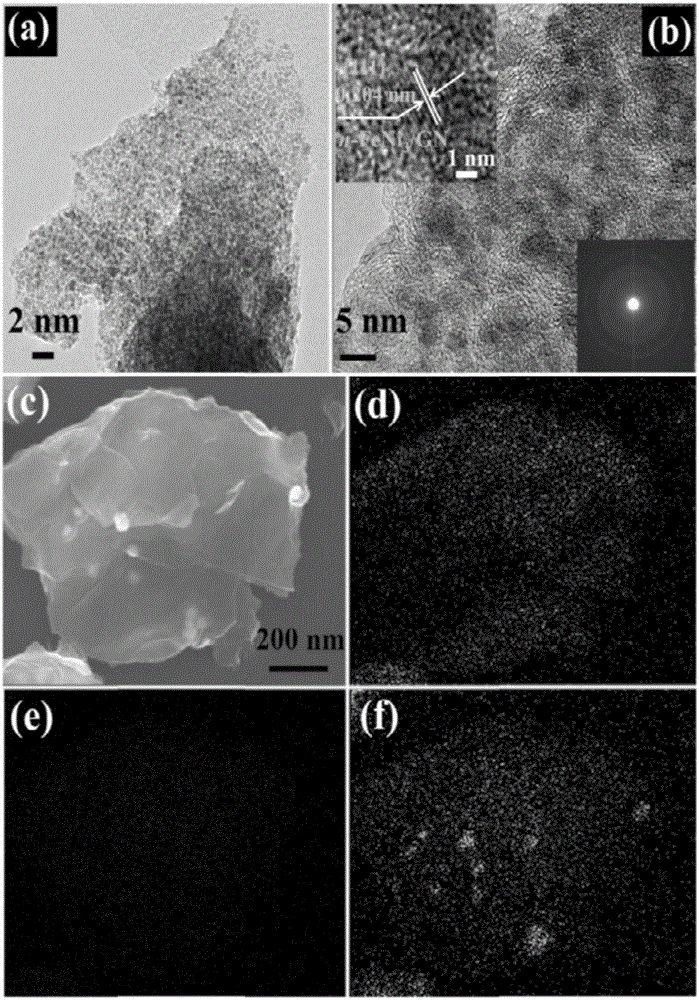

Examples

Embodiment 1

[0059] Weigh 40mg of graphite oxide and 40mL of N-methylpyrrolidone in a 50mL beaker, ultrasonically disperse for about 2 hours to obtain a brown mixed solution; and 2g of octadecylamine were added to the above brown solution, the mixture was first heated to 120°C and maintained at this temperature for 30min, then raised to 202°C and maintained at this temperature for 2h, the entire reaction process was carried out under the protection of argon, and Magnetic stirring was maintained at all times. Then, 20 mL of ethanol was added to quench the reaction, and the temperature of the reaction system was rapidly lowered to room temperature. Finally, the reaction product was separated by centrifugation, washed alternately with n-hexane and acetone, and the product was vacuum-dried at 40°C.

Embodiment 2

[0061] Weigh 40 mg of graphite oxide and 50 mL of oleylamine in a 100 mL beaker, and ultrasonically disperse for about 2 hours to obtain a brown mixed solution; next, 159 mg (0.45 mmol) of iron acetylacetonate, 257 mg (1 mmol) of nickel acetylacetonate and 1.6 g of octadecyl The amine was added to the above brown solution, the mixture was first heated to 100°C and maintained at this temperature for 50 minutes, then raised to 290°C and maintained at this temperature for 5 hours, the whole reaction process was carried out under the protection of nitrogen, and magnetic stirring was maintained. Then, 20 mL of ethanol was added to quench the reaction, and the temperature of the reaction system was rapidly lowered to room temperature. Finally, the reaction product was separated by filtration, washed alternately with n-hexane and acetone, and the product was vacuum-dried at 40°C.

Embodiment 3

[0063] Weigh 40mg of graphite oxide and 34mL of 2-pyrrolidone in a 50mL beaker, and ultrasonically disperse for about 2h to obtain a brown mixed solution; Add octaamine to the above brown solution, first heat the mixture to 150°C and maintain this temperature for 20 minutes, then increase the temperature to 245°C, and maintain this temperature for 1 hour. The whole reaction process is carried out under the protection of argon, and the magnetic force is kept Stir. Then, 20 mL of ethanol was added to quench the reaction, and the temperature of the reaction system was rapidly lowered to room temperature. Finally, the reaction product was separated by centrifugation, washed alternately with n-hexane and acetone, and the product was vacuum-dried at 40°C.

[0064] In order to better analyze the iron-nickel alloy nanocluster-graphene composite material prepared in the embodiment, the embodiment of the present invention also prepared graphene, and the preparation method is as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com