Patents

Literature

64results about How to "Uniform pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

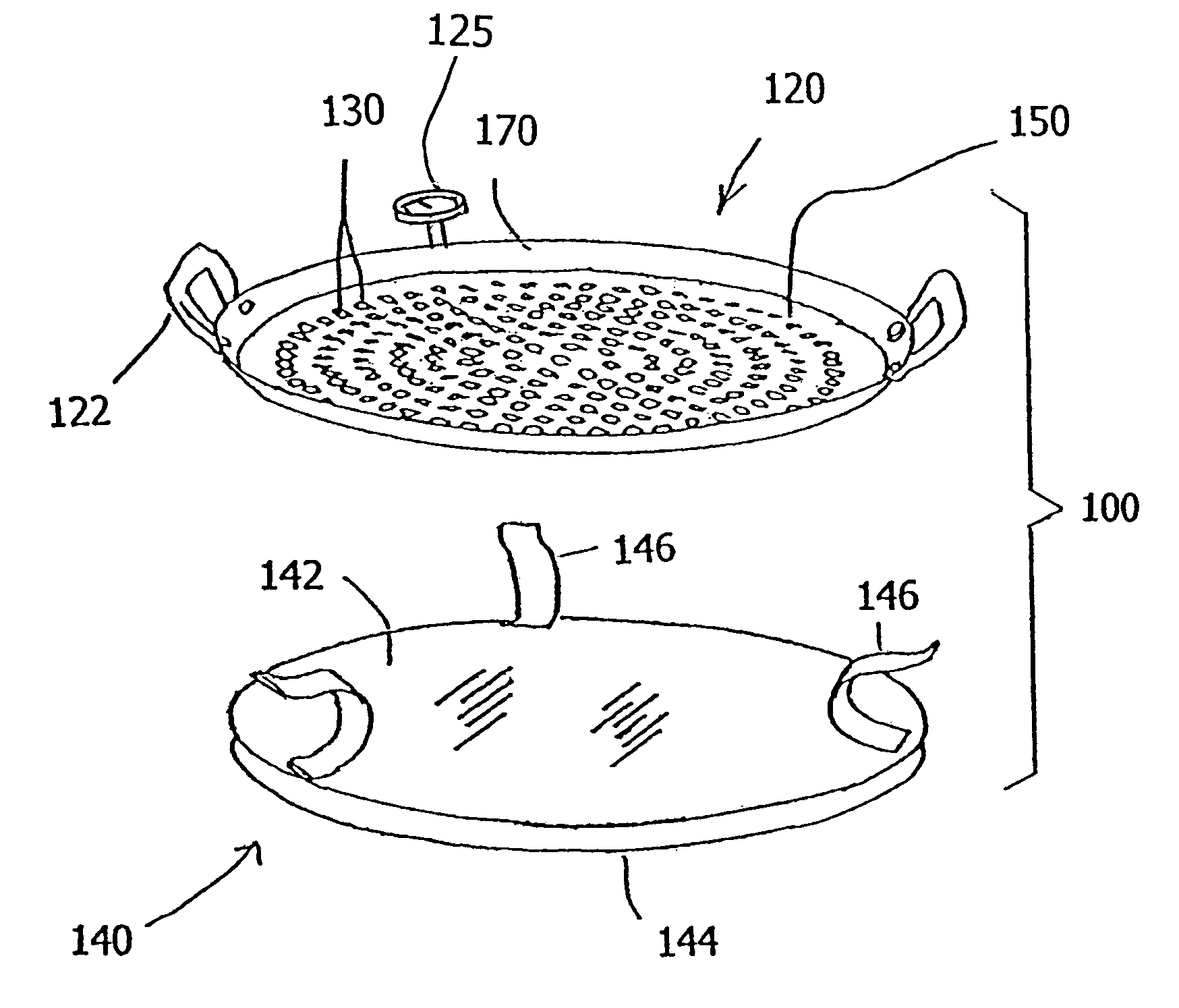

