Single Crytalline Noble Metal Ultrathin-Film-Like Nanoparticle Formed in Adsorbed Micelle Film as Reaction Filed Formed at Solid-Liquid Interface, and Production Method Thereof

a technology of noble metals and nanoparticles, applied in the direction of catalyst activation/preparation, metal/metal-oxide/metal-hydroxide catalysts, etc., can solve the problems of high production quantities of noble metal elements, particularly pt materials, and the difficulty of sufficiently addressing a demand, etc., to achieve the effect of extreme fine precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0151]Added into a weighing bottle was 10 mL of a weighed water solution (0.5 mM) of polyoxyethylene (20) sorbitan monostearate (Tween60: product name sold by Atlas Powder Company in U.S.). Immersed into this solution was a highly oriented graphite substrate (HOPG), thereby causing semicylindrical rod-like micelles to be spontaneously formed at a graphite / solution interface.

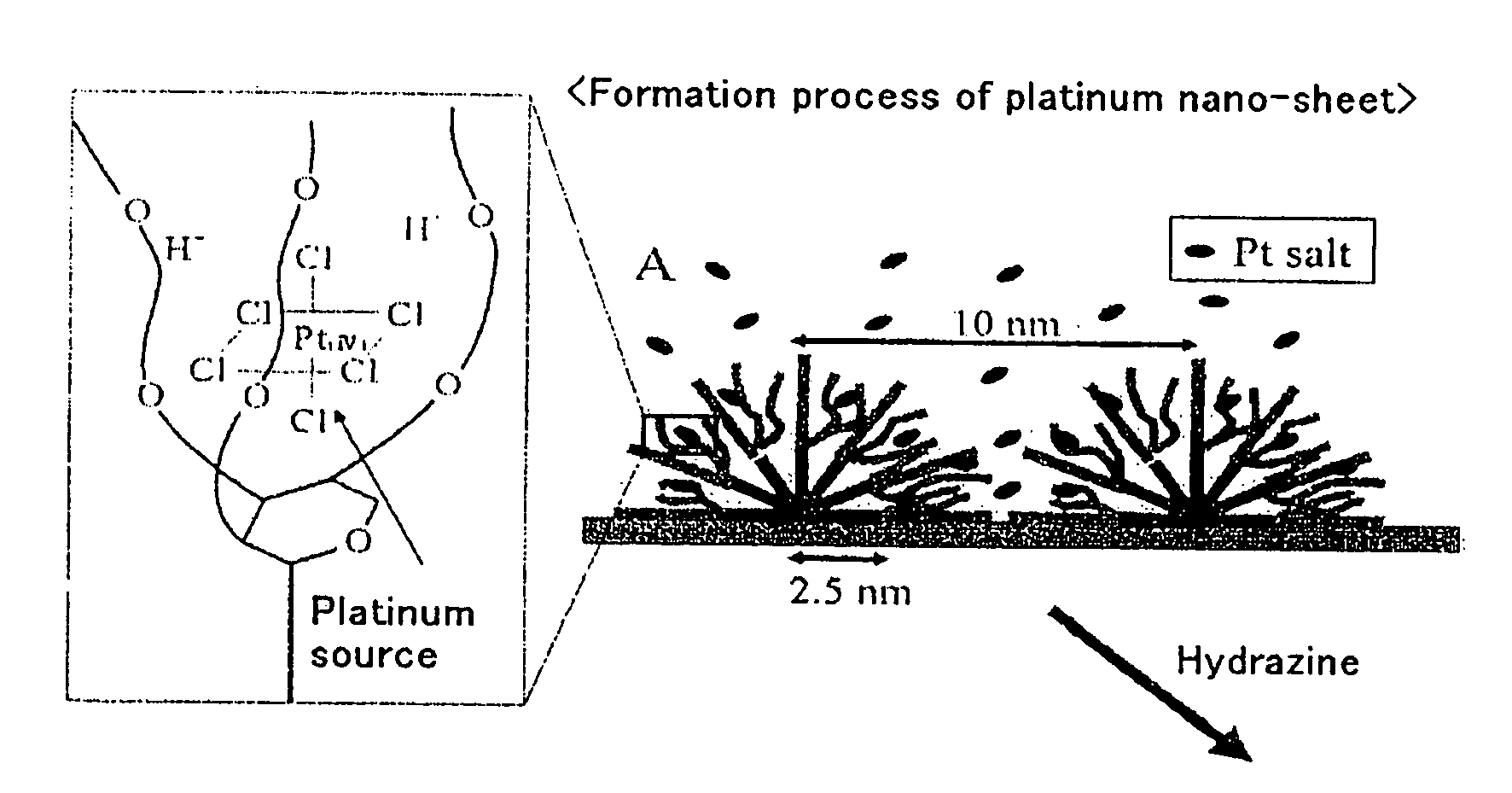

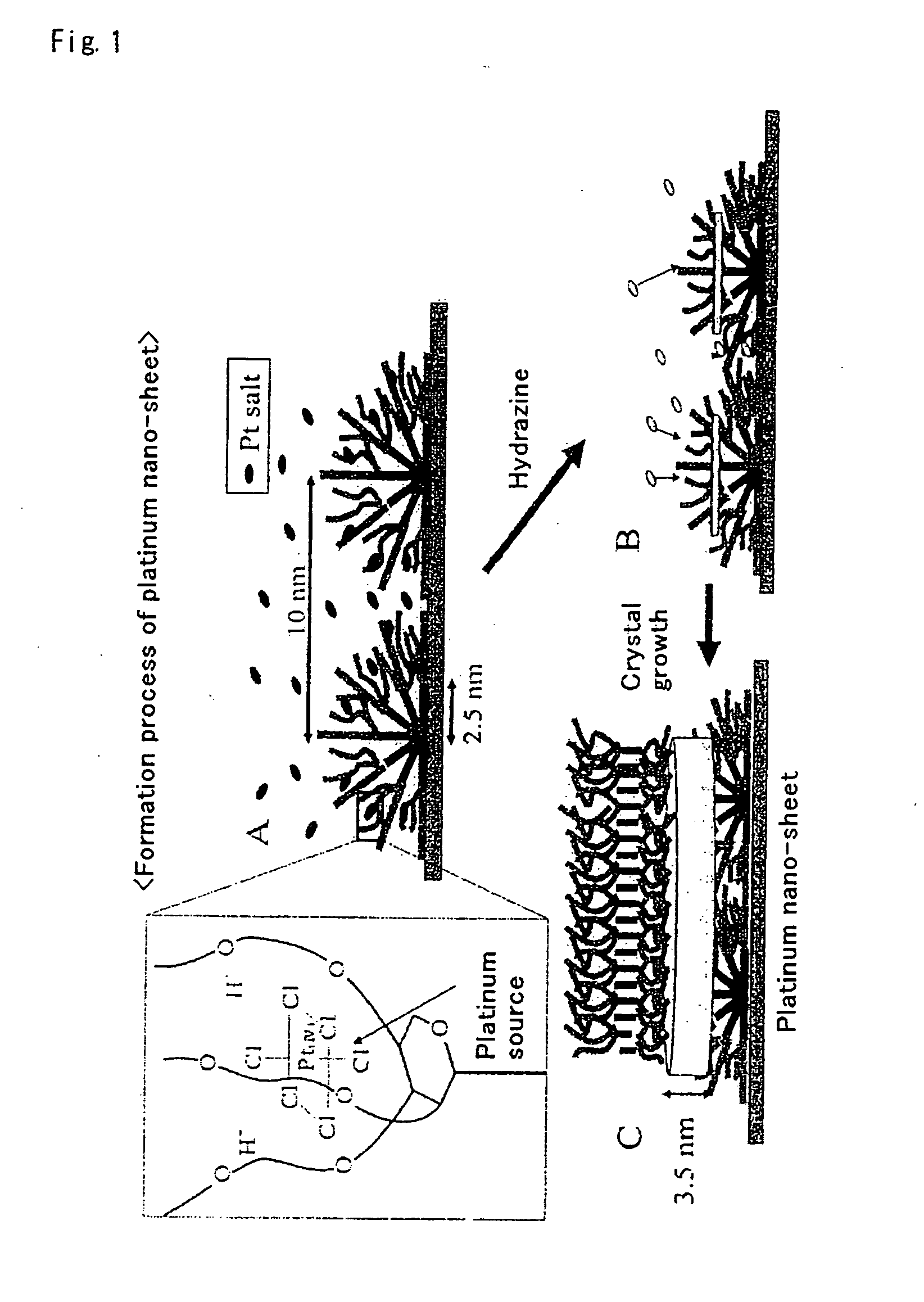

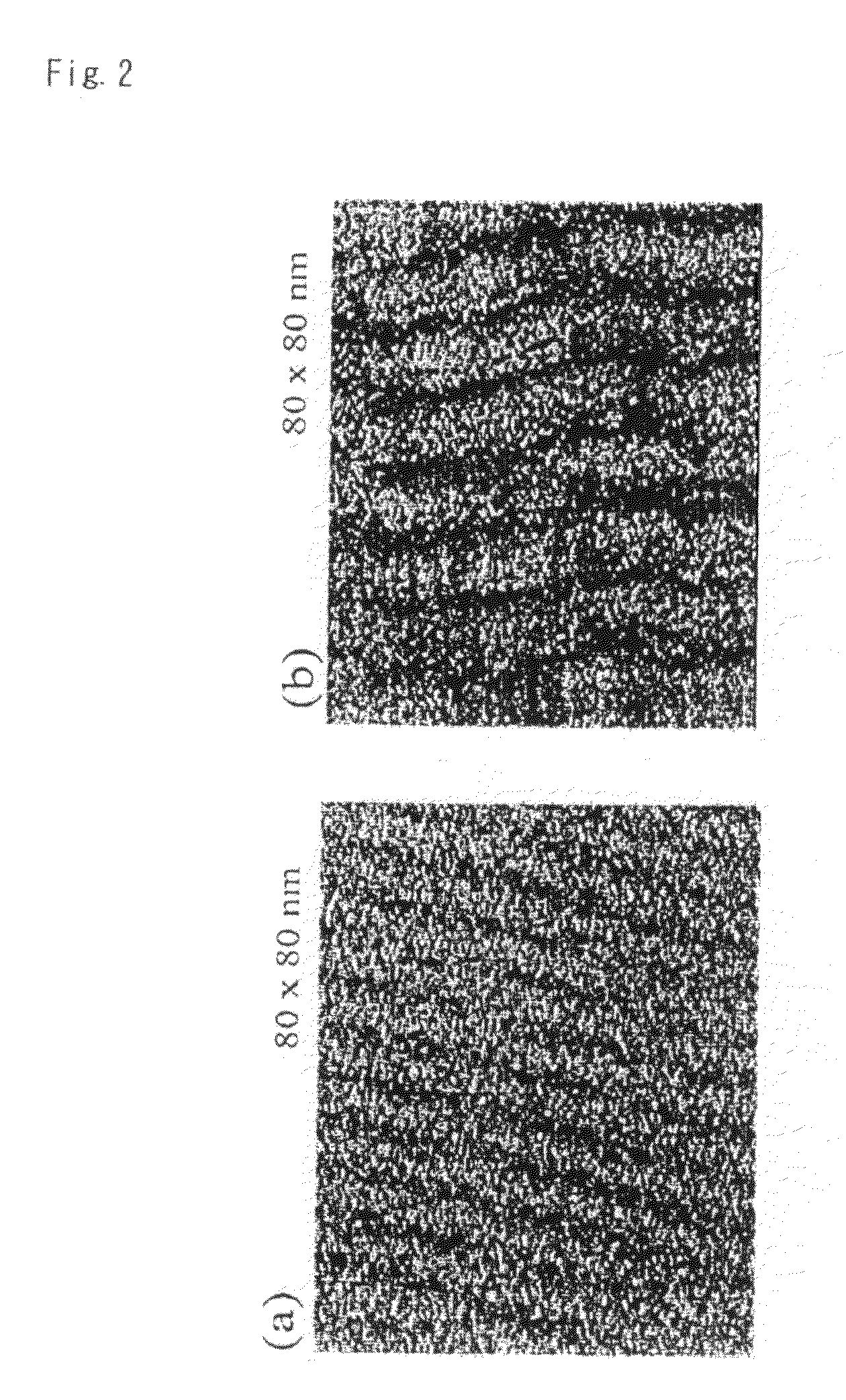

