Patents

Literature

178 results about "Gmr sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

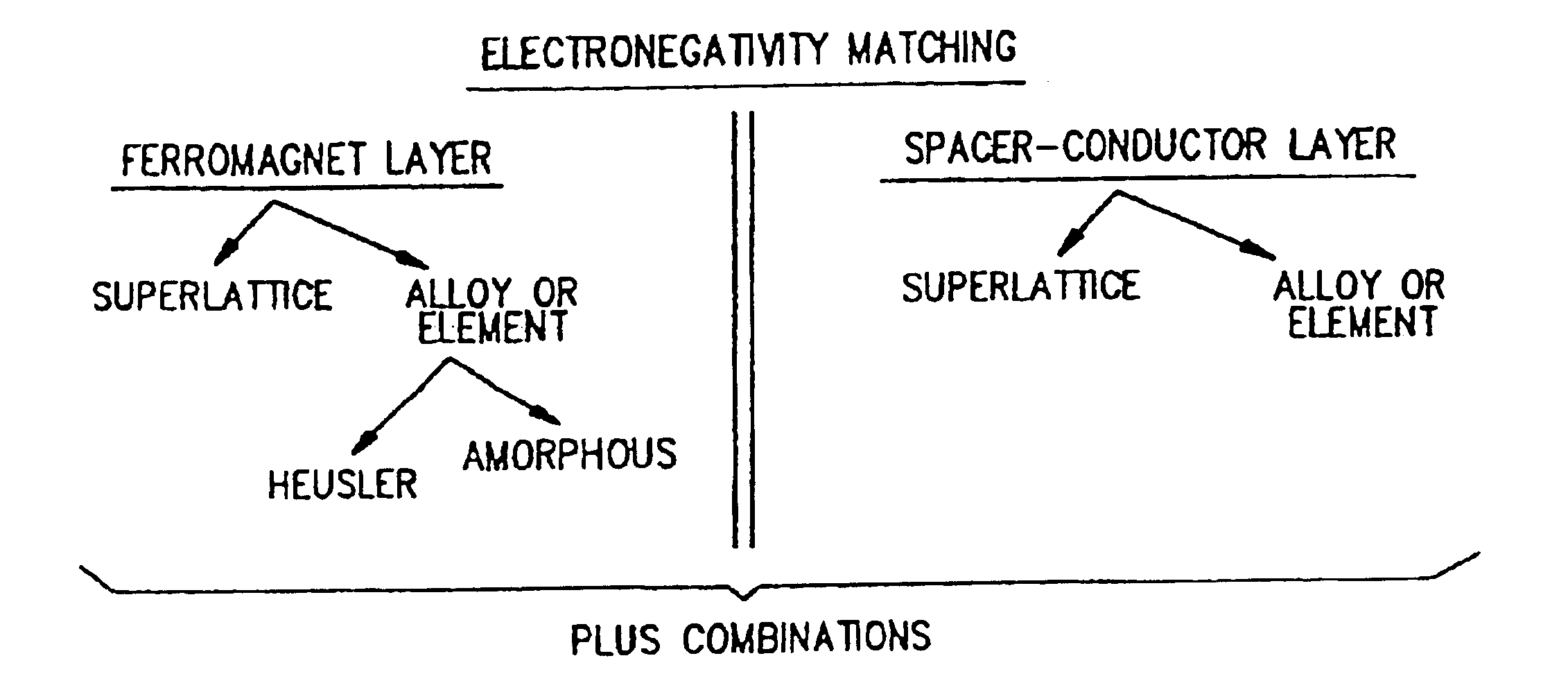

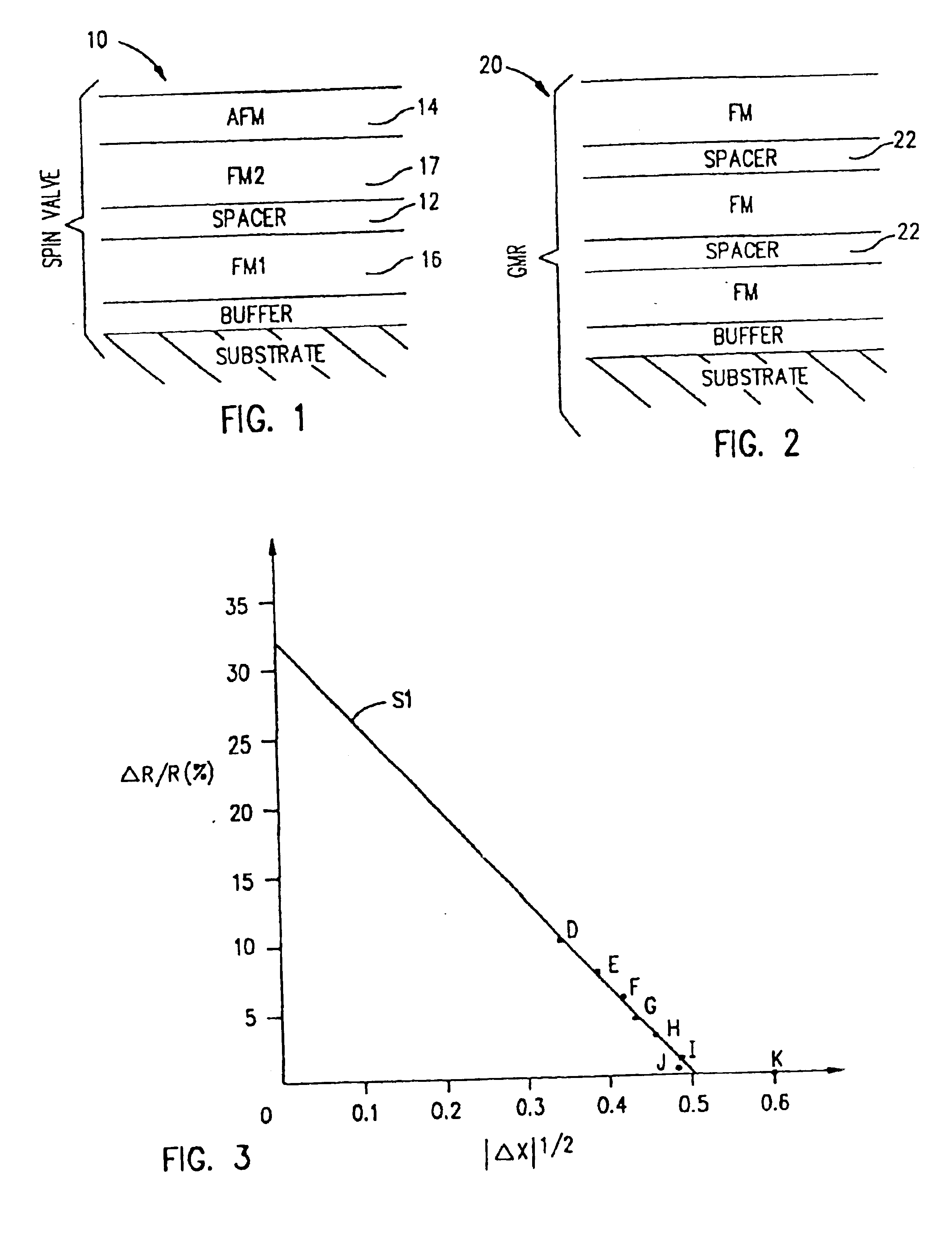

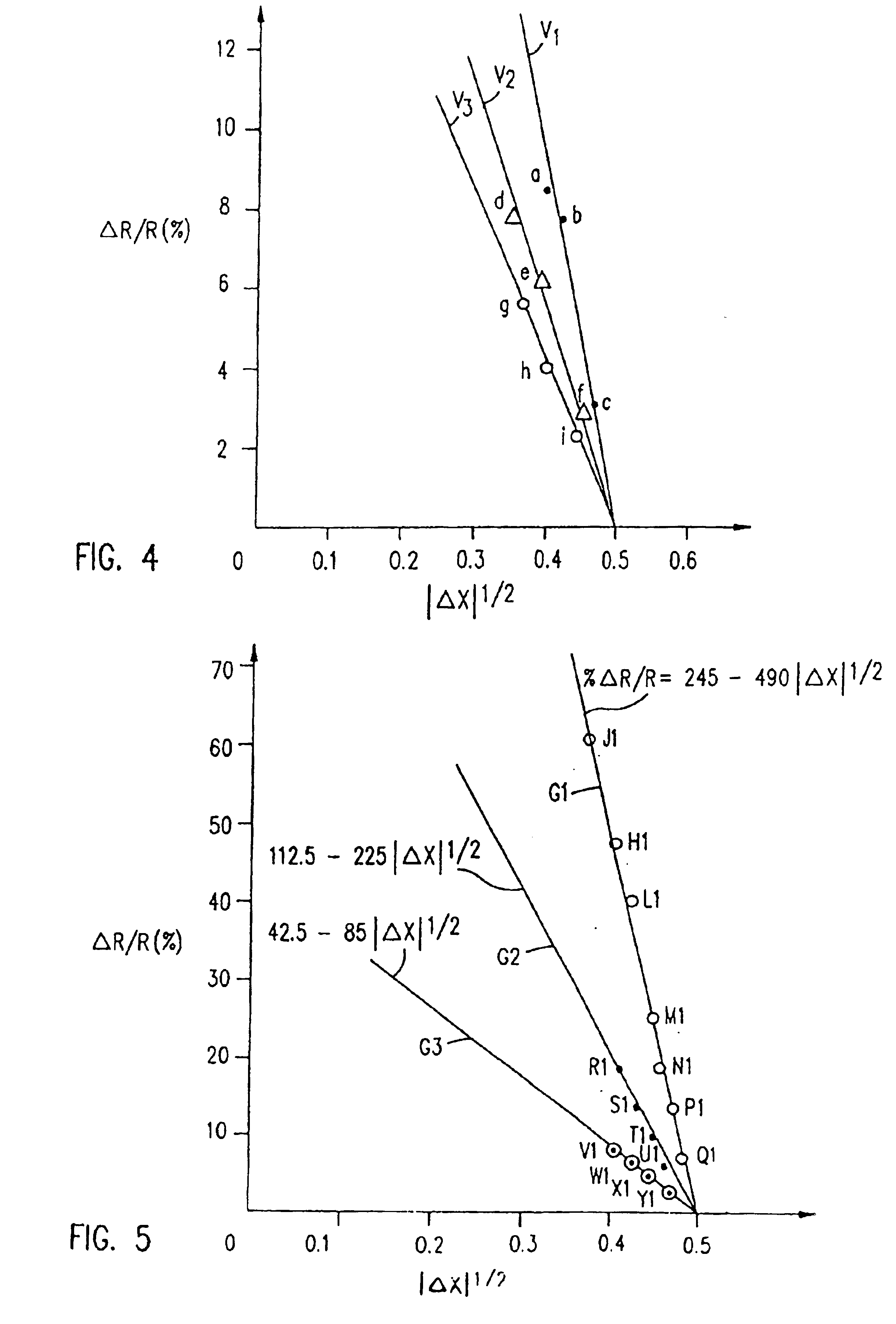

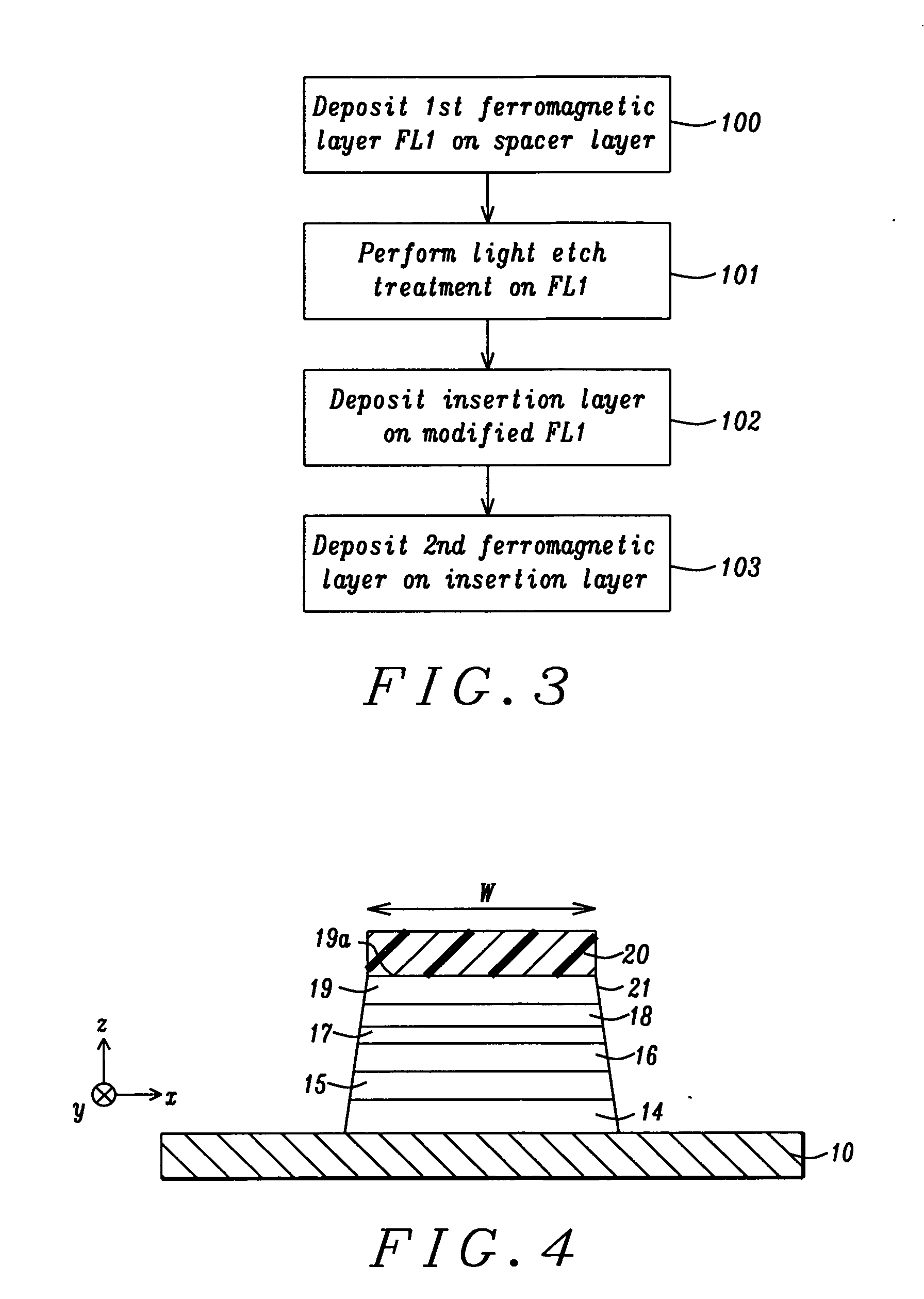

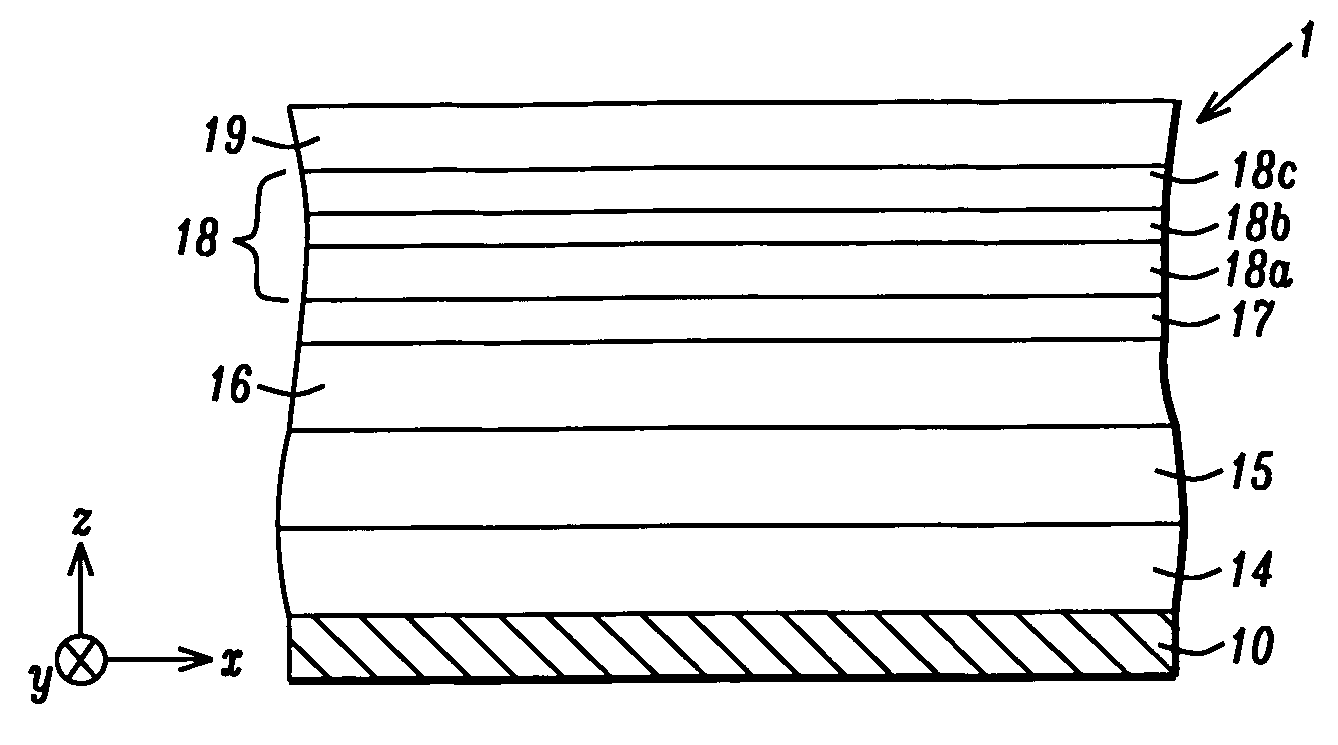

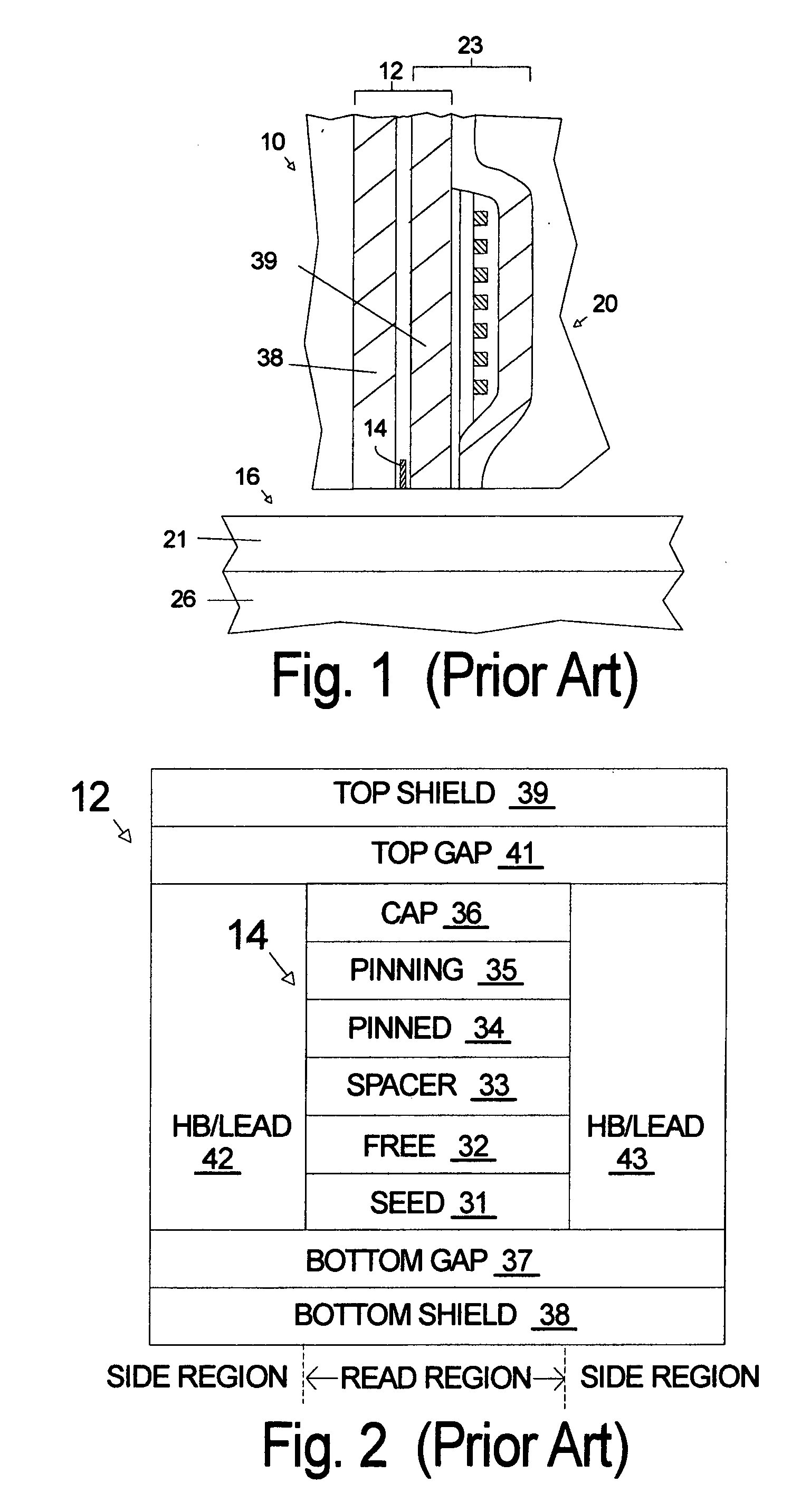

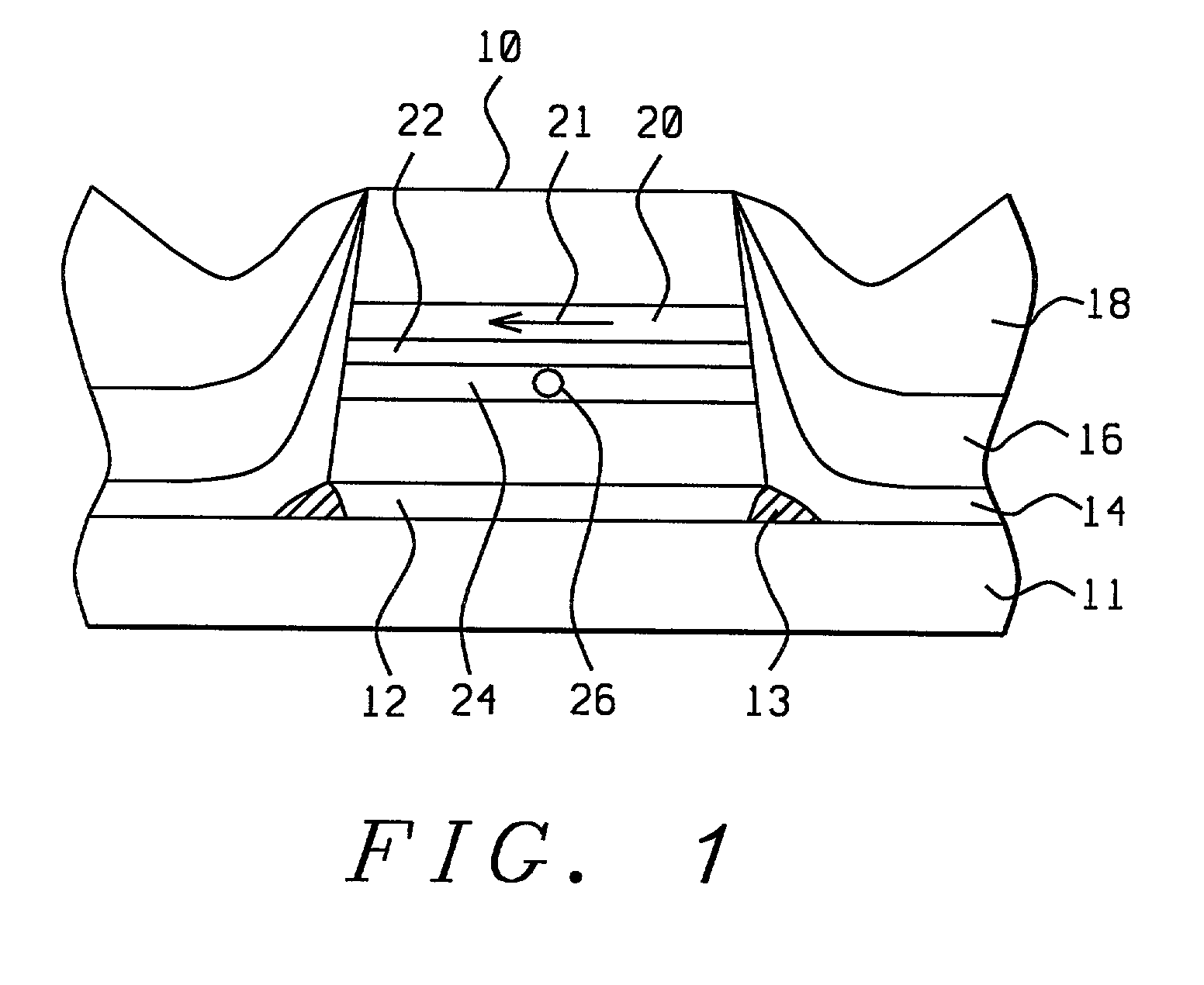

Methods and compositions for optimizing interfacial properties of magnetoresistive sensors

InactiveUS6828897B1Minimize electromigrationExtended service lifeNanomagnetismFixed microstructural devicesMean free pathElectronegativity

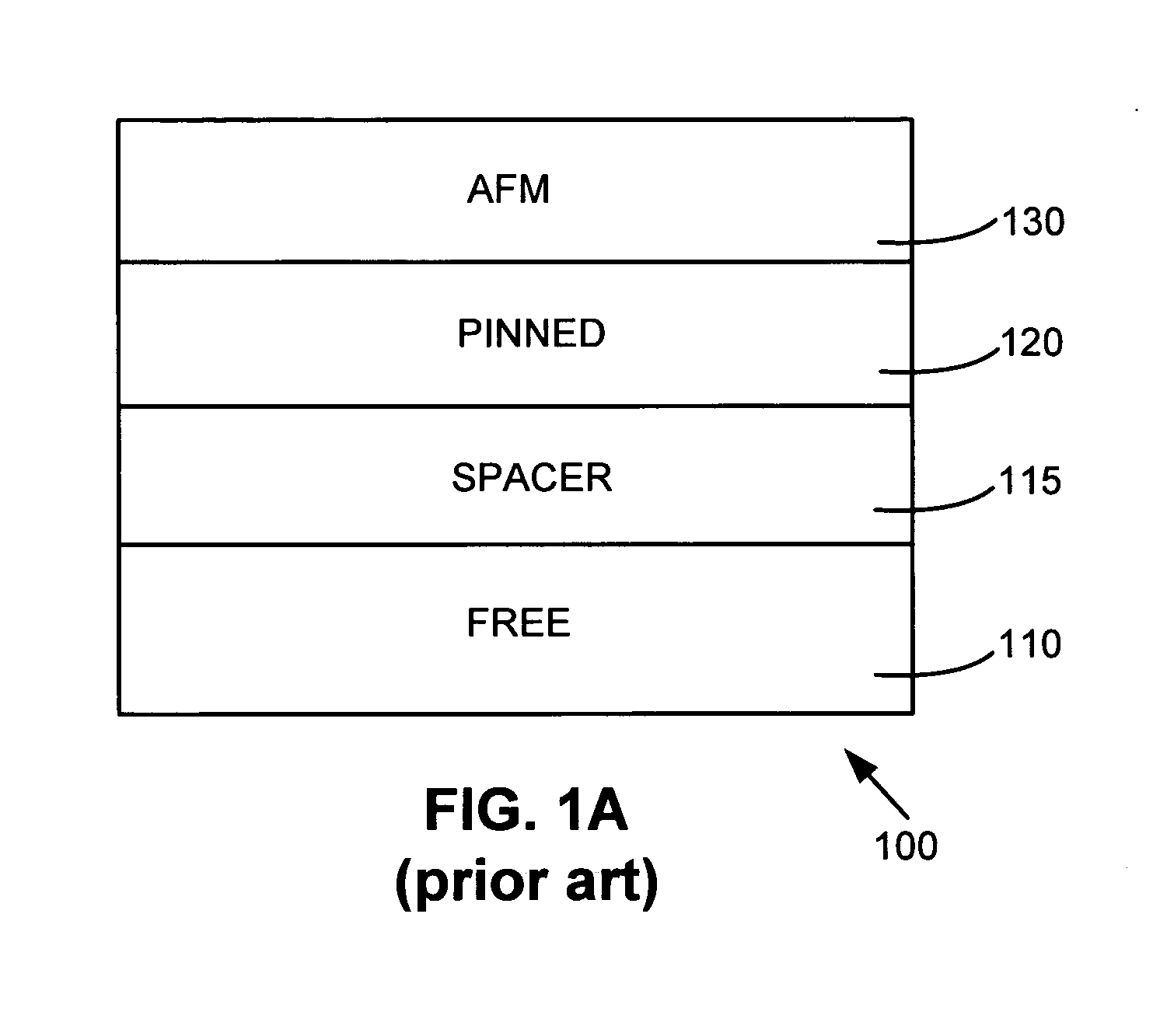

A method for maximizing the interfacial properties of magnetoresistive sensors, such as spin valve and GMR sensors used in storage devices, comprises selecting the materials for ferromagnetic layers and for electrically conductive spacers that are interposed between the ferromagnetic layers. The electronegativities of the selected materials are substantially matched so that an absolute value of the differences in electronegativities is minimized. The conductive spacer material provides a relatively low resistivity and a large mean free path. The sensors experience greater chemical and thermal stability, are corrosion resistant, and realize an increased signal output.