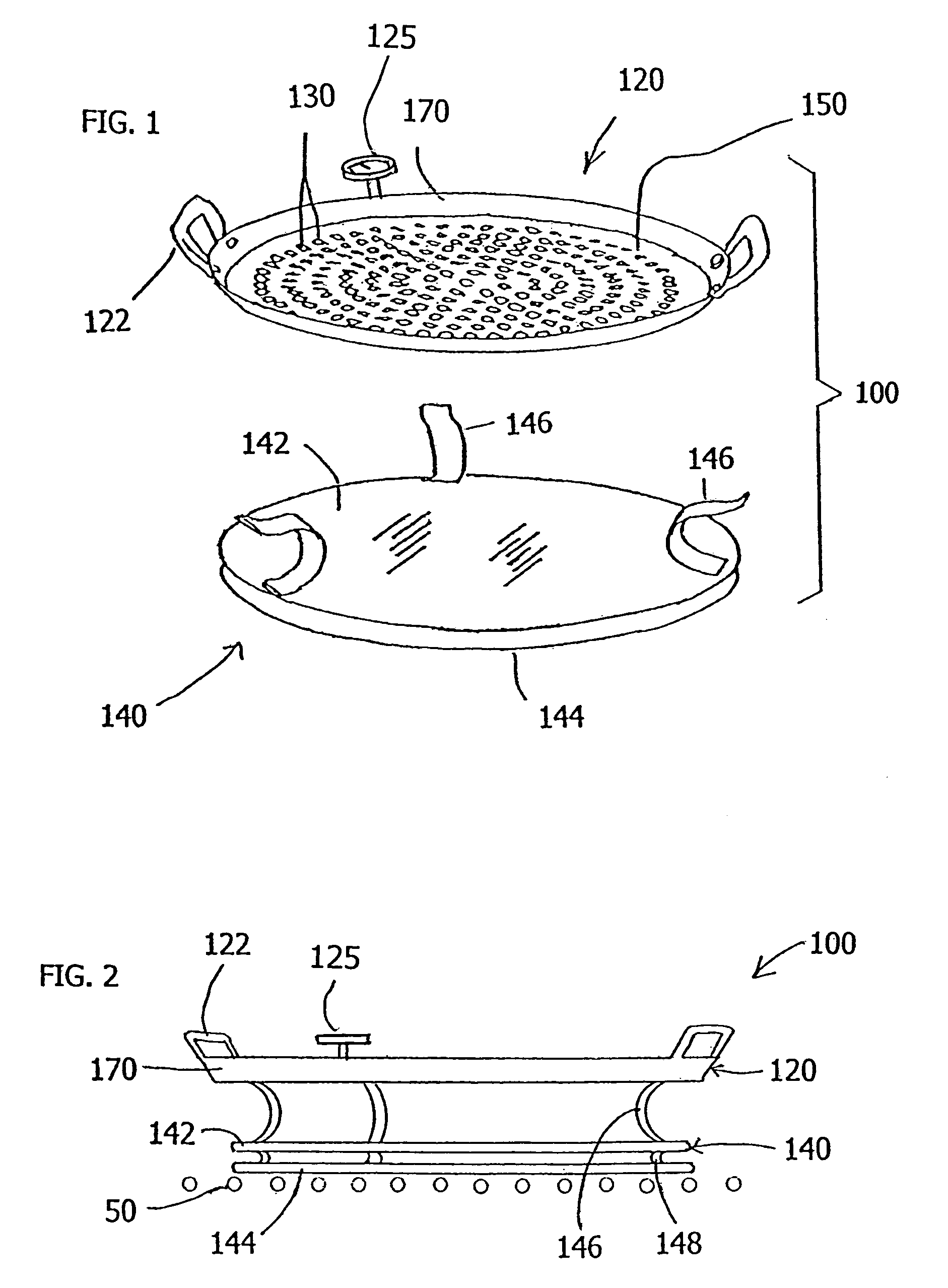

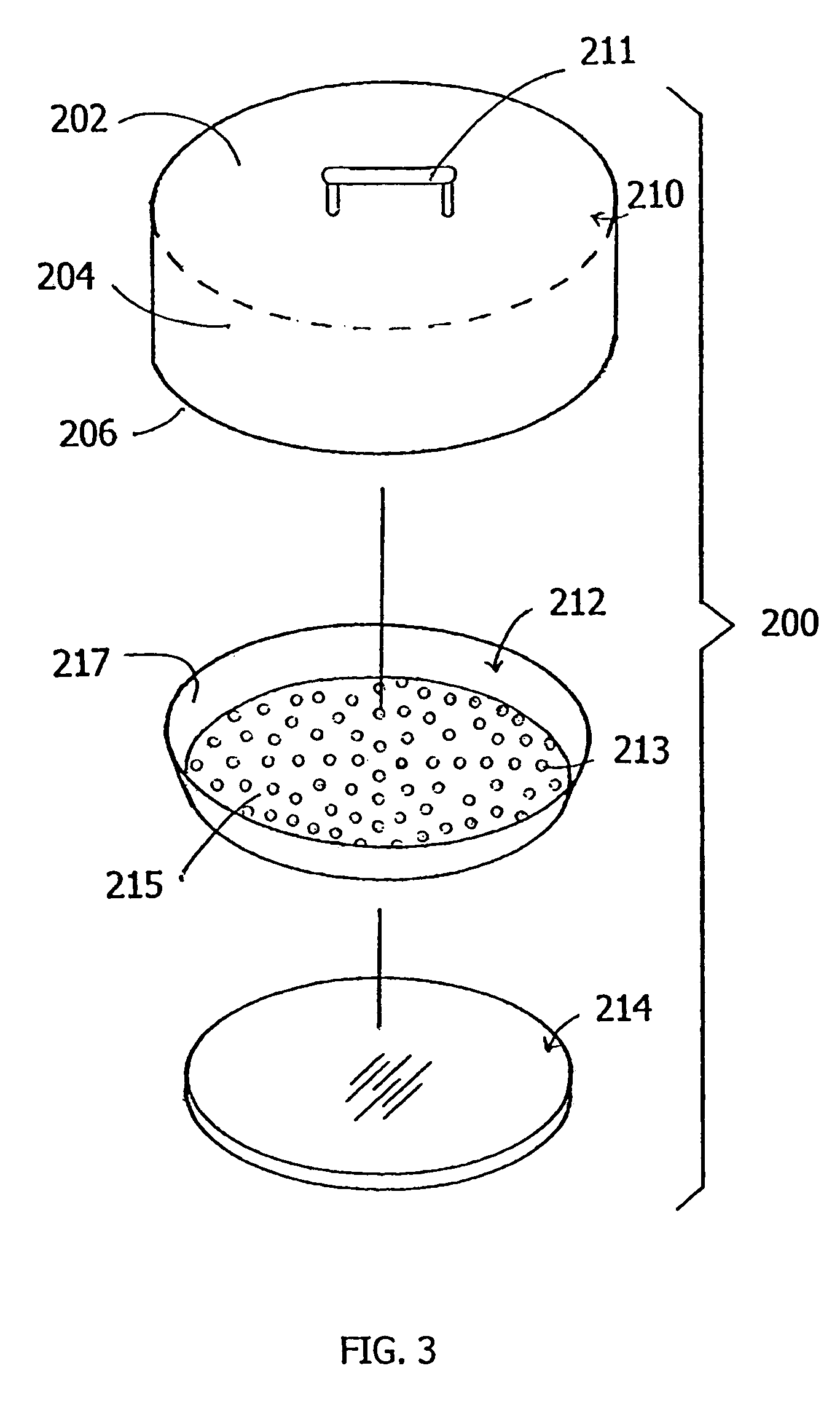

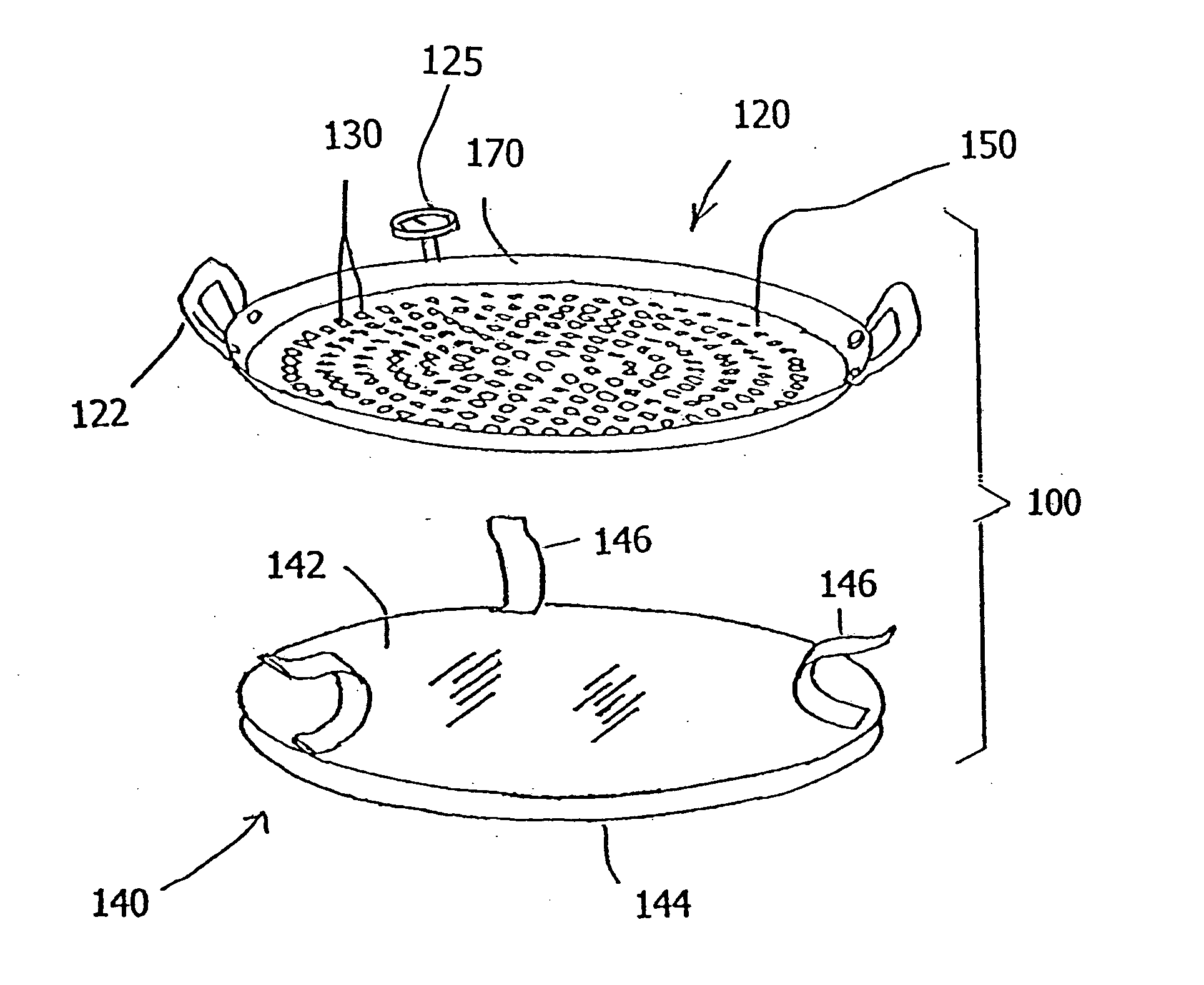

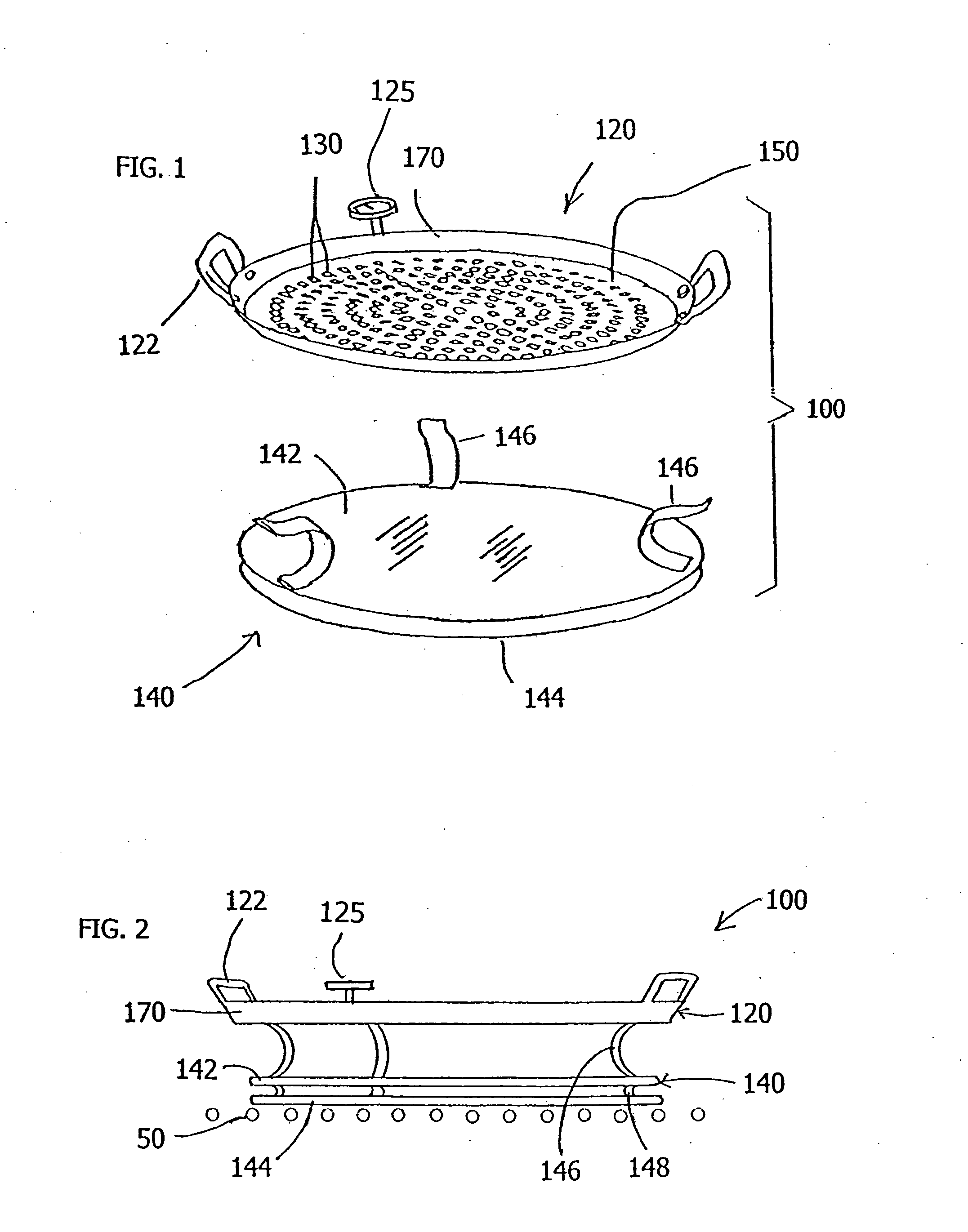

