Matrix for electroplating diamond products and electroplating process thereof

An electroplating process and diamond technology, applied in the direction of electrolytic coating, coating, etc., can solve the problem of high nickel price of the carcass material, achieve the effects of reducing production costs, good bezel performance, and improving sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

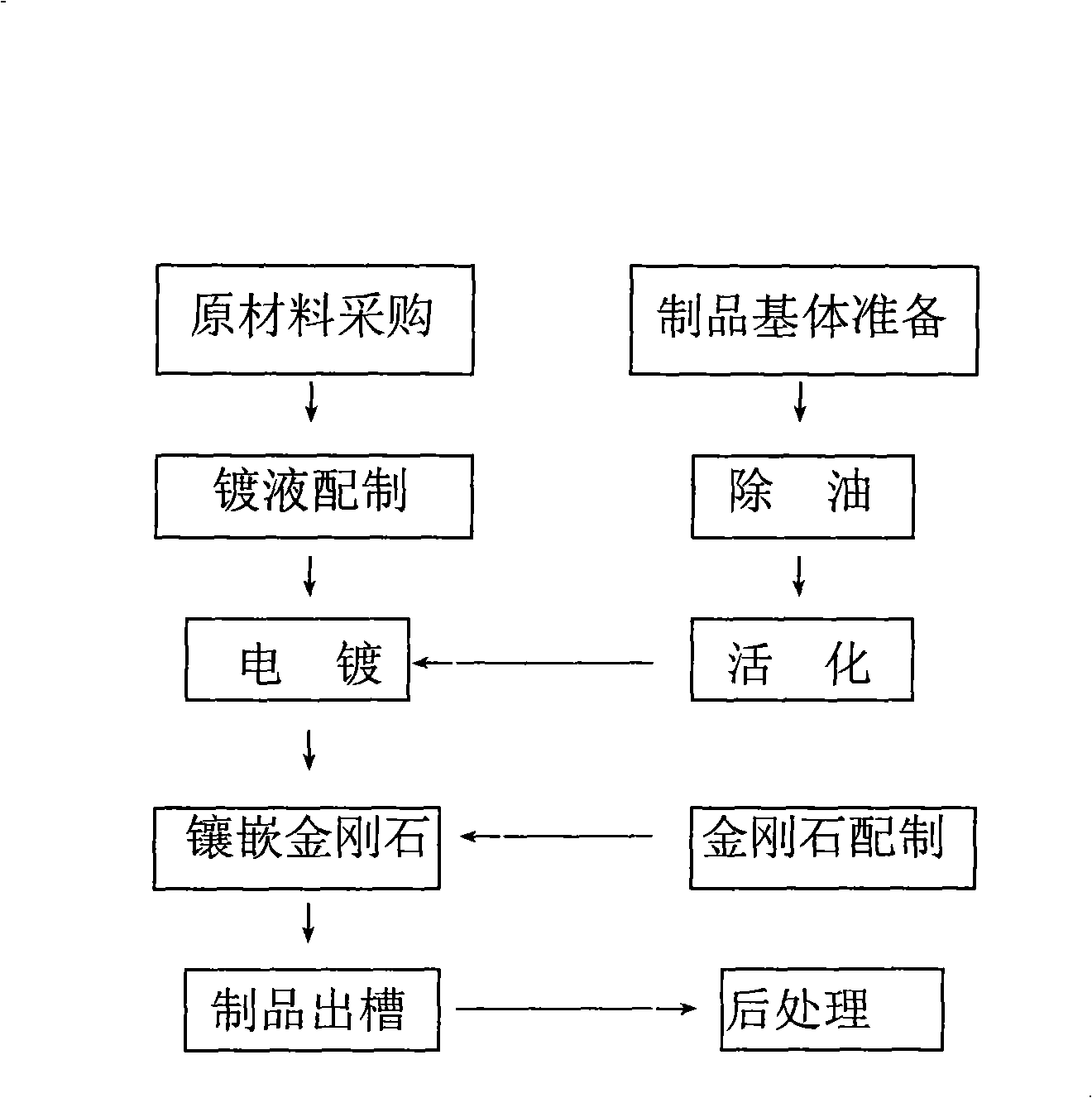

Image

Examples

Embodiment 1

[0027] Example 1: ferrous sulfate 180g / l, magnesium sulfate 150g / l, pH=4.0, electroplating temperature 30°C, current density 1.5A / dm 2 .

Embodiment 2

[0028] Example 2: ferrous sulfate 180g / l, ammonium sulfate 100g / l, pH=5.2, electroplating temperature 30°C, current density 0.6-0.7A / dm 2 .

Embodiment 3

[0029] Example 3: Ferrous ammonium sulfate 400g / l, PH=3.2, electroplating temperature 30°C, current density 2.2A / dm 2 .

[0030] 2. Ferrous chloride iron plating formula and process:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com