Owner:WESTERN DIGITAL TECH INC

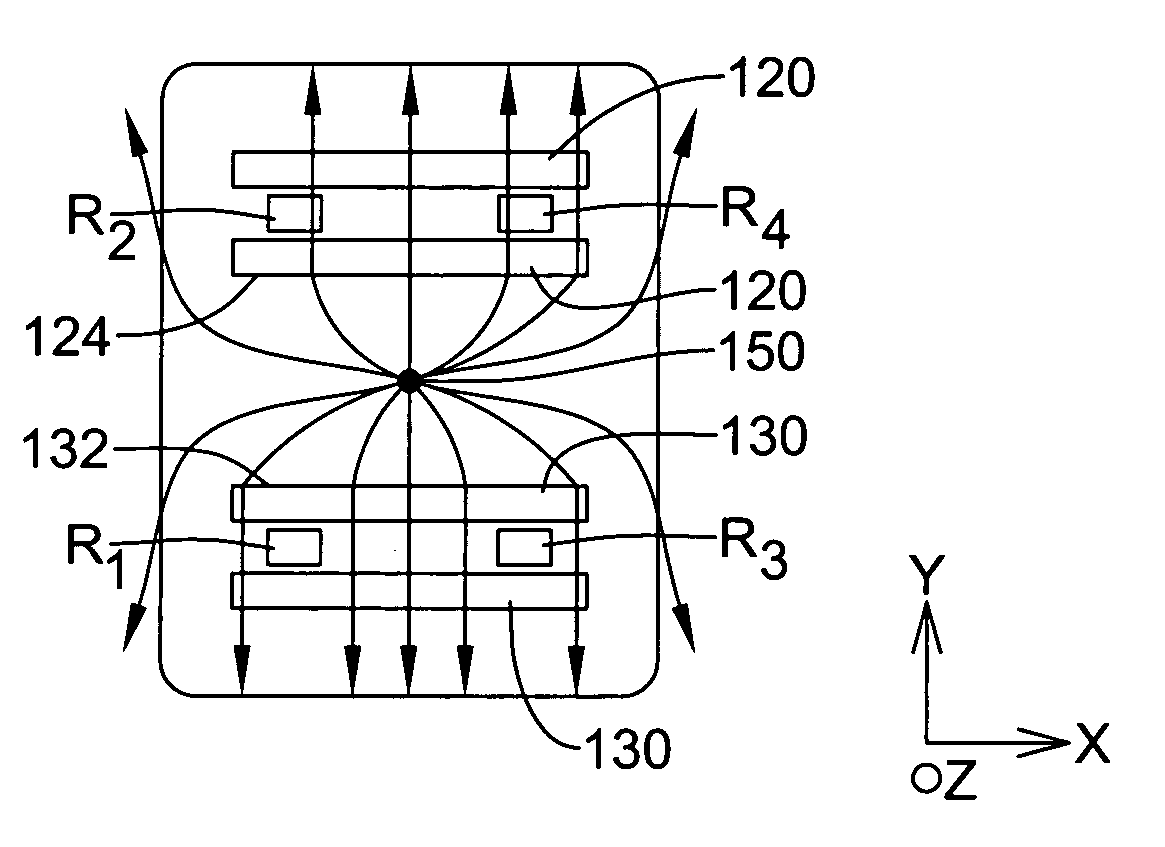

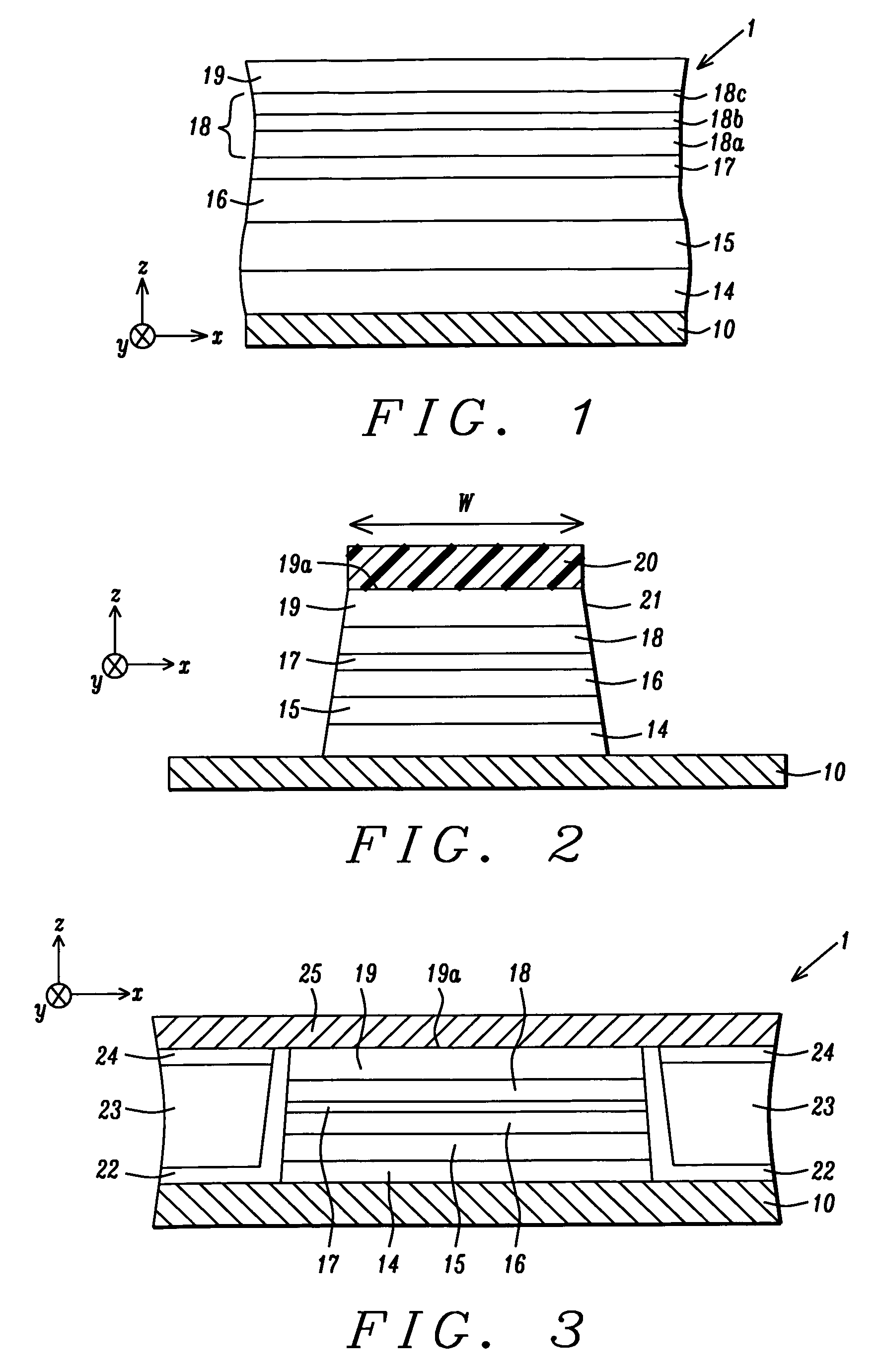

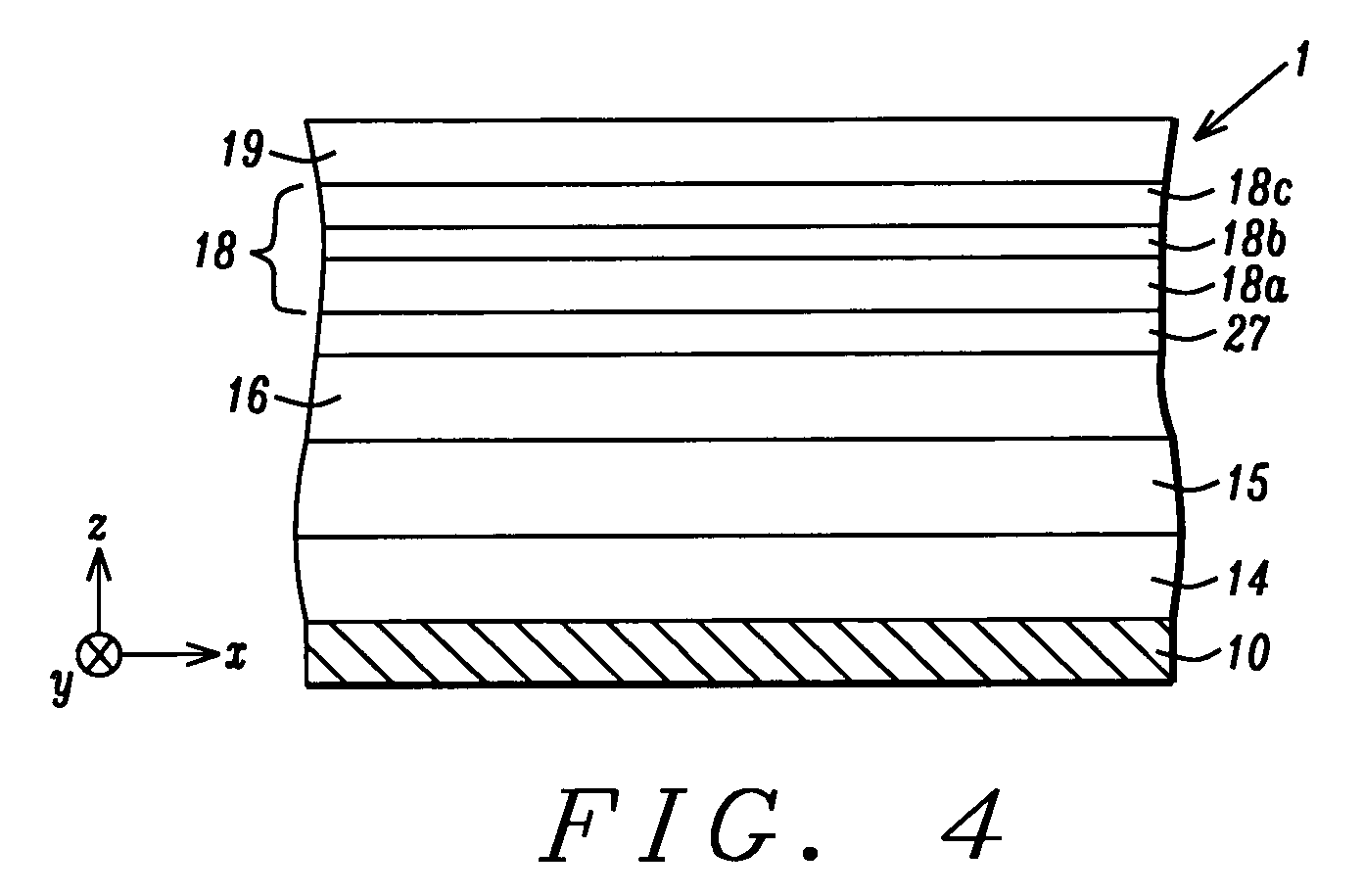

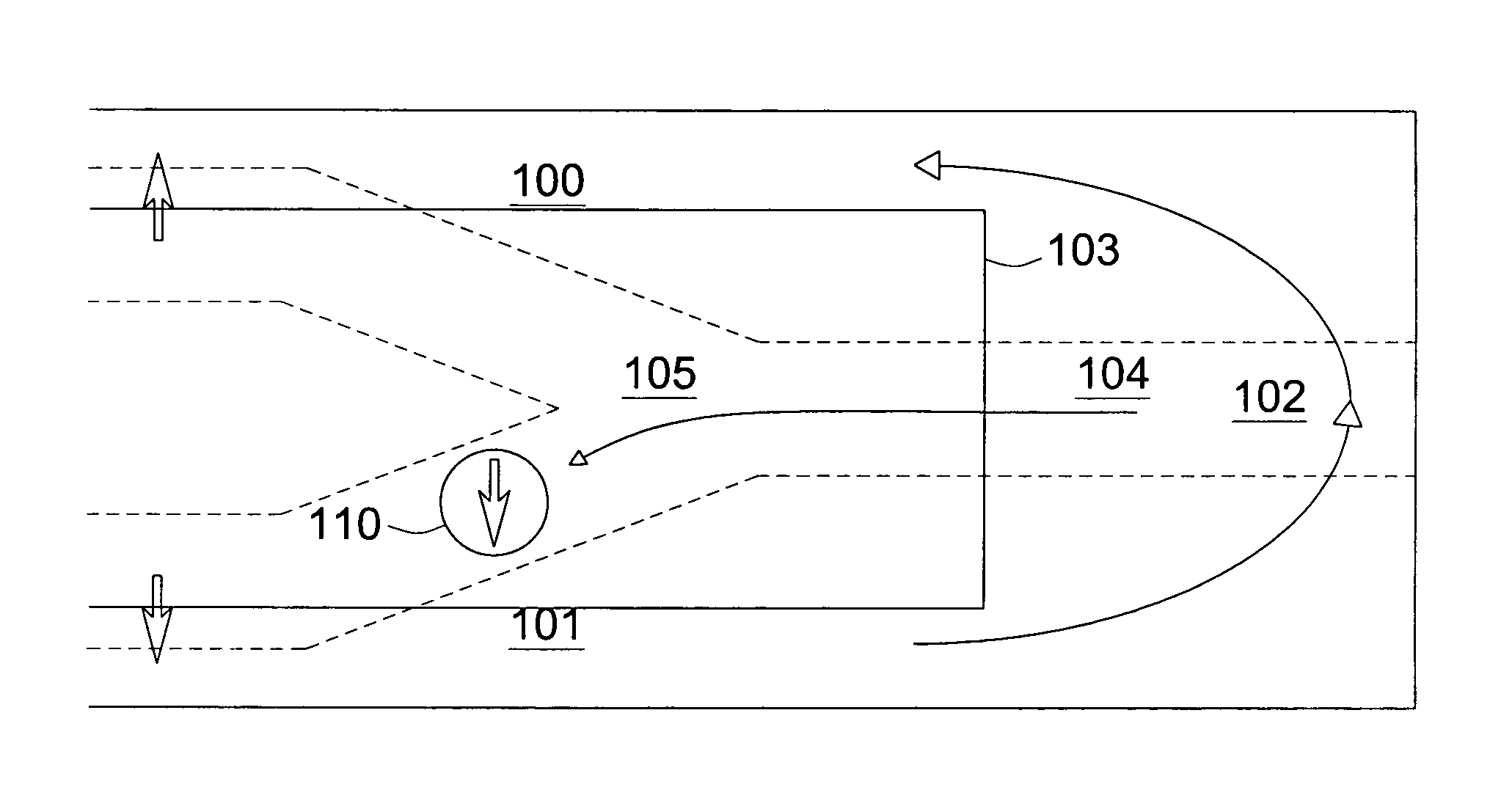

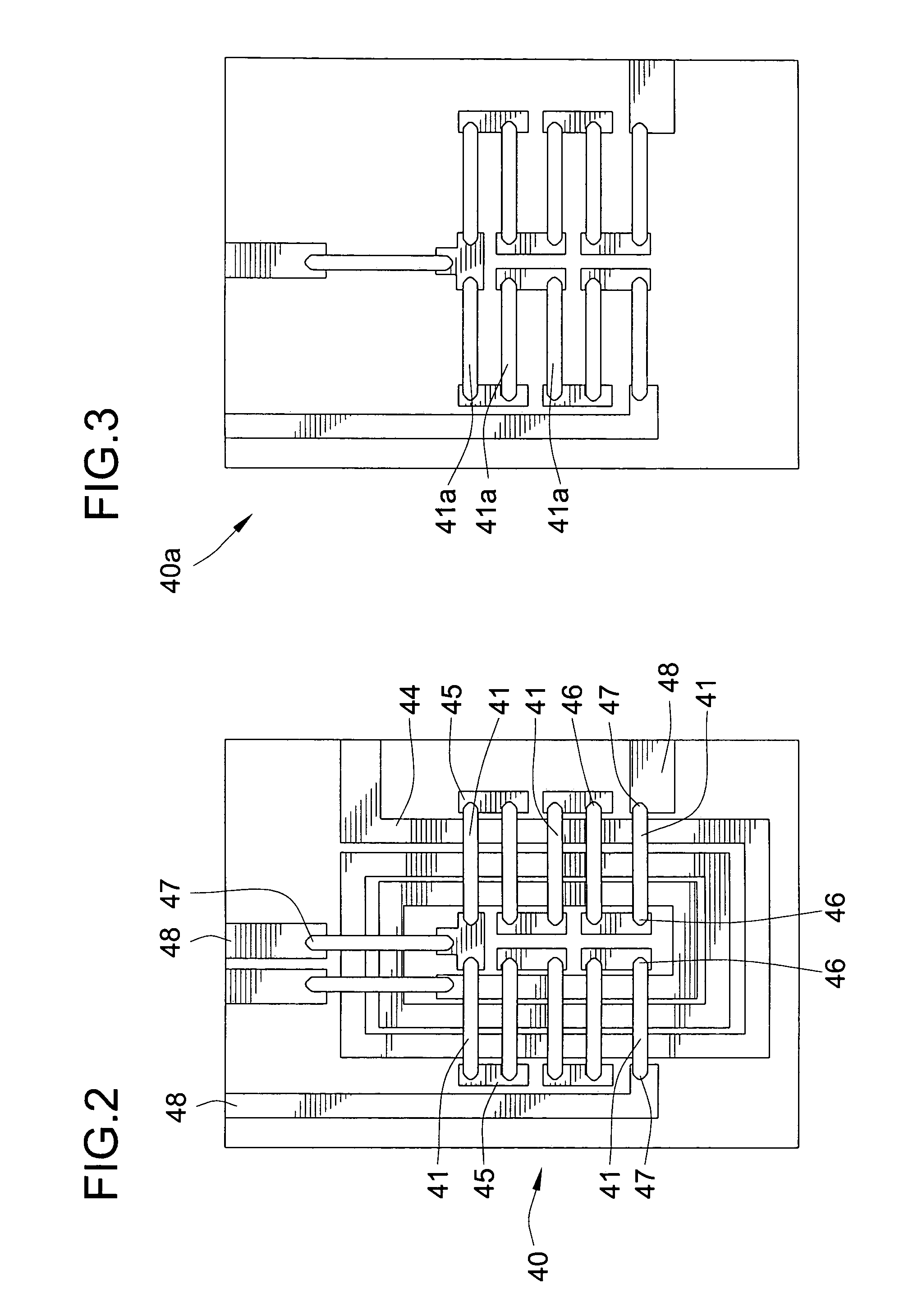

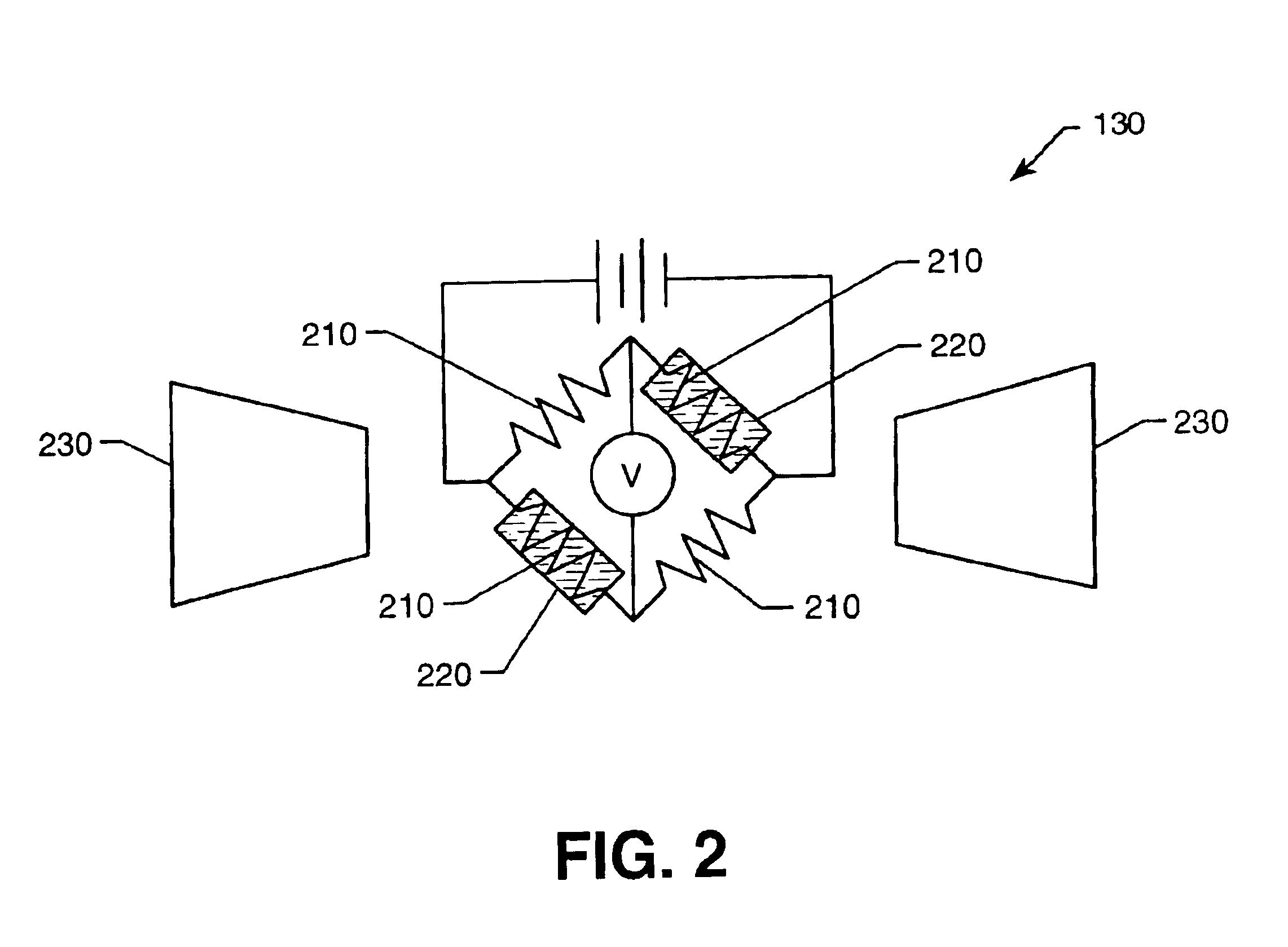

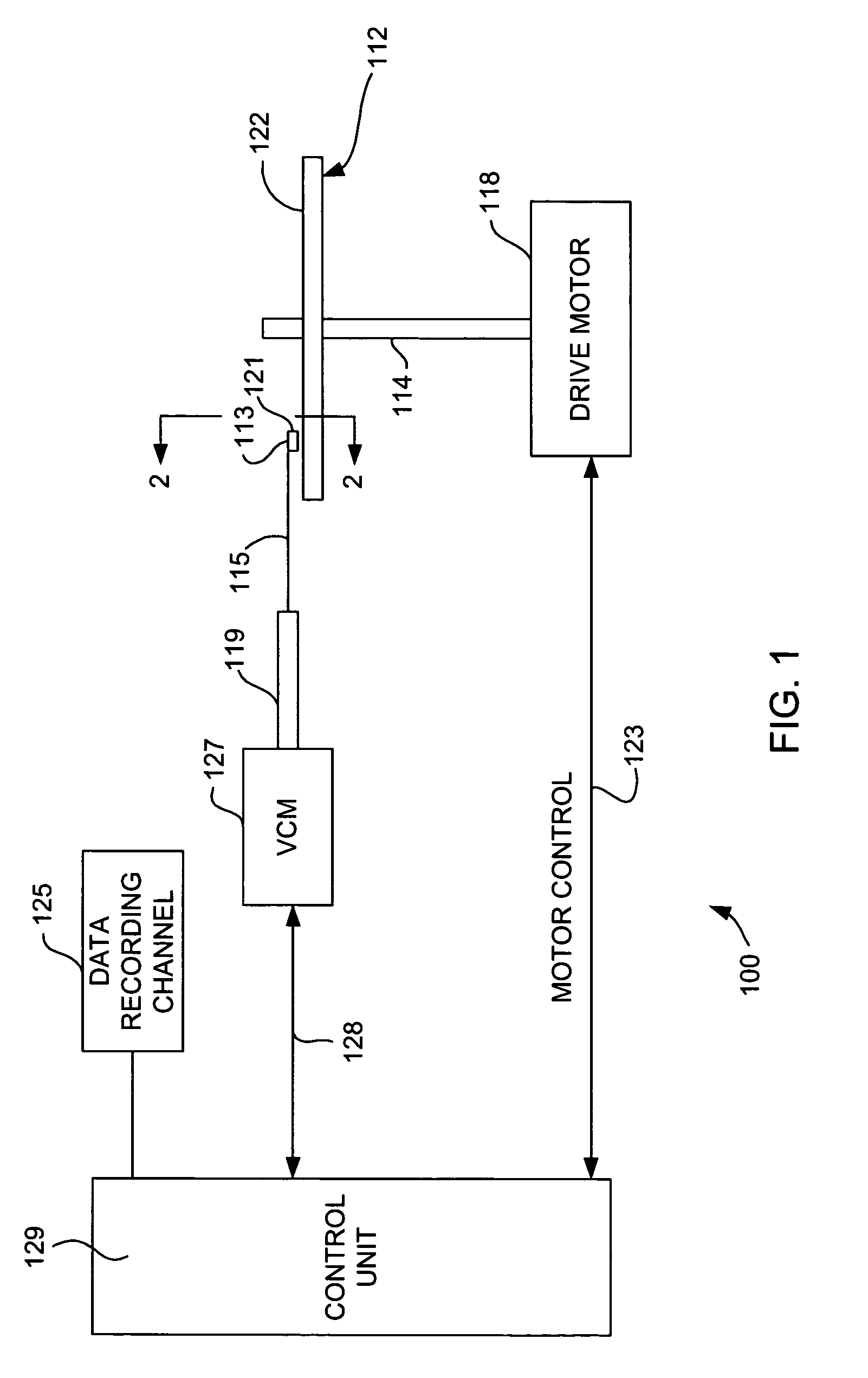

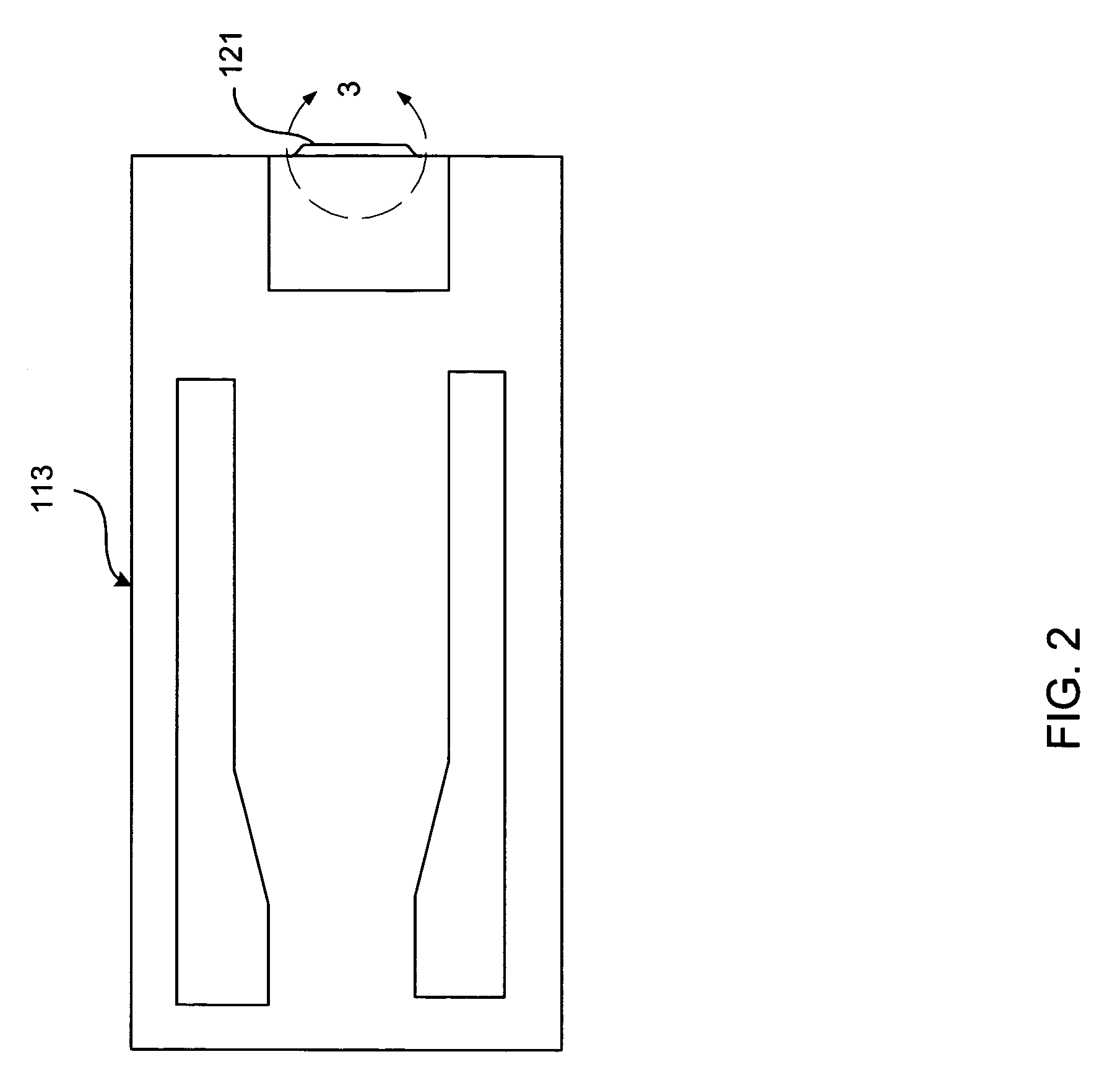

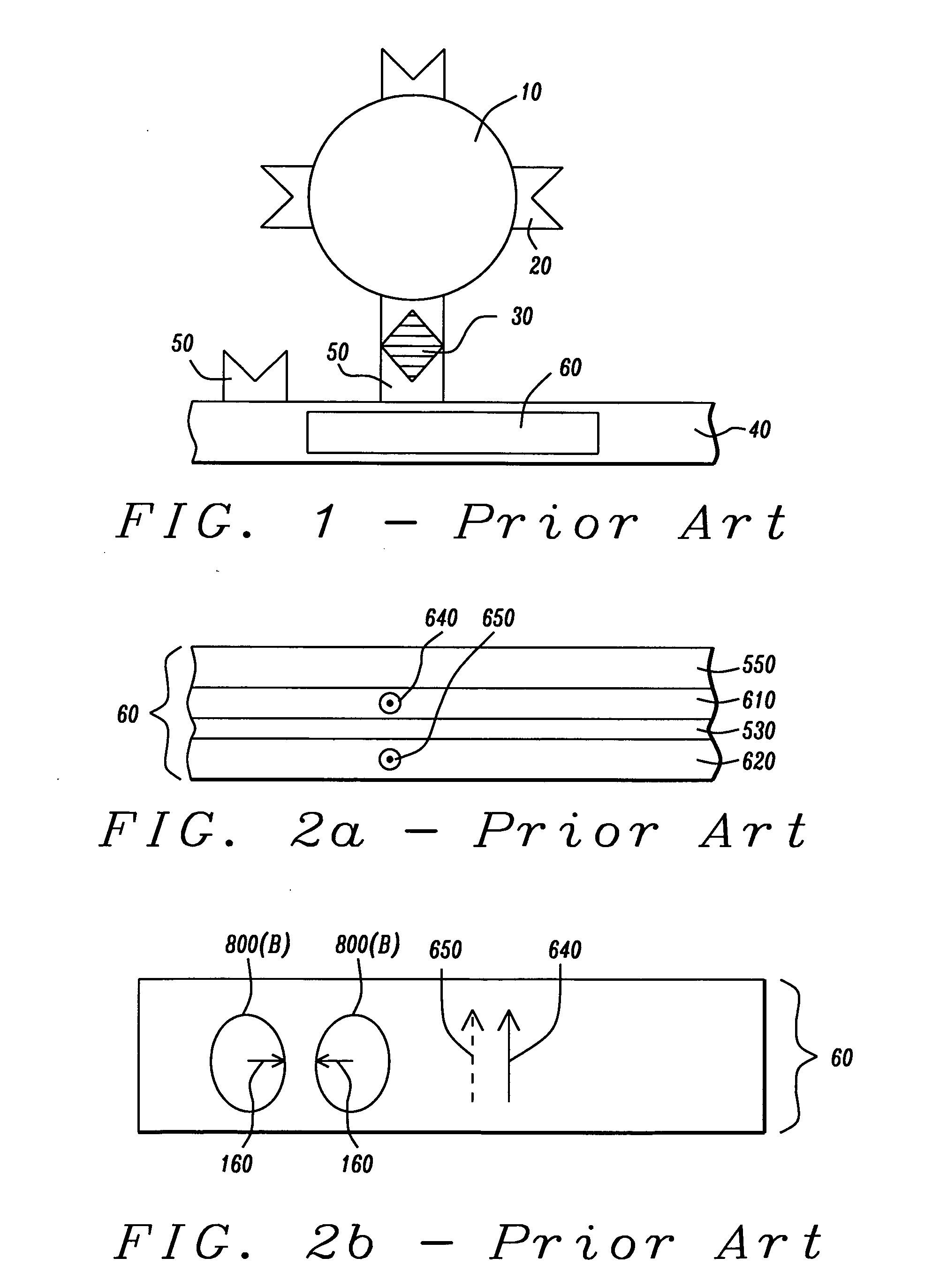

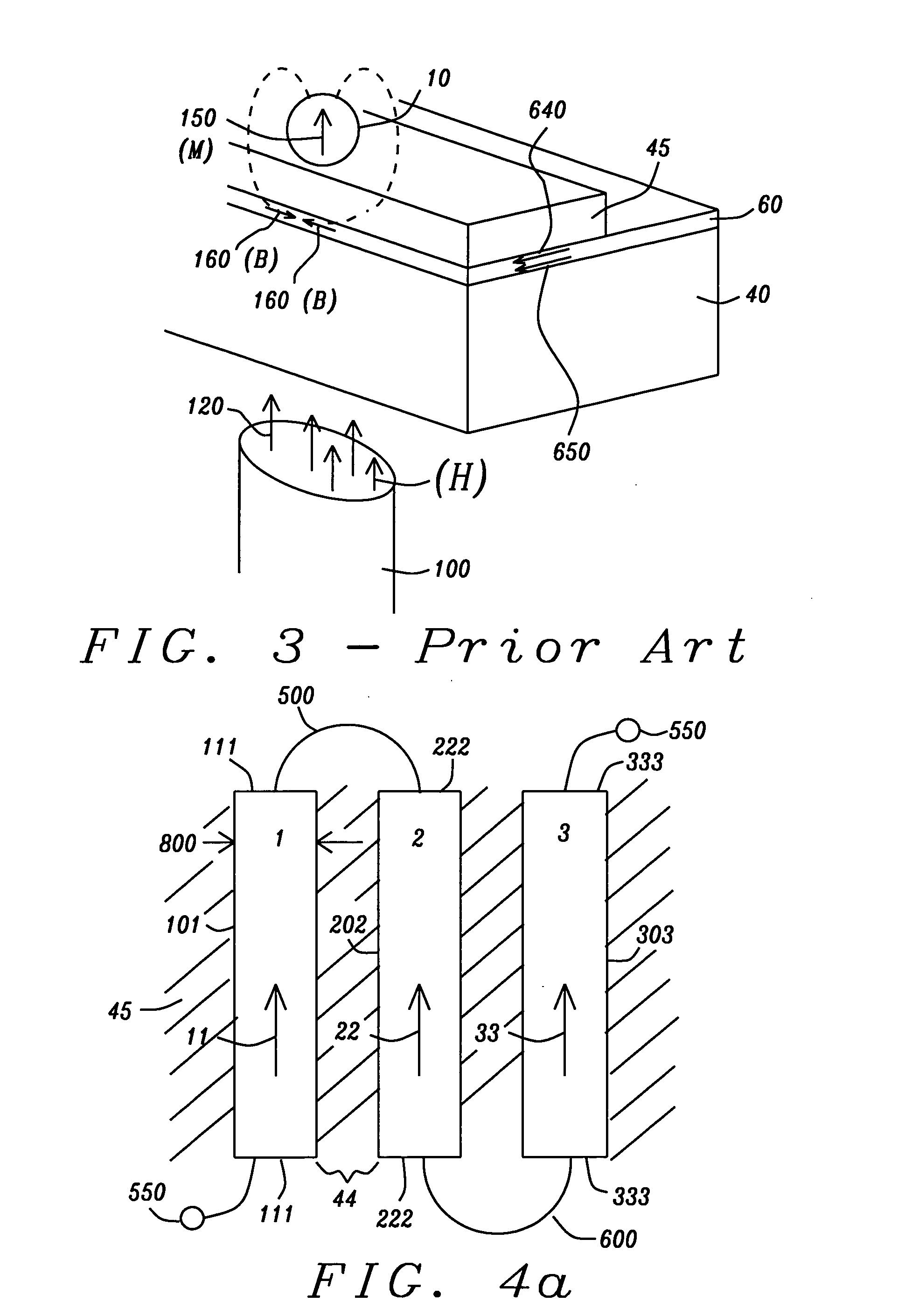

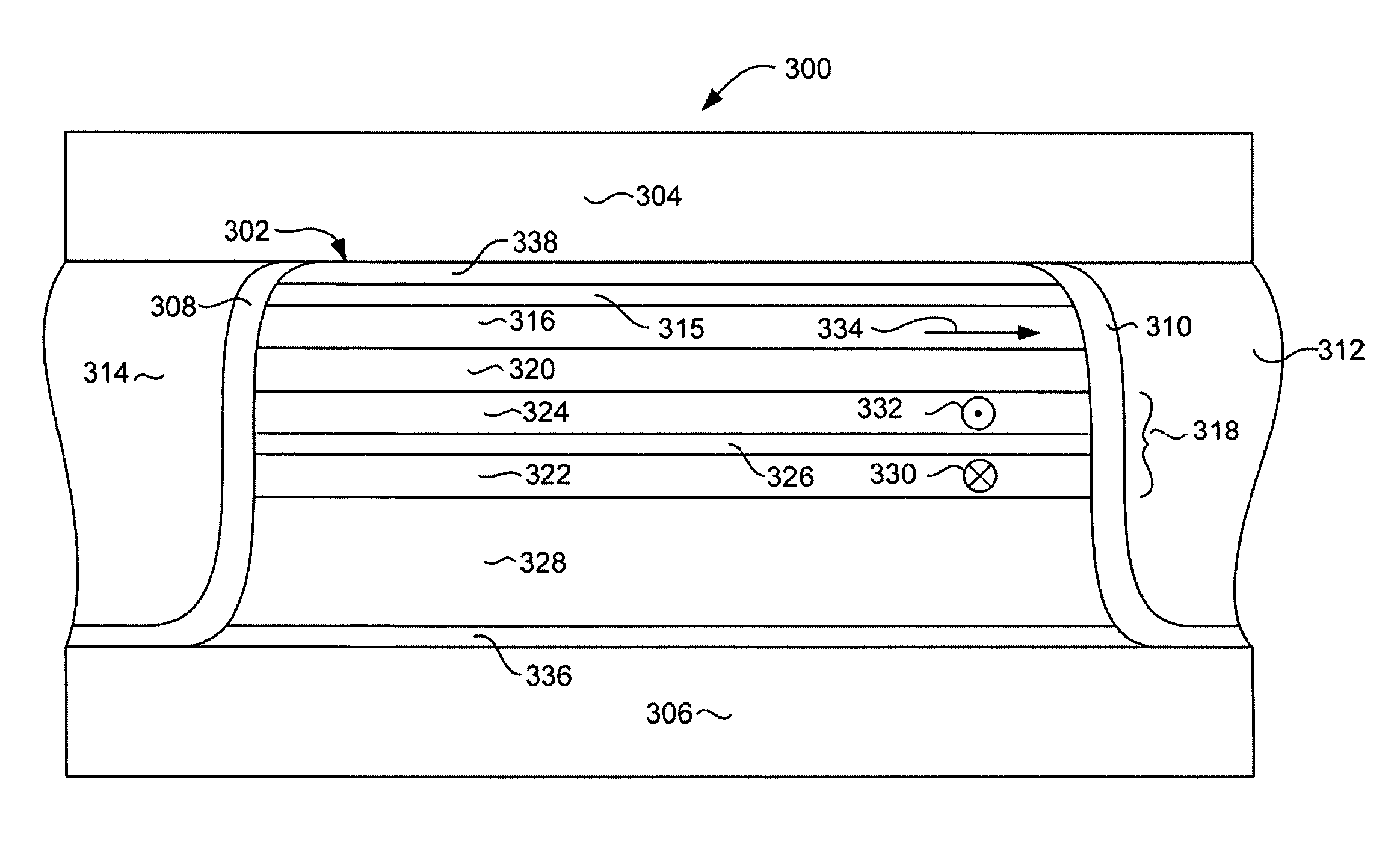

GMR sensor with flux concentrators

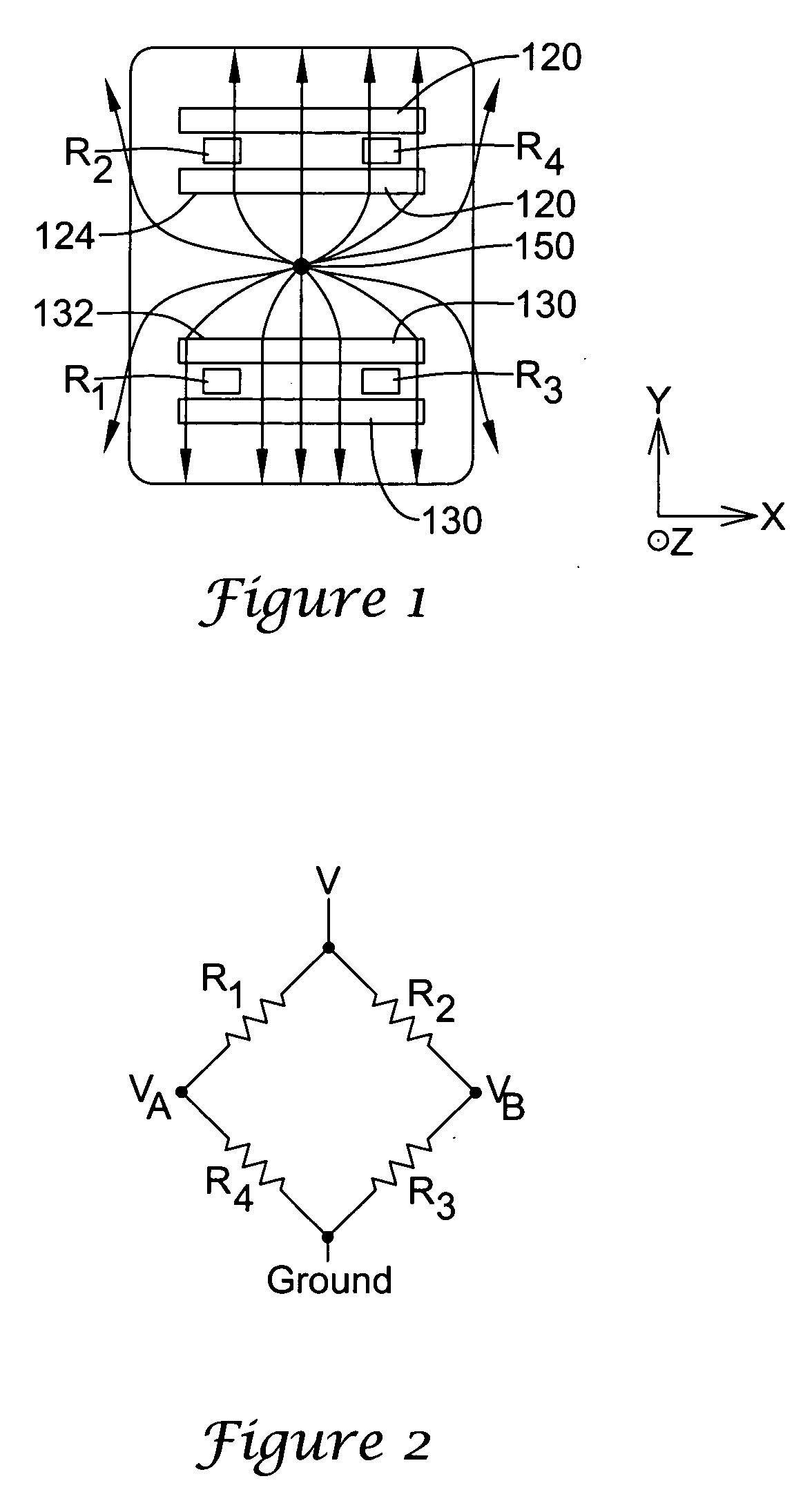

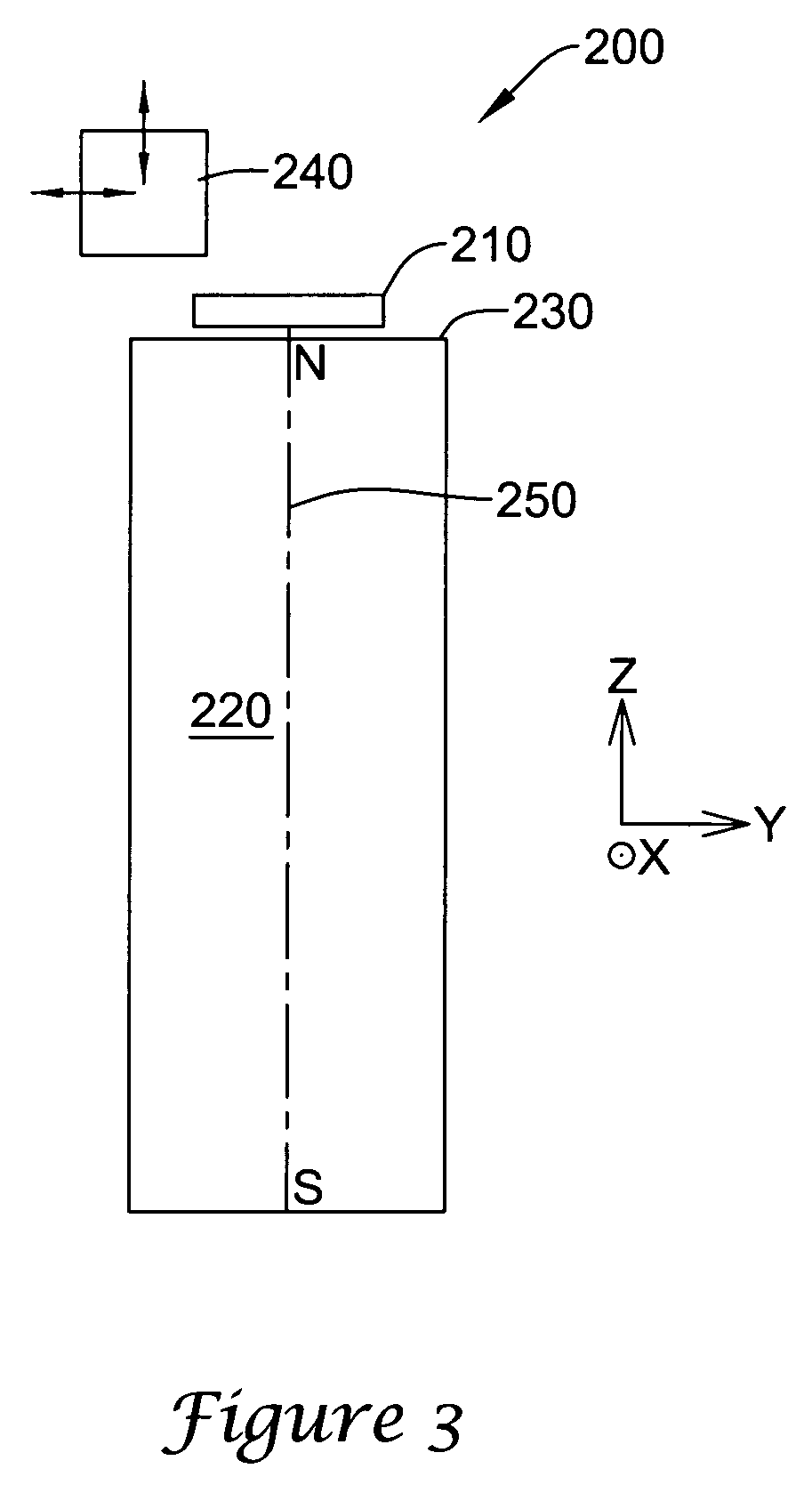

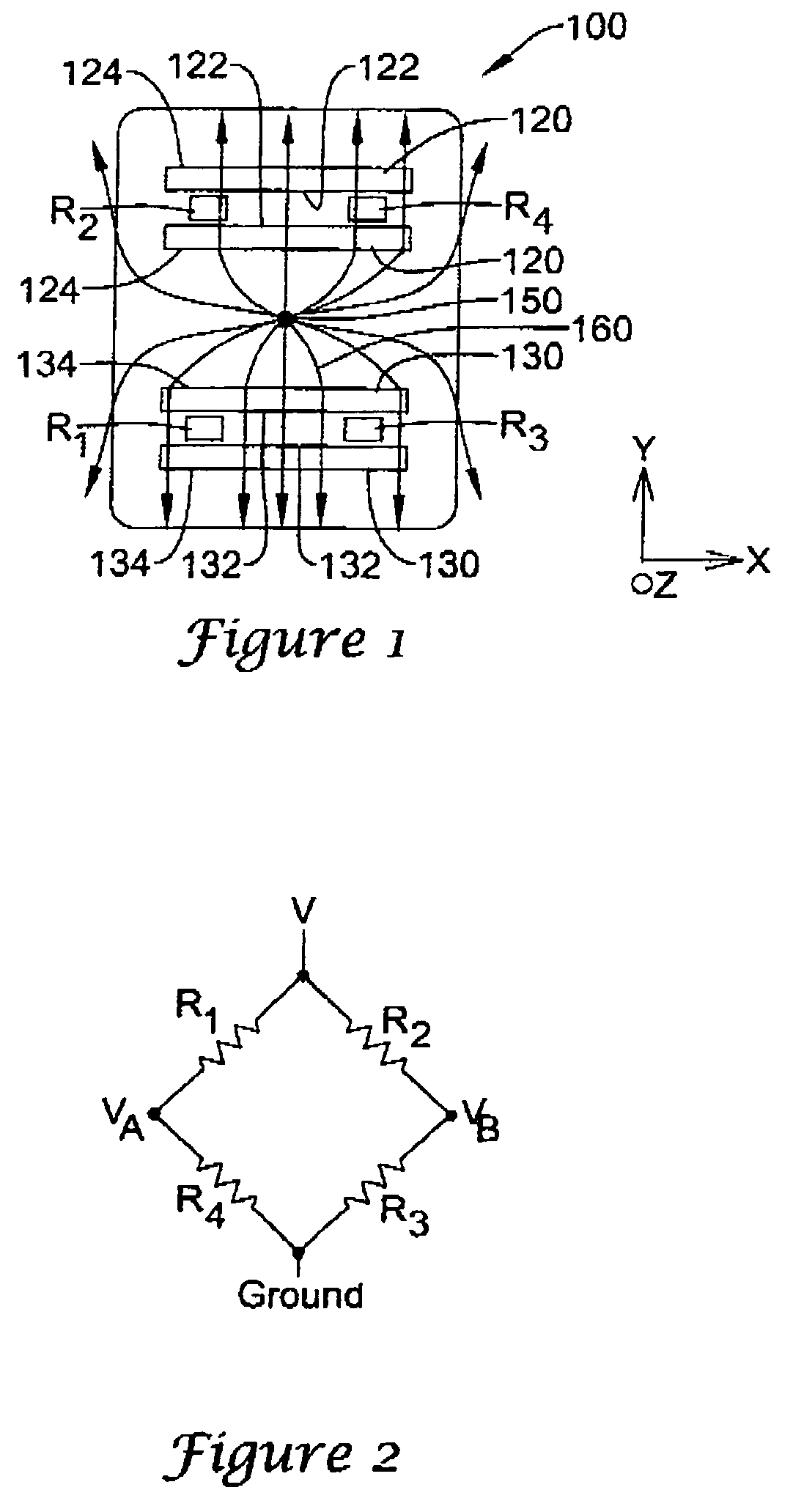

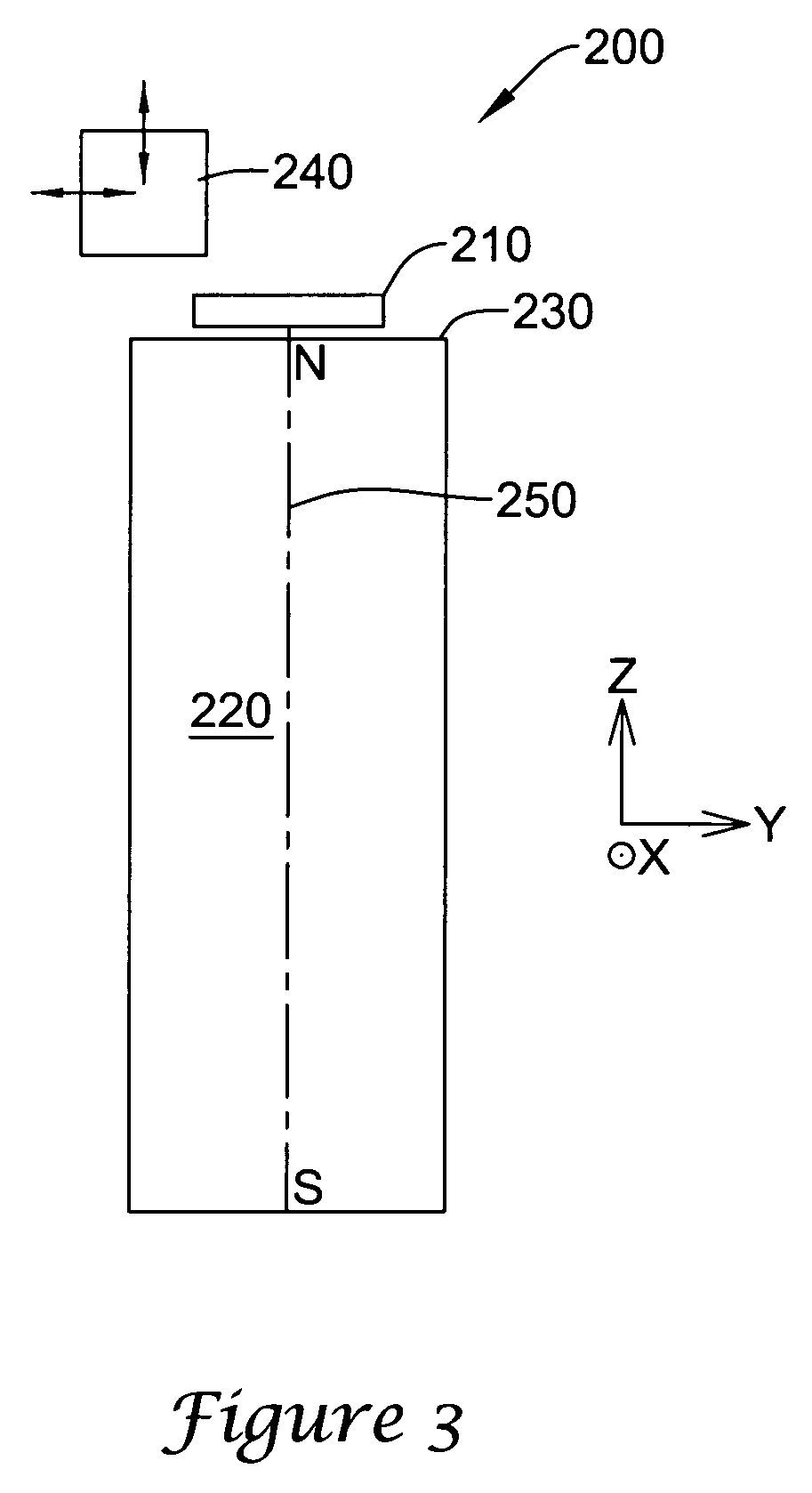

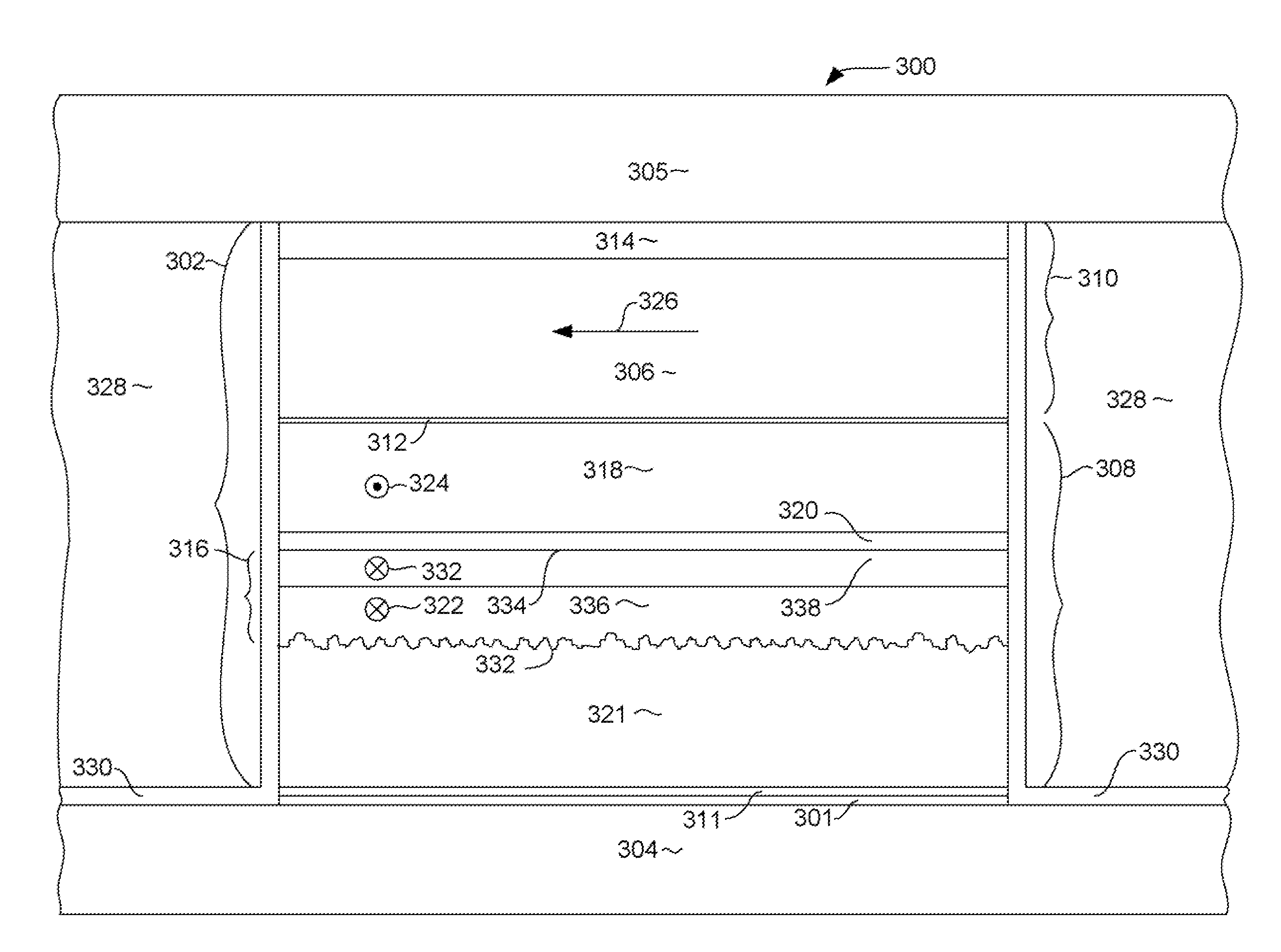

ActiveUS20050280411A1Improve dynamic rangeMinimize impactMagnetic-field-controlled resistorsSolid-state devicesMagnetic sourceProximity sensor

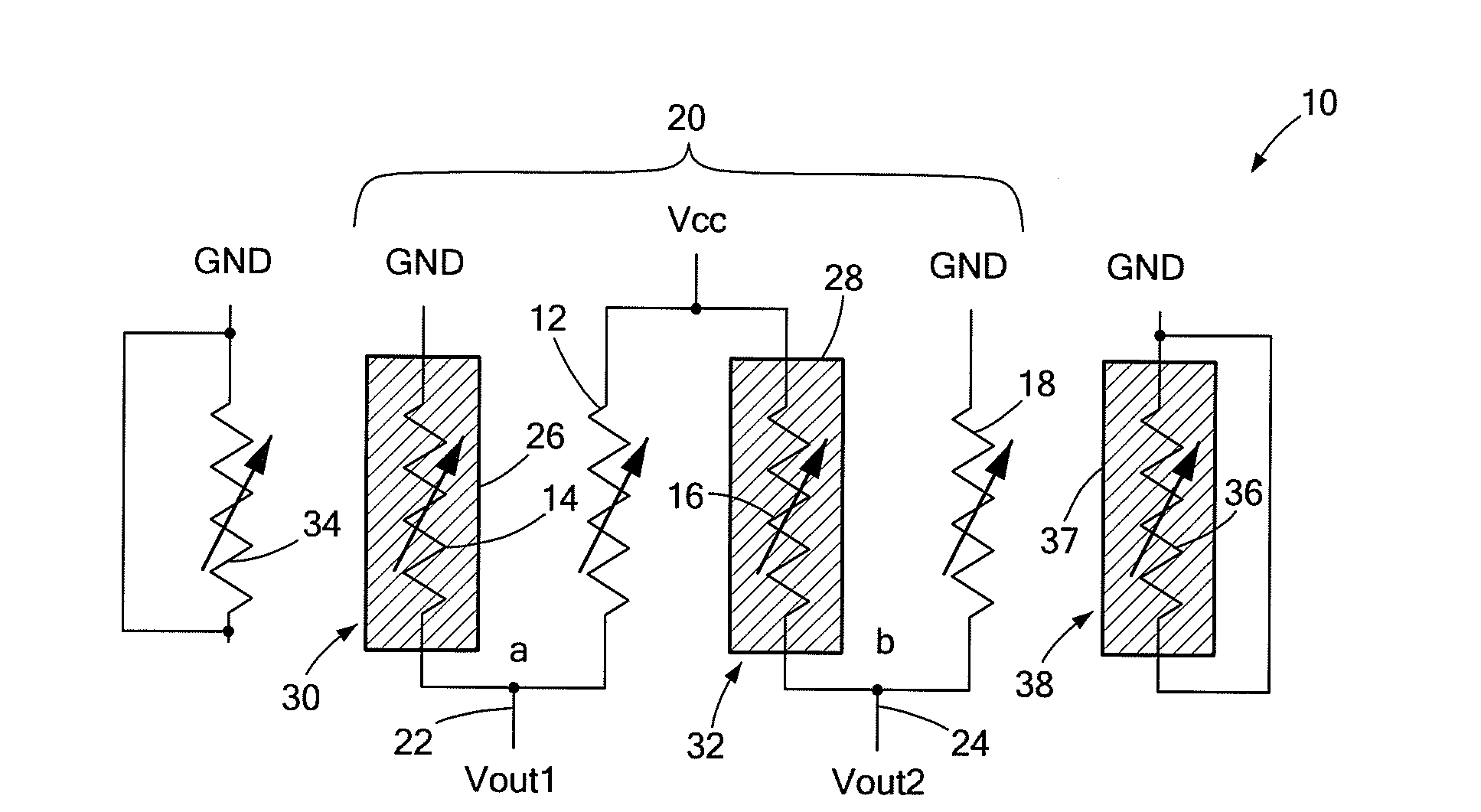

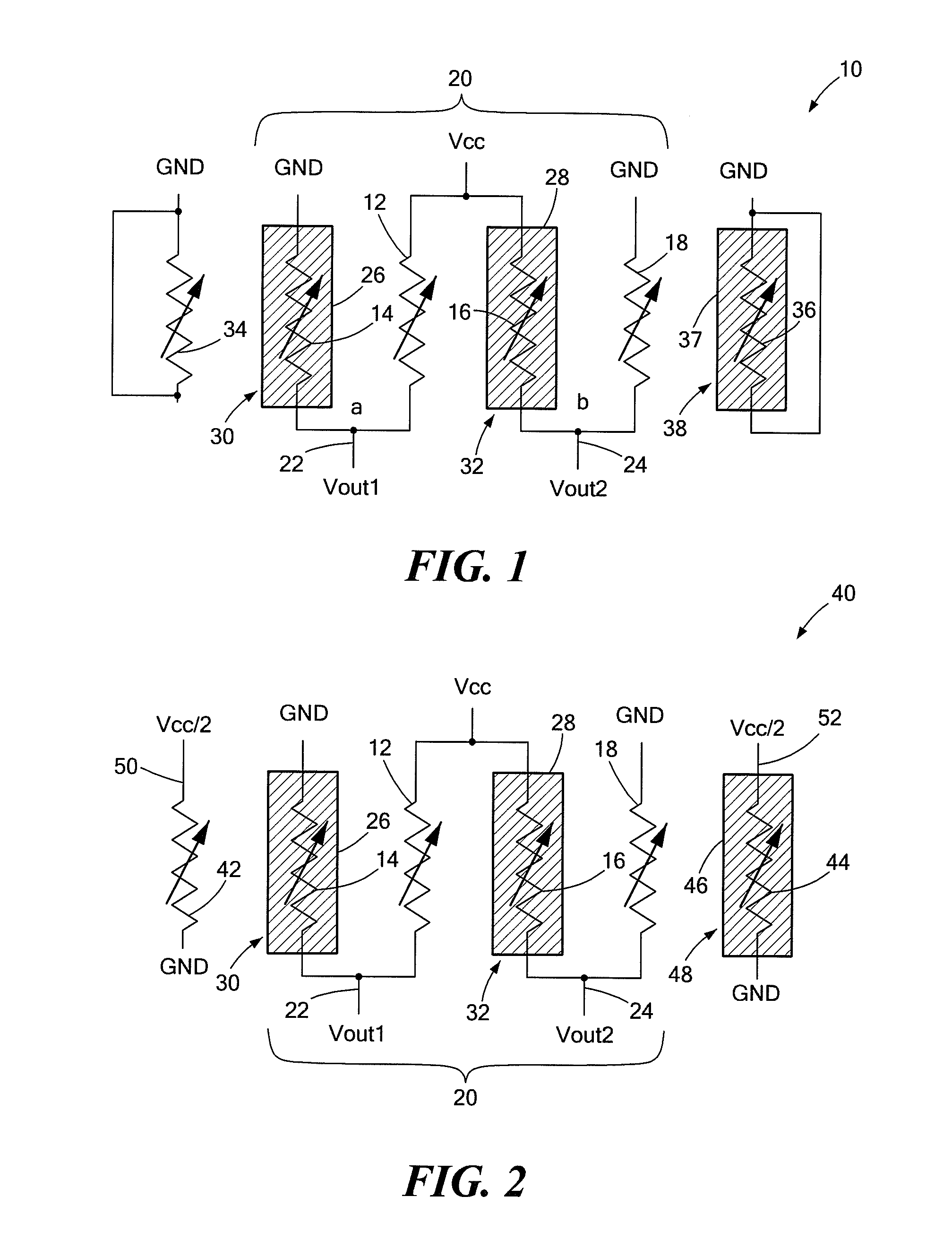

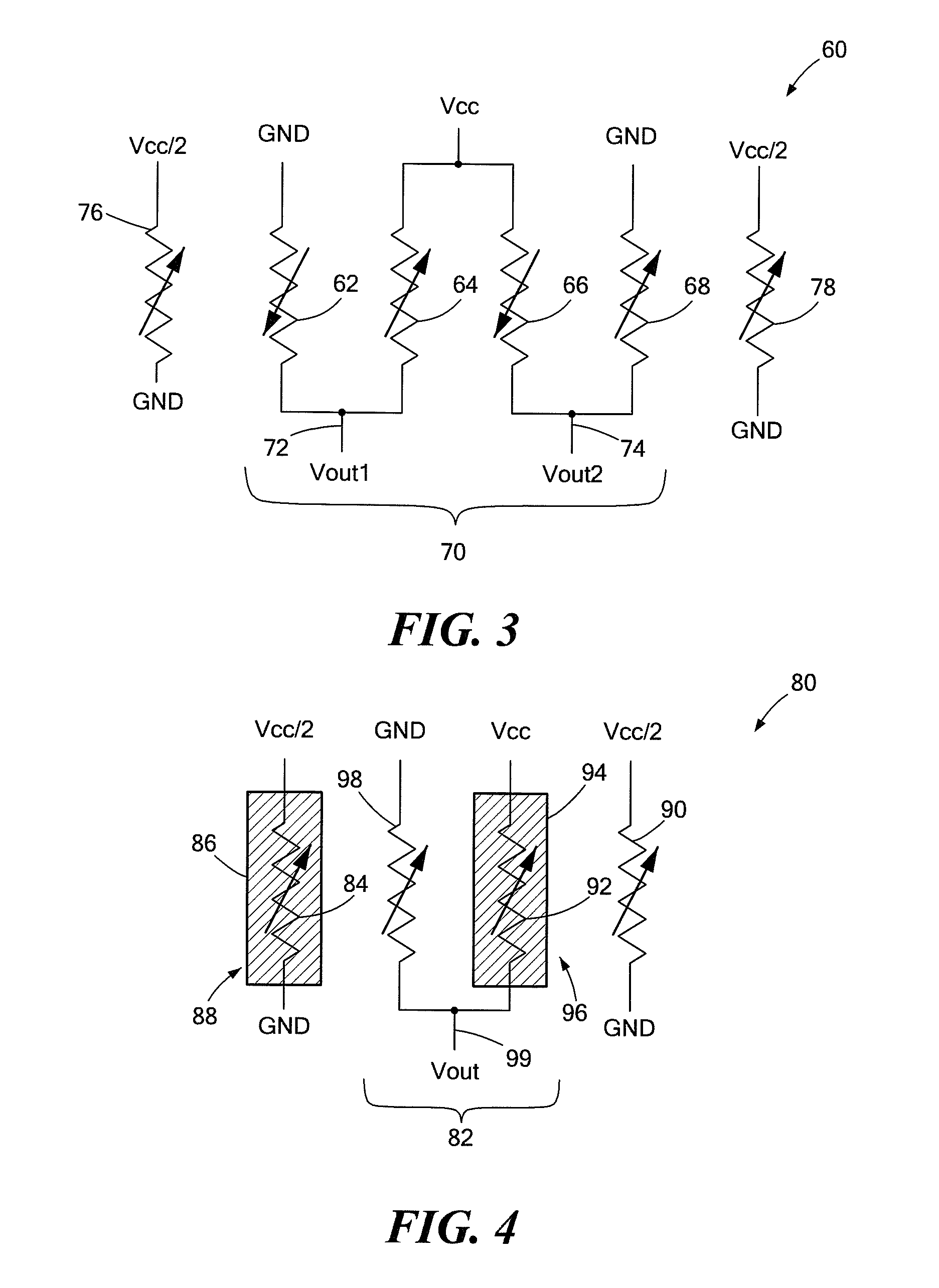

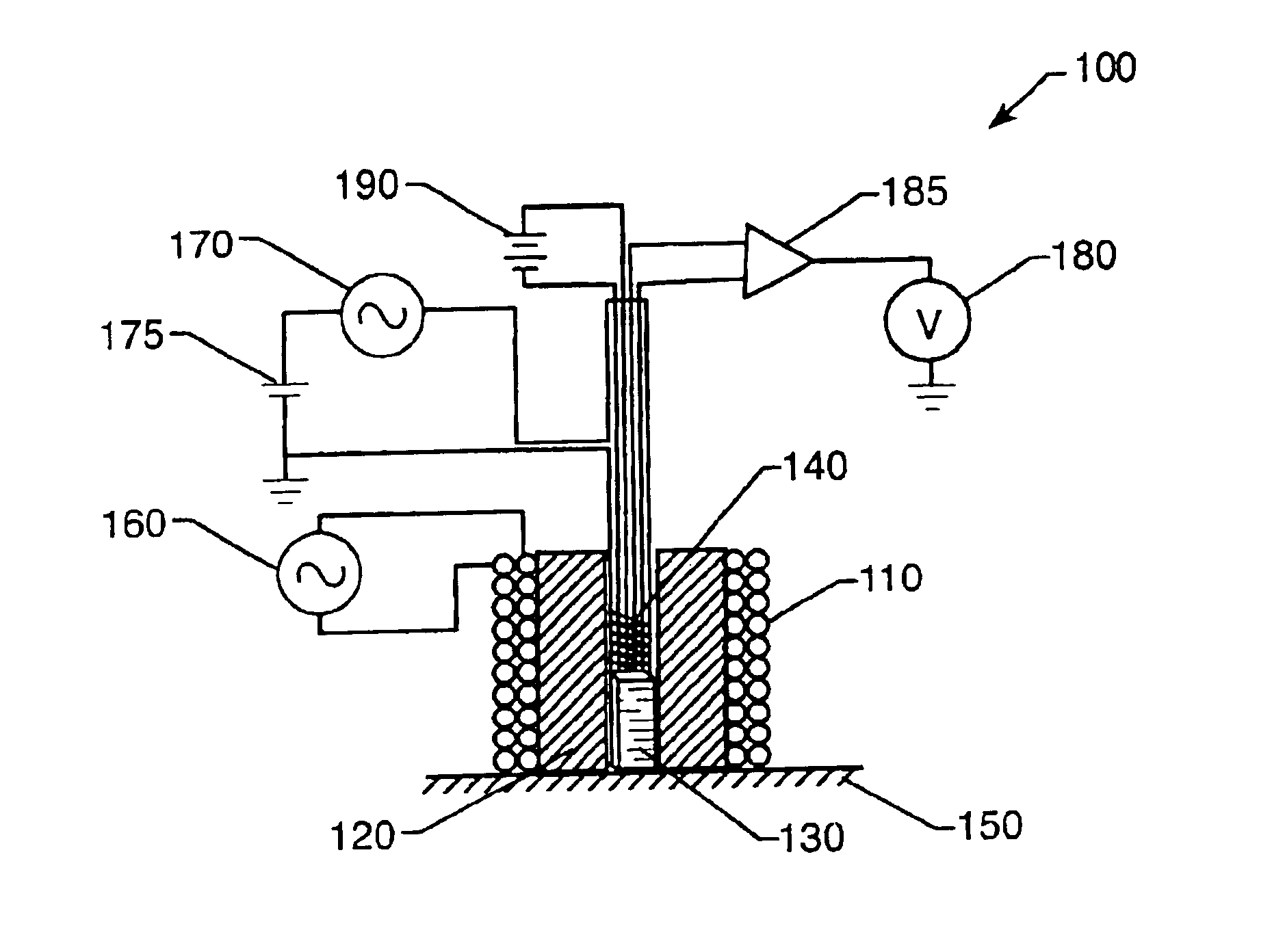

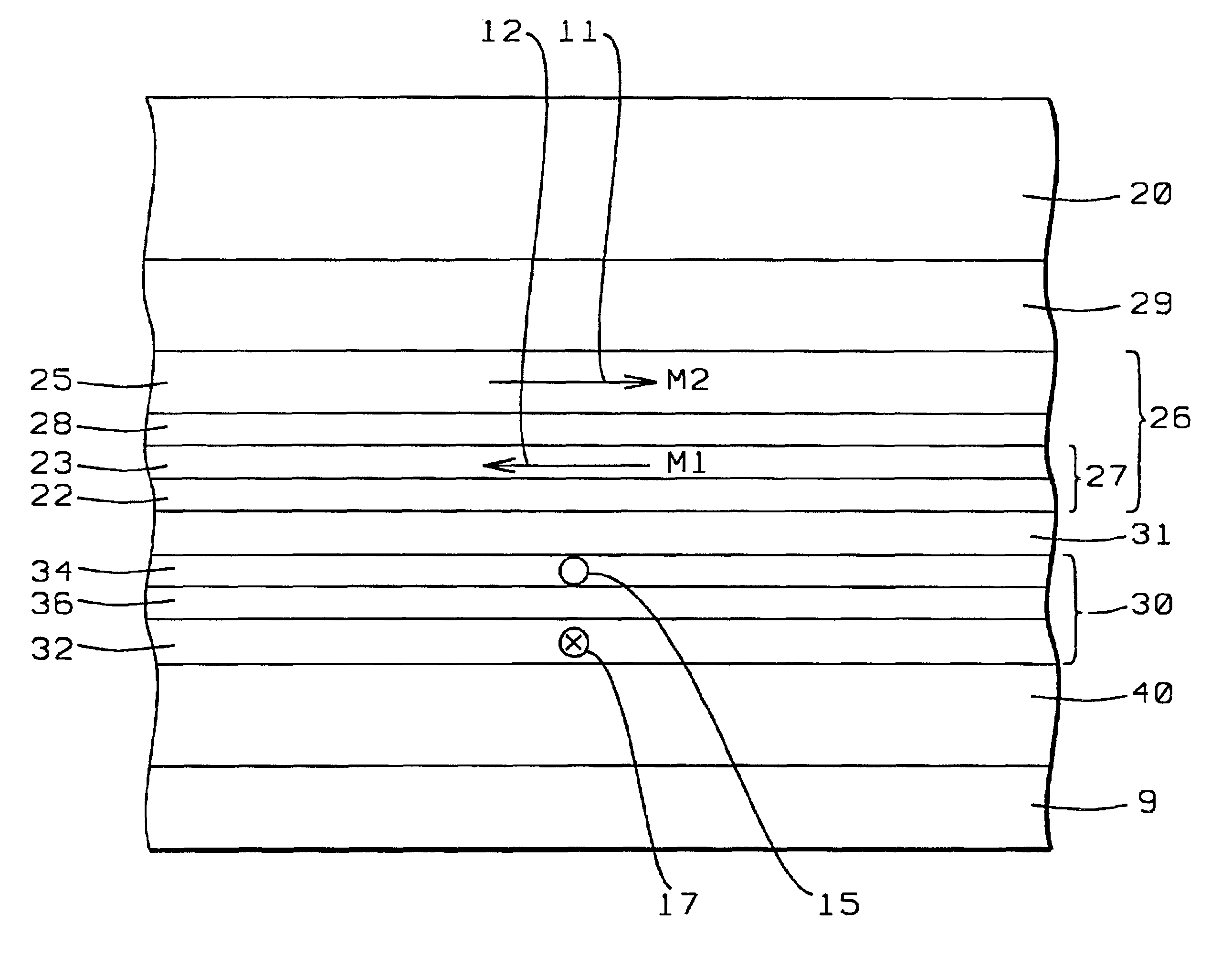

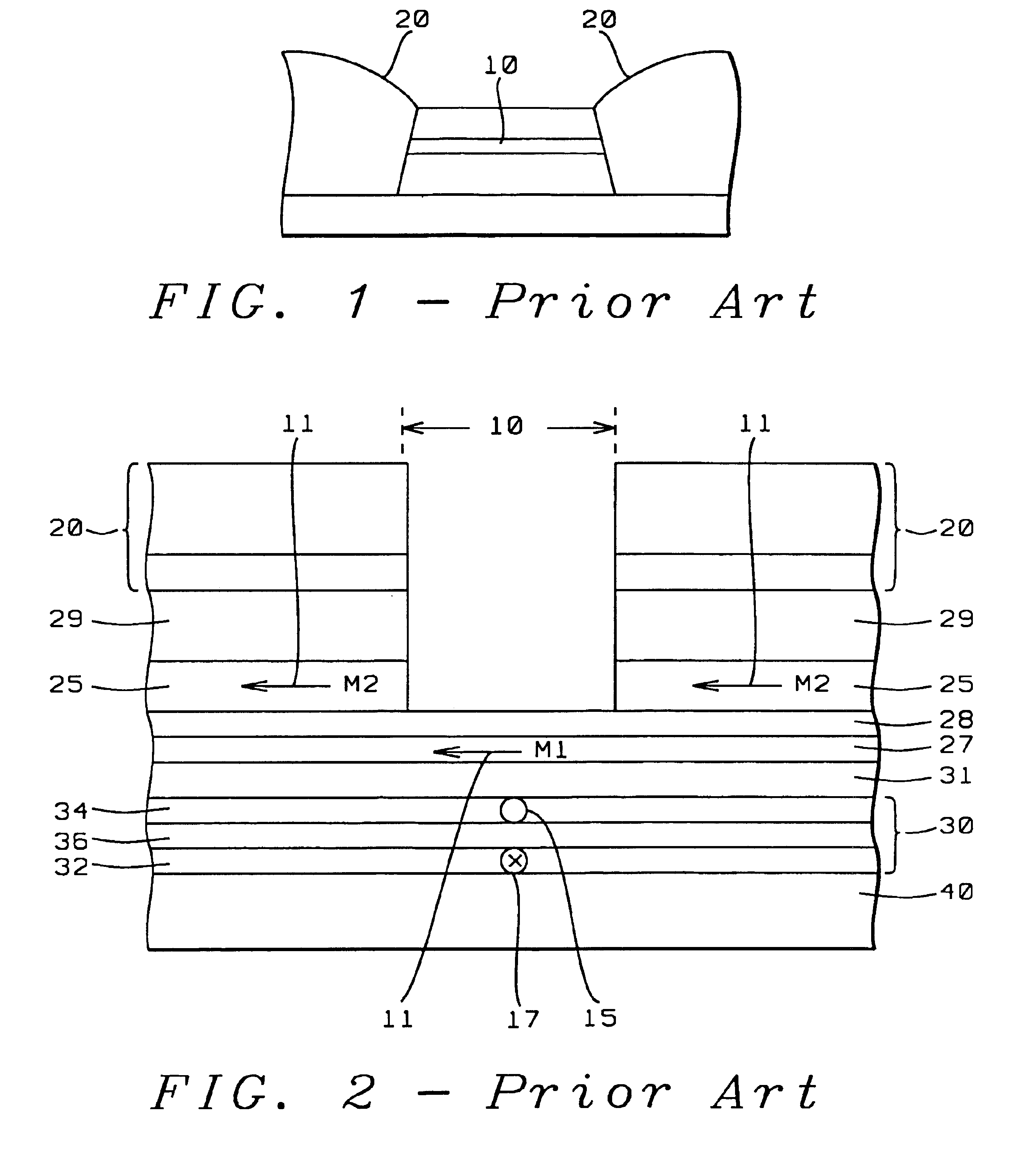

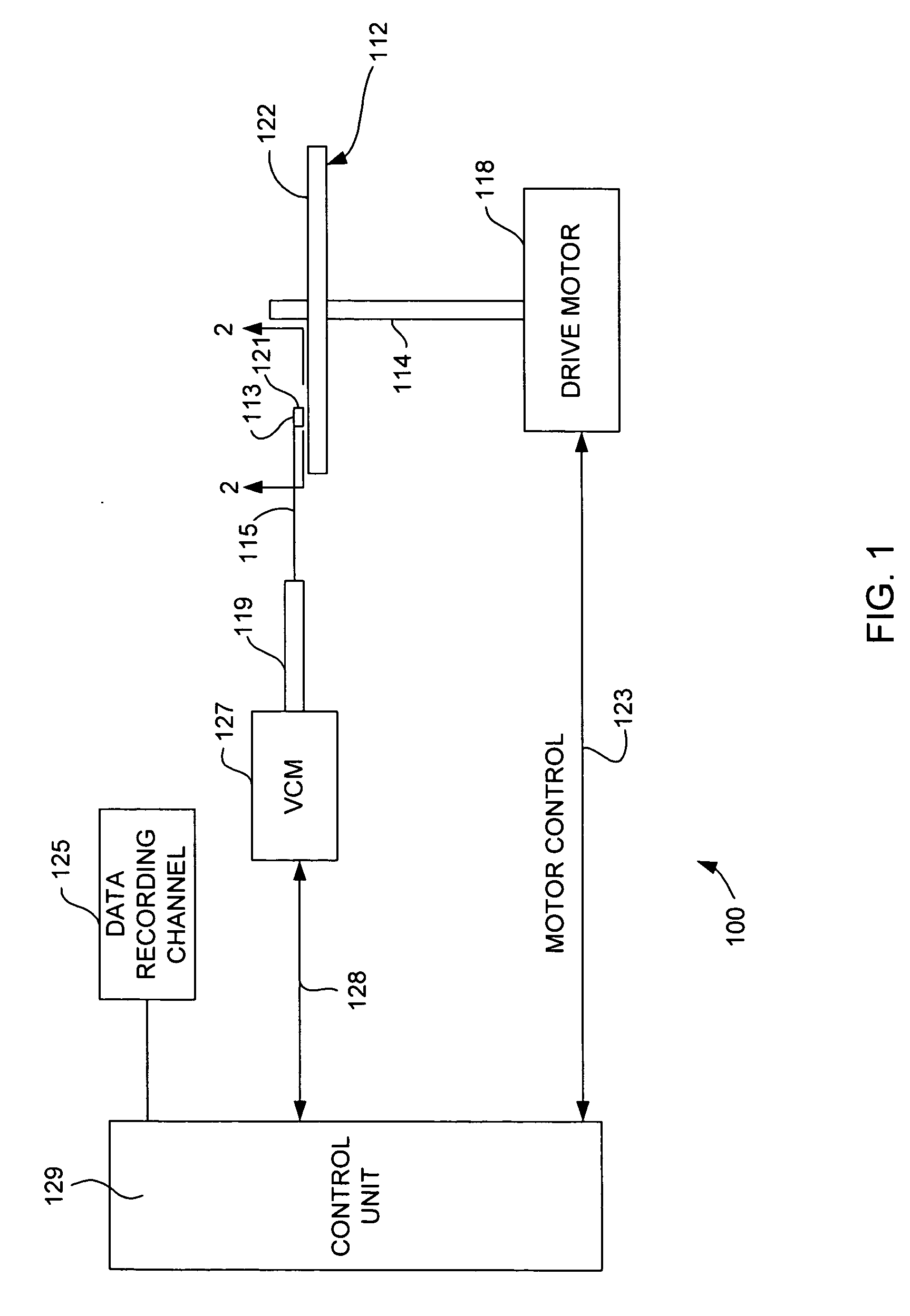

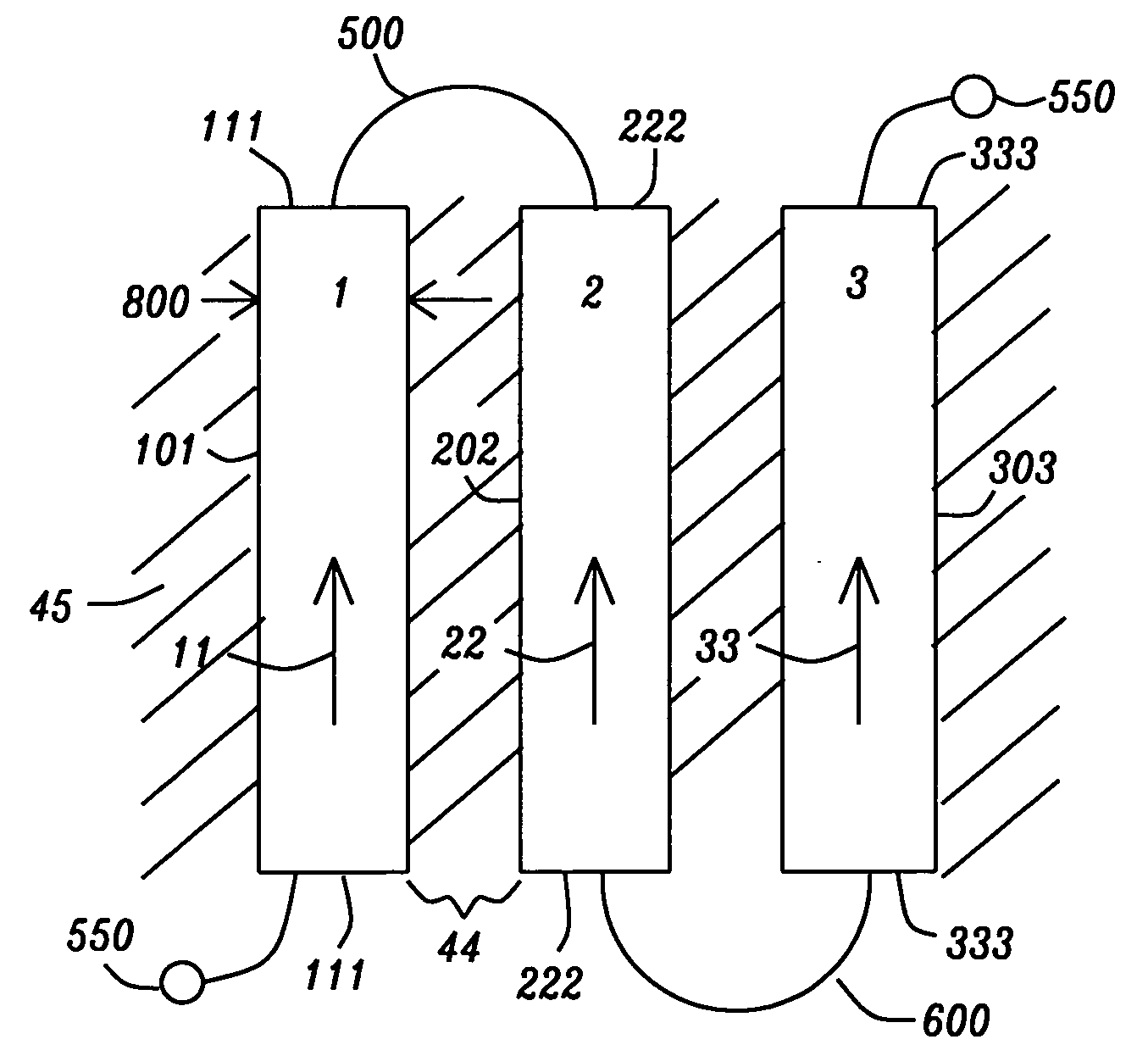

A proximity sensor that is capable of producing a relatively larger output signal than past proximity sensors, and in some cases, an output signal that is relatively independent of the speed at which a target passes the sensor. In one illustrative embodiment, the proximity sensor includes a first magnetoresistive resistor and a second magnetoresistive resistor connected in a bridge configuration. The first magnetoresistive resistor is spaced from the second magnetoresistive resistor along the path of a moving ferrous target. A bias magnet source is positioned behind the proximity sensor, and the ferrous target passes in front of the proximity sensor. The ferrous target alters the direction of the bias magnetic field in the vicinity of the