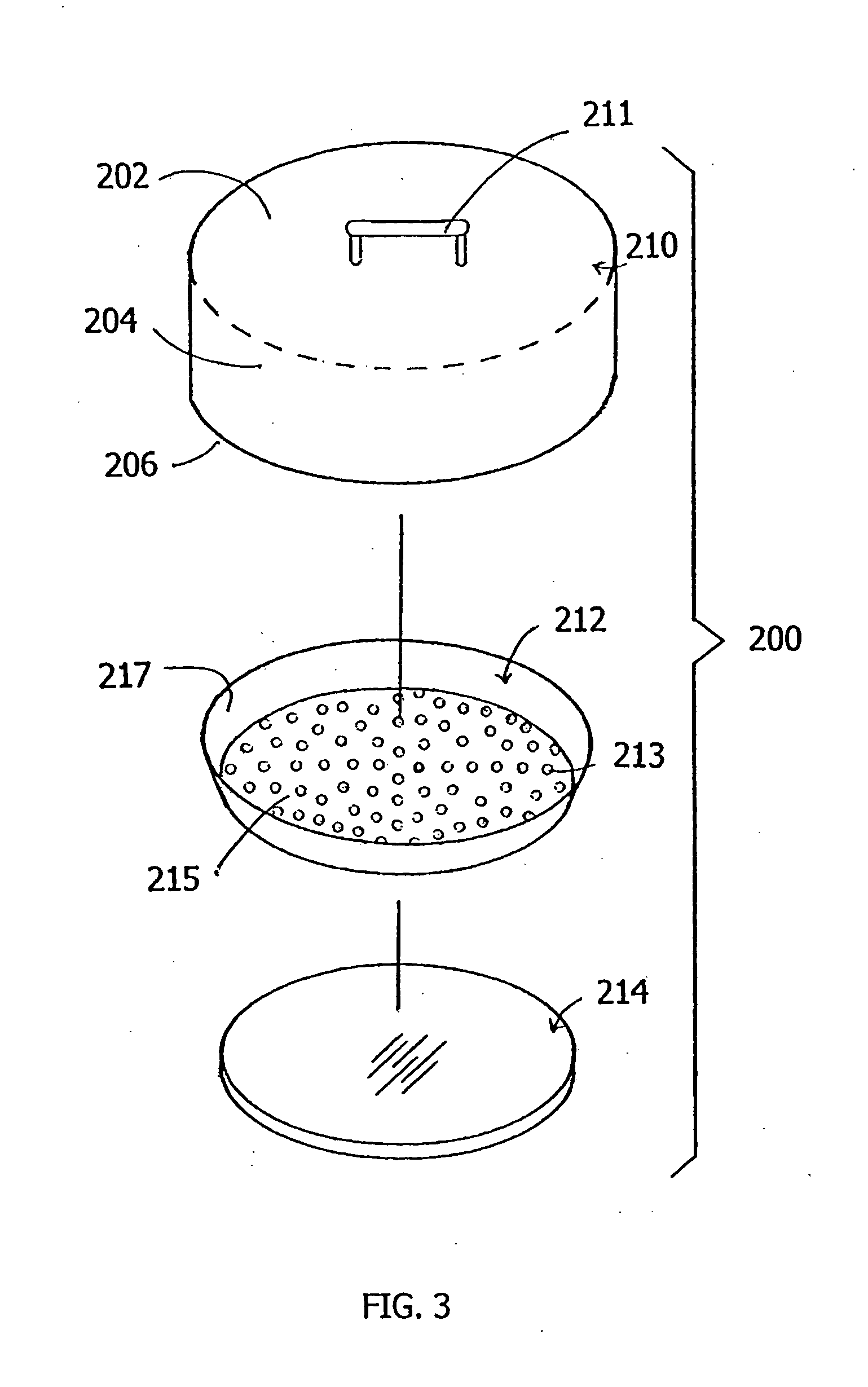

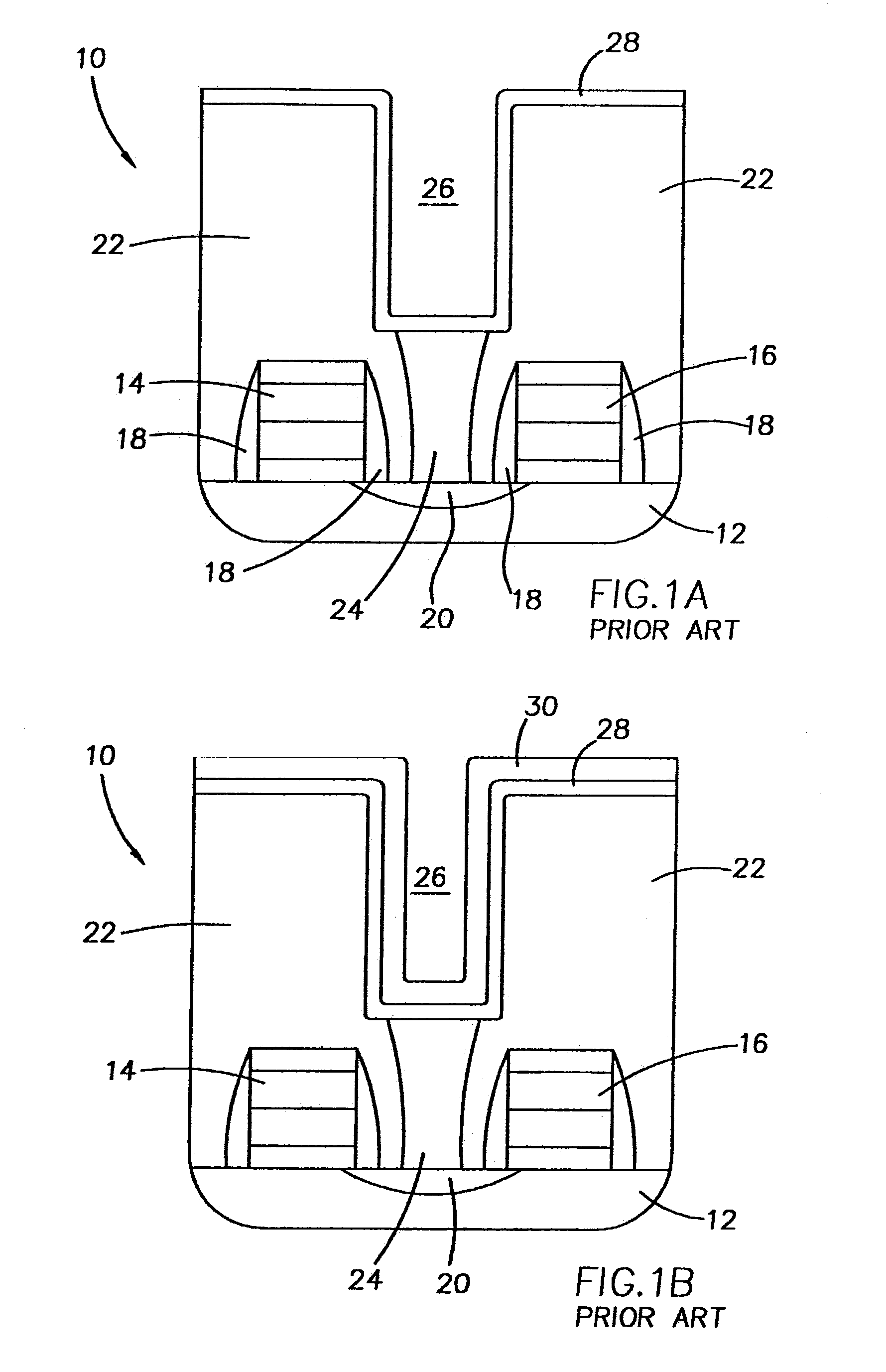

Kit, apparatus and method for use in cooking over an intense heat source

InactiveUS7219663B2Firm supportModerates being transferredDomestic stoves or rangesLiquid heating fuelEngineeringHeat shield

