Coax

A coaxial cable, axial technology, applied in the direction of coaxial cable/analog cable, etc., can solve the problems of unachievable foaming rate, deterioration of dielectric properties of insulators, etc., and achieve the effect of cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

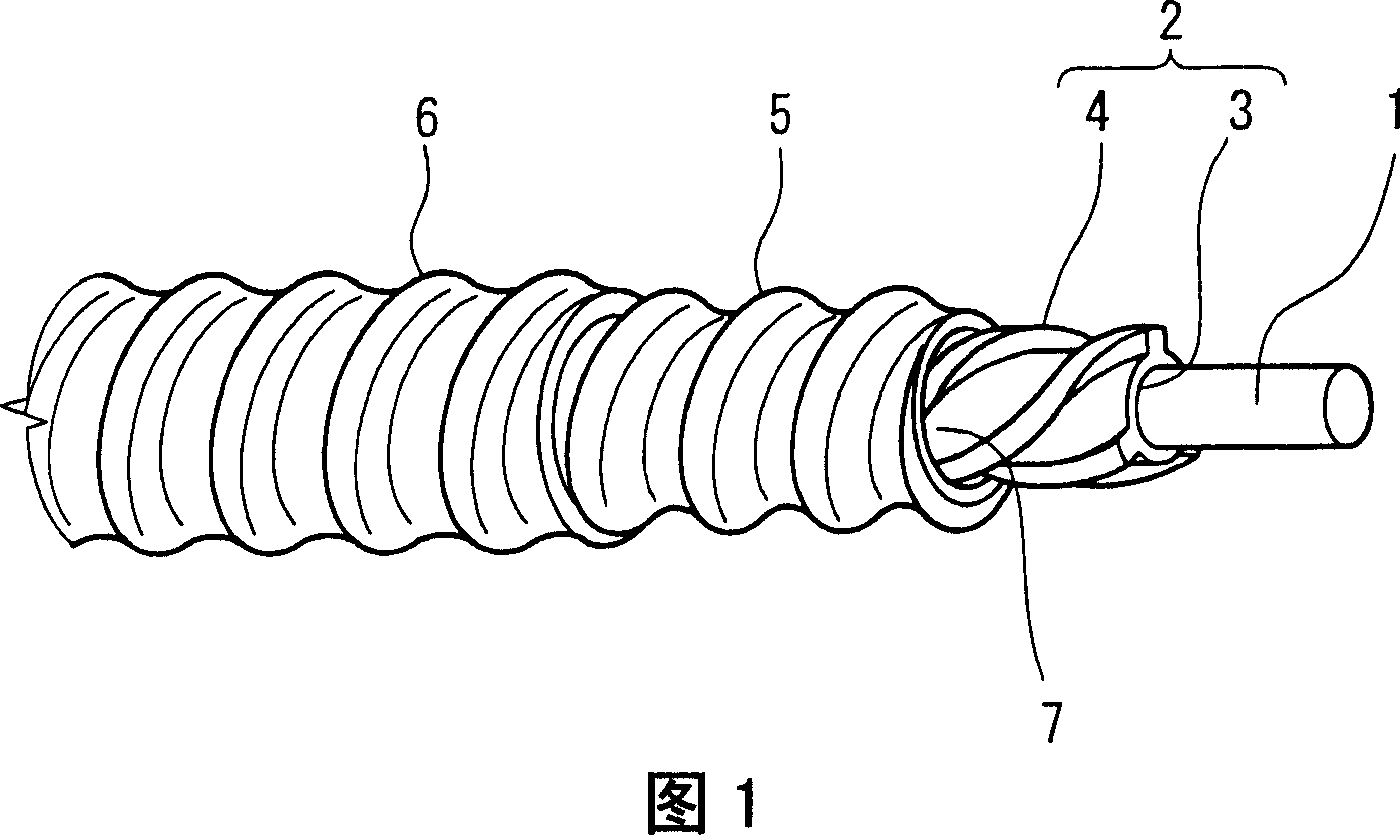

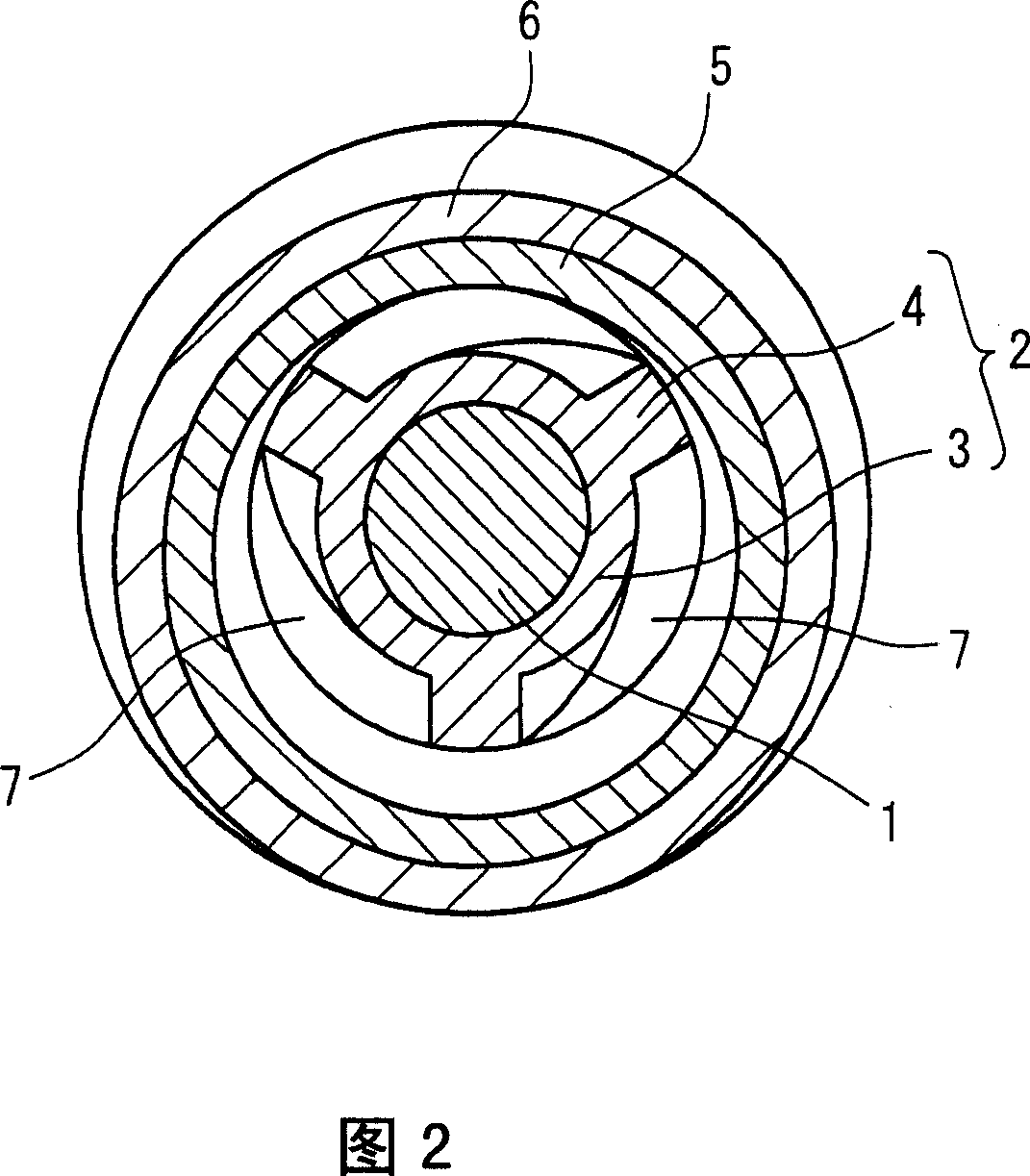

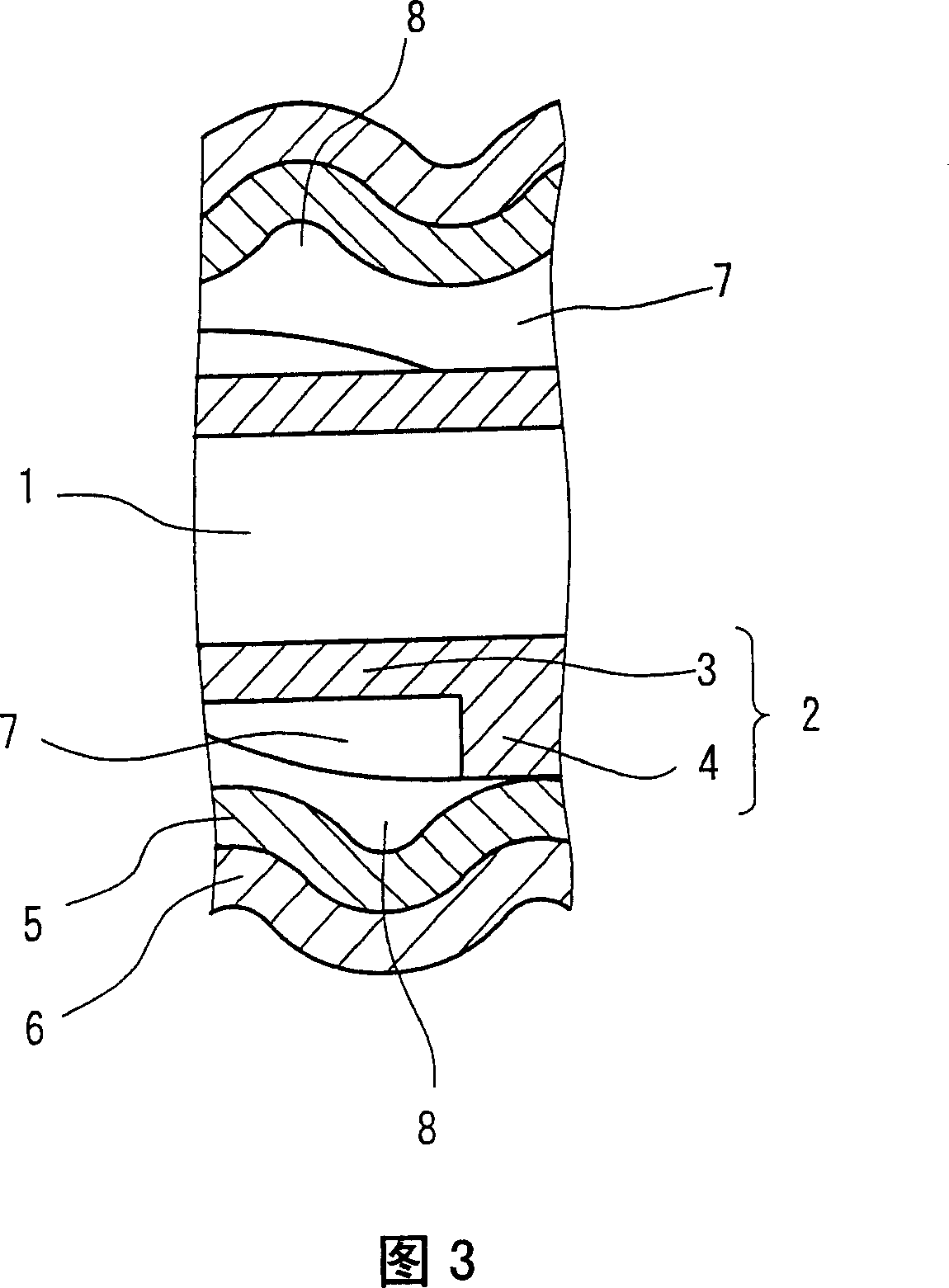

[0027] Hereinafter, an embodiment of the present invention will be described based on blueprints. 1 to 4 are diagrams showing an embodiment of the present invention, FIG. 1 is a perspective view of a coaxial cable, FIG. 2 is a cross-sectional view thereof, FIG. 3 is a side view showing the interior of the coaxial cable after breaking it, and FIG. 4 It is a perspective view showing a modified example.

[0028] Symbol 1 is the inner conductor and 2 is the insulator. The insulator 2 has an insulating layer 3 covering the inner conductor 1 , and an insulating rib 4 integrated with the insulating layer 3 and in contact with the outer conductor 5 . 5 is an external conductor, which is set to surround the periphery of the internal conductor 2 ; 6 is a cover, which covers the periphery of the external conductor 5 . The internal conductor 1 is formed, for example, by silver-plating a copper-coated steel wire. The outer conductor 5 is made of a copper tube. The outer conductor 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com