first and second magnetoresistive resistors as the ferrous target passes by the proximity sensor. Flux concentrators are positioned proximate to each of the first and second magnetoresistive resistors. The flux concentrators may help redirect or shunt the magnetic field component produced by the bias magnet source that is perpendicular to the direction of motion of the target through the first and second magnetoresistive resistors in a direction that is parallel to the direction of motion of the target.

Owner:HONEYWELL INT INC

GMR sensor with flux concentrators

ActiveUS7112957B2Improve dynamic rangeMinimize impactMagnetic-field-controlled resistorsSolid-state devicesProximity sensorEngineering

A proximity sensor that is capable of producing a relatively larger output signal than past proximity sensors, and in some cases, an output signal that is relatively independent of the speed at which a target passes the sensor. In one illustrative embodiment, the proximity sensor includes a first magnetoresistive resistor and a second magnetoresistive resistor connected in a bridge configuration. The first magnetoresistive resistor is spaced from the second magnetoresistive resistor along the path of a moving ferrous target. A bias magnet source is positioned behind the proximity sensor, and the ferrous target passes in front of the proximity sensor. The ferrous target alters the direction of the bias magnetic field in the vicinity of the first and second magnetoresistive resistors as the ferrous target passes by the proximity sensor. Flux concentrators are positioned proximate to each of the first and second magnetoresistive resistors. The flux concentrators may help redirect or shunt the magnetic field component produced by the bias magnet source that is perpendicular to the direction of motion of the target through the first and second magnetoresistive resistors in a direction that is parallel to the direction of motion of the target.