A portable cooking kit, apparatus and method is usable for moderating heat from an intense heat source, such as an outdoor grill or 1. The apparatus includes a food support member, including a perforated panel surrounded by a rim. The food support member rests on top of a heat shield made from a heat-tolerant material. During use, the heat shield is stably suspended over direct, intense heat from a heat source. The food to be cooked is placed on the food support member, and the food support member may then be placed on top of the heat shield. By buffering the direct heat from the heat source, the heat shield allows food placed on the food support member to cook, but protects the underside of the food from becoming scorched. Optionally, a dome-shaped cover may be used to cover both the food support member and the heat shield.

Owner:ISLANDER INNOVATIONS

Kit, apparatus and method for use in cooking over an intense heat source

InactiveUS20050051157A1Firm supportModerates being transferredDomestic stoves or rangesLiquid heating fuelEngineeringIngested food

A portable cooking kit, apparatus and method is usable for moderating heat from an intense heat source, such as an outdoor grill or camprife. The apparatus includes a food support member, including a perforated panel surrounded by a rim. The food support member rests on top of a heat shield made from a heat-tolerant material. During use, the heat shield is stably suspended over direct, intense heat from a heat source. The food to be cooked is placed on the food support member, and the food support member may then be placed on top of the heat shield. By buffering the direct heat from the heat source, the heat shield allows food placed on the food support member to cook, but protects the underside of the food from becoming scorched. Optionally, a dome-shaped cover may be used to cover both the food support member and the heat shield.

Owner:ISLANDER INNOVATIONS

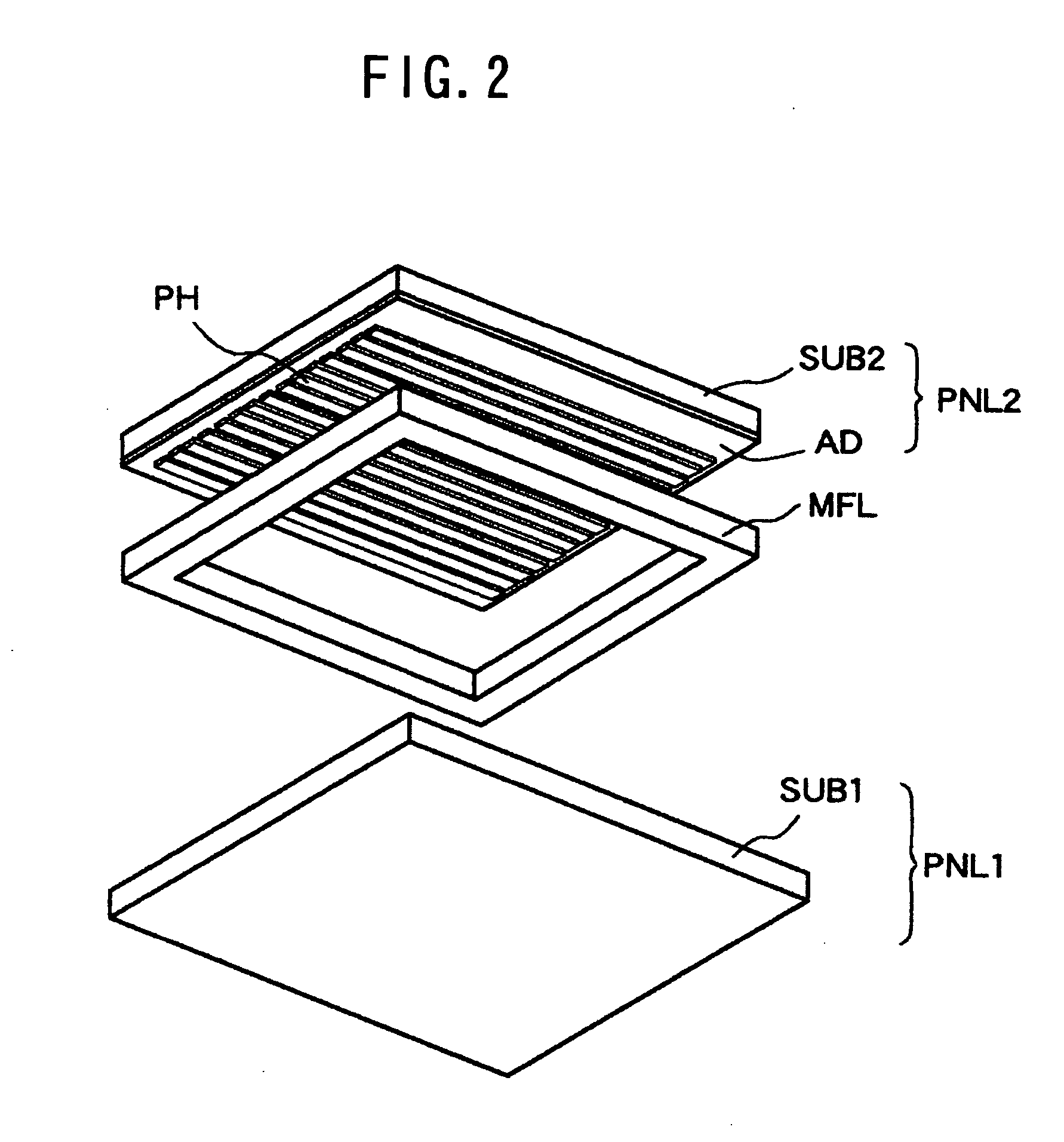

Touch panel

InactiveUS20140041999A1Increase awarenessUniform patternContact surface shape/structureInput/output processes for data processingTouchpadEngineering

Disclosed herein is a touch panel including a transparent substrate, an electrode formed to have a mesh pattern on the transparent substrate, and a wiring formed to have a zigzag pattern on the transparent substrate, having first and second peaks alternately continued in a length direction, and connected to the electrode. Since the electrode and the wiring are formed to have a uniform pattern overall, the electrode and the wiring can be disposed in an active region of the touch panel, and thus, a bezel region can be reduced.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

