Array-type ultrasonic probe and ultrasonic diagnostic apparatus

An ultrasonic and array-type technology, applied in ultrasonic/acoustic/infrasonic diagnostics, acoustic diagnostics, infrasonic diagnostics, etc., can solve the problem of sound velocity, attenuation rate, acoustic Impedance and other acoustic characteristics, to achieve the effect of excellent consistency of thermal expansion coefficient, small mutual interference, and improved image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] SCR1011 resin A and SCR1011 resin B manufactured by Shin-Etsu Chemical Co., Ltd., which are two-component silicone resins, were accurately weighed in a weight ratio of 100:100. This siloxane resin mixture was put into a polyethylene container, stirred for 3 minutes with a rotary mixer, and mixed uniformly. This liquid resin was defoamed for 10 minutes in a vacuum container, and it put into the container with Teflon (registered trademark). Next, after preliminary curing at 85° C. for 1 hour, main curing was performed at 125° C. for 2 hours, and a third acoustic matching layer material containing a mixture containing a silicone resin was produced.

[0086] For the cured product containing the silicone resin mixture obtained in Example 1 (the third acoustic matching layer material), TG / DTA was measured using a thermogravimetric analyzer / differential thermal analyzer (TG / DTA) under the following conditions curve. In addition, for the same cured silicone resin, the FTIR sp...

Embodiment 2~9

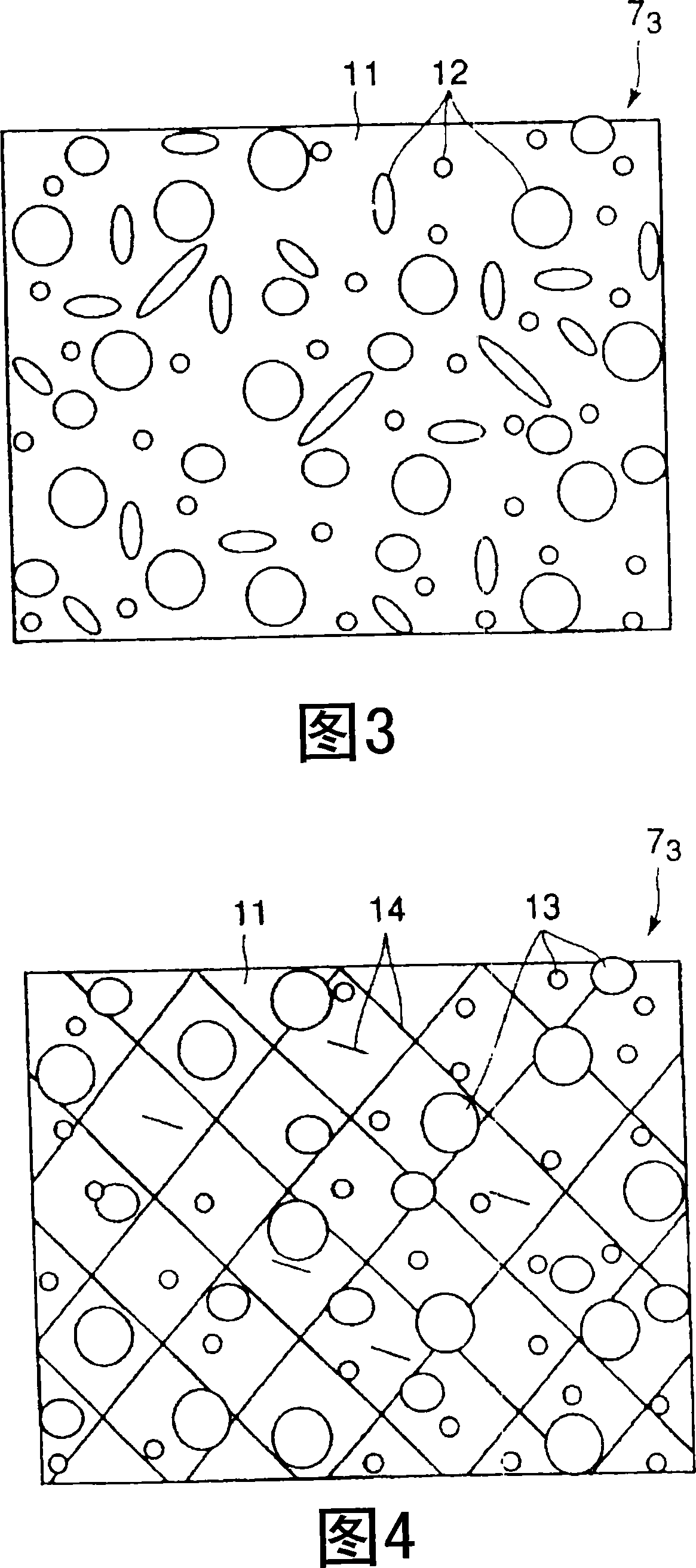

[0102] As shown in the following Table 1, as the two-component silicone resin (siloxane resin-based mixture), SCR1012, SCR1011, and SCR1004 produced by Shin-Etsu Chemical Co., Ltd. were used, and the third was produced by the same method as in Example 1. Material for acoustic matching layer. Among these materials, several prescribed filler materials are dispersed. As fillers, silicone rubber particles with an average particle size of 3 μm, epoxy resin particles with an average particle size of 10 μm, powdered silicon oxide with an average particle size of 20 nm, powdered zinc oxide with an average particle size of 30 nm, and Powdered titanium oxide with a diameter of 50 nm, fibrous glass with an average particle diameter of 5 μm and an average length of 100 μm, and fibrous carbon with an average particle diameter of 7 μm and an average length of 100 μm.

Embodiment 10、11、 comparative example 1~6

[0104] As shown in the following Table 2, as the two-component silicone resin-containing mixture (silicone resin-based mixture), SCR1011, SCR1012, polyurethane rubber, silicone rubber, epoxy resin, polyester, etc. manufactured by Shin-Etsu Chemical Co., Ltd. Ethylene, high-hardness siloxane resin (trade name produced by Shin-Etsu Silicone Co., Ltd.: KER2500), as the base resin, use (trade name produced by MomentivePerformance Materials Company [former name: GE Toshiba Silicon Company]: IVSM4500), through and embodiment 1 The same method is used to make the materials for the third acoustic matching layer respectively. Among these materials, several prescribed filler materials are dispersed. As fillers, silicone rubber particles with an average particle size of 3 μm, powdered silica with an average particle size of 20 nm, powdered alumina with an average particle size of 100 nm, and fibrous fibers with an average particle size of 5 μm and an average length of 100 μm are used. s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com