Owner:HONEYWELL INT INC

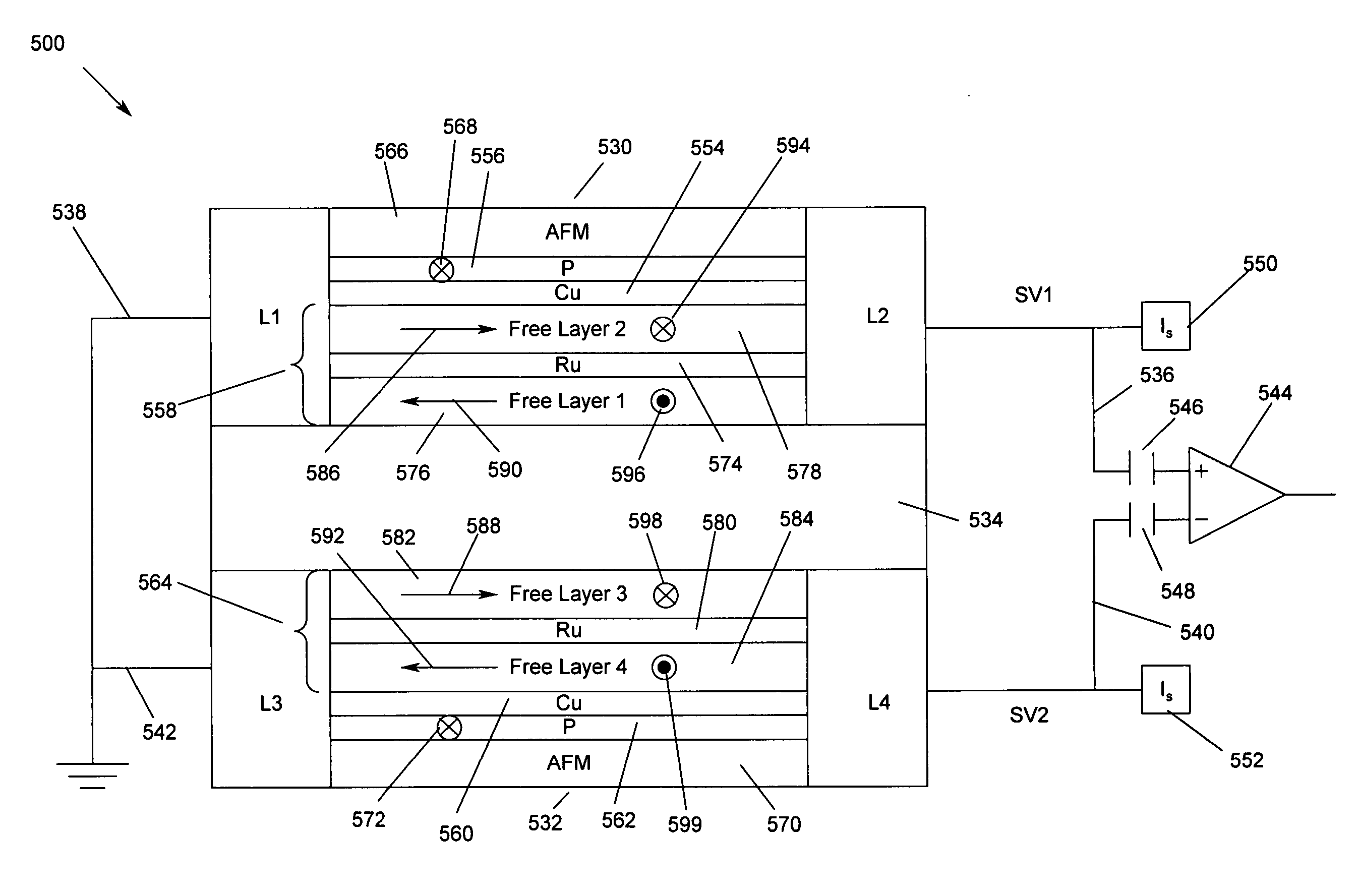

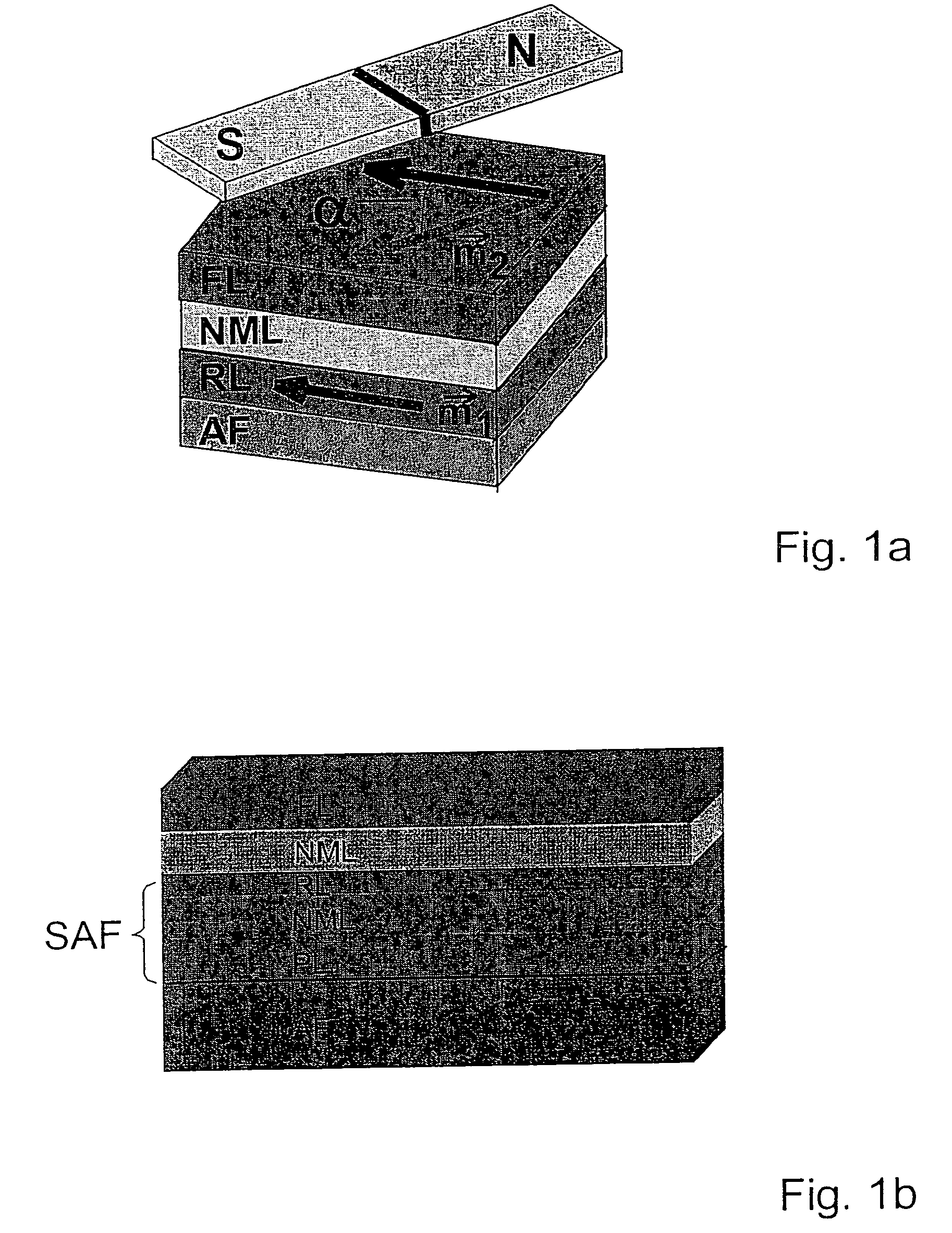

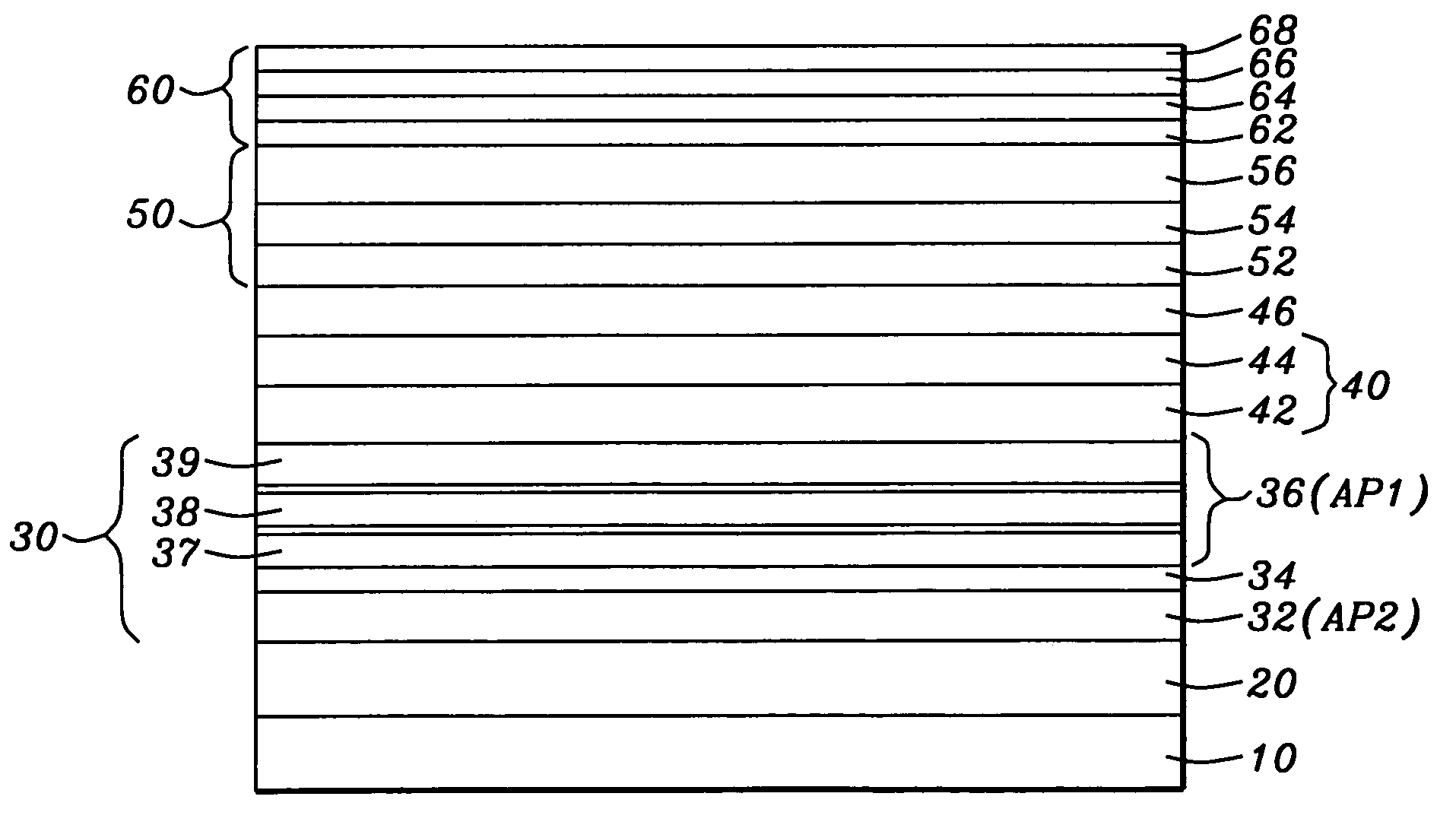

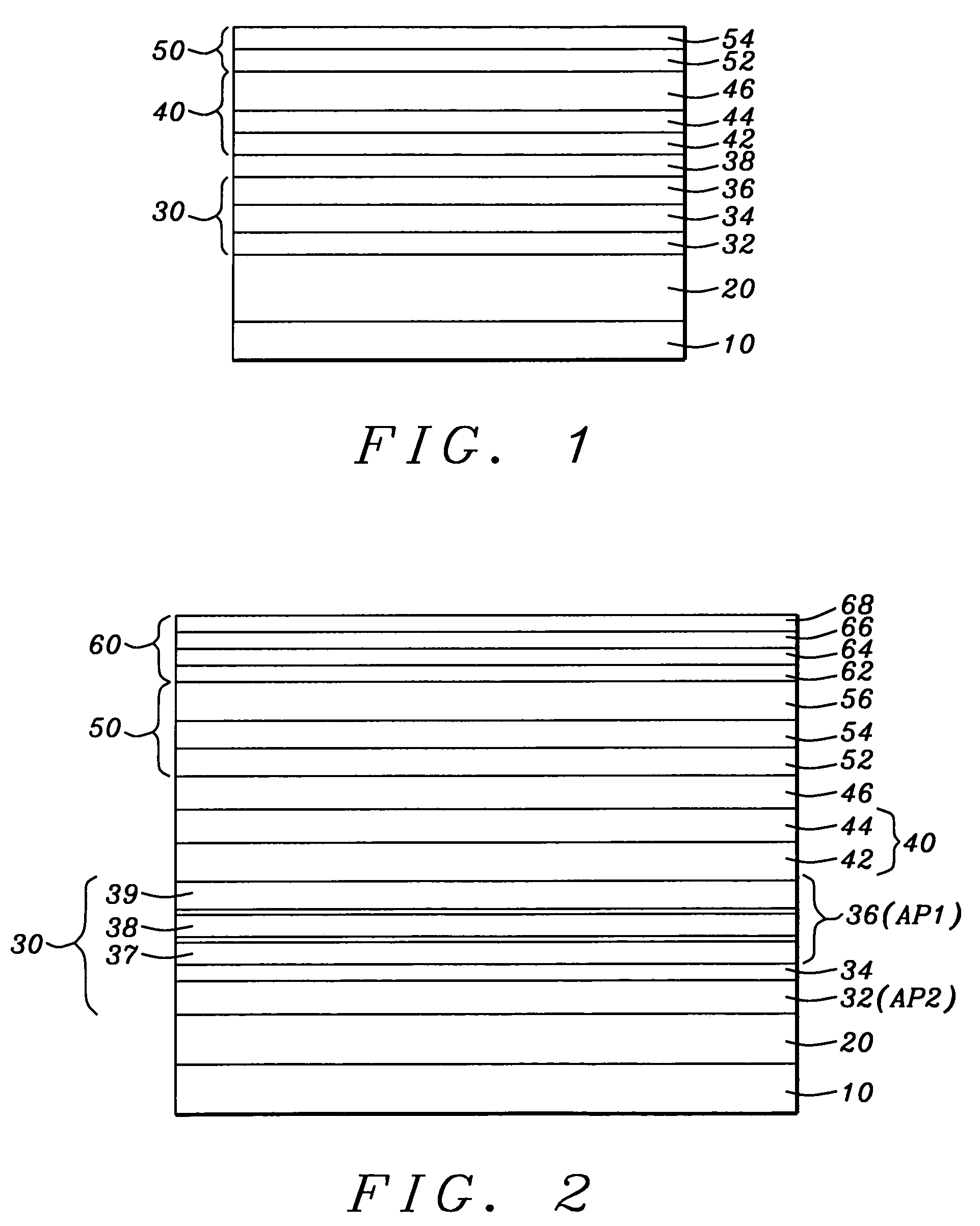

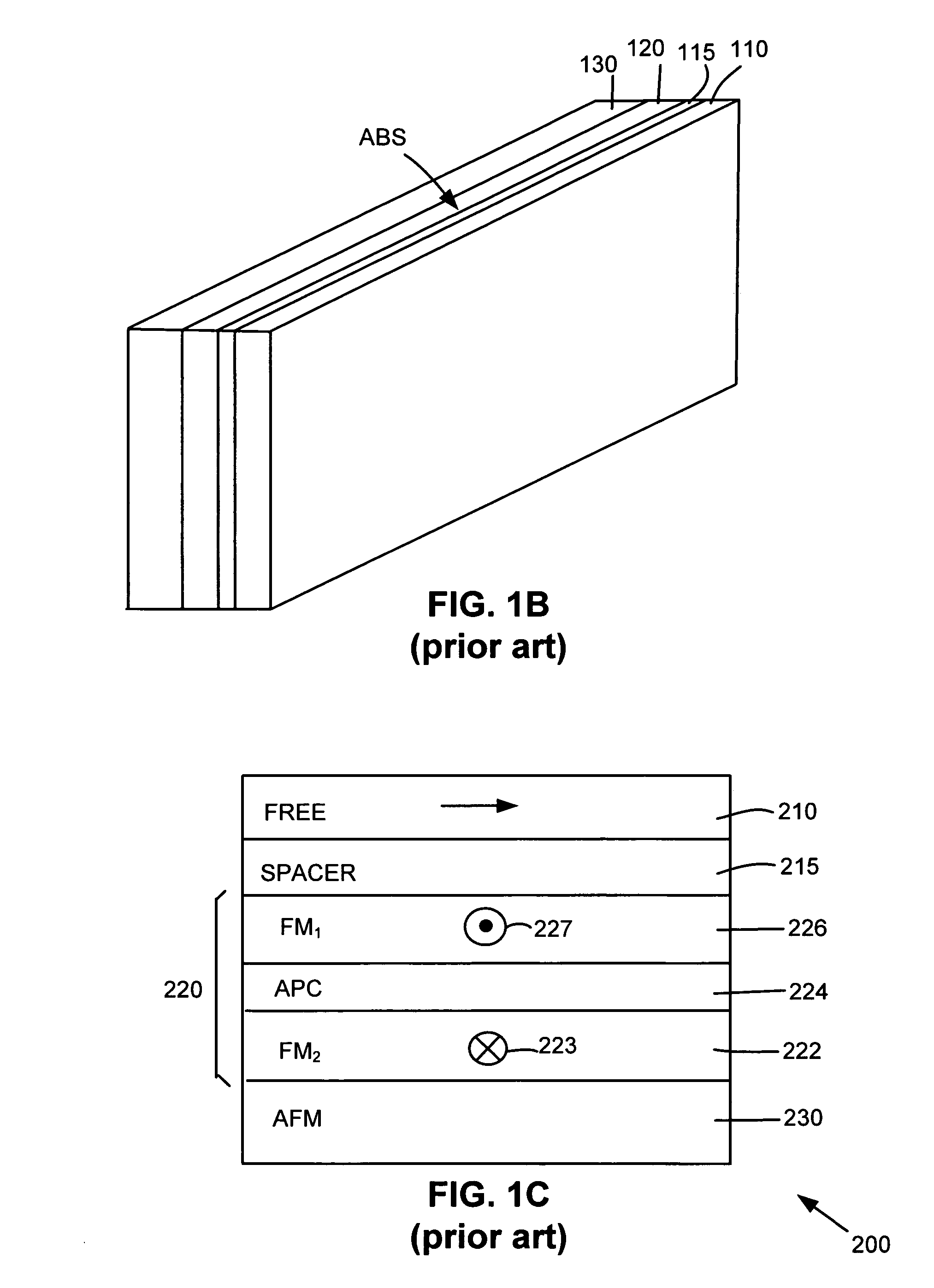

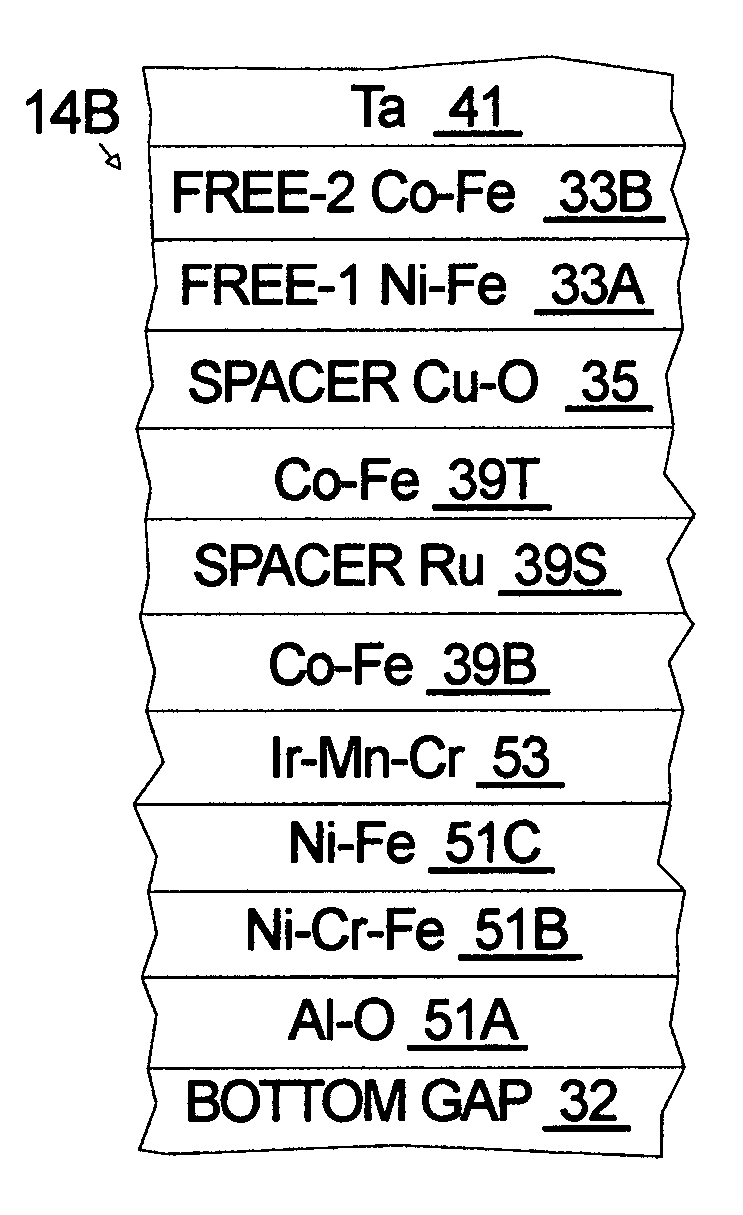

Method for providing a self-pinned differential GMR sensor and self-pinned differential GMR sensor

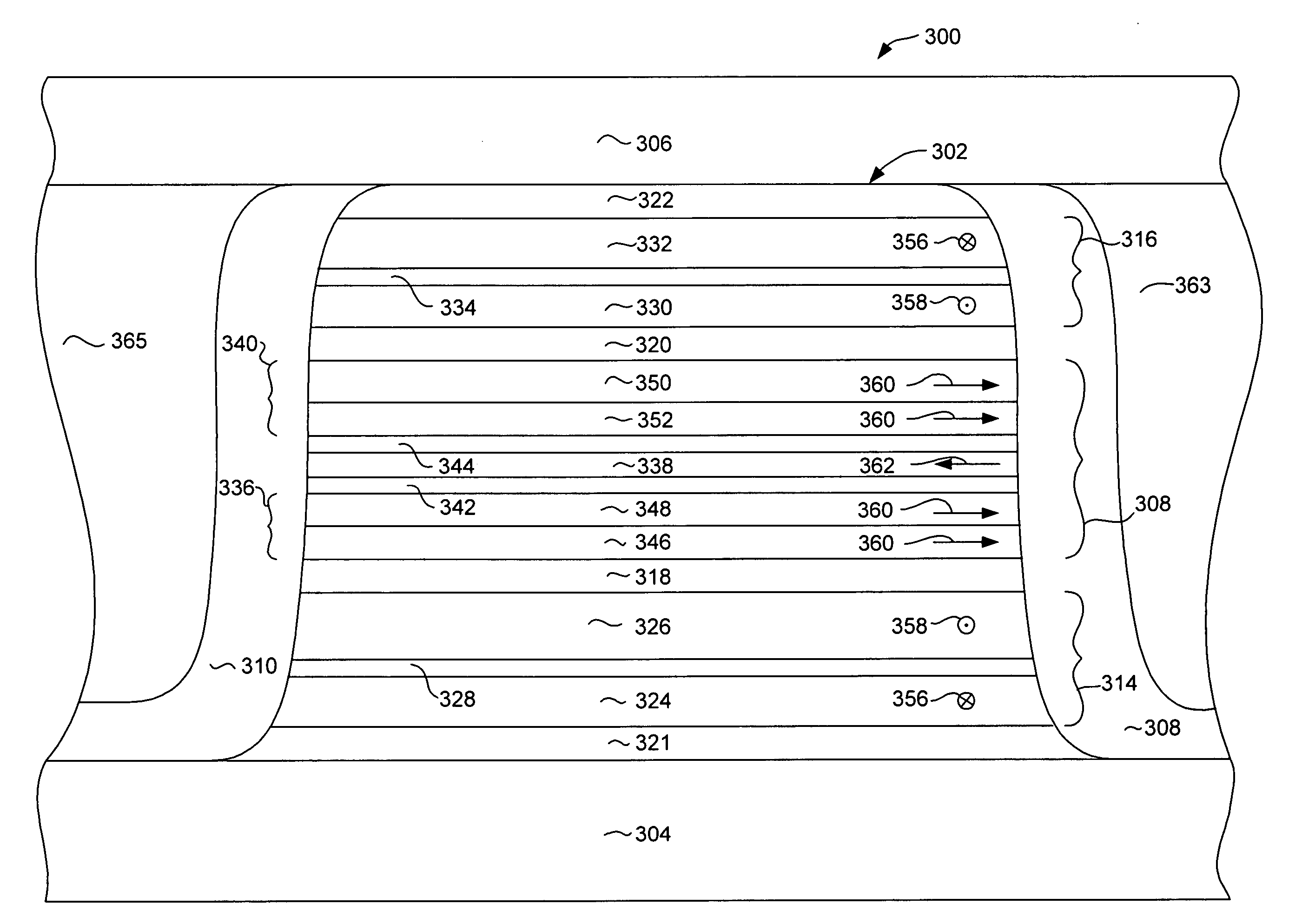

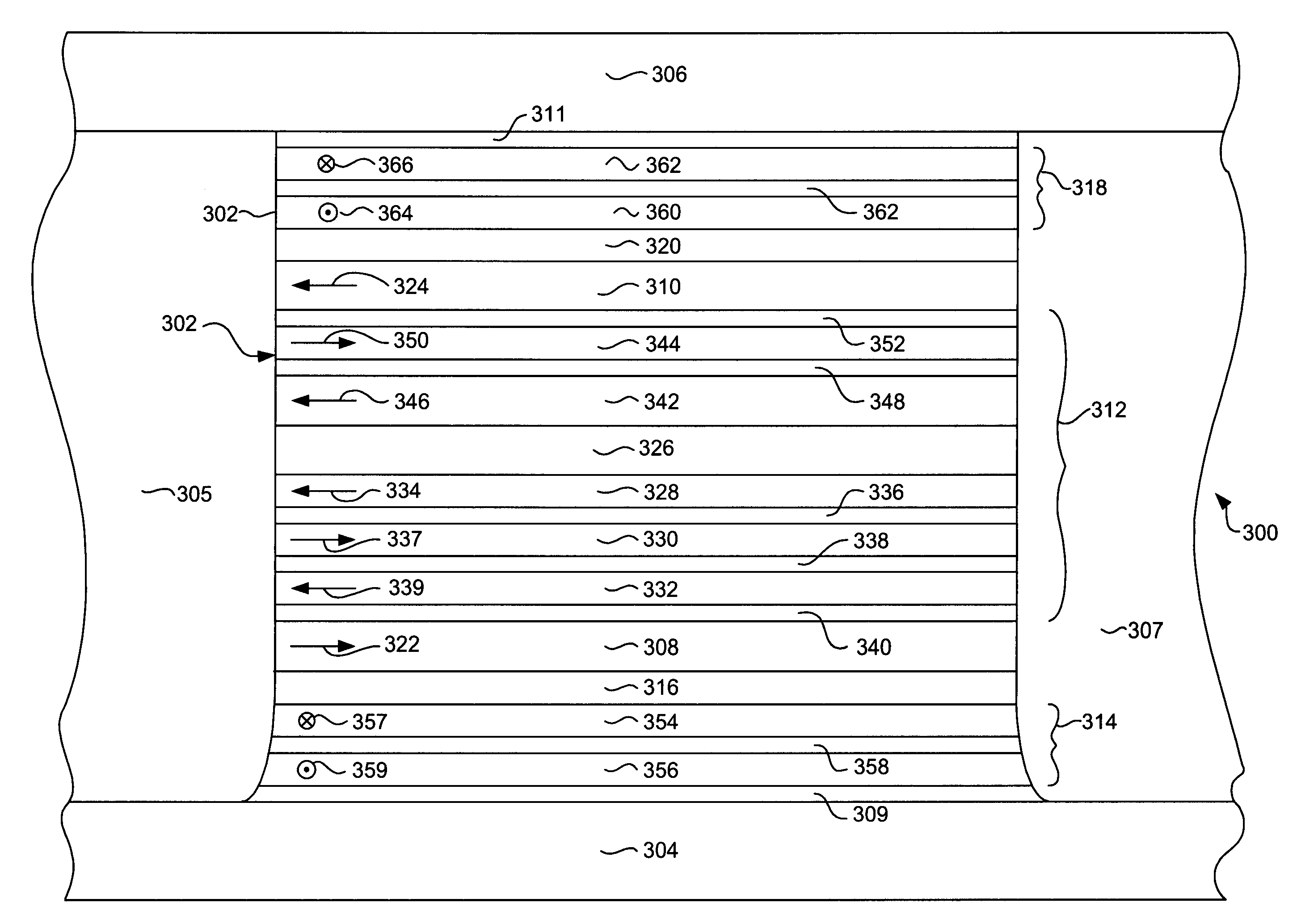

A method for providing a self-pinned differential GMR sensor and self-pinned differential GMR sensor. The differential GMR head includes two self-pinned GMR sensors separated by a gap layer. The gap layer may act as a bias structure to provide antiparallel magnetizations for the first and second free layers without using an antiferromagnetic layer. The gap layer may include four NiFe ferromagnetic layers separated with three interlayers. The gap may also be formed to include a structure defined by Ta / Al2O3 / NiFeCr / CuOx. One of the pinned layer may include three ferromagnetic layers so that the top ferromagnetic layer of the bottom pinned layer and the bottom ferromagnetic layer of the bottom pinned layer have a magnetization 180° out of phase. The self-pinned GMR sensors may include synthetic free layers that includes a first free sublayer, an interlayer and a second free sublayer that are biased 180° out of phase.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