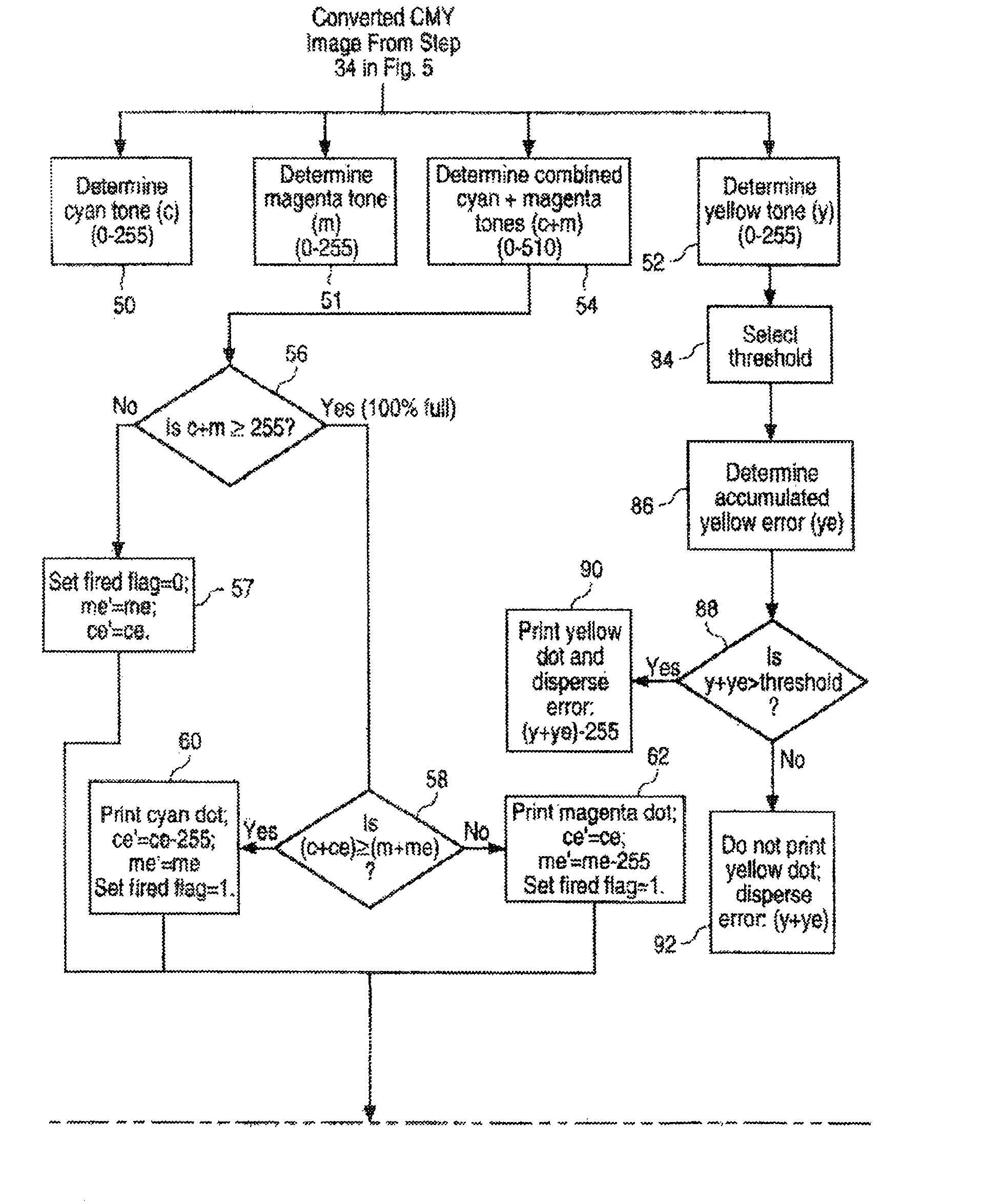

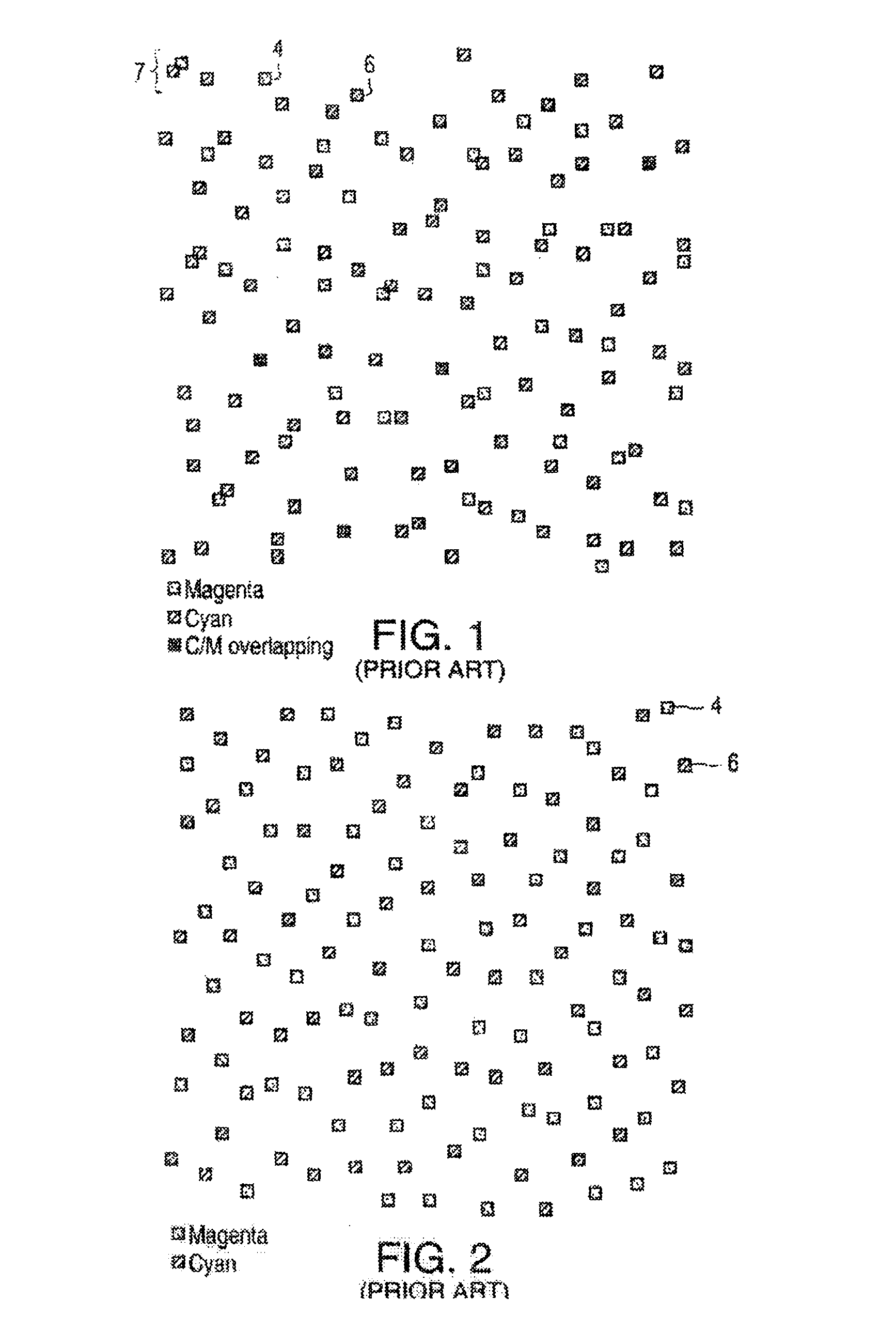

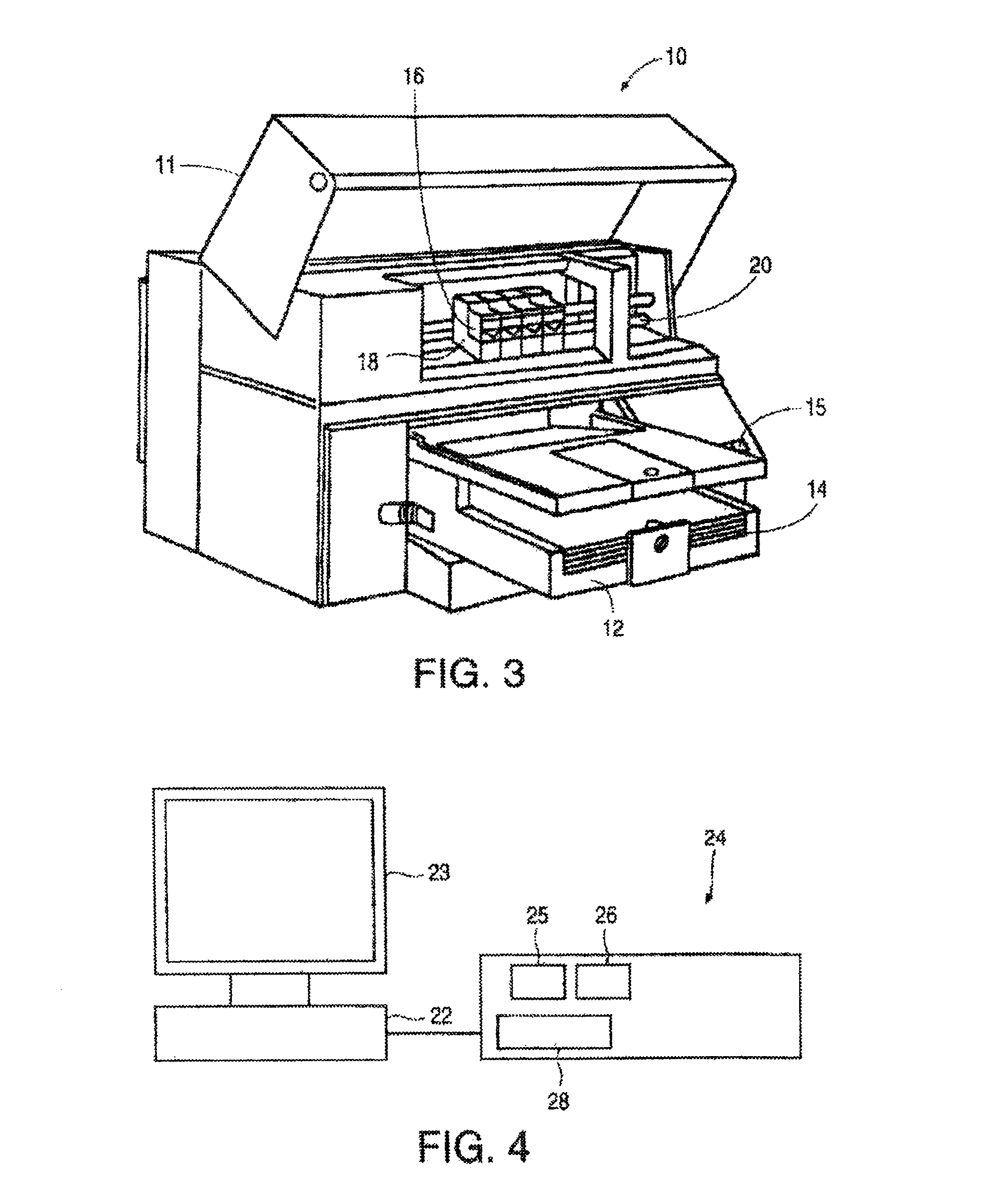

Tone dependent plane dependent error diffusion halftoning

InactiveUS6870644B2Avoid cakingAvoid unintentional overlappingImage enhancementDigitally marking record carriersError diffusionColor plane

Tone dependent plane dependent error diffusion halftoning takes into account multiple color planes, such as cyan and magenta, when determining the placement of a dot in any of the color planes. The combined tones of the correlated color planes is used to determine the threshold levels against which the combined tones and the accumulated errors for the correlated color planes is compared. Further, tone dependent error weightings are determined based on the combined tones of the correlated color planes. The tone dependent error weightings are used to diffuse the final accumulated errors for each color plane. A prerendered mid-tone bitmap may be used to break up any structured patterns that occur in the mid-tones. Using this technique, printed dots of two or more colors are dispersed so as to avoid noticeable clumping of dots of two or more colors to provide a more uniform pattern and to avoid the unintentional overlapping of colors. This technique can be used to augment any existing error diffusion method.

