Method for enhancing blade surface of metal hydraulic turbine runner by combining electrical sparkle deposition and plasma cladding

A technology of plasma cladding and electric spark deposition, applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of high cost of wear-resistant materials, poor mechanical strength, insufficient strength, etc., and achieve wear resistance Good corrosion resistance, long service life and large coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

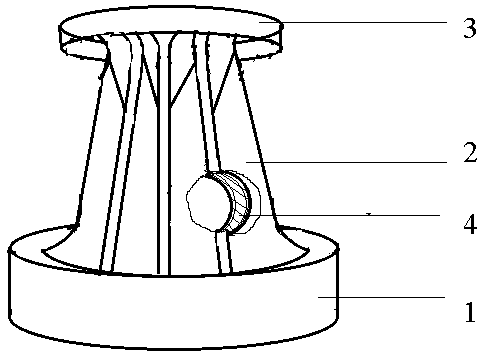

[0016] The present invention is realized by the following methods in concrete implementation:

[0017] (1) Prepare iron-nickel alloy powder, which is calculated by weight percentage: Ni 30.5%, Cr 28%, C 1.5%, Mo 4%, B 1.5%, Si 4%, W 6% and Fe 24.5 %composition;

[0018] (2) Iron-nickel alloy powder layer cladding is carried out on the surface of the turbine runner with plasma cladding wear-resistant equipment, cladding input power supply voltage: 380V±10%, rated input capacity: 30KVA, output voltage: 75V, working voltage: 10~30V, output current: 300~600A, scanning speed: 200~500mm / min, powder feeder airflow: 0.65~0.75m 3 / h, ion gas flow rate: 0.65~0.75m 3 / h, protective gas flow rate: 0.65~0.75m 3 / h;

[0019] (3) Start the worktable operation of the plasma cladding wear-resistant equipment, move the plasma torch above the cladding part of the turbine runner blade, turn on the plasma torch protective gas argon and power supply to start the arc, and enter the plasma beam c...

Embodiment 2

[0023] When the described iron-nickel alloy powder is specifically implemented, it can also be calculated by weight percentage: Ni 30.5%, Cr 30%, C 1%, Mo 4.5%, B 1%, Si 5%, W 5.5%, and the balance is Fe powders, mixed together to form.

Embodiment 3

[0025] When the described iron-nickel alloy powder is specifically implemented, it can also be calculated by weight percentage: Ni 32%, Cr 26%, C 2%, Mo 3%, B 1%, Si 5%, W 8%, and the balance is Fe powders, mixed together to form.

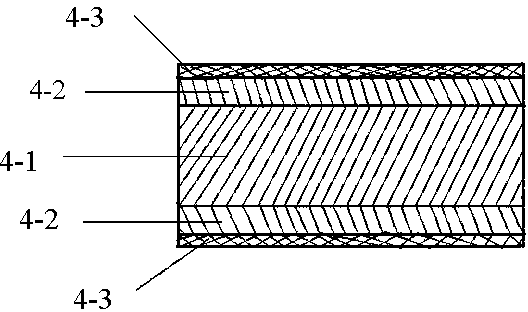

[0026] Through experiments and tests of the present invention, a large number of nano-amorphous and microcrystalline particles appear in the coating, resulting in high density of the coating; the high temperature of 16000 ° C in plasma cladding and 24500 ° C in EDM makes the composite coating and the substrate produce metallurgical bonding The surface hardness of the coating can reach 1688.6HV~1891.3HV, while the hardness of the substrate is 331.2HV, and the hardness can be increased by 4-6 times; the wear resistance of the composite coating can be increased by 3-5 times than that of the substrate. Compared with the prior art, it has the following outstanding beneficial technical effects:

[0027] 1. The present invention adopts the metal water tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com