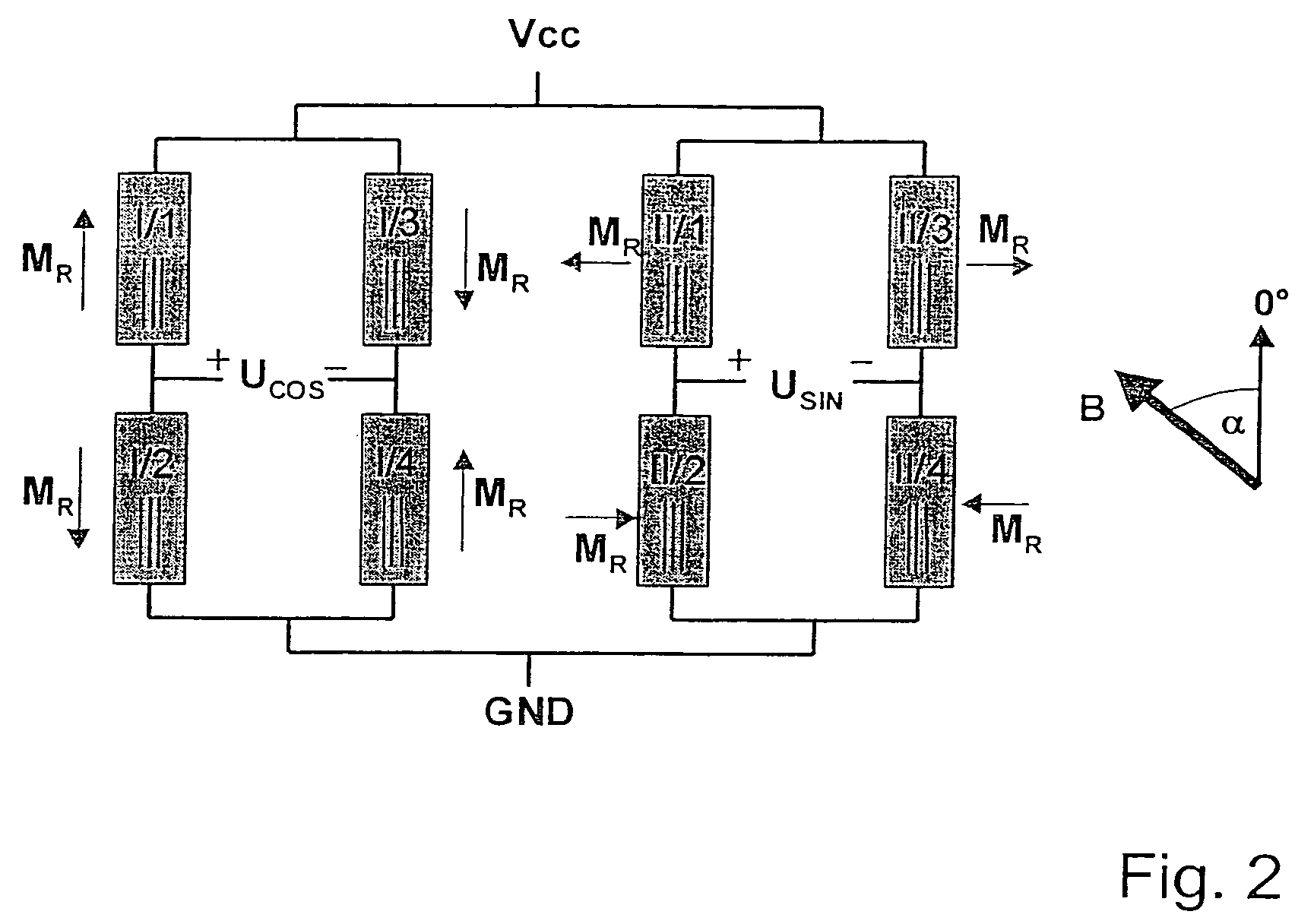

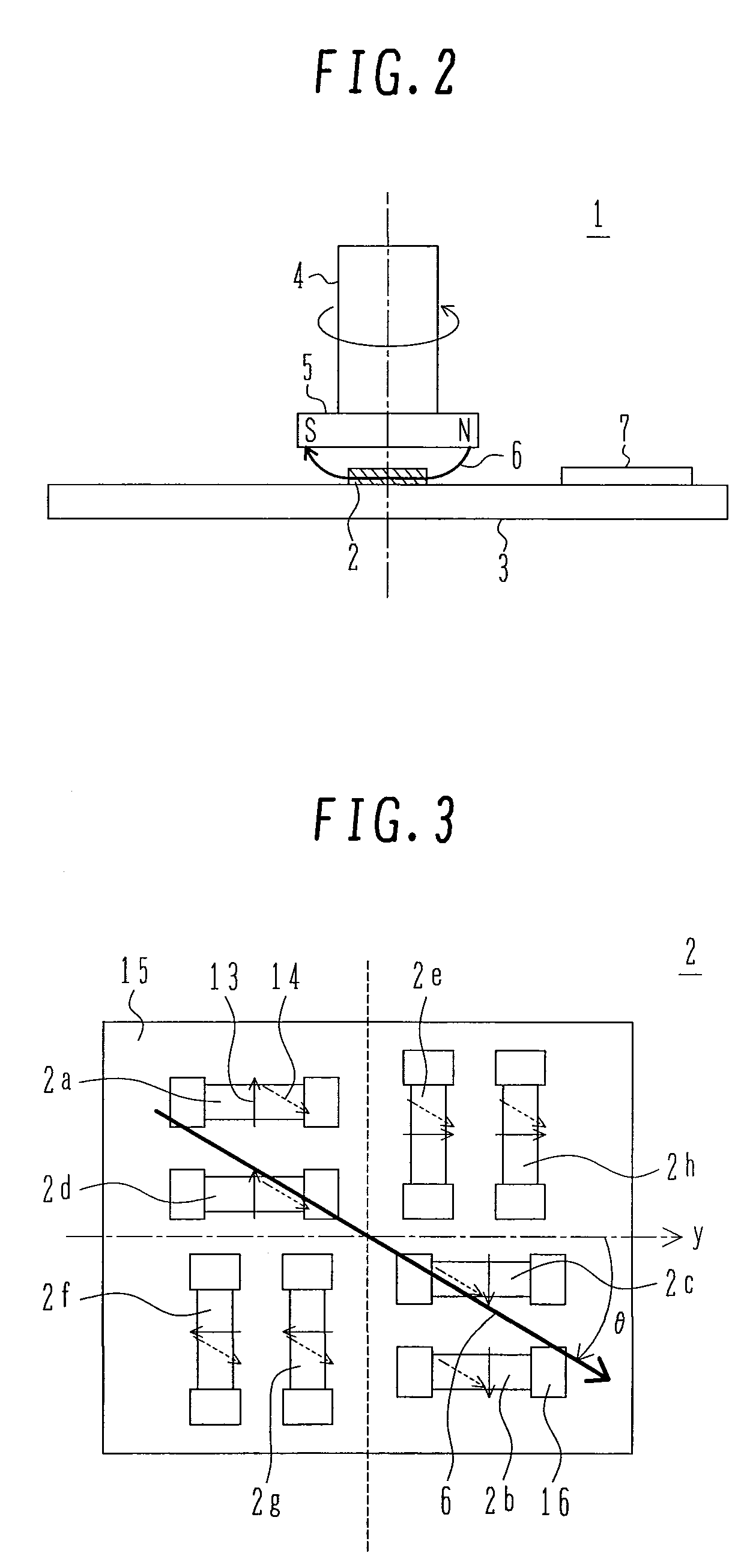

Gmr sensor element and its use

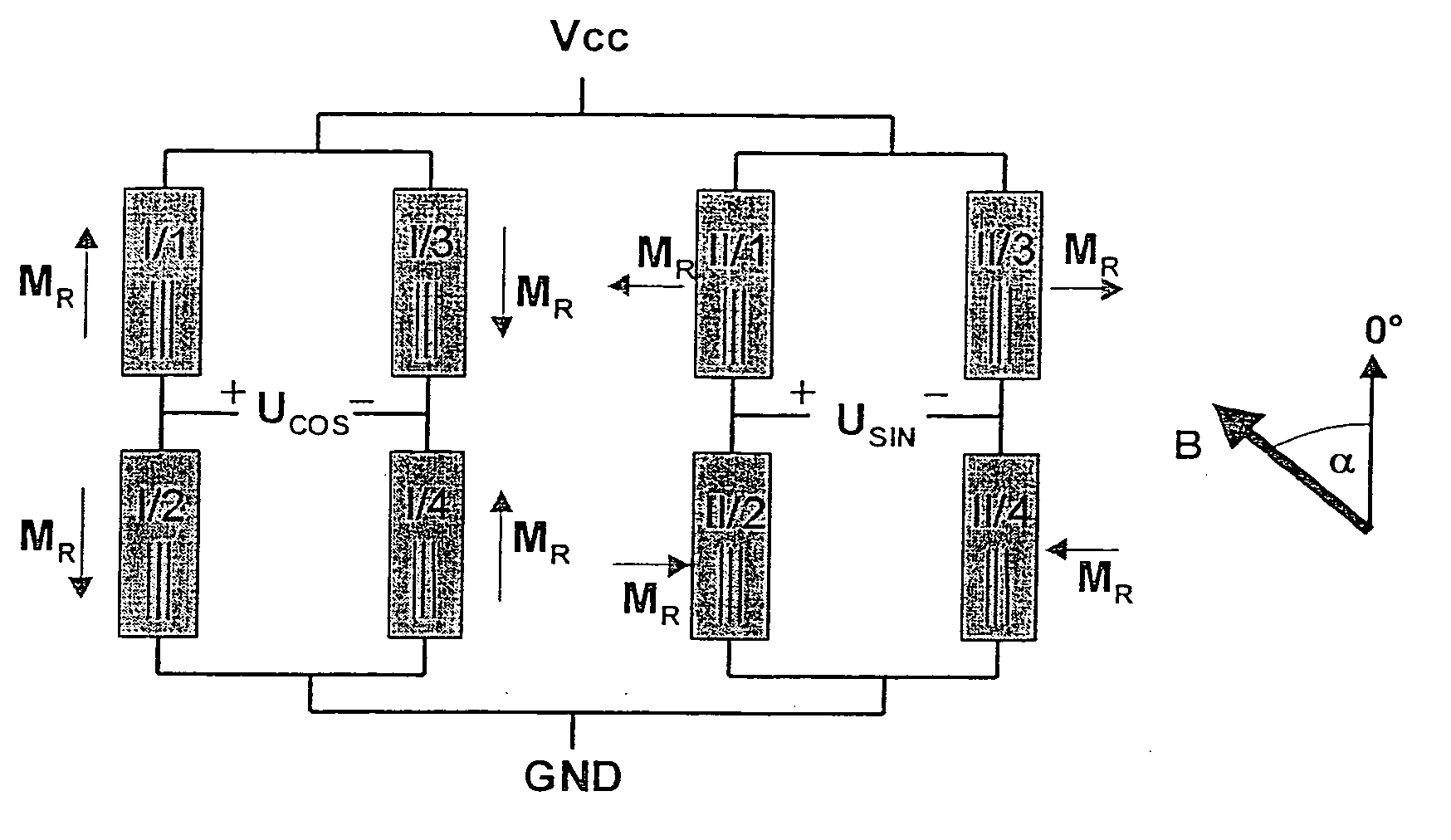

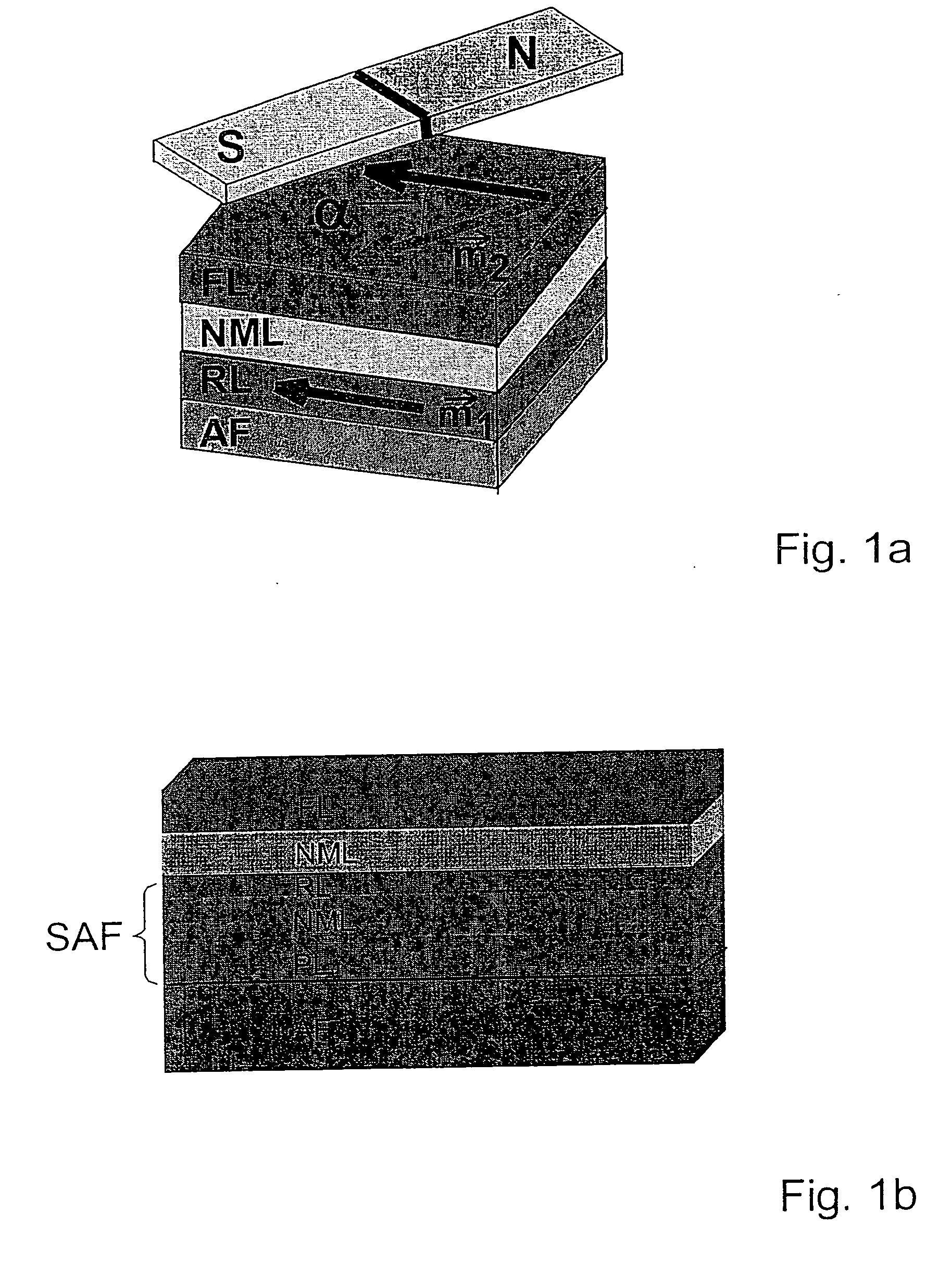

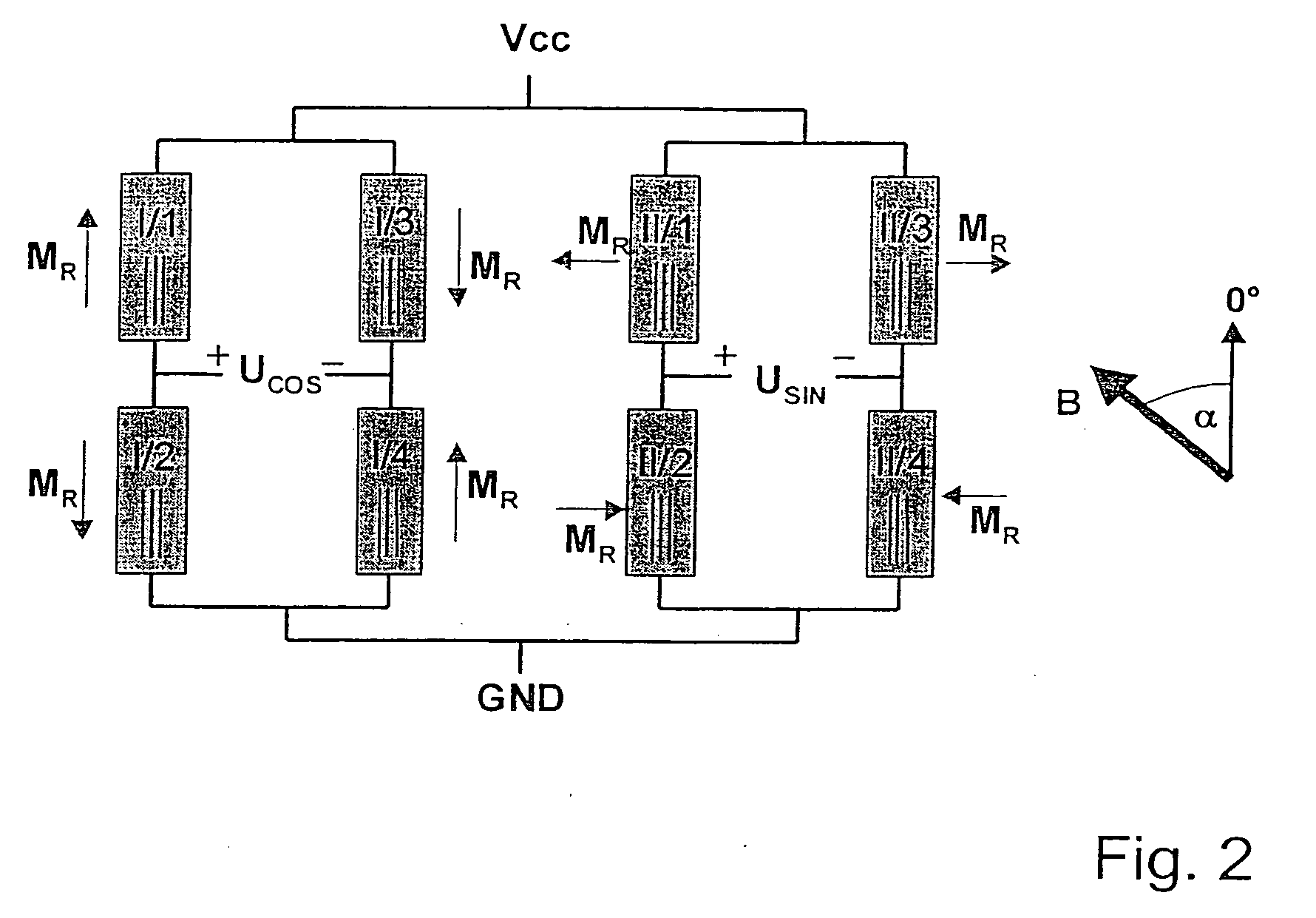

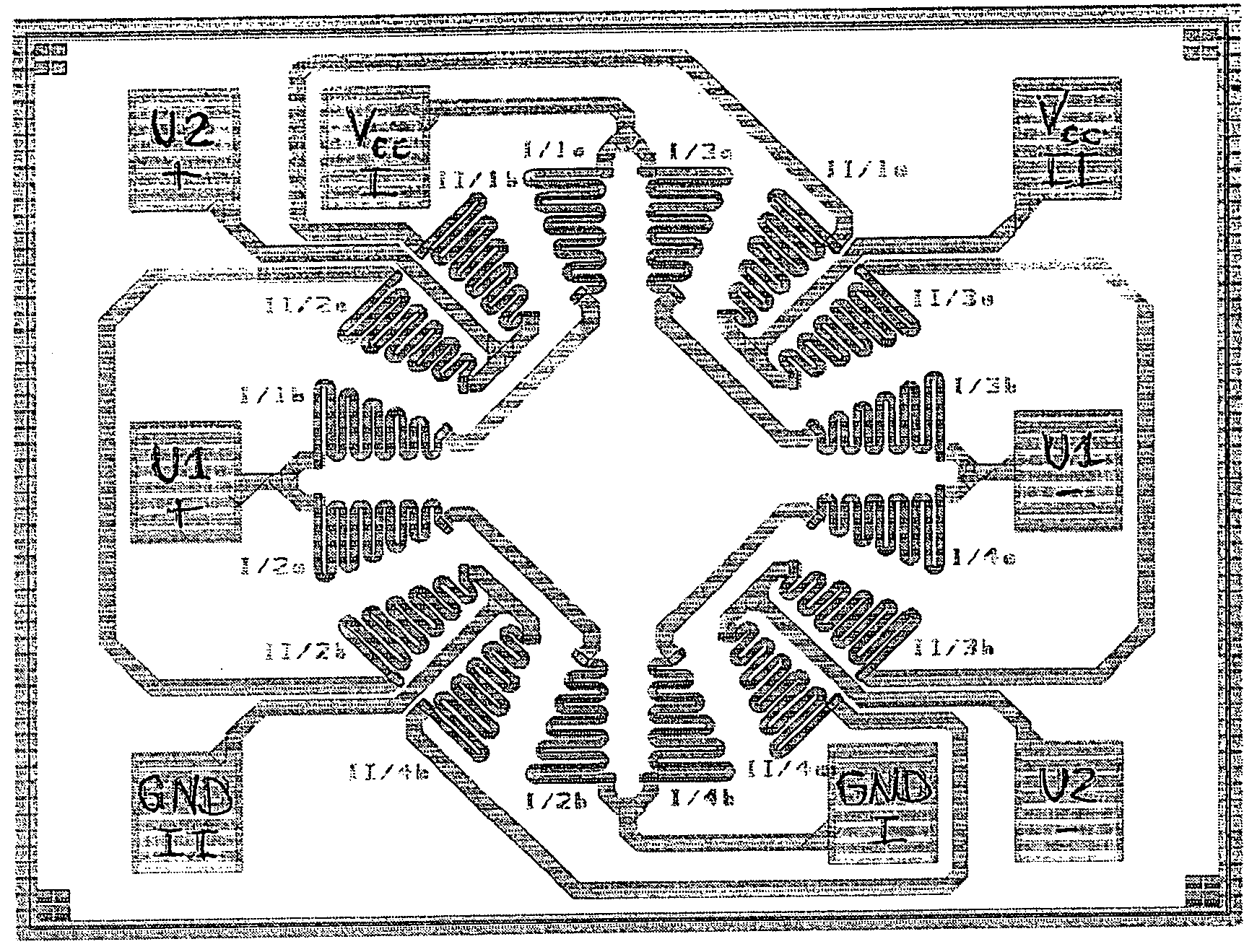

InactiveUS20060103381A1Improve long-term stabilityImprove signal stabilityValve arrangementsNanomagnetismSteering angleFull bridge

A GMR sensor element is proposed, having a rotationally symmetrical positioning of especially eight GMR resistor elements which are connected to each other to form two Wheatstone's full bridges. This GMR sensor element is especially suitable for use in an angle sensor for the detection of the absolute position of the camshaft or the crankshaft in a motor vehicle, particularly in the case of a camshaft-free engine having electrical or electrohydraulic valve timing, of a motor position of an electrically commutated motor, or of detection of a windshield wiper position, or in the steering angle sensor system in motor vehicles.

Owner:ROBERT BOSCH GMBH

GMR sensor element and its use

InactiveUS7312609B2Reduce sensitivityUndesired AMR signal contributionValve arrangementsNanomagnetismMobile vehicleSteering angle

A GMR sensor element is proposed, having a rotationally symmetrical positioning of especially eight GMR resistor elements which are connected to each other to form two Wheatstone's full bridges. This GMR sensor element is especially suitable for use in an angle sensor for the detection of the absolute position of the camshaft or the crankshaft in a motor vehicle, particularly in the case of a camshaft-free engine having electrical or electrohydraulic valve timing, of a motor position of an electrically commutated motor, or of detection of a windshield wiper position, or in the steering angle sensor system in motor vehicles.

Owner:ROBERT BOSCH GMBH

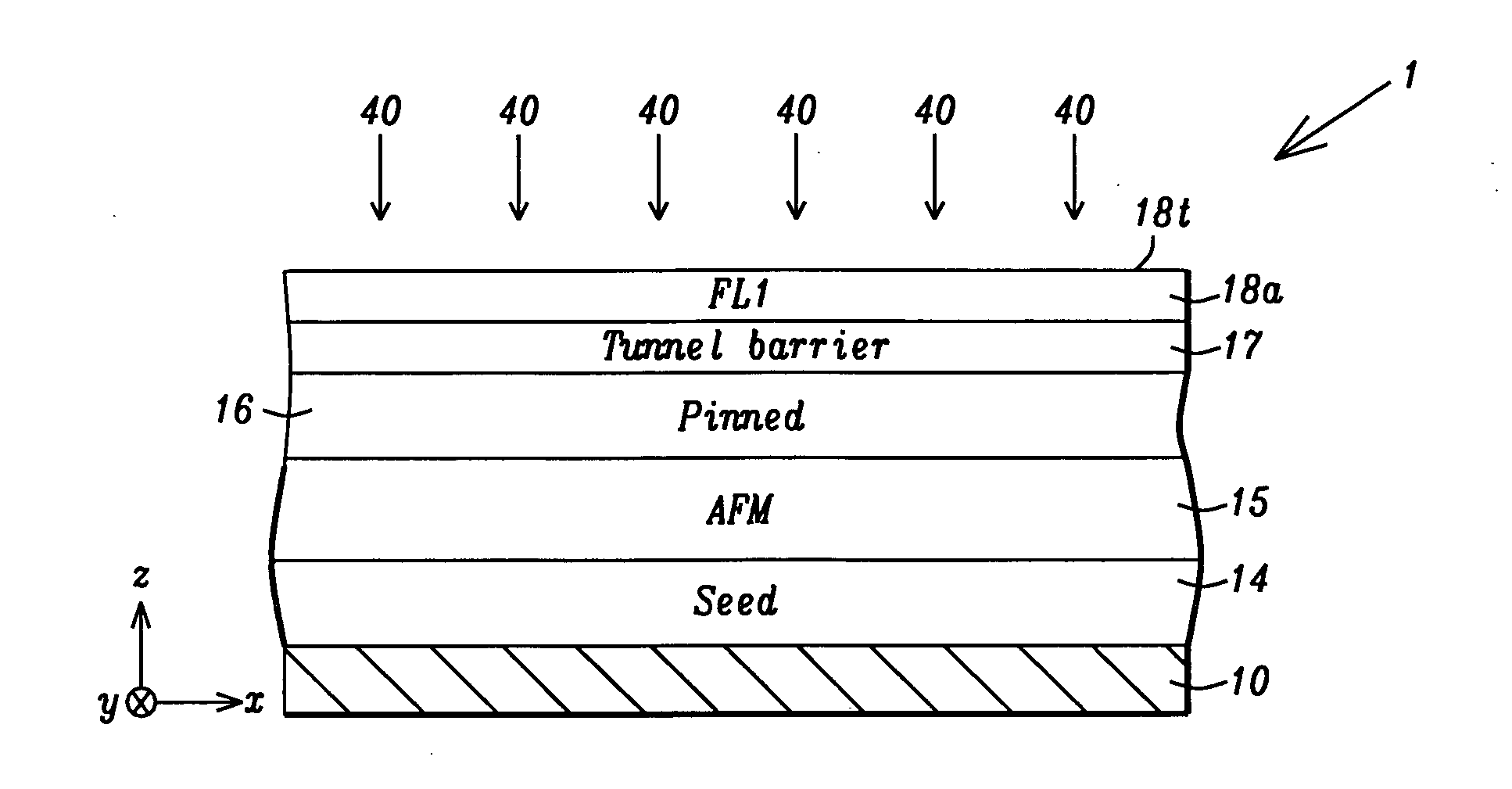

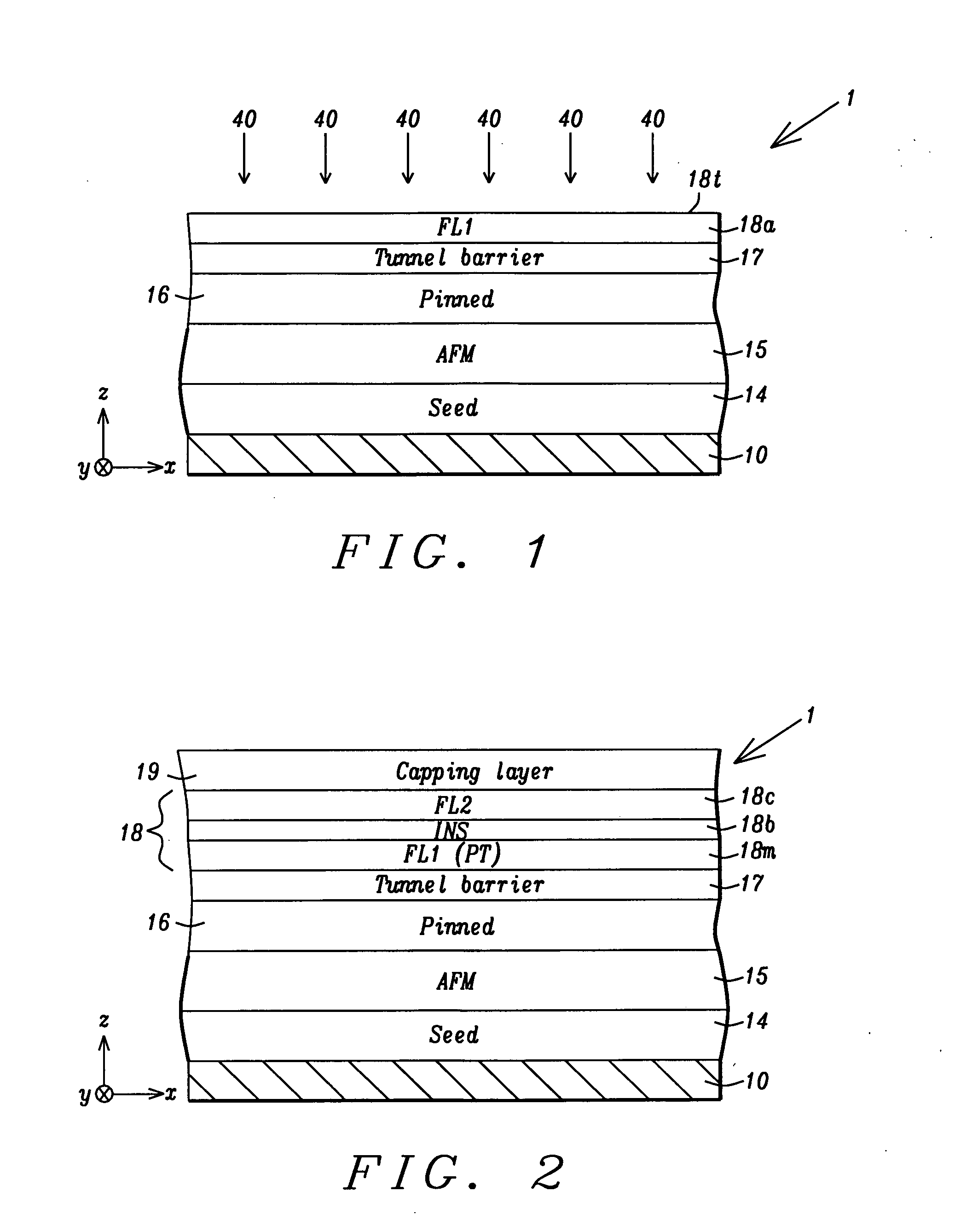

TMR device with novel free layer structure

ActiveUS20110188157A1Improve crystal orientationLow magnetostrictionMagnetic measurementsDecorative surface effectsAlloyNon magnetic

Owner:HEADWAY TECH INC

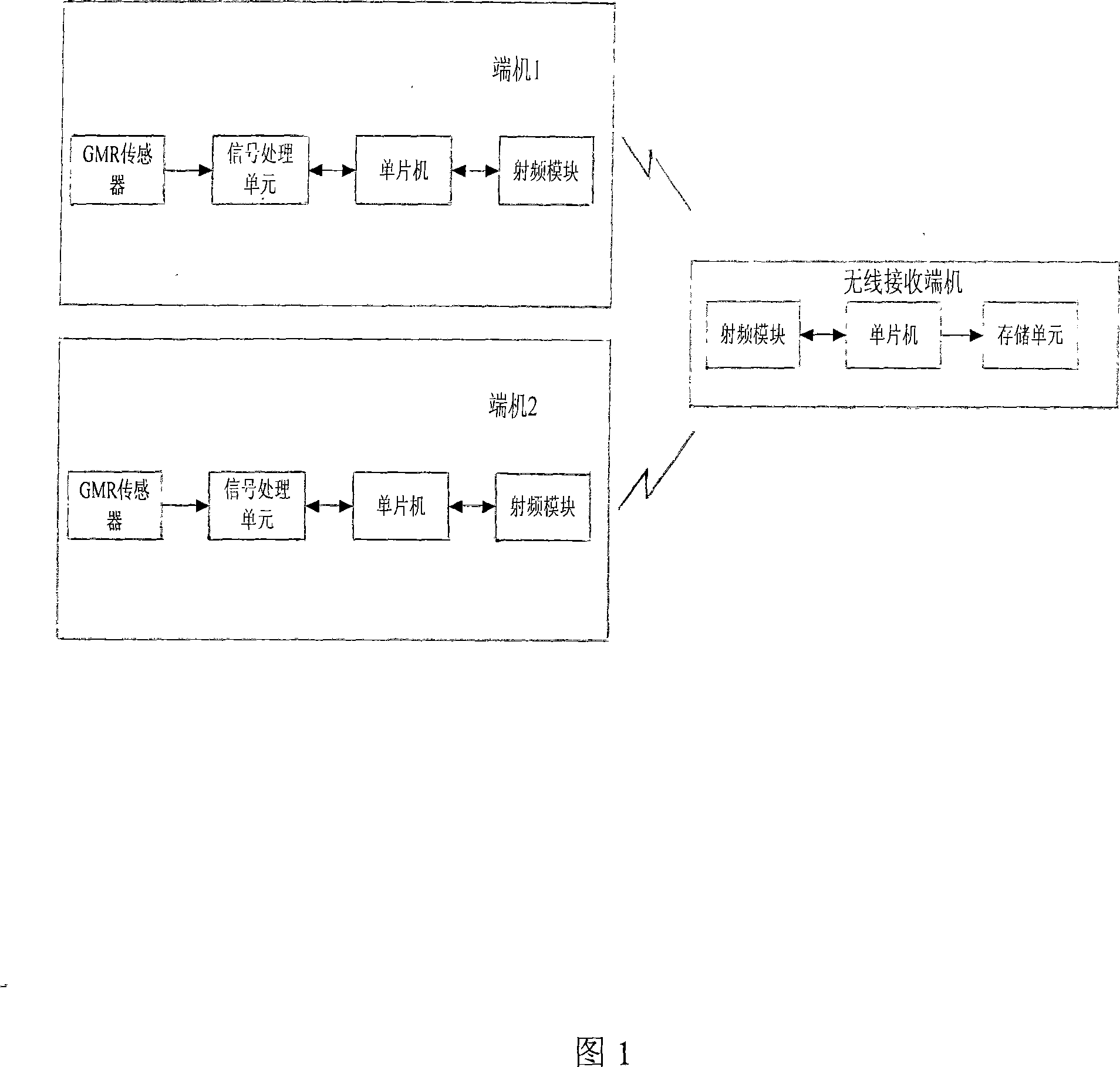

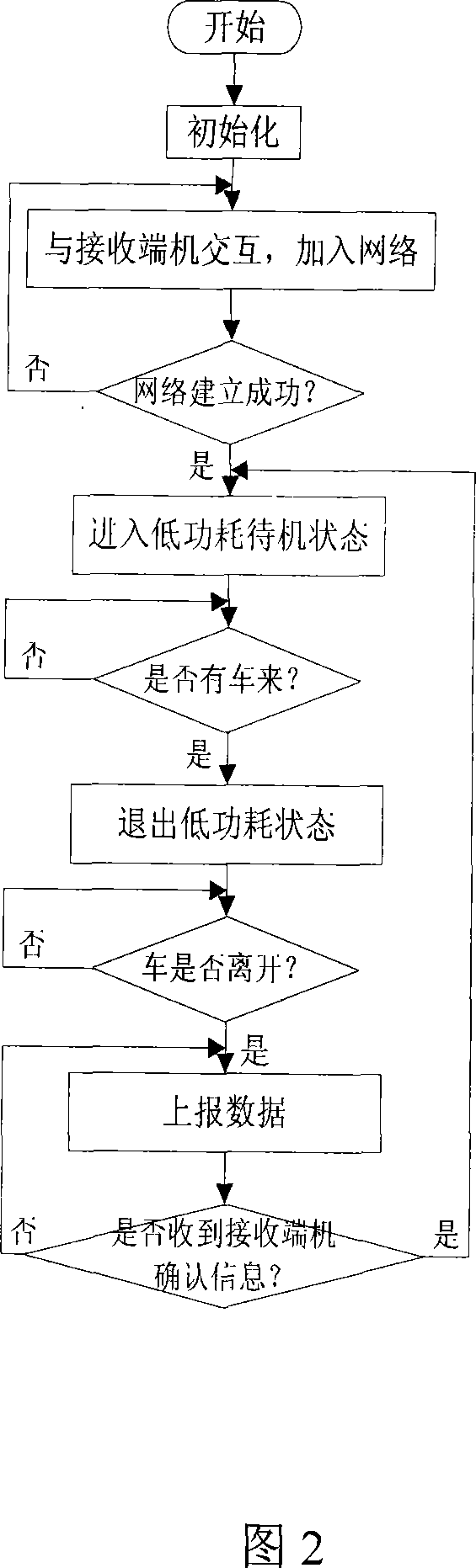

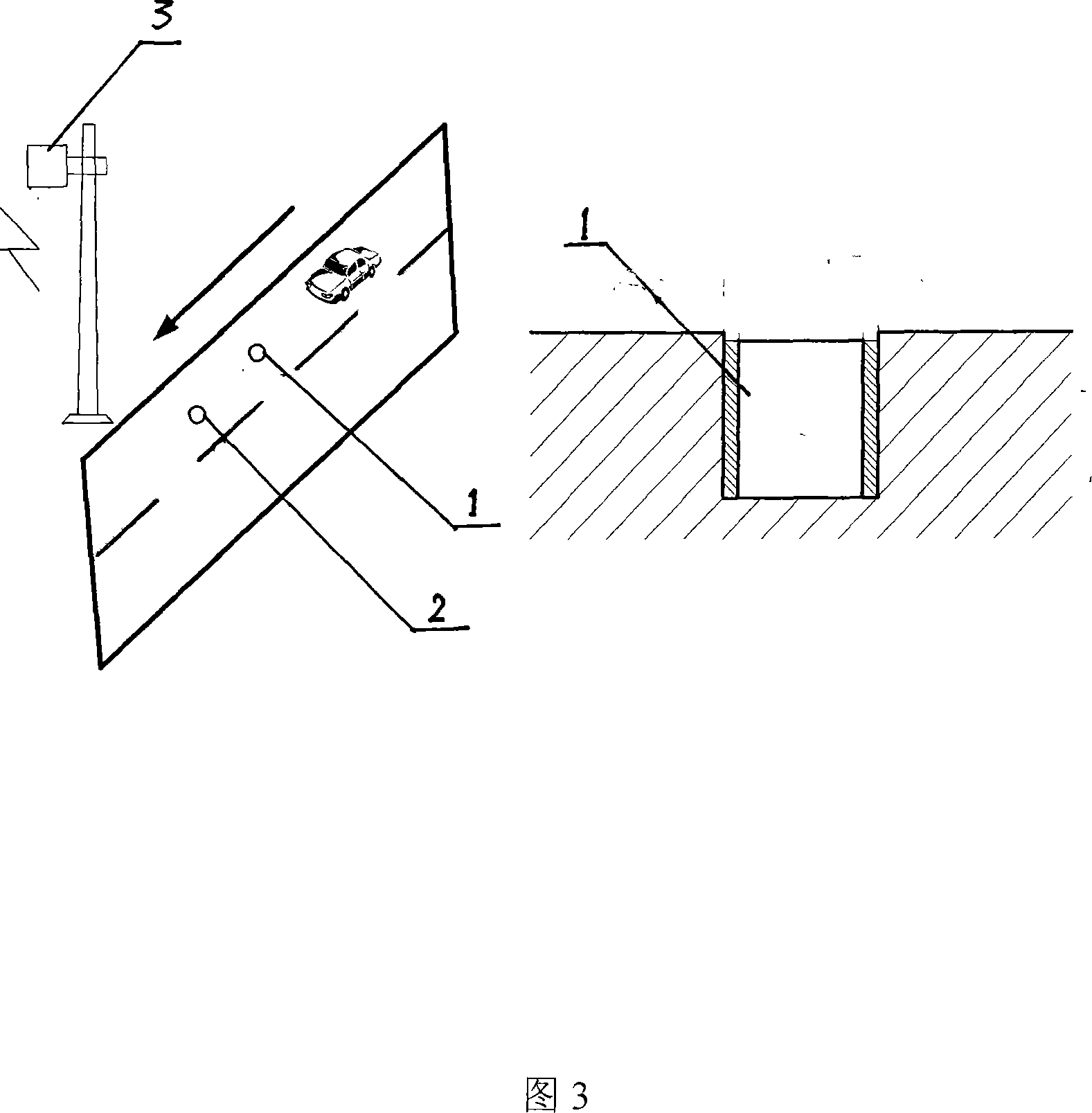

Wireless sensor network system and detection method utilizing huge magneto-resistance magnetic-sensing technology for detecting vehicle information

InactiveCN101236697ARealize the function of countingAvoid damageRoad vehicles traffic controlInterference resistanceWireless sensor networking

A wireless sensor network system using GMR magnetic sensitive technology to detect vehicle information of the invention consists of two GMR sensor detecting end machines and a wireless receiving end machine. The two GMR sensor detecting end machines are connected with the wireless receiving end machine. The detection method of the invention detects information such as vehicle speed, vehicle length, driving direction, vehicle flow, lane occupancy ratio, etc., according to change data of the surrounding ground magnetic field sensed by the GMR sensor when the vehicles pass. The wireless sensor network system is characterized in having high precision of detecting speed, adaptability to various roads, low cost, convenient maintenance and high anti-interference ability and causing small destroy to road surface, etc.

Owner:JIAXING WIRELESS SENSOR NETWORKS CENT CAS

TMR device with novel free layer stucture

ActiveUS20100177449A1Low magnetostrictionHigh magnetoresistive (MR) ratioNanomagnetismMagnetic measurementsAlloyNon magnetic

Owner:HEADWAY TECH INC

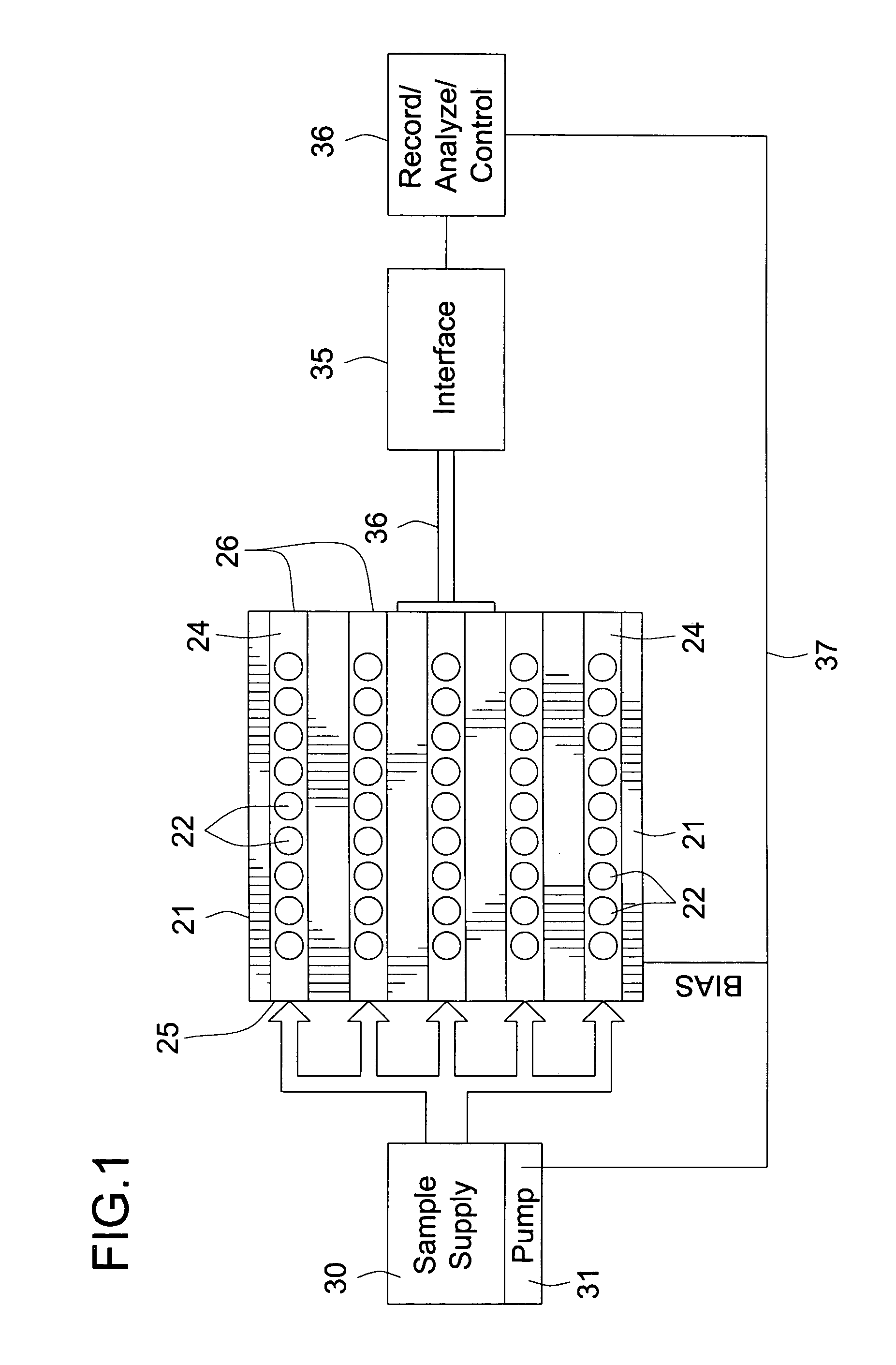

Method and apparatus for magnetoresistive monitoring of analytes in flow streams

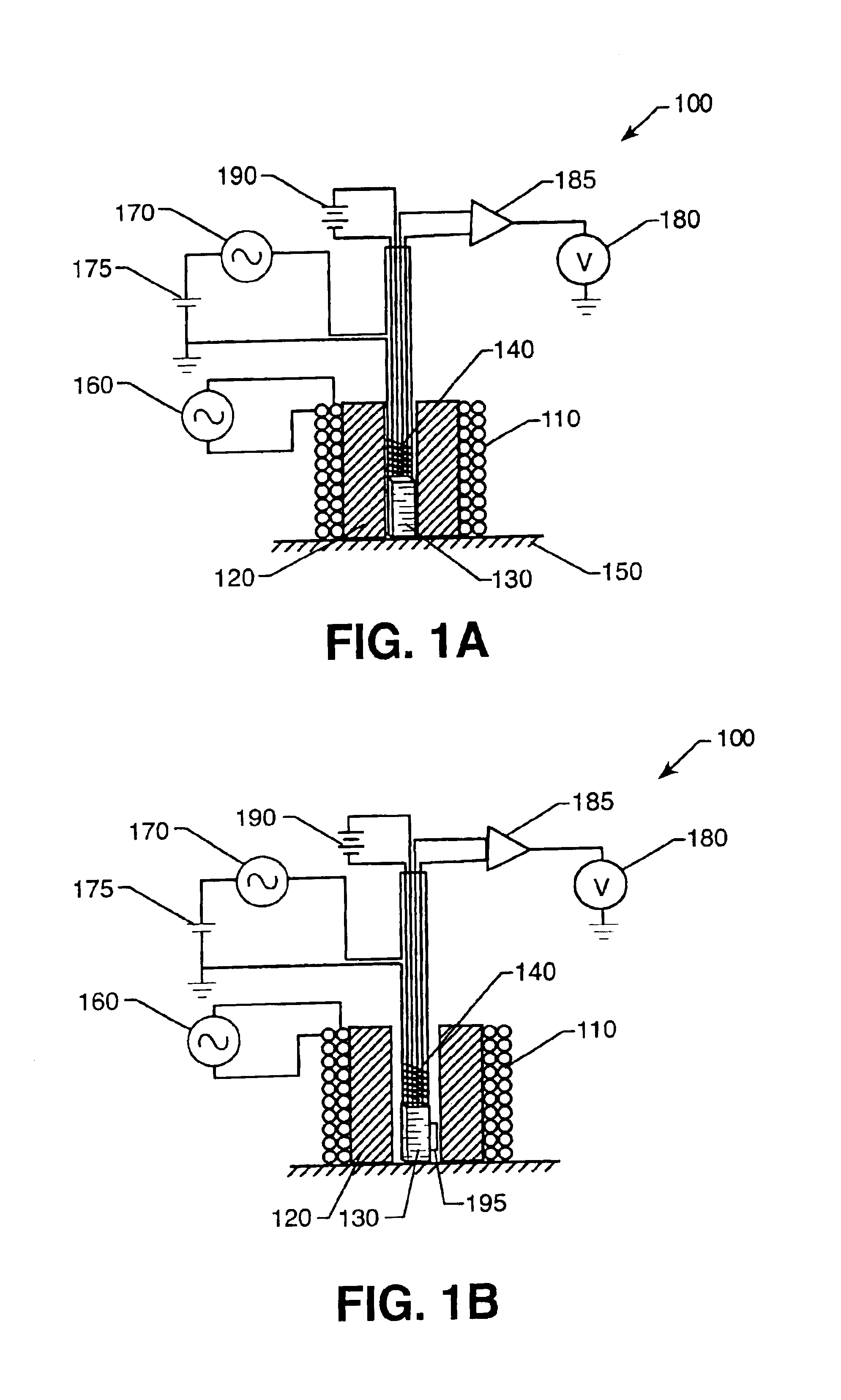

InactiveUS7179383B1High sensitivityMaterial thermal conductivityVolume/mass flow measurementElectricityStream flow

Method and apparatus for manipulating and monitoring analyte flowing in fluid streams. A giant magnetoresistive sensor has an array of sensing elements that produce electrical output signals which vary in dependence on changes in the magnetic field proximate the sensing elements. The analyte is included in a stream, such that the stream has a magnetic property which is dependent on the concentration and distribution on the analyte therein. The stream is flowed past the giant magnetoresistive sensor and in sufficiently close proximity to cause the magnetic properties of the stream to produce electrical output signals. The electrical output signals are monitored as an indicator of analyte concentration or distribution in the stream flowing past the GMR sensor. Changes in the magnetic field produced by the background stream are introduced by analyte molecules, whose presence in the flow past the GMR will effect the output reading.

Owner:IOWA STATE UNIV RES FOUND +1

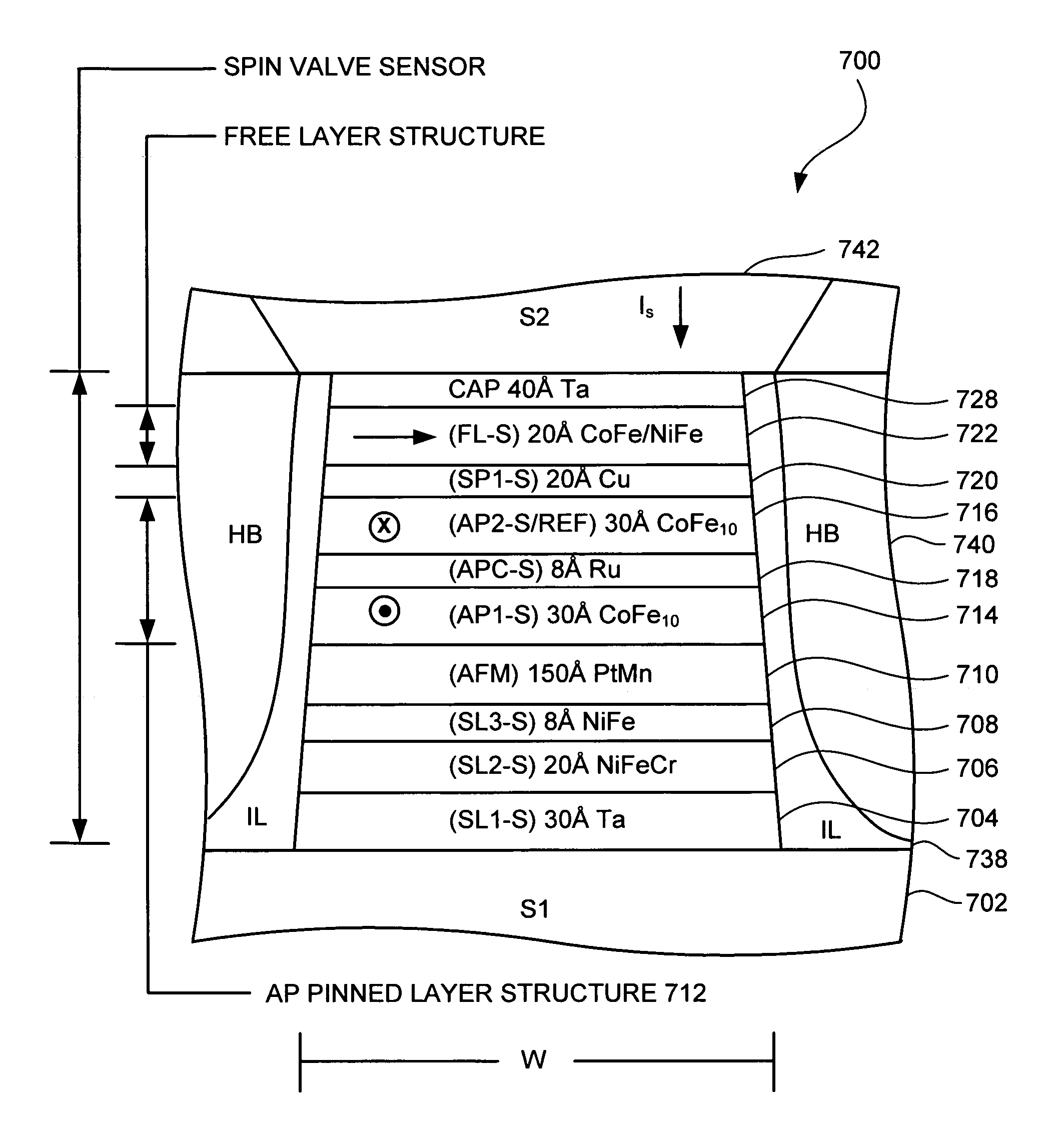

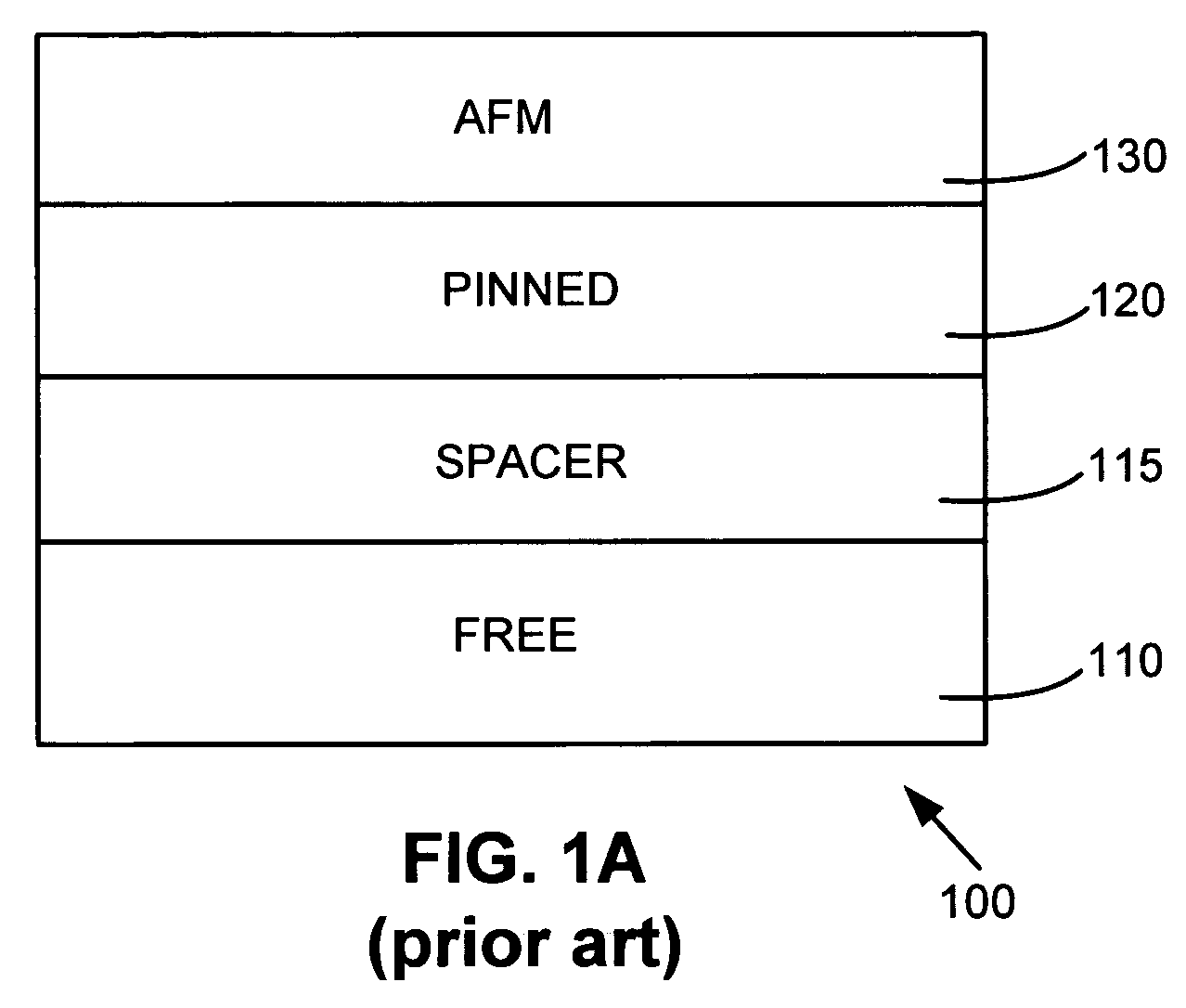

Magnetoresistive spin valve sensor with tri-layer free layer

ActiveUS7333306B2High MR ratioLow coercivityNanomagnetismElectrical transducersMagnetic reluctanceThin layer

A TMR sensor, a CPP GMR sensor and a CCP CPP GMR sensor all include a tri-layered free layer that is of the form CoFe / CoFeB / NiFe, where the atom percentage of Fe can vary between 5% and 90% and the atom percentage of B can vary between 5% and 30%. The sensors also include SyAP pinned layers which, in the case of the GMR sensors include at least one layer of CoFe laminated onto a thin layer of Cu. In the CCP CPP sensor, a layer of oxidized aluminum containing segregated particles of copper is formed between the spacer layer and the free layer. All three configurations exhibit extremely good values of coercivity, areal resistance, GMR ratio and magnetostriction.