Owner:HEWLETT PACKARD DEV CO LP

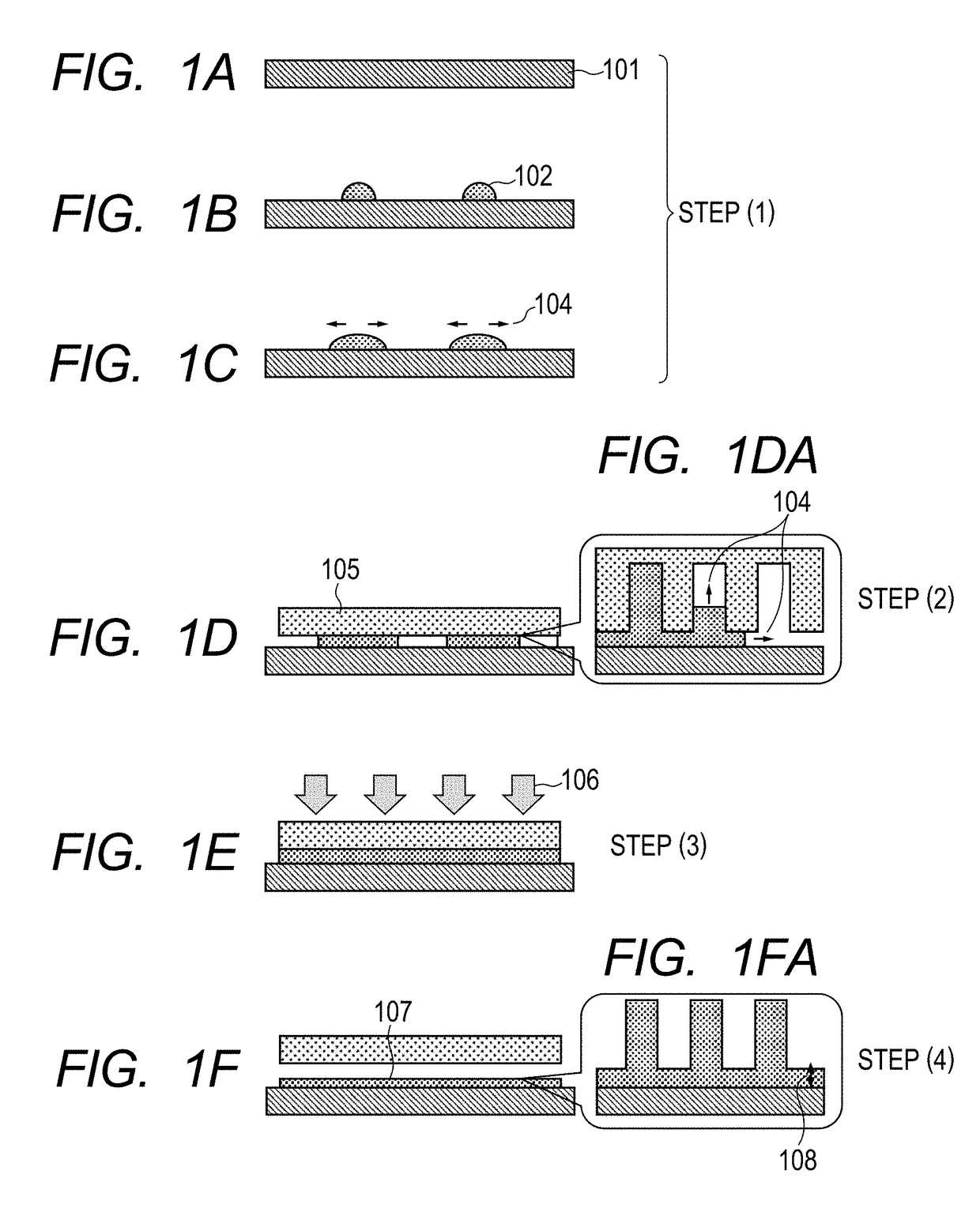

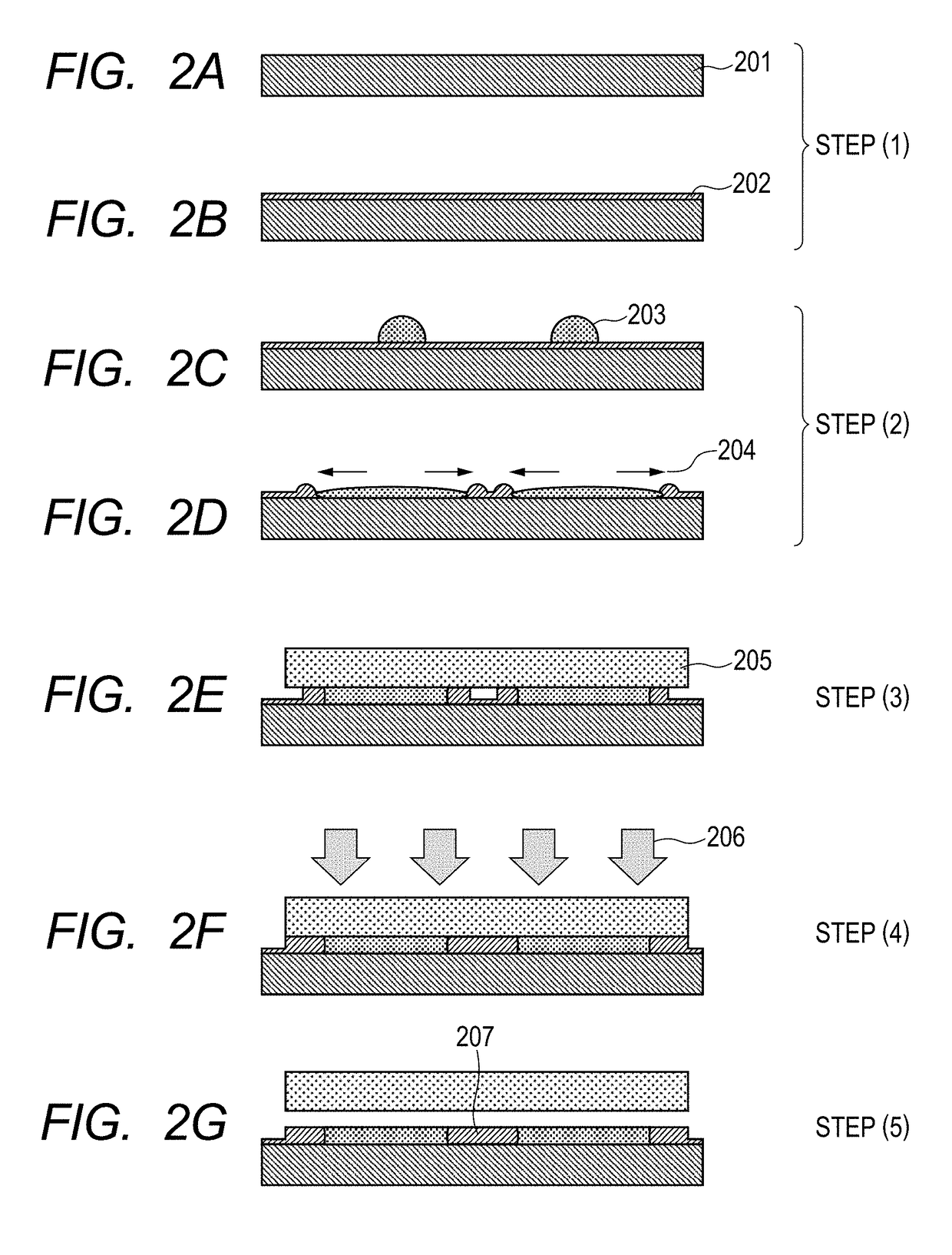