[0152]Next, 1 mL of hexachloro platinate water solution (0.1 M) was added, thereby establishing a reaction solution. At this time, rod-like micelles adsorbed on the graphite substrate surface cooperated with platinum complex compounds to form composites which acted as templates for growth of thinfilm-like platinum particles. FIG. 2 shows images observed within a liquid by an atomic force microscope (AFM) of shapes of rod-like micelles formed at a graphite / solution interface.

[0153]Subsequently, 1.5 molar equivalent of hydrazine relative to chloroplatinic acid was added to the reaction solution held at 25° C. to co...

example 2

Concentration Effect of Chloroplatinic Acid Water Solution on Production of Platinum Thinfilm-Like Particle in Sheet-Like Shape

[0157]Semicylindrical rod-like micelles were spontaneously formed at graphite / solution interfaces, by the same procedures and under the same conditions as Example 1, respectively. Next, added into the water solutions including precursory rod-like micelles at the graphite substrate surfaces, were chloroplatinic acid water solutions so as to attain their concentrations of 0.02 mM, 0.1 mM, 1 mM, and 10 mM, respectively.

[0158]Next, 2 molar equivalent of hydrazine relative to chloroplatinic acid was added into each reaction solution held at 25° C., followed by reaction for 24 hours as it was. In this way, thinfilm-like platinum particles were grown within rod-like micelles immobilized on the graphite substrates, respectively. At this time, the graphite substrates were downwardly oriented and fixed, to avoid deposition of massive platinum particles produced in the...

example 3

Production of Platinum Thinfilm-Like Particle in Sheet-Like Shape by Two-Kind Mixed Surfactant System

[0160]Semicylindrical rod-like micelles were spontaneously formed at graphite / solution interfaces, by the same procedures and under the same conditions as Example 1, respectively, by each adopting a two-kind mixed system of Tween60 and nonaethyleneglycol monohexadecyl ether (C12EO9: product name: Nikkol BL-9EX by Wako, Japan) as surfactants, instead of Tween60 only. The whole concentrations of surfactants were fixed at 0.5 mM, and the mole fractions (γ) of Tween60 in the two-kind mixed systems were varied, respectively.

[0161]Next, 1.5 molar equivalent of hydrazine relative to chloroplatinic acid was added into each reaction solution held at 25° C., followed by reaction for 24 hours as it was. In this way, thinfilm-like platinum particles were grown within rod-like micelles immobilized on the graphite substrates, respectively. At this time, the graphite substrates were downwardly orie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com