Owner:HEADWAY TECH INC

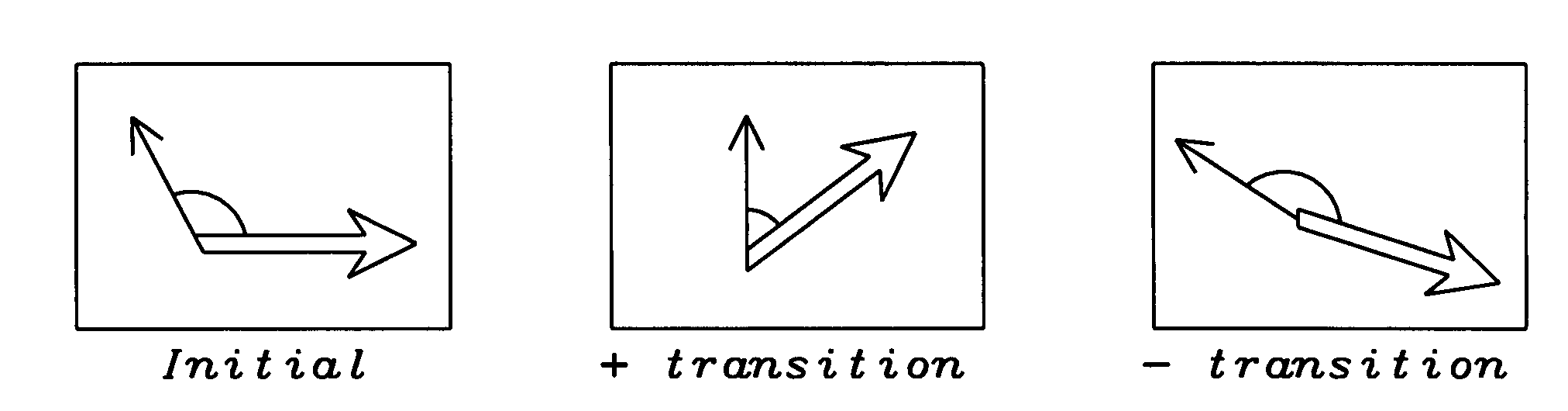

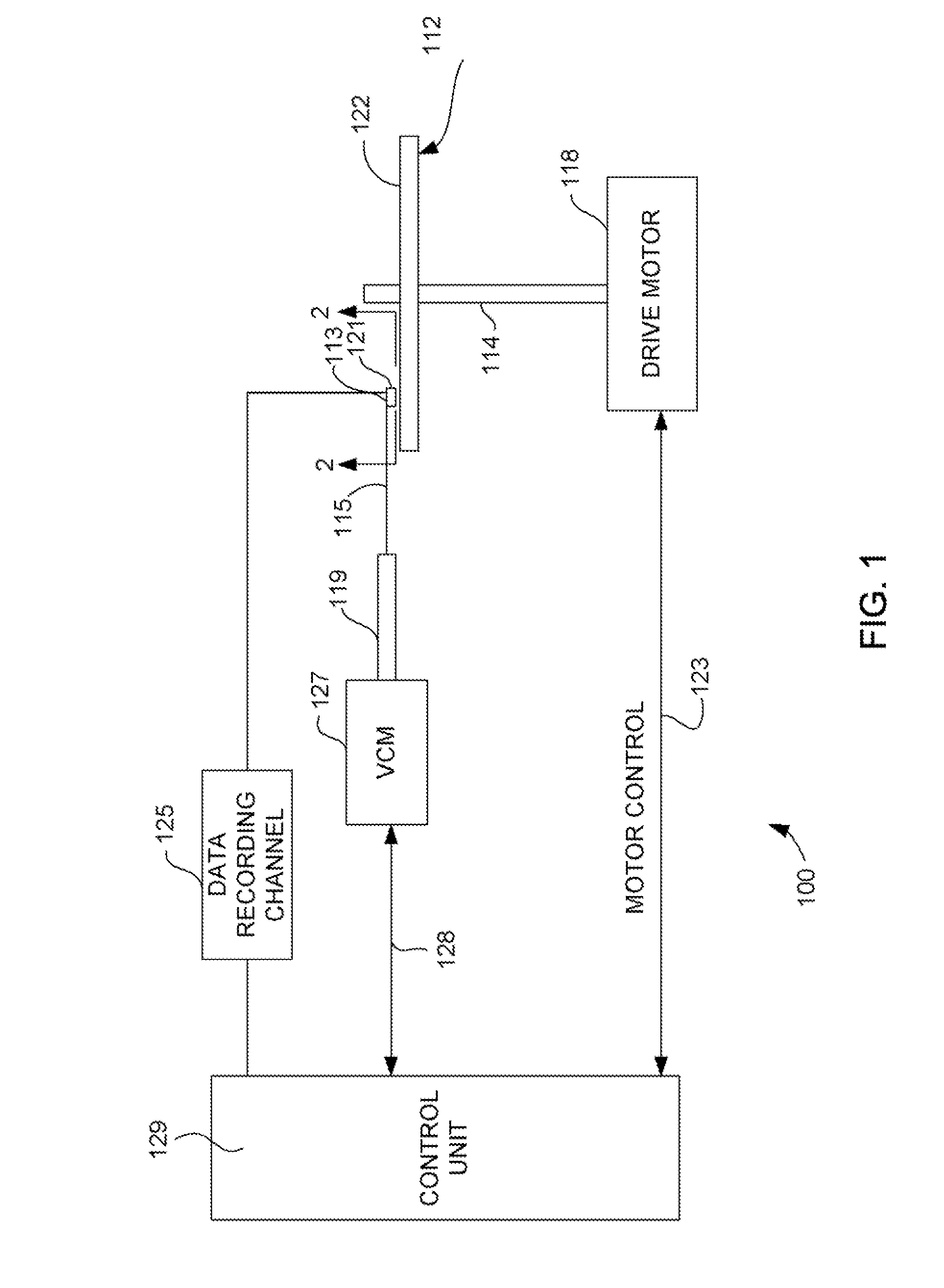

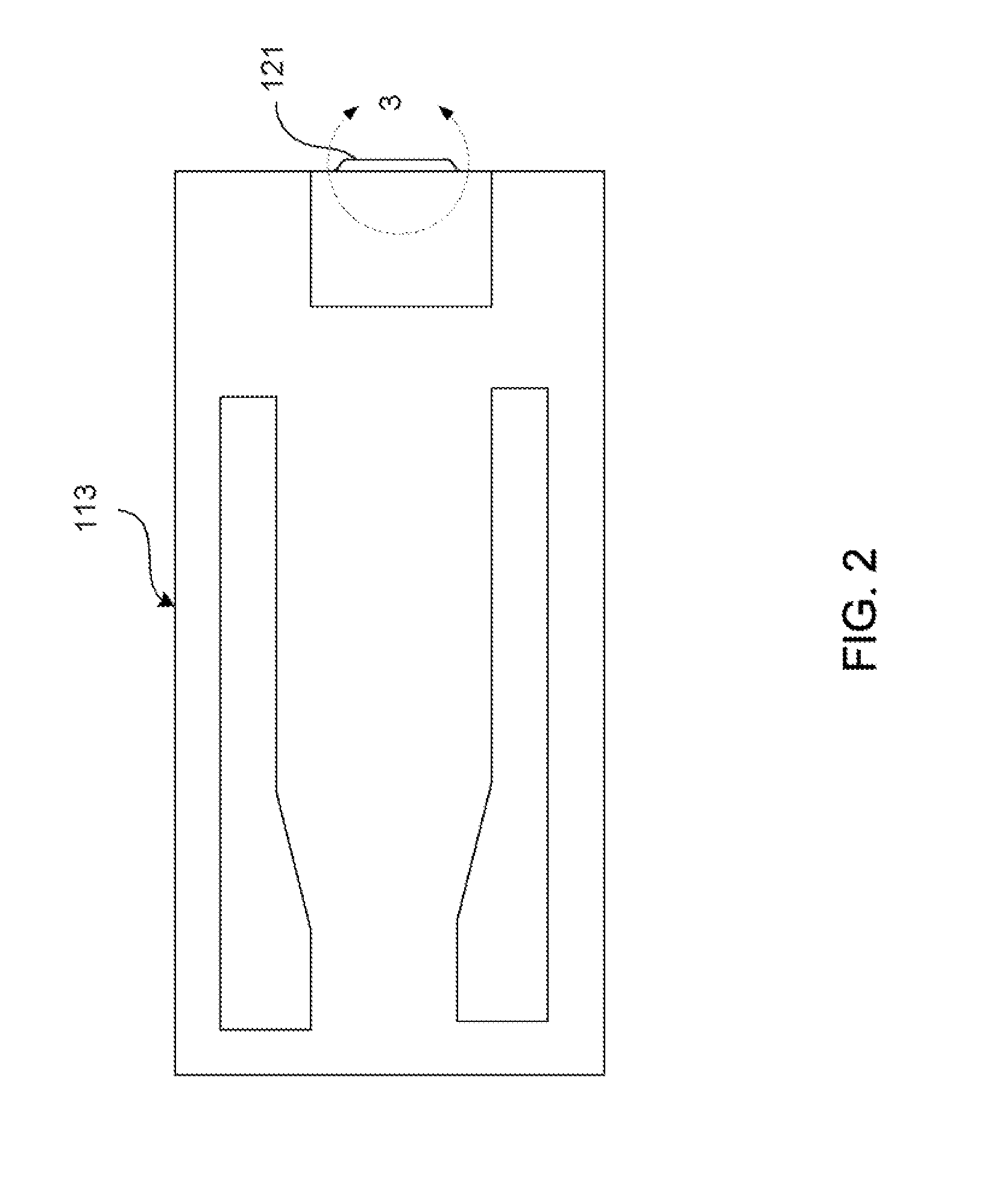

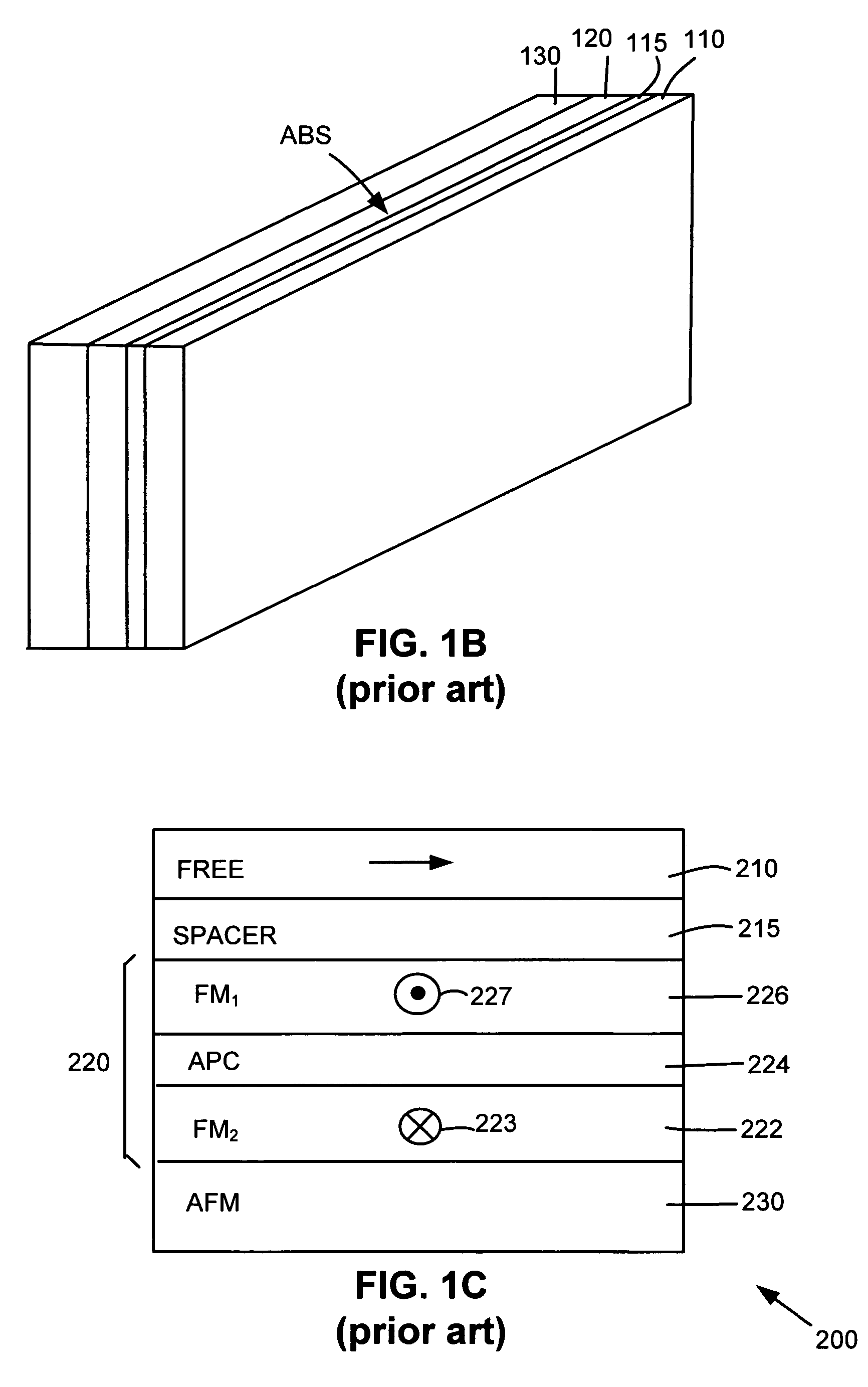

CPP-GMR sensor with non-orthogonal free and reference layer magnetization orientation

A CPP GMR sensor structure having free and reference layers, where the magnetic orientations of the free and reference layers are non-orthogonal. In one embodiment, a ferromagnetic free layer film has a bias-point magnetization nominally oriented in plane of the film thereof, in a first direction at an angle θfb with respect to a longitudinal axis being defined as the intersection of the plane of deposition of the free layer and the plane of the ABS. A ferromagnetic reference layer film has a bias-point magnetization nominally oriented in a plane of the film thereof, in a second direction at angle θrb with respect to said longitudinal axis that is not orthogonal to the said first direction.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

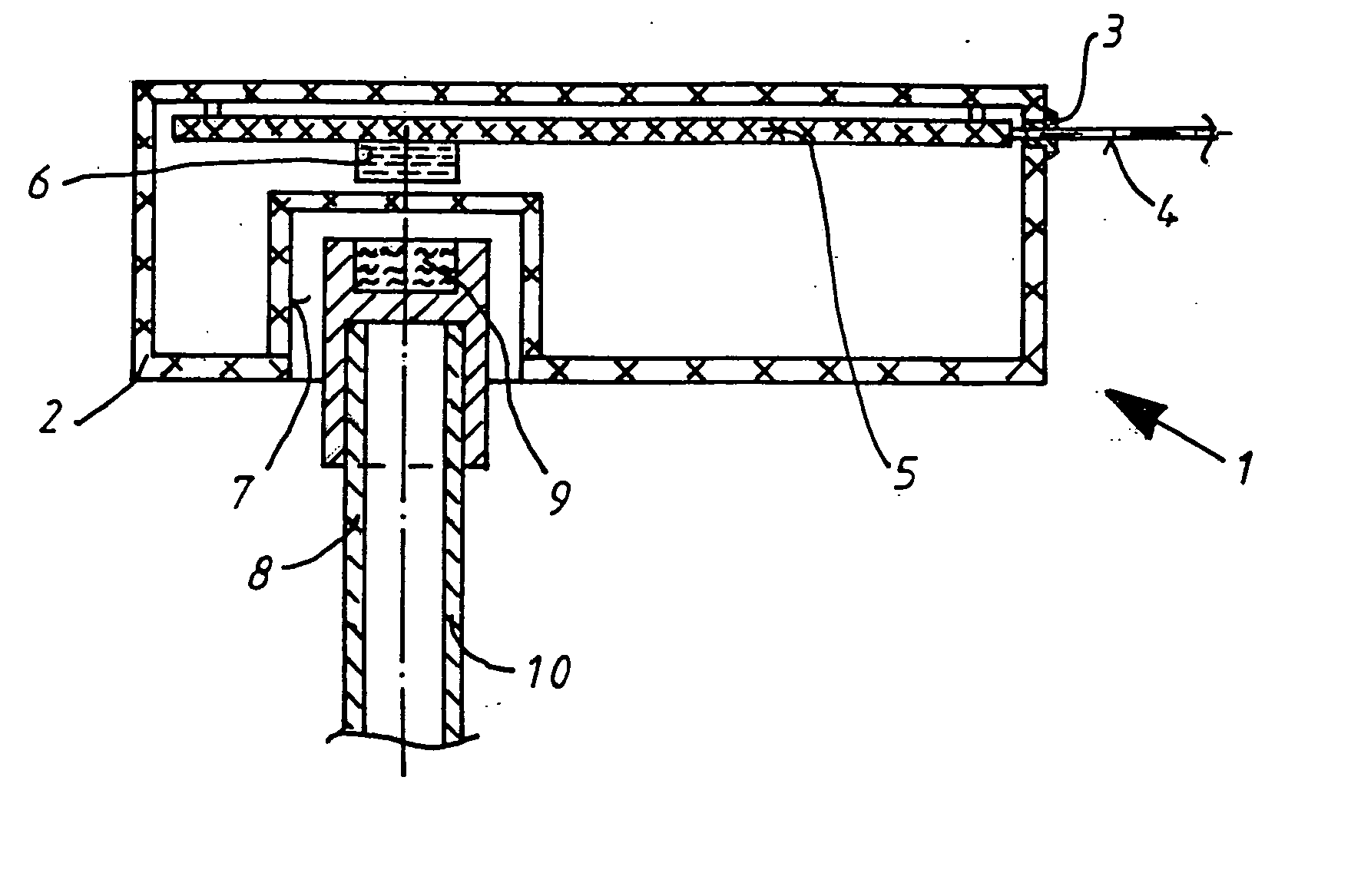

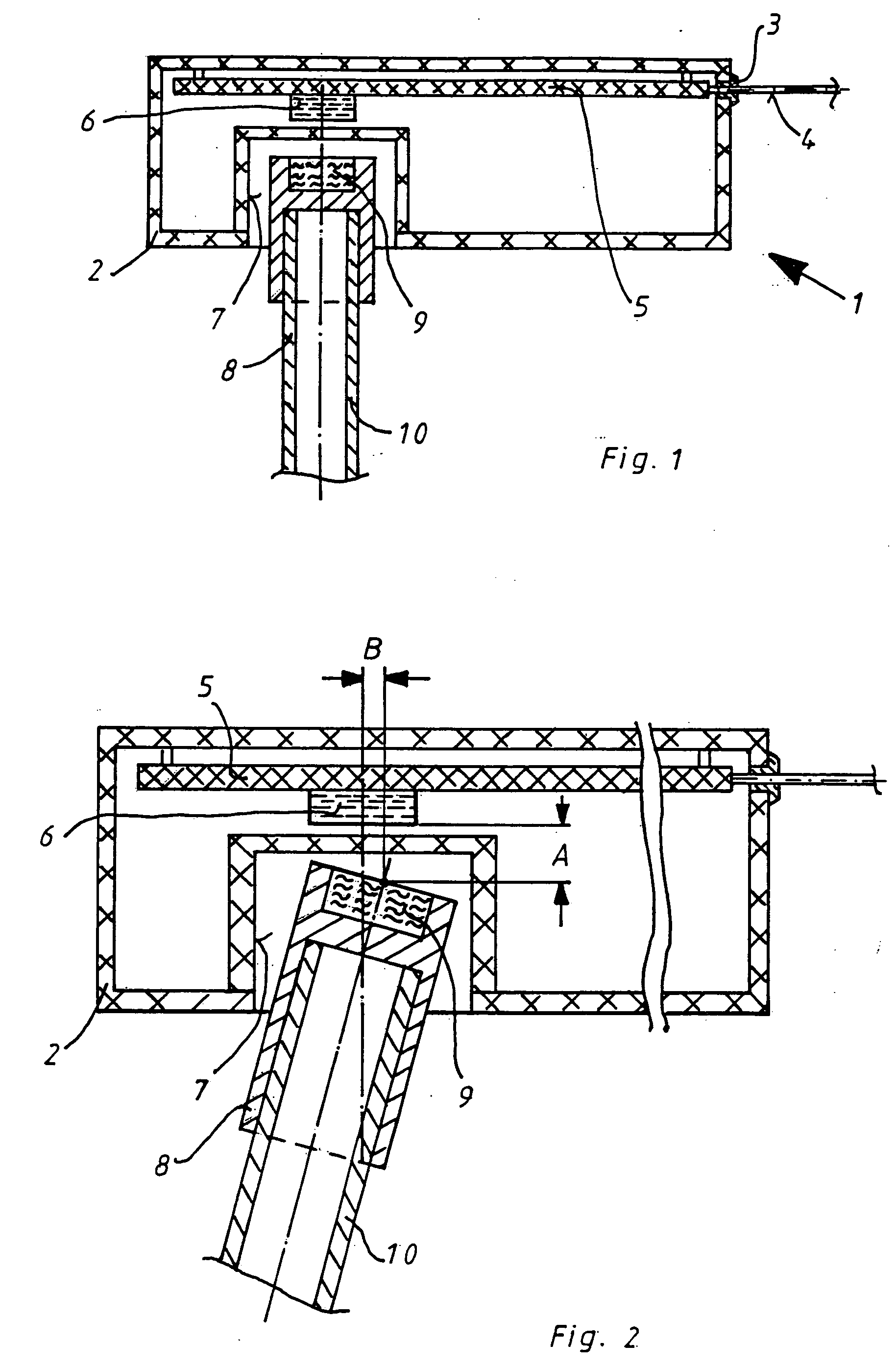

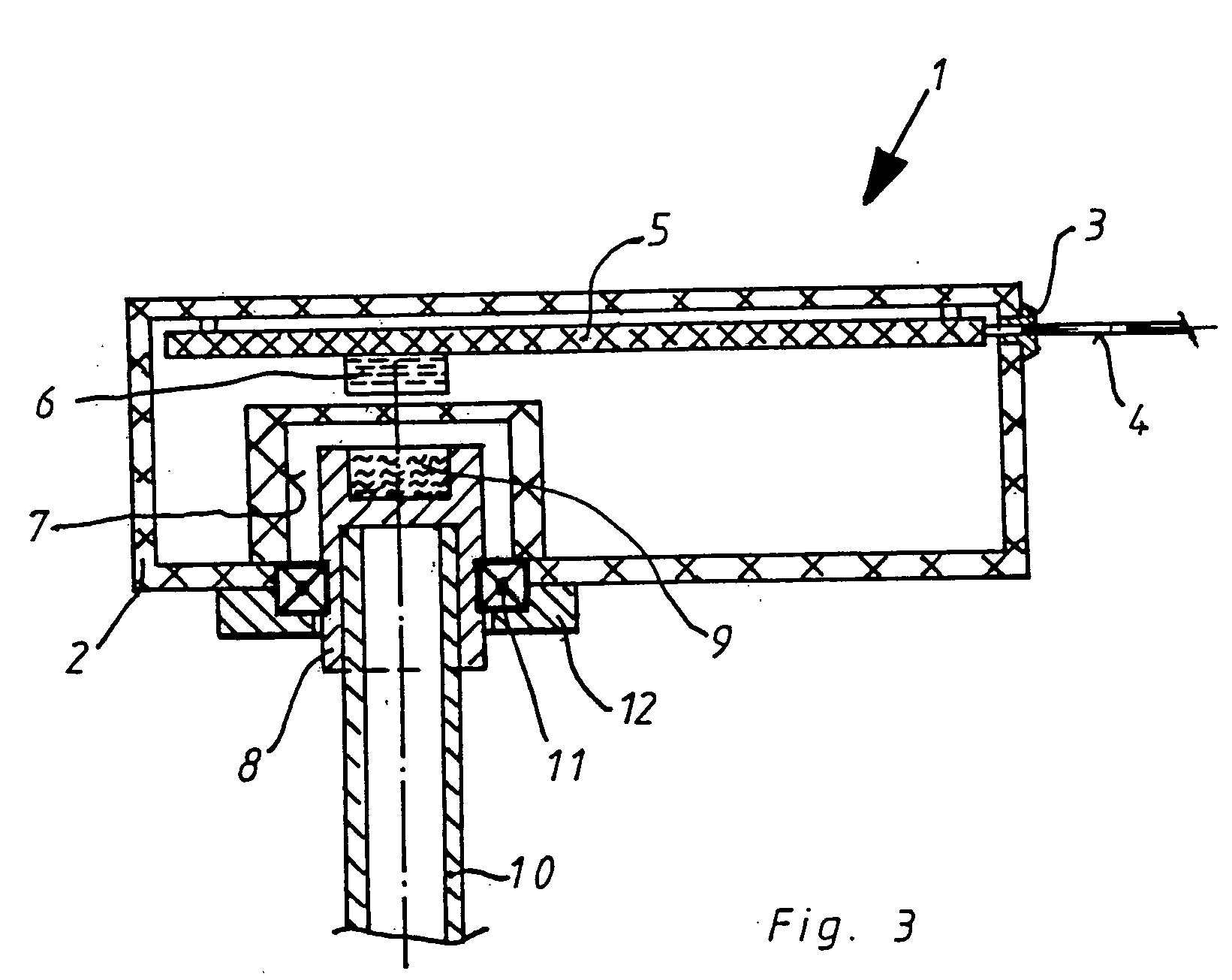

Position transmitter and method for determining a position of a rotating shaft

ActiveUS20060006861A1Easy to replaceMagnetic-field-controlled resistorsSolid-state devicesMicrocontrollerEngineering

A position transmitter for determining a position of a rotating shaft, has an AMR sensor unit or a GMR sensor unit which, for determining the position, has only one magnet disposed on a shaft to be monitored, whereby the position transmitter can be used as a single-turn and a multi-turn unit. Furthermore, a method for determining a position of a rotating shaft with the position transmitter is also provided. In accordance with the method, signals are produced using a diametrically magnetized magnet in a sensor unit, so that sine and cosine signals are obtained as output signals of the AMR sensor unit, the sine and cosine signals are digitalized, and these signals are processed by a microcontroller, with regard to the detection and evaluation of the angle of rotation, for detecting, filtering, and evaluating the number of revolutions, for detection of the direction of rotation or for data transmission of the angle of rotation and the number of revolutions to an overriding control.

Owner:FEIG ELECTRONICS MBH

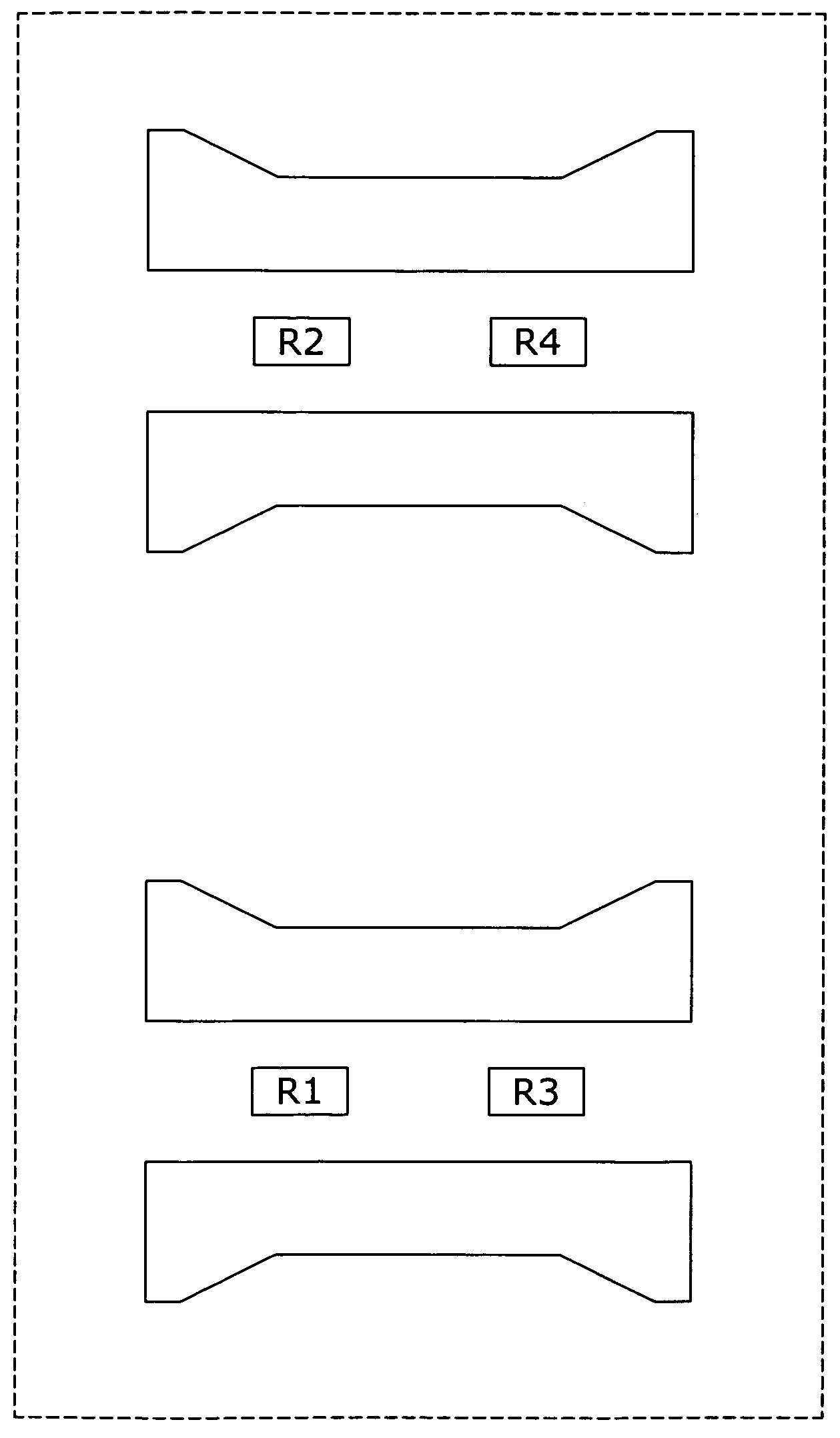

Matching of gmr sensors in a bridge

ActiveUS20090102464A1Reduce variationUniform patternNanomagnetismMagnetic-field-controlled resistorsElectricityEngineering

A magnetoresistive (MR) sensing device includes MR elements electrically connected to form a bridge circuit and one or more non-functional (or “dummy”) MR elements for improved matching of the bridge circuit MR elements.

Owner:ALLEGRO MICROSYSTEMS INC

Magnetoresistive flux focusing eddy current flaw detection

InactiveUS6888346B2Effectively deep flawIncrease flux densityMagnetic property measurementsMaterial magnetic variablesHigh fluxHand held

A giant magnetoresistive flux focusing eddy current device effectively detects deep flaws in thick multilayer conductive materials. The probe uses an excitation coil to induce eddy currents in conducting material perpendicularly oriented to the coil's longitudinal axis. A giant magnetoresistive (GMR) sensor, surrounded by the excitation coil, is used to detect generated fields. Between the excitation coil and GMR sensor is a highly permeable flux focusing lens which magnetically separates the GMR sensor and excitation coil and produces high flux density at the outer edge of the GMR sensor. The use of feedback inside the flux focusing lens enables complete cancellation of the leakage fields at the GMR sensor location and biasing of the GMR sensor to a location of high magnetic field sensitivity. In an alternate embodiment, a permanent magnet is positioned adjacent to the GMR sensor to accomplish the biasing. Experimental results have demonstrated identification of flaws up to 1 cm deep in aluminum alloy structures. To detect deep flaws about circular fasteners or inhomogeneities in thick multilayer conductive materials, the device is mounted in a hand-held rotating probe assembly that is connected to a computer for system control, data acquisition, processing and storage.

Owner:NASA

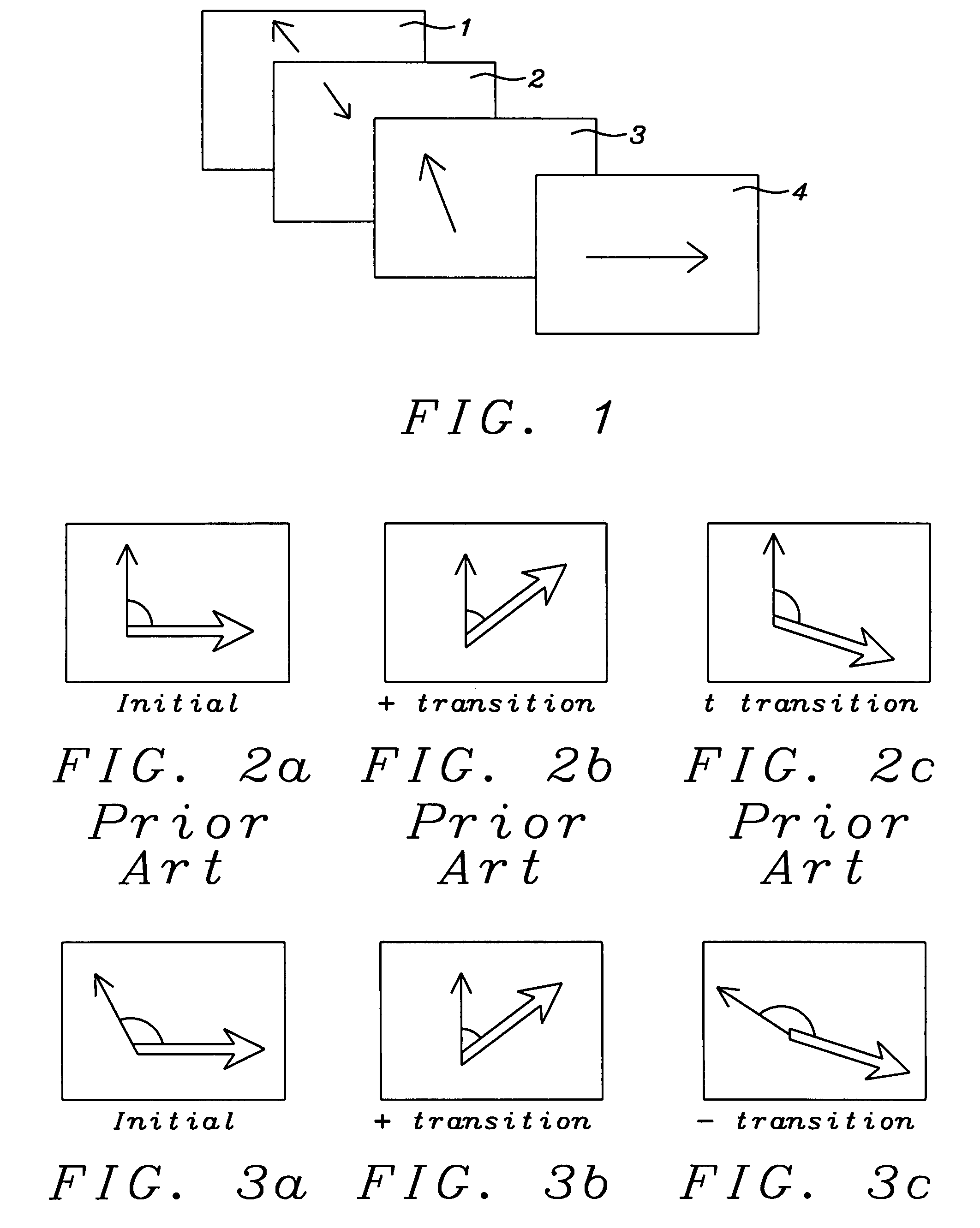

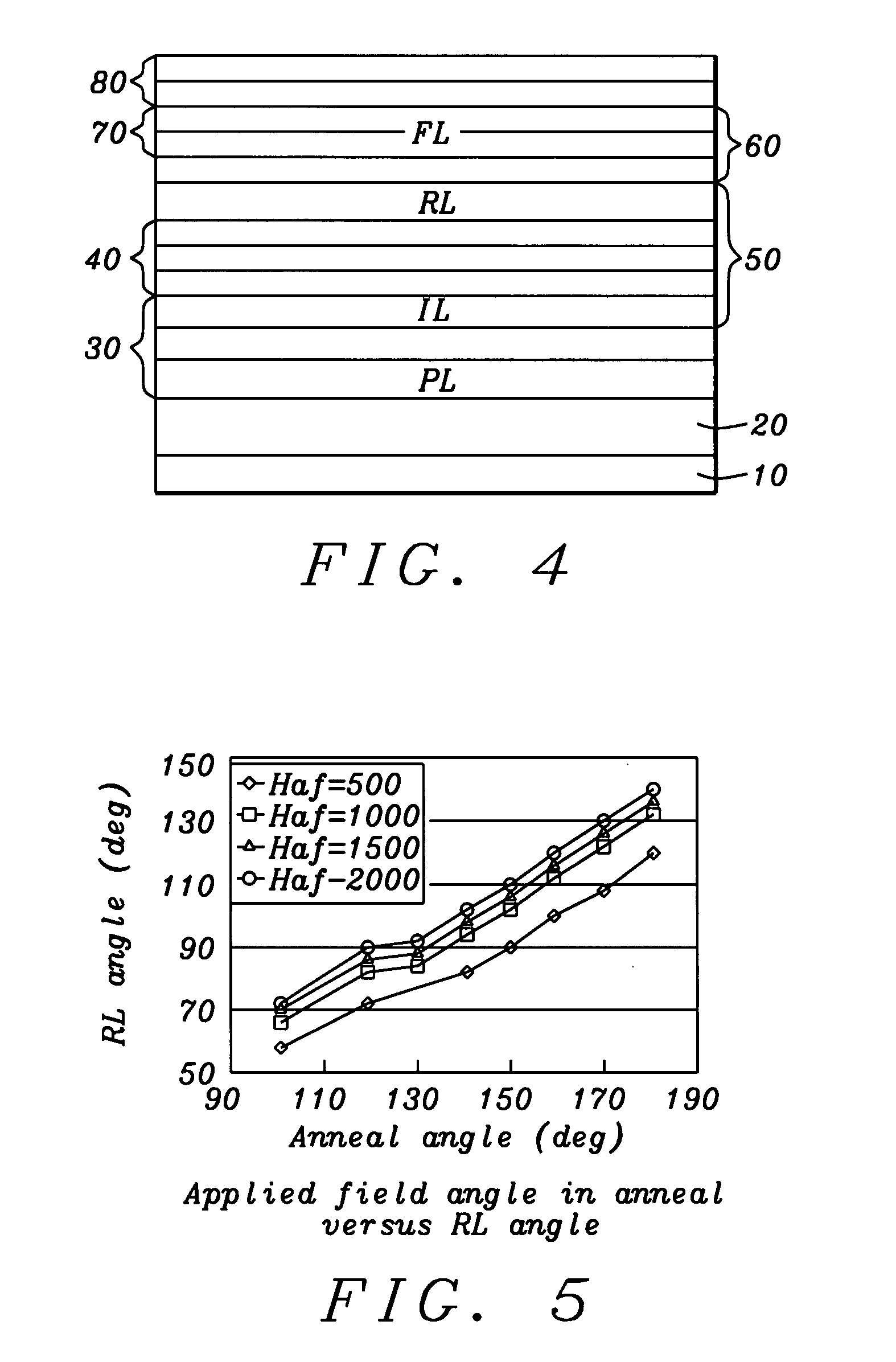

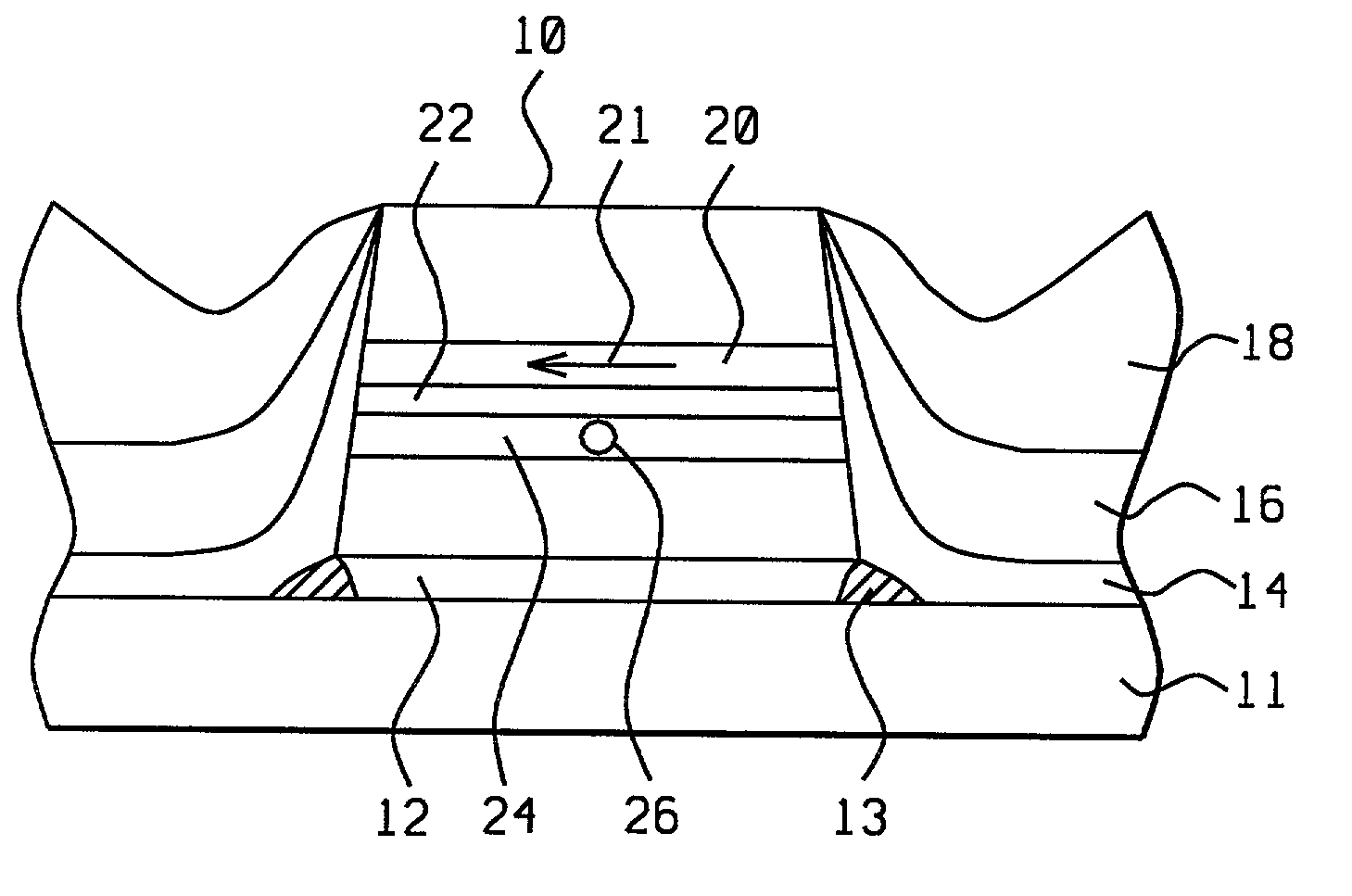

GMR sensor having a reference layer with movable magnetization

ActiveUS7345854B2High sensitivityLow limitRecord information storageManufacture of flux-sensitive headsInter layerCoupling

A method for fabricating a spin-valve GMR sensor having a reference layer with a magnetic moment that moves in an opposite direction to that of the free layer in the presence of external magnetic field transitions. The reference layer is a part of a three ferromagnetic layer structure, including pinned, intermediate and reference layers, that when the layers are taken pairwise and separated by spacer layers, includes a strongly exchange coupled synthetic ferrimagnetic pinned and intermediate layer pair and a weakly exchange coupled synthetic ferrimagnetic intermediate and reference layer pair. The reference layer, because of its weak coupling to the intermediate layer, has a magnetic moment that is free to move. During sensor operation, the reference layer and free layer move in opposite directions under the influence of external magnetic field transitions The novel three layer structure provides a sensor of increased sensitivity for a given track width.

