Vertical modified stir ball-milling reactor for reinforcing polysaccharide polymers

A technology of polymer modification and stirring ball milling, which is applied in chemical/physical/physicochemical stationary reactors, grain processing, etc., can solve the problem of uneven temperature of reactants, temperature rise of stirring ball mill, and uneven mixing of reactants To achieve the effect of enhancing the disturbance and activity, eliminating the dead angle of grinding reaction, and reducing the phenomenon of sieve clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

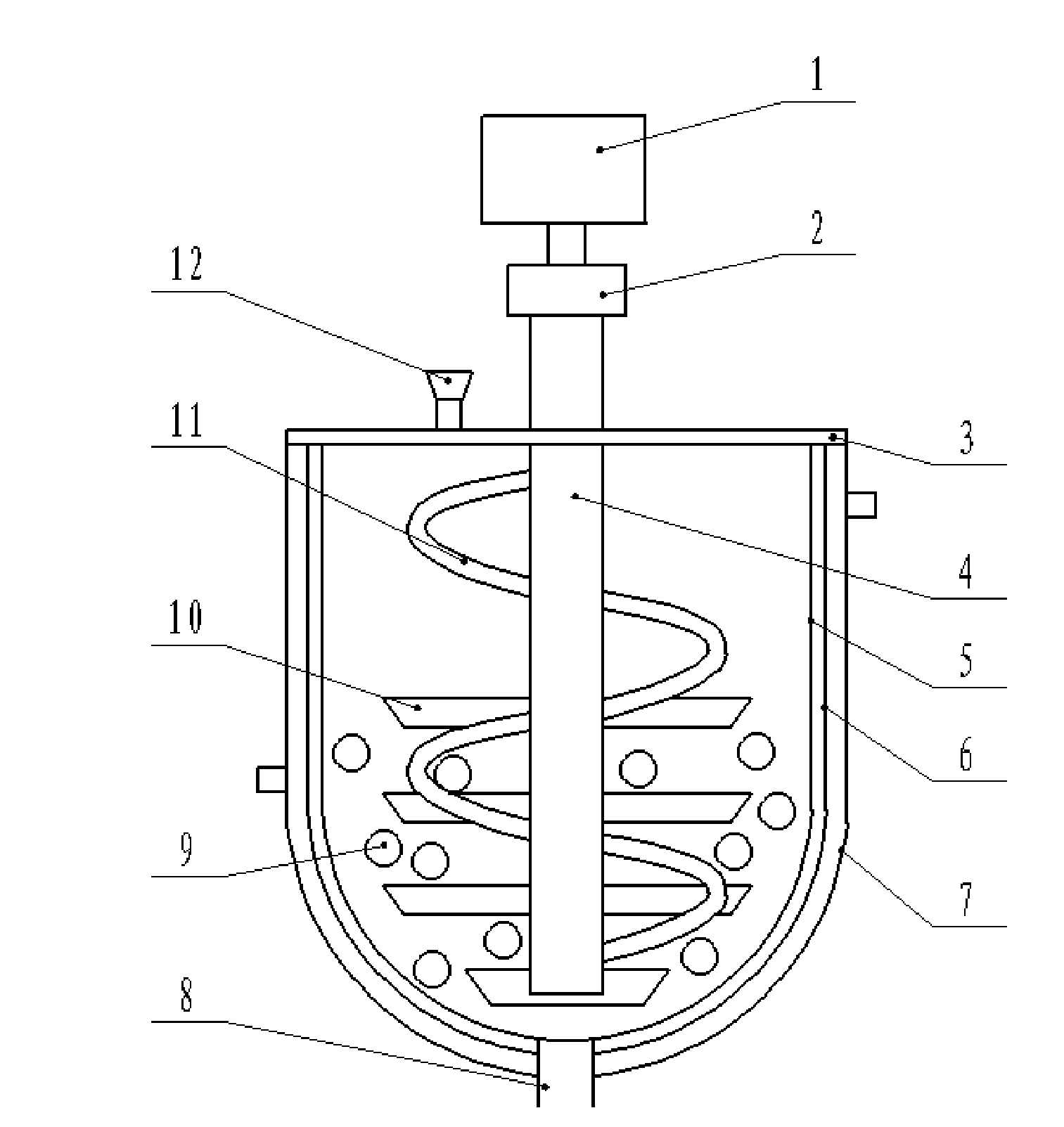

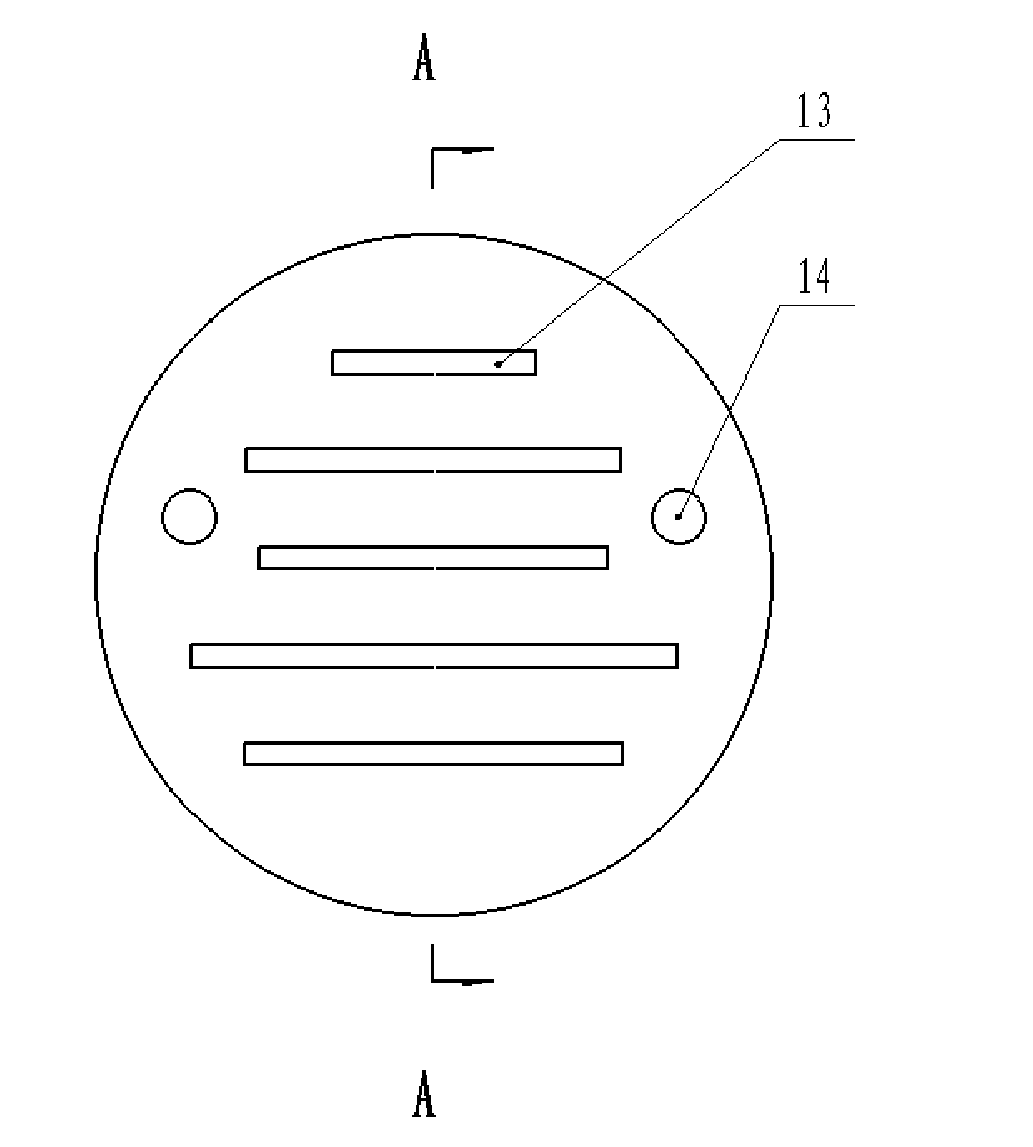

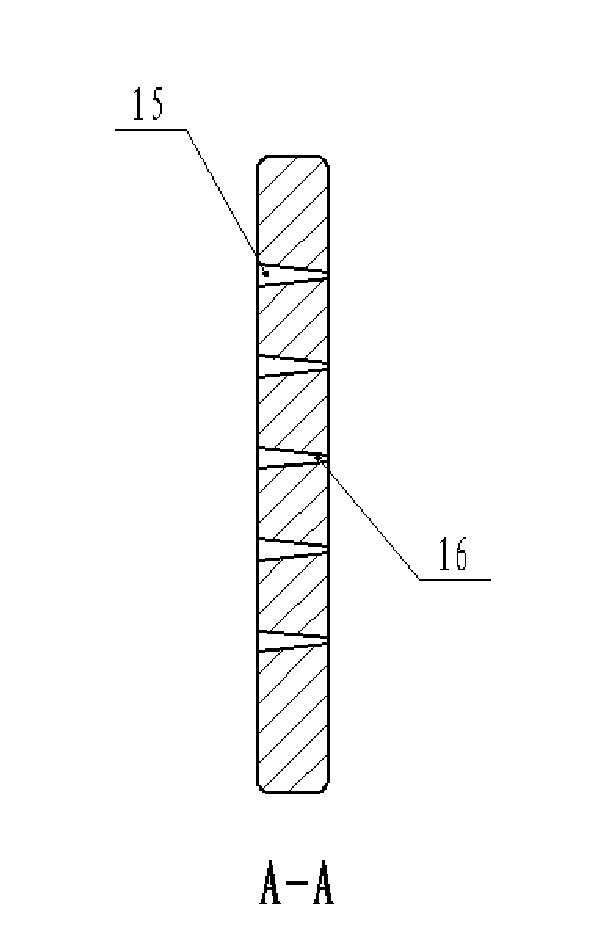

[0029] Such as figure 1 As shown, a vertical reinforced polysaccharide high polymer modified stirring ball mill reactor, it is driven by the drive device 