Owner:HEADWAY TECH INC

Wireless sensor network device for measuring car throughput based on high magnetic resistance and magnetic sensitive technology and its realizing method

InactiveCN101241646AHigh detection sensitivityLarge magnetic field measurement rangeRoad vehicles traffic controlHysteresisRadio frequency

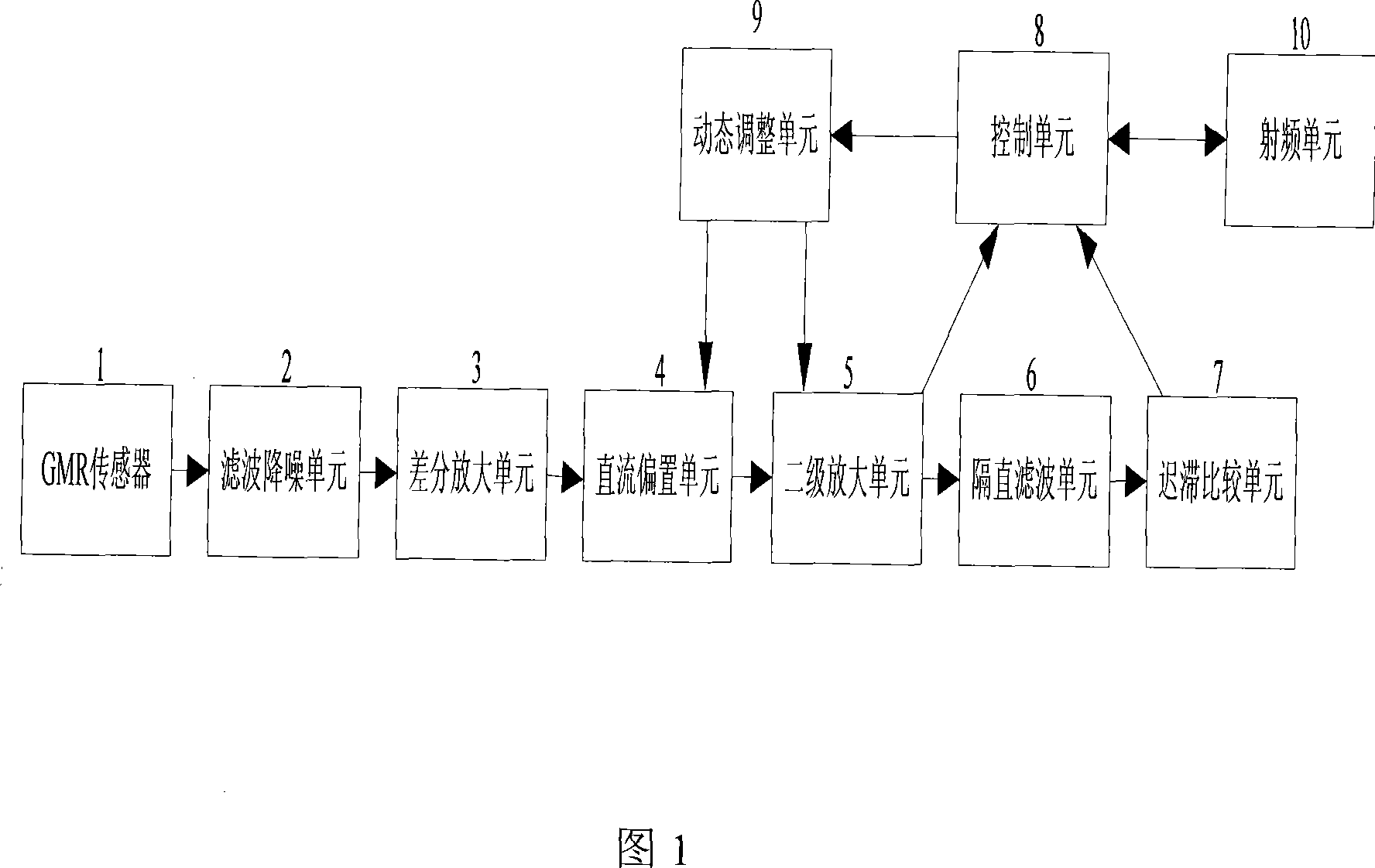

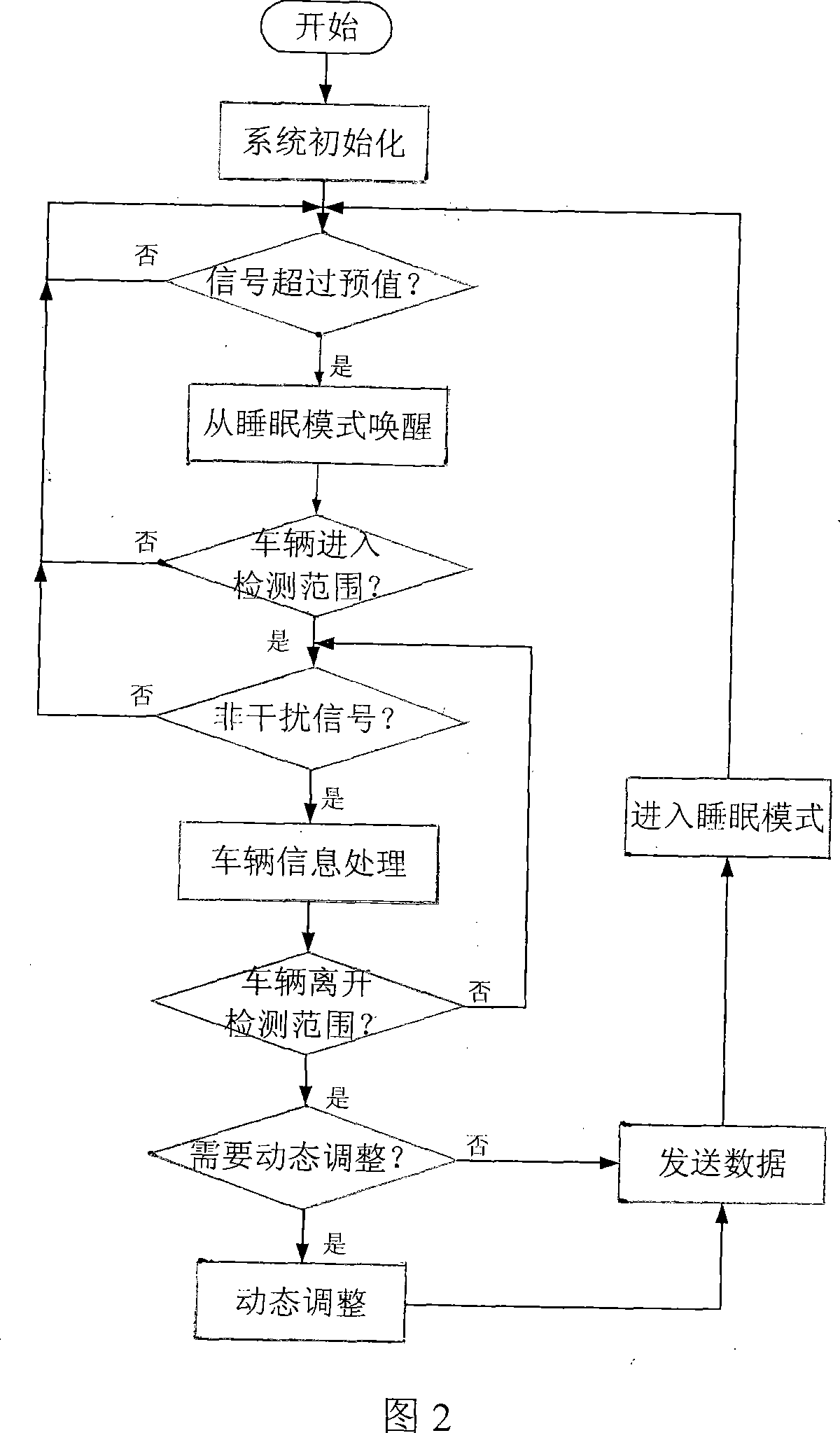

The invention provides a device which relates to road vehicle information measuring field. Said device comprises a GMR sensor, a filter denoising unit, a differential amplification unit, a DC bias unit, a second-level amplification unit, a blocking filter unit, a hysteresis comparison unit, a dynamic adjustment unit, a control unit and a RF unit. Said realization method is: a bias magnetic field is set beside the GMR sensor, the sensor output changes when a car passing by the magnetic field; the device judges the passed car through the changes by using the sensor, and transmits the measured vehicle flowrate into base station through RF and controls or saves. The device has broad prospect in road vehicle measuring, park management, road crossing management etc.

Owner:JIAXING WIRELESS SENSOR NETWORKS CENT CAS

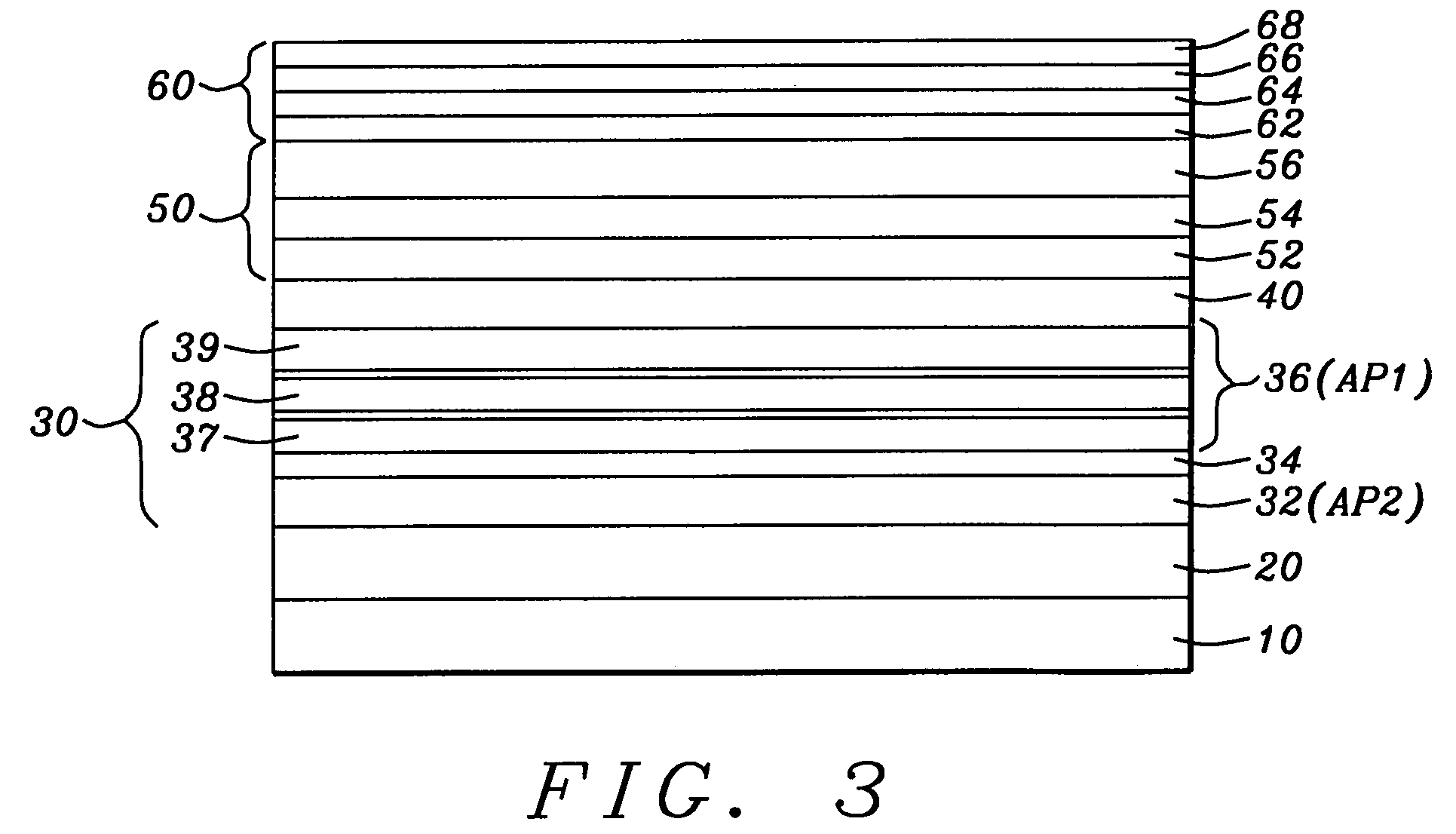

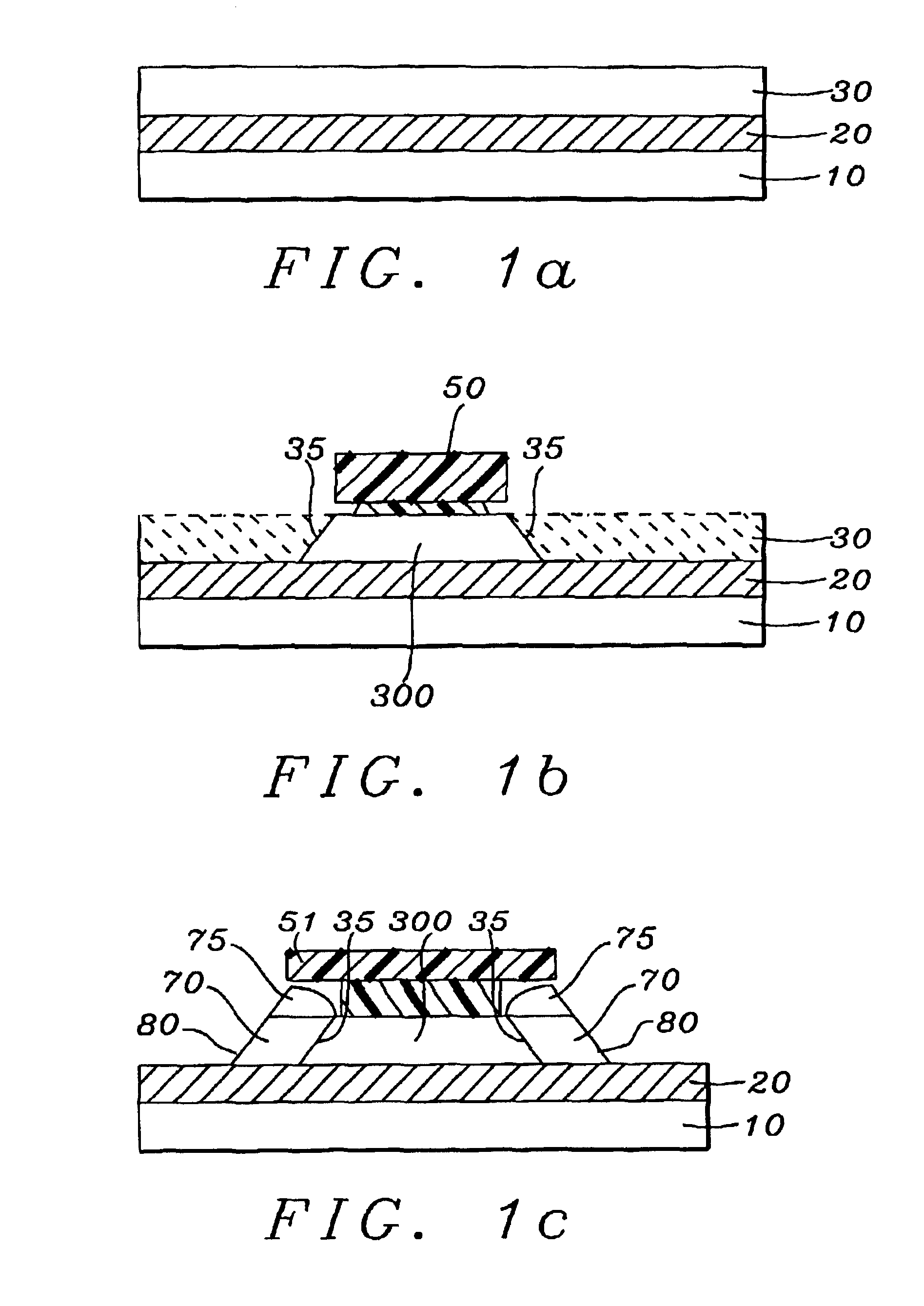

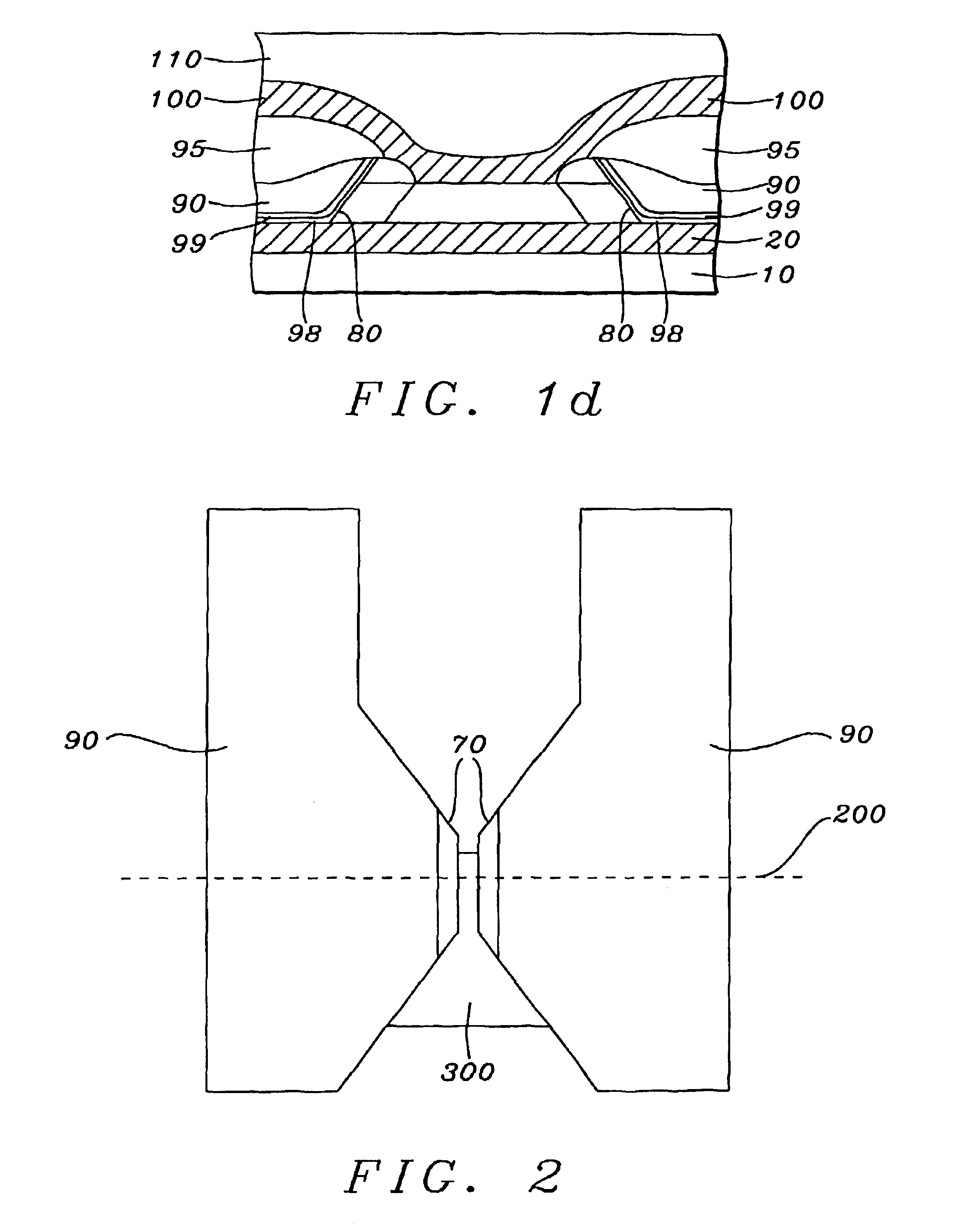

Method for fabricating a patterned synthetic longitudinal exchange biased GMR sensor

InactiveUS6857180B2Reduce contribution of signal AStabilizing bias pointNanomagnetismElectrical transducersMagnetizationExchange bias

Patterned, longitudinally and transversely antiferromagnetically exchange biased GMR sensors are provided which have narrow effective trackwidths and reduced side reading. The exchange biasing significantly reduces signals produced by the portion of the ferromagnetic free layer that is underneath the conducting leads while still providing a strong pinning field to maintain sensor stability. In the case of the transversely biased sensor, the magnetization of the free and biasing layers in the same direction as the pinned layer simplifies the fabrication process and permits the formation of thinner leads by eliminating the necessity for current shunting.

Owner:HEADWAY TECH INC

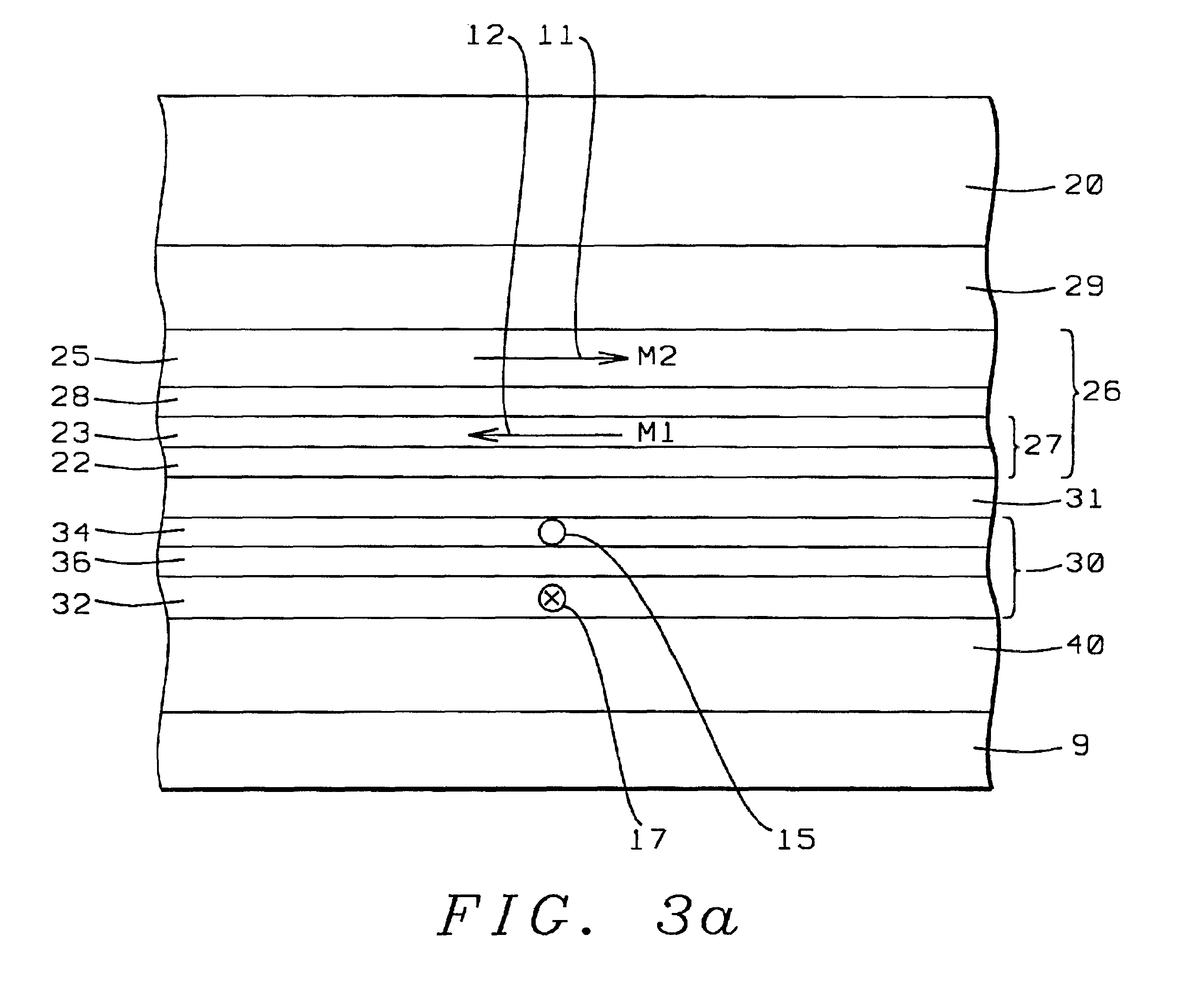

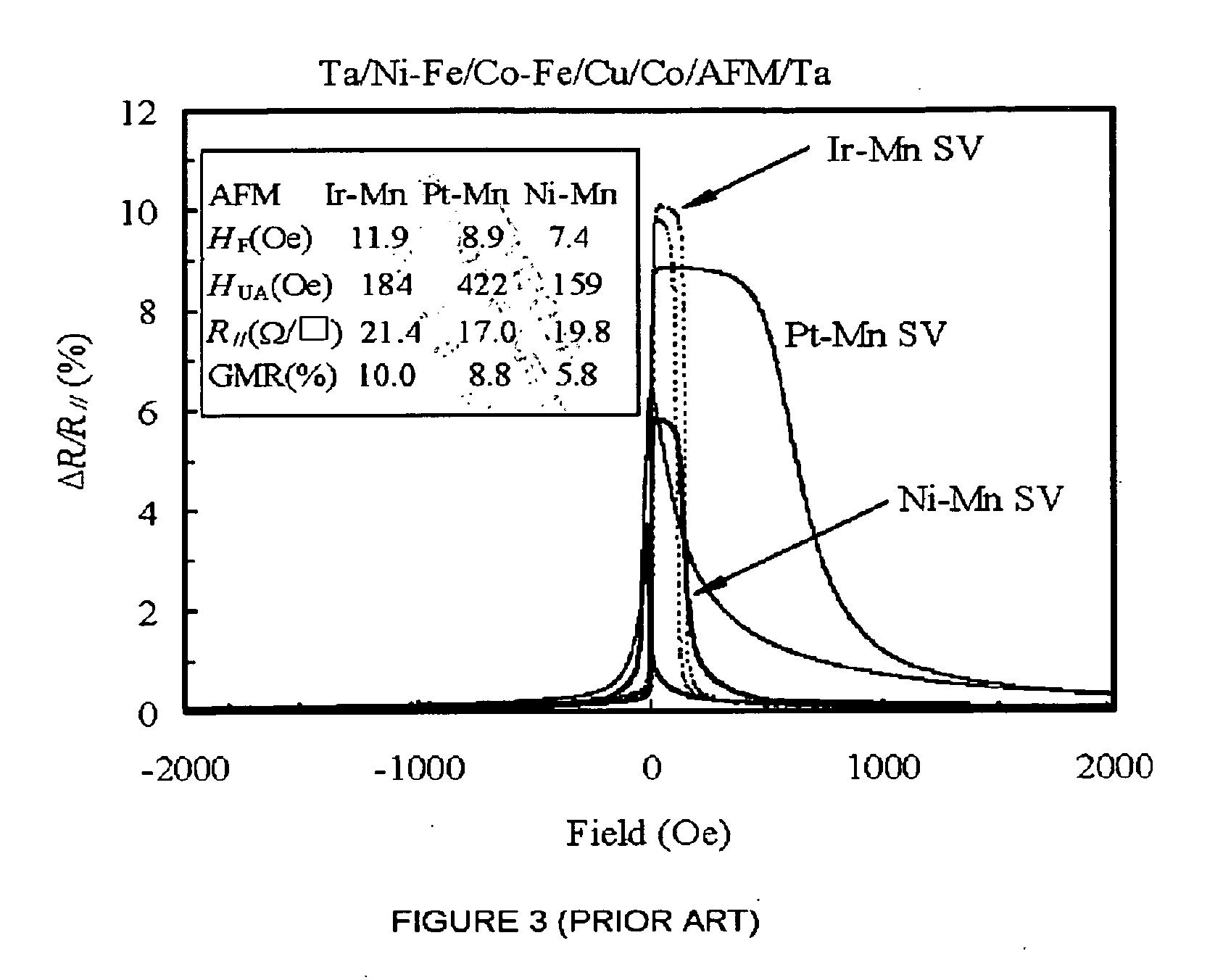

GMR sensors with strongly pinning and pinned layers

InactiveUS20060193089A1Simple designEasy to operateNanomagnetismNanoinformaticsIridiumFerromagnetism

A giant magnetoresistance (GMR) sensor with strongly pinning and pinned layers is described for magnetic recording at ultrahigh densities. The pinning layer is an antiferromagnetic (AFM) iridium-manganese-chromium (Ir—Mn—Cr) film having a Mn content of approximately from 70 to 80 atomic percent and having a Cr content of approximately from 1 to 10 atomic percent. The first pinned layer is preferably a ferromagnetic Co—Fe having an Fe content of approximately from 20 to 80 at % and having high, positive saturation magnetostriction. The second pinned layer is preferably a ferromagnetic Co—Fe having an Fe content of approximately from 0 to 10 atomic percent. The net magnetic moment of the first and second pinned layers is designed to be nearly zero in order to achieve a pinning field of beyond 3,000 Oe.

Owner:WESTERN DIGITAL TECH INC

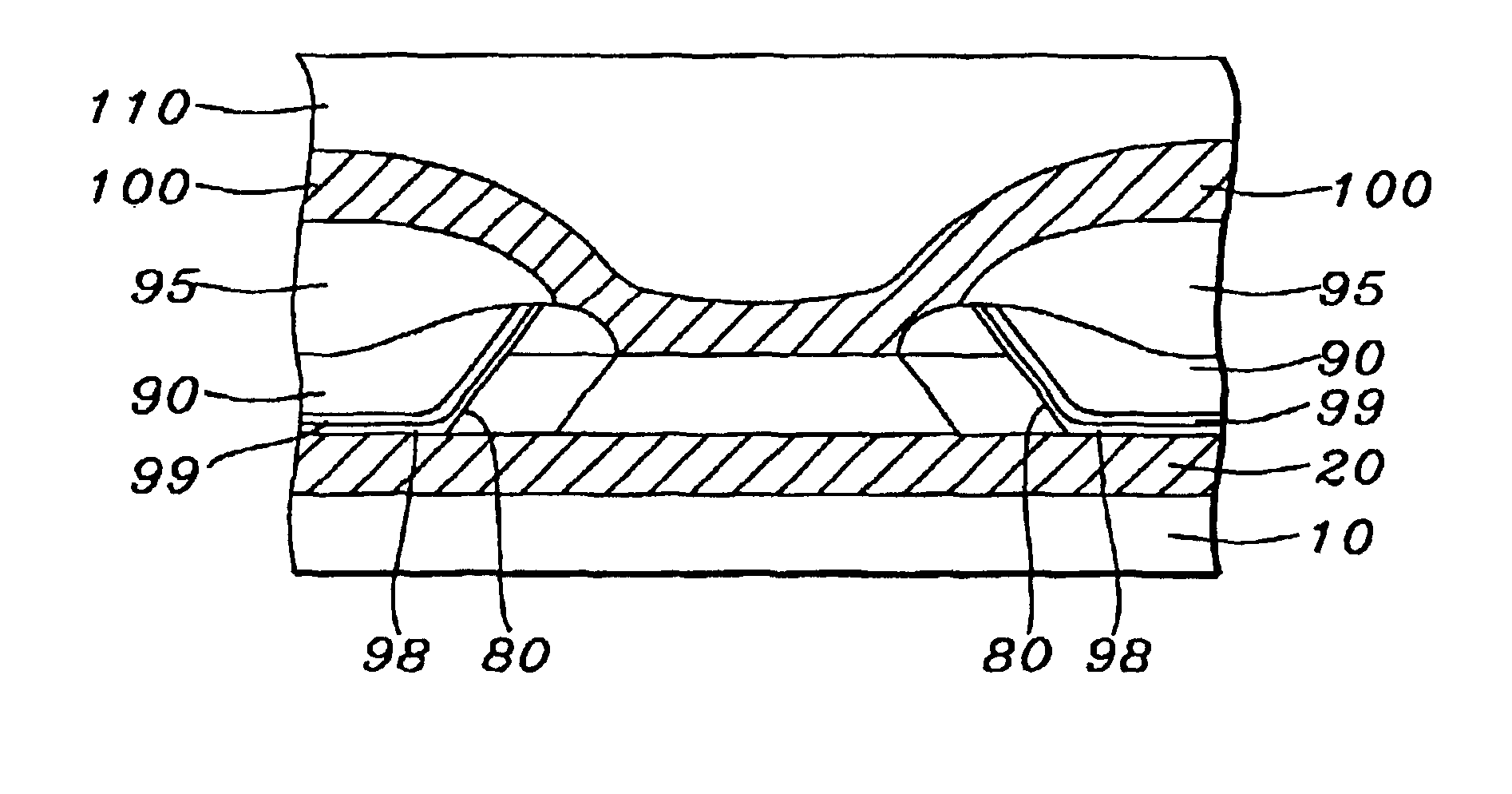

Trilayer SAF with current confining layer

InactiveUS20060023376A1Electrical resistance is minimizedReduce the impactRecord information storageManufacture of flux-sensitive headsPartial oxidationInter layer

A current perpendicular to plane (CPP) GMR sensor having first and second outer pinned layers and a trilayer free layer therebetween. The free layer includes first and second outer magnetic layers, and a partially oxidized magnetic layer disposed there between. The middle partially oxidized layer is antiparallel coupled with the outer magnetic layers of the free layer by first and second coupling alyers which prevent oxygen migration from the central layer into the outer magnetic layers of the free layer. The partial oxidation of the middle layer provides a limited amount of electrical resistance at a desired location within the free layer to increase GMR.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

CPP differential GMR sensor having antiparallel stabilized free layers for perpendicular recording

InactiveUS7242556B2DesensitizationNanomagnetismMagnetic measurementsTransverse magnetic fieldEngineering

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

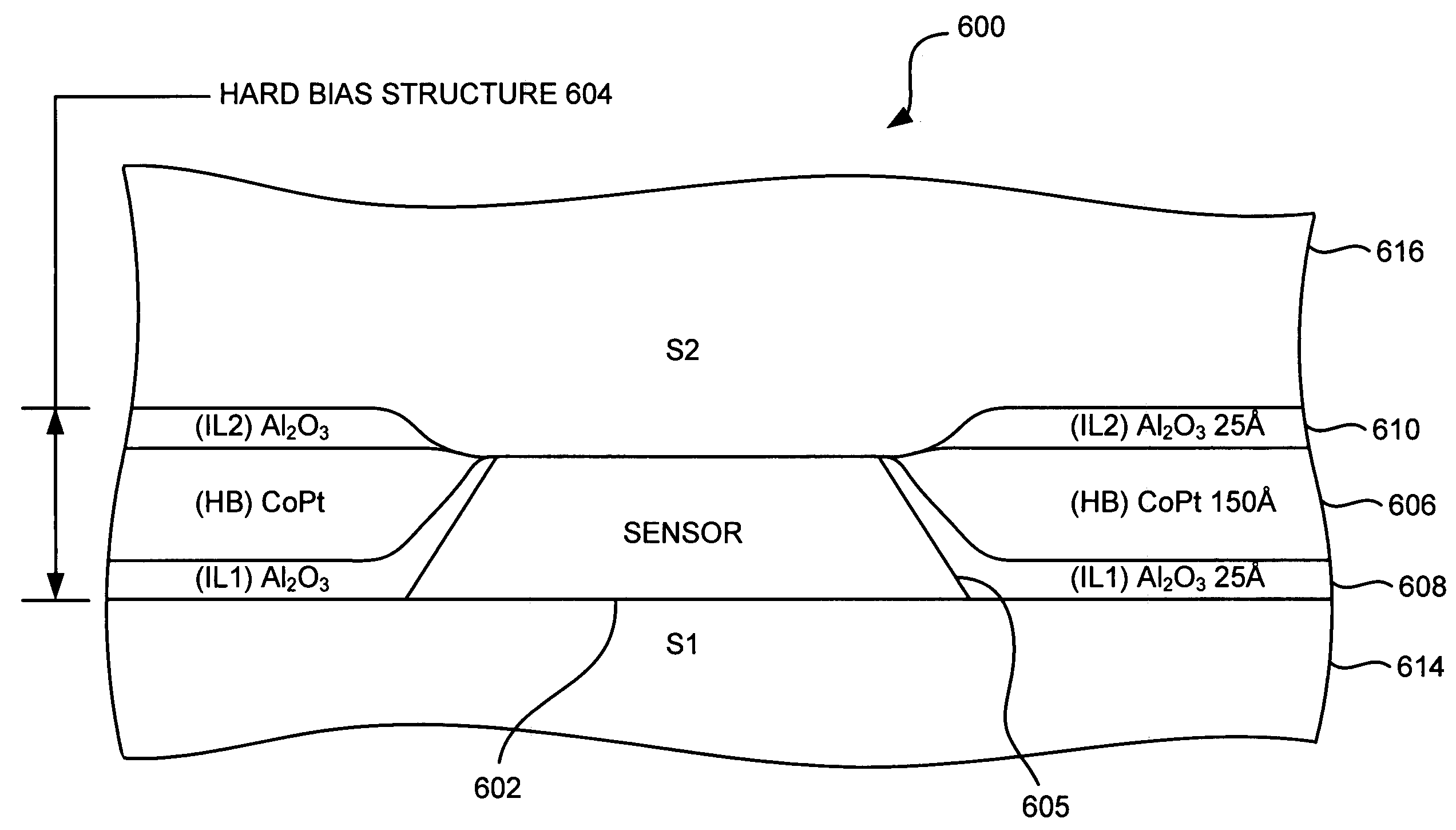

Method for forming a GMR sensor having improved longitudinal biasing

InactiveUS6944939B2Good magnetic stabilityEasily and efficiently fabricatedNanomagnetismElectrical transducersEngineeringMagnetic layer

A GMR sensor having improved longitudinal biasing is provided as is a method of forming it. The improved biasing is provided by longitudinal biasing structures in which a soft magnetic layer is interposed between a hard magnetic biasing layer and the lateral edge of the GMR sensor element. The soft magnetic layer eliminates the need for a seed layer directly between the hard magnetic layer and the GMR element and provides improved coupling to the free layer of the GMR element and a substantial reduction in random domain variations.

Owner:HEADWAY TECH INC

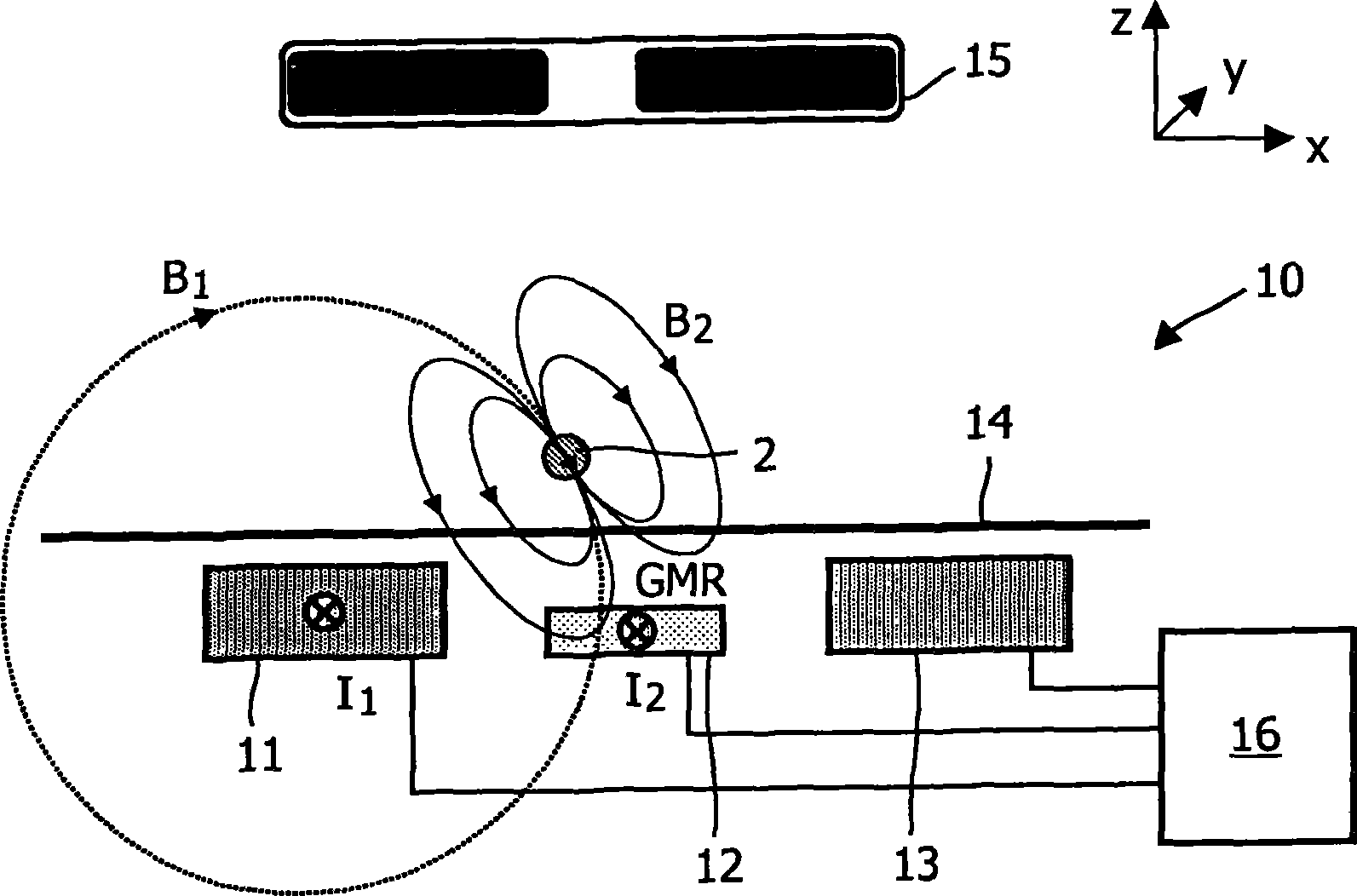

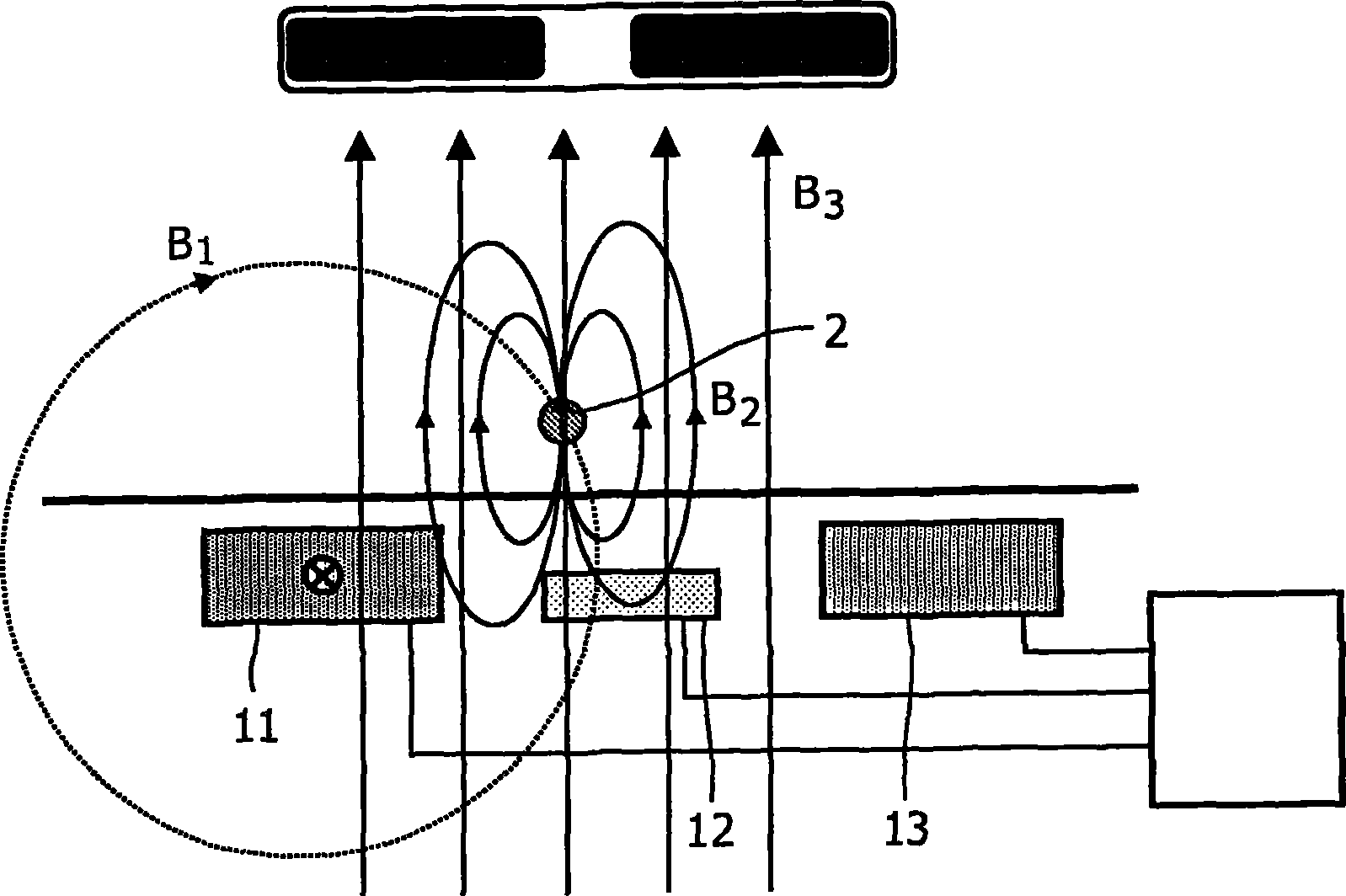

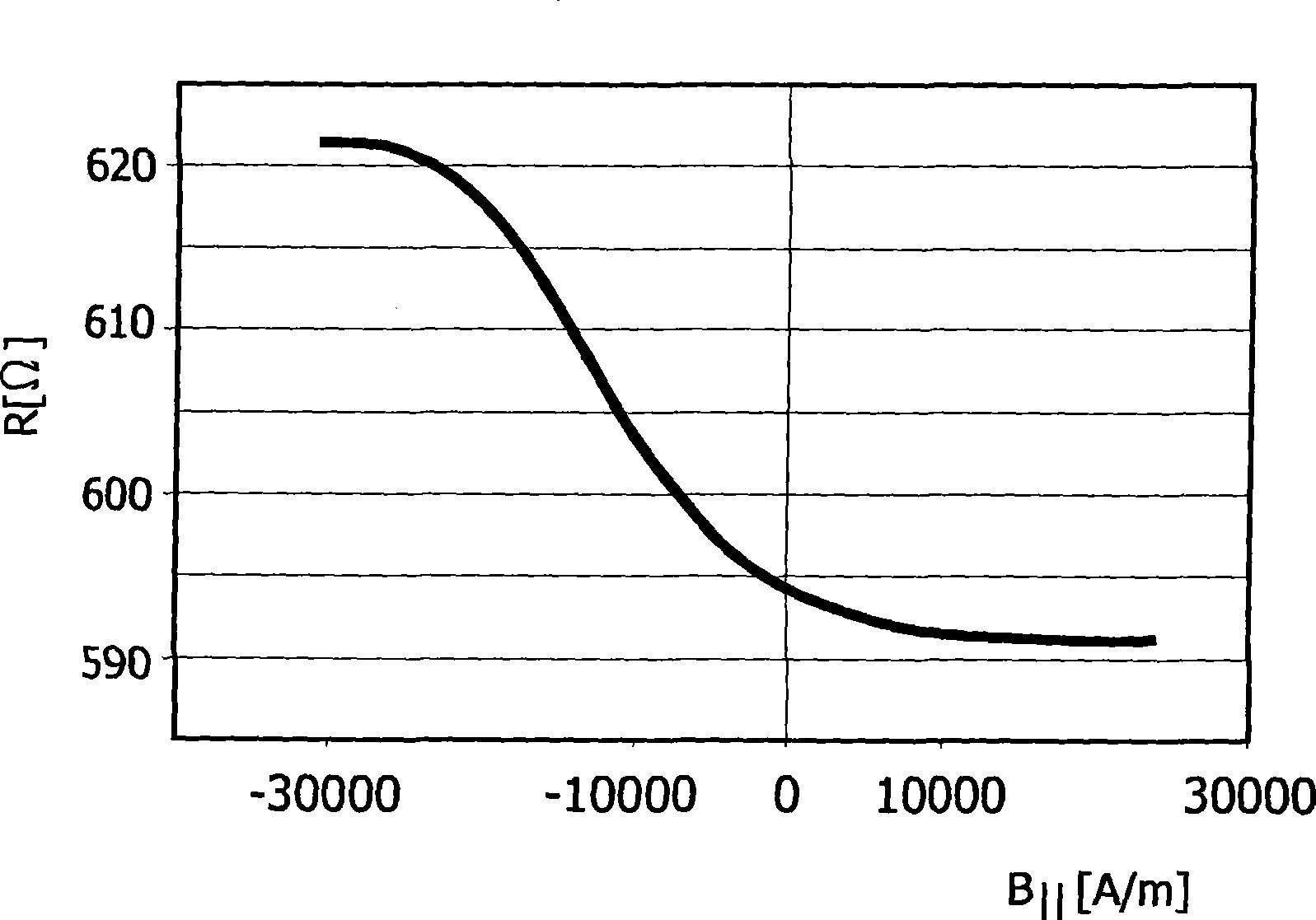

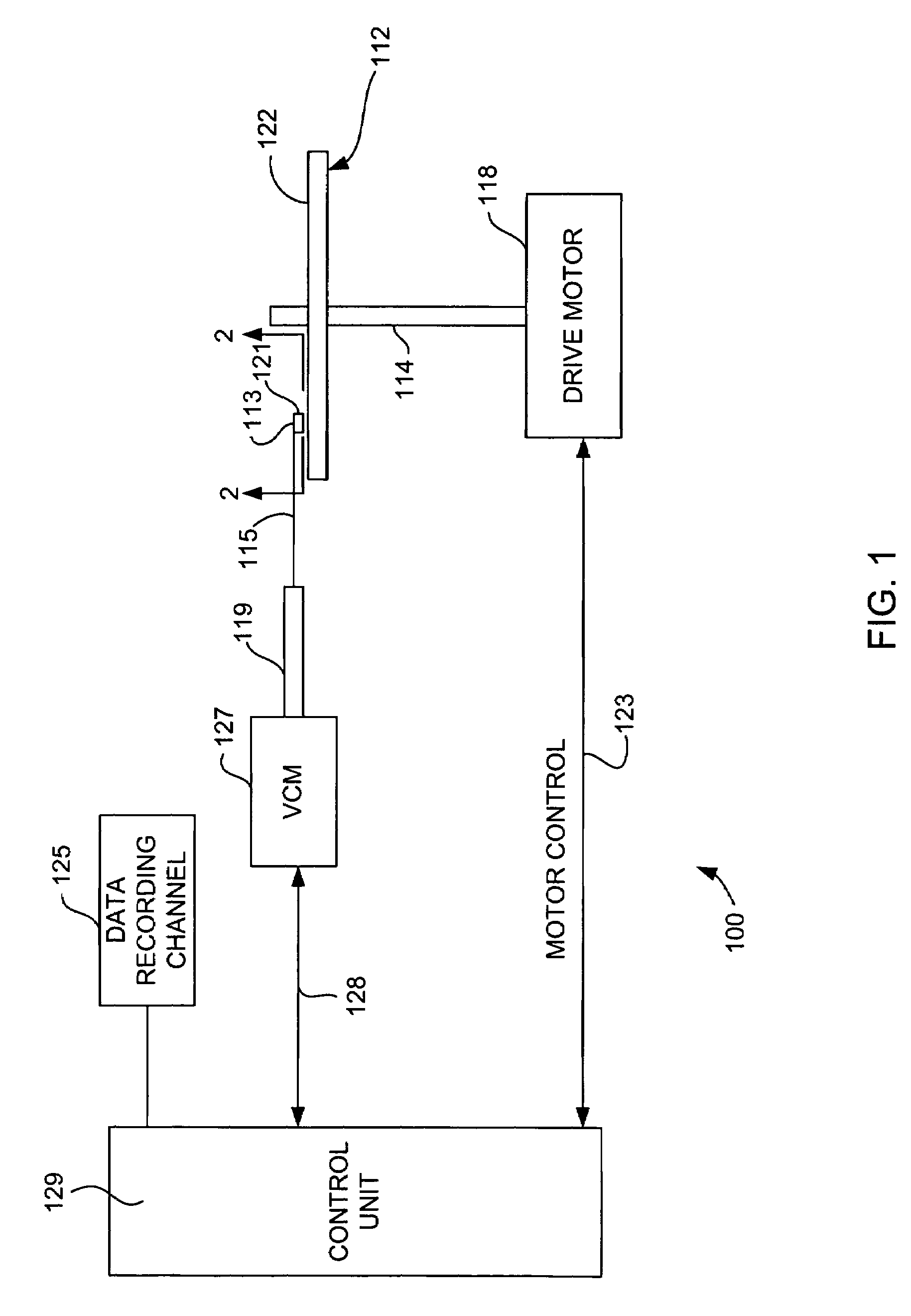

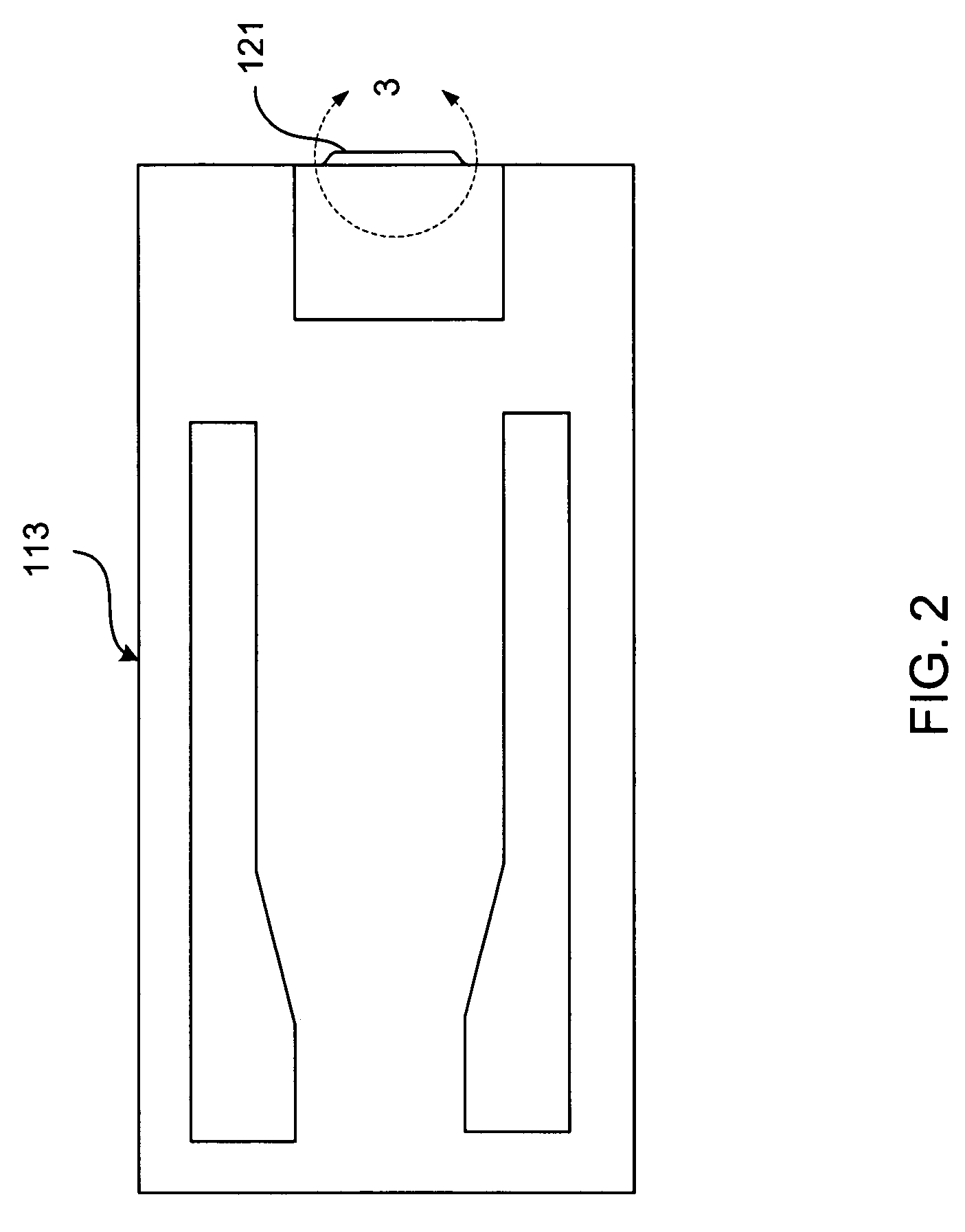

Calibration of a magnetic sensor device

The invention relates to the calibration of the magnetic sensor device comprising magnetic excitation wires (11, 13) and a magnetic sensor element, for example a GMR sensor (12), for measuring reaction fields (B2) generated by magnetic particles (2) in reaction to an excitation field (B1) generated by the excitation wires. The magnetic sensor element (12) can be calibrated by saturating the magnetic particles (2) with a magnetic calibration field (B3). Thus the direct (crosstalk) action of the excitation field (B1) on the magnetic sensor element (12) can be determined without disturbing contributions of the magnetic particles (2).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

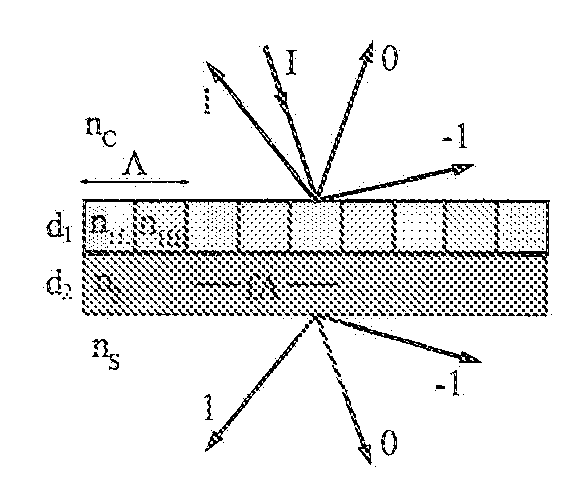

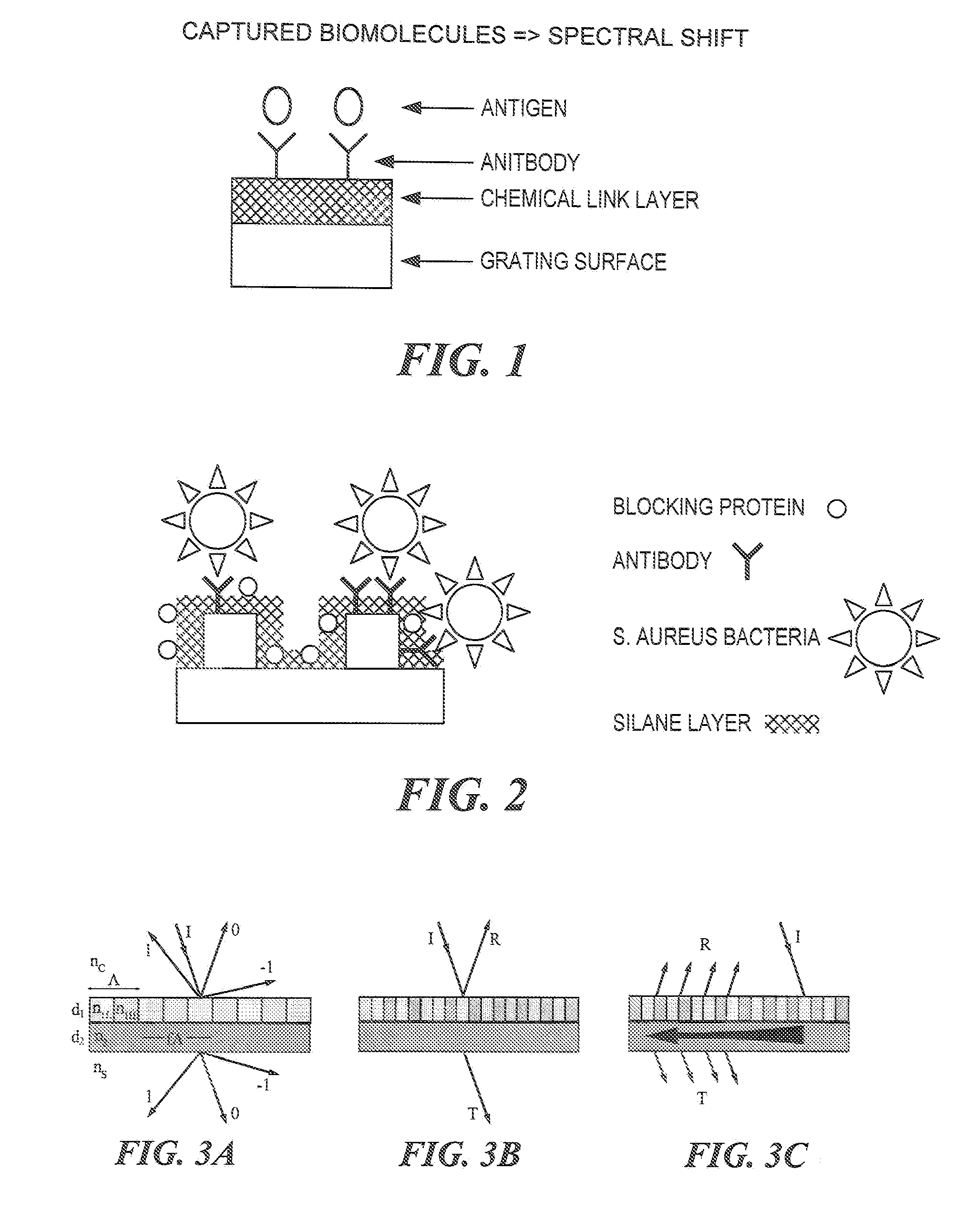

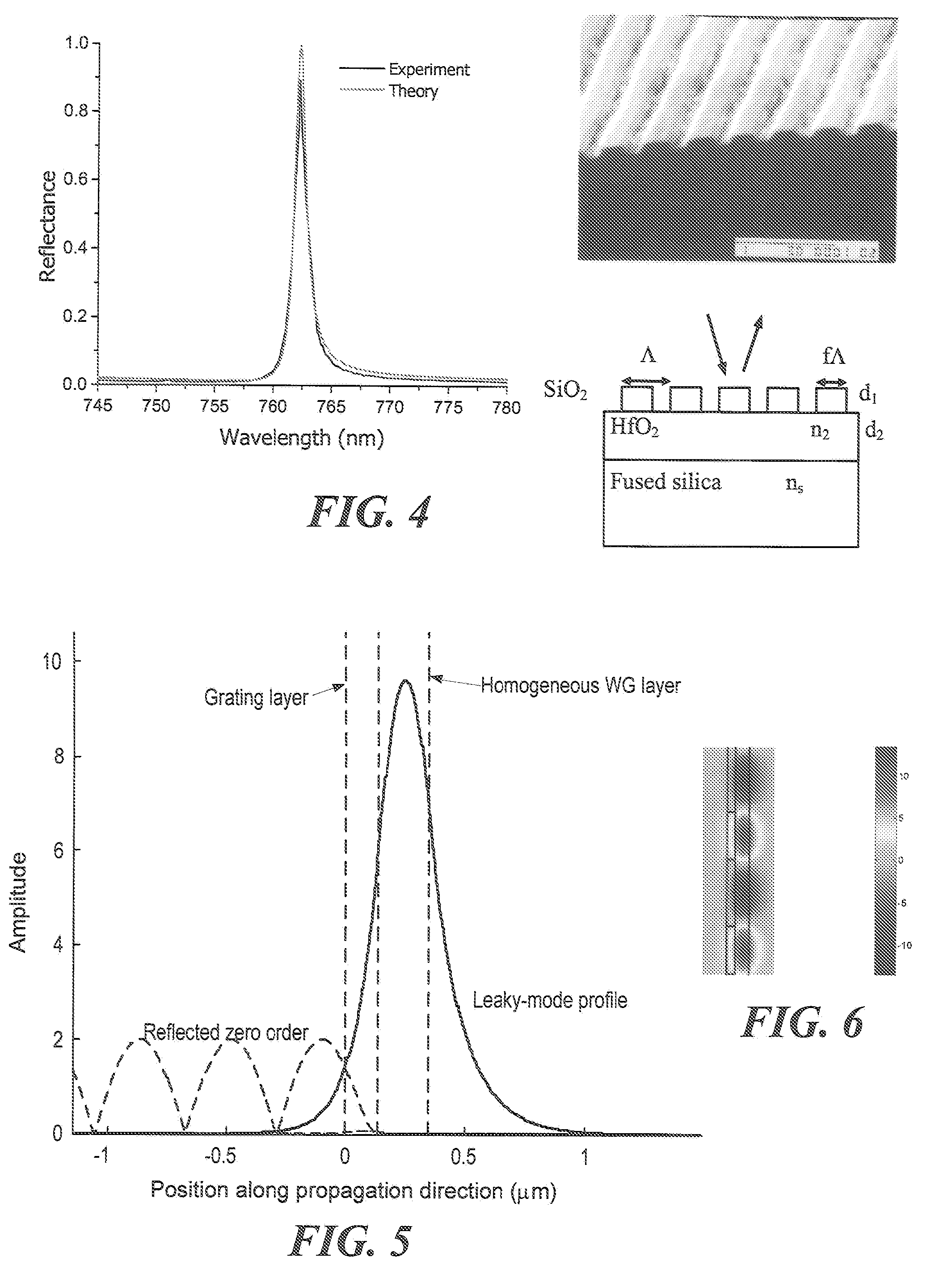

Guided-mode resonance sensors employing angular, spectral, modal, and polarization diversity for high-precision sensing in compact formats

InactiveUS20080062418A1Quality improvementHigh precisionRadiation pyrometrySpectrum investigationPolarization diversityLeaky mode

A guided mode resonance (GMR) sensor assembly and system are provided. The GMR sensor includes a waveguide structure configured for operation at or near one or more leaky modes, a receiver for input light from a source of light onto the waveguide structure to cause one or more leaky TE and TM resonant modes and a detector for changes in one or more of the phase, waveshape and / or magnitude of each of a TE resonance and a TM resonance to permit distinguishing between first and second physical states of said waveguide structure or its immediate environment.

Owner:MAGNUSSON ROBERT +1

GMR biosensor with enhanced sensitivity

ActiveUS20080032423A1Adverse hysteresis effectPointing stableNanomagnetismBiological particle analysisHysteresisSensor array

A sensor array comprising a series connection of parallel GMR sensor stripes provides a sensitive mechanism for detecting the presence of magnetized particles bonded to biological molecules that are affixed to a substrate. The adverse effect of hysteresis on the maintenance of a stable bias point for the magnetic moment of the sensor free layer is eliminated by a combination of biasing the sensor along its longitudinal direction rather than the usual transverse direction and by using the overcoat stress and magnetostriction of magnetic layers to create a compensatory transverse magnetic anisotropy. By making the spaces between the stripes narrower than the dimension of the magnetized particle and by making the width of the stripes equal to the dimension of the particle, the sensitivity of the sensor array is enhanced.

Owner:APPLIED SPINTRONICS +1

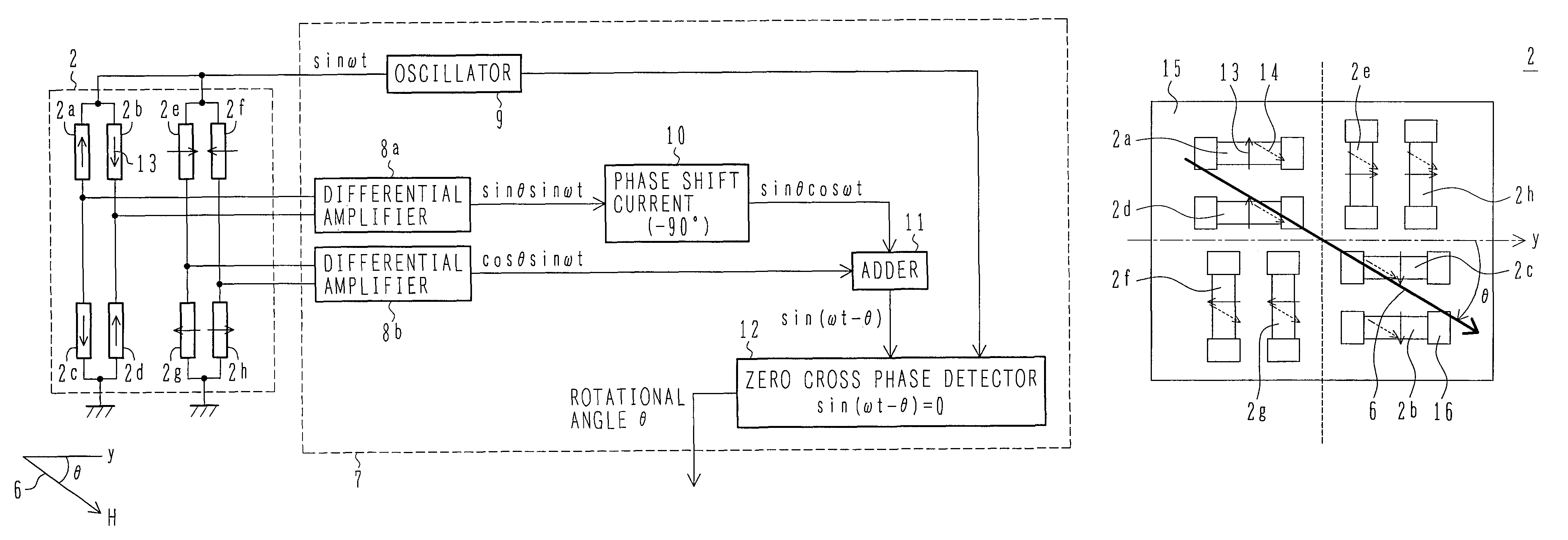

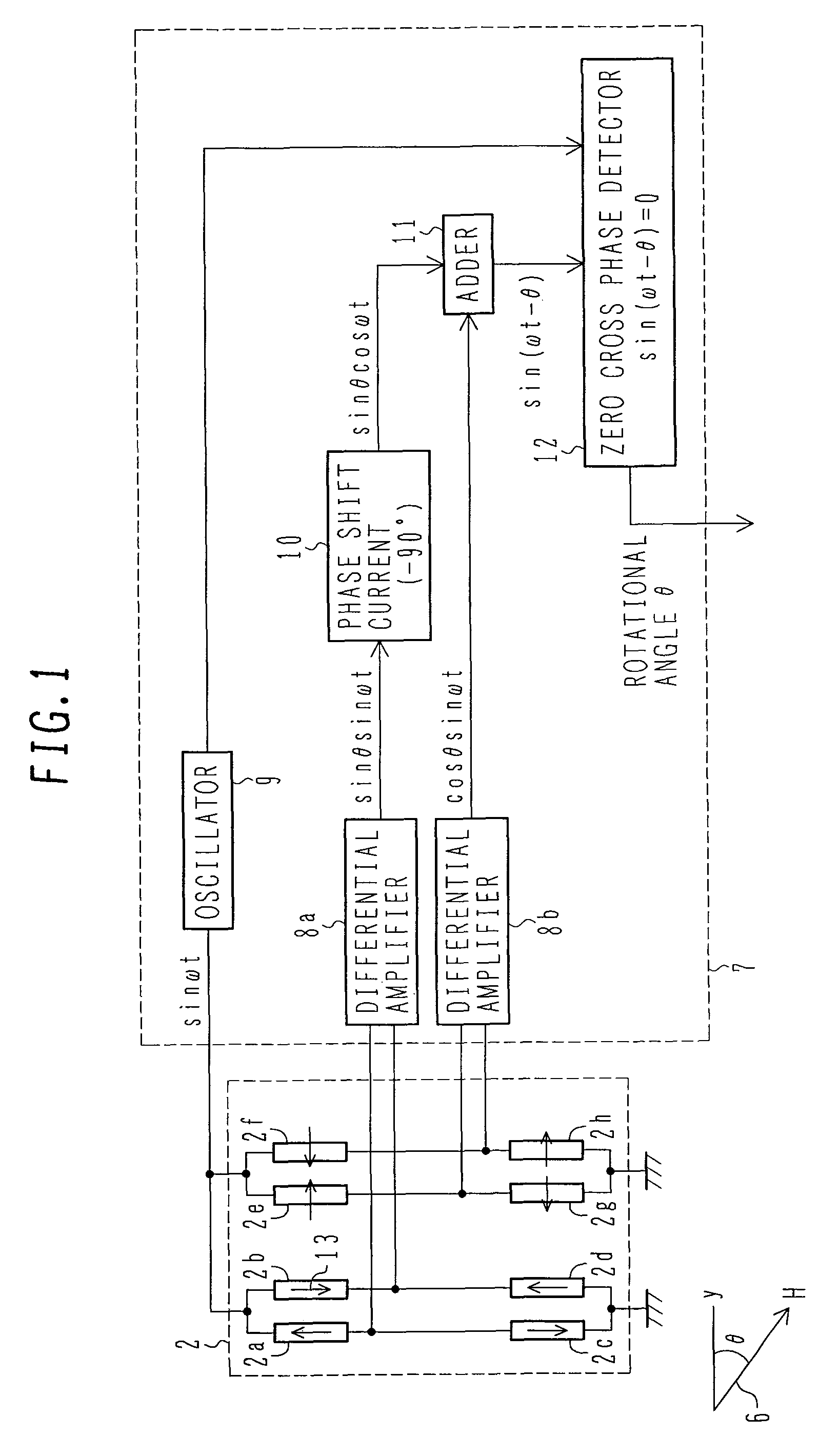

GMR sensor device having AC power supply

InactiveUS7852070B2Avoid it happening againWithout impairing industrial productivityMagnetic-field-controlled resistorsSolid-state devicesMagnetizationWaveform distortion

Owner:HITACHI LTD

Current-perpendicular-to-plane sensor with dual keeper layers

InactiveUS20080144234A1Reduce couplingLower junction resistance-area productNanomagnetismMagnetic measurementsRough surfaceAmorphous phase

This invention provides a CPP TMR or GMR sensor with an amorphous ferromagnetic lower keeper layer and a crystalline ferromagnetic upper keeper layer. The amorphous ferromagnetic lower keeper layer strongly exchange-couples to an underlying antiferromagnetic pinning layer and planarizes its rough surface. The crystalline ferromagnetic upper keeper layer strongly antiparallel-couples to an adjacent ferromagnetic reference layer across a nonmagnetic spacer layer. The amorphous ferromagnetic lower keeper layer is preferably made of a Co—Fe—B alloy film with an Fe content high enough to ensure strong exchange-coupling to the underlying antiferromagnetic pinning layer, and with a B content high enough to ensure the formation of an amorphous phase for planarizing an otherwise rough surface due to the underlying antiferromagnetic pinning layer. The crystalline ferromagnetic upper keeper layer is preferably made of a Co—Fe alloy film with an Fe content low enough to ensure strong antiparallel-coupling to the adjacent ferromagnetic reference layer across the nonmagnetic spacer layer. The sensor is annealed at temperatures low enough to prevent the amorphous phase from transforming into a polycrystalline phase, but also high enough to maximize TMR.

Owner:WESTERN DIGITAL TECH INC

CPP-GMR sensor with non-orthogonal free and reference layer magnetization orientation

A CPP GMR sensor structure having free and reference layers, where the magnetic orientations of the free and reference layers are non-orthogonal. In one embodiment, a ferromagnetic free layer film has a bias-point magnetization nominally oriented in plane of the film thereof, in a first direction at an angle θfb with respect to a longitudinal axis being defined as the intersection of the plane of deposition of the free layer and the plane of the ABS. A ferromagnetic reference layer film has a bias-point magnetization nominally oriented in a plane of the film thereof, in a second direction at angle θrb with respect to said longitudinal axis that is not orthogonal to the said first direction.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Abutted junction GMR read head with an improved hard bias layer and a method for its fabrication

InactiveUS7016165B2Improved coercivityImprove squarenessNanomagnetismMagnetic measurementsMagnetic characteristicSpin valve

A method for forming a spin-valve type abutted junction GMR sensor element with a thinner hard magnetic longitudinal bias layer having significantly improved magnetic properties in the junction region and a spin-valve type abutted junction GMR sensor element with a thinner hard magnetic longitudinal bias layer having significantly improved magnetic properties in the junction region fabricated according to that method.

Owner:HEADWAY TECH INC

CPP GMR/TMR structure providing higher dR

InactiveUS7408749B2Eliminates oxygen migrationAvoid performanceNanomagnetismNanoinformaticsTunnel junctionPhysics

A current perpendicular to plane (CPP) sensor having FeN in their free and pinned layers. A tunnel junction sensor (TMR) according to the present invention can have a MgO barrier layer, and a CPP GMR sensor according to the present invention can have a Cr spacer layer.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com