1 through the coupling 2 to drive the stirring shaft 4, the outer side of the grinding inner cylinder 6 is wrapped with a jacket 7 with cooling water, A lining plate 5 is arranged inside the grinding inner cylinder, a funnel-type feed inlet 12 is arranged on the cylinder cover plate 3, a discharge outlet 8 is arranged at the bottom of the grinding inner cylinder 6, and grinding balls 9 are filled in the grinding inner cylinder 6, wherein , the stirring shaft 4 is equipped with a stirring paddle group composed of inclined plate blades 10 and S-shaped screw blades 11, the inclined plate blades 10 are installed on the stirring shaft 4 in parallel and are perpendicular to the stirring shaft 4, and the S-shaped spiral The type paddle 11 is installed on the stirring shaft 4 up and down, and the inclined plate type paddle 10 is prov...

Embodiment 2

[0032] The difference from Example 1 is that the stirring shaft 4 and the S-shaped propeller blade 11 are made into a hollow structure, and cooling water is passed into the hollow part, thereby making up for the lack of uneven cooling of the jacket 7 and ensuring the stability of the grinding reaction field. The reaction environment with uniform temperature and constant temperature effectively ensures the reaction of heat-sensitive reactants.

Embodiment 3

[0034] The difference from Example 2 is that the bottom of the grinding inner cylinder 6 is hemispherical, and the reactants to be ground will not stagnate in the dead corner, but rely on the gravity of the reactants themselves, sliding from the arc-shaped periphery to the bottom to be repeatedly Grinding avoids dead angles that occur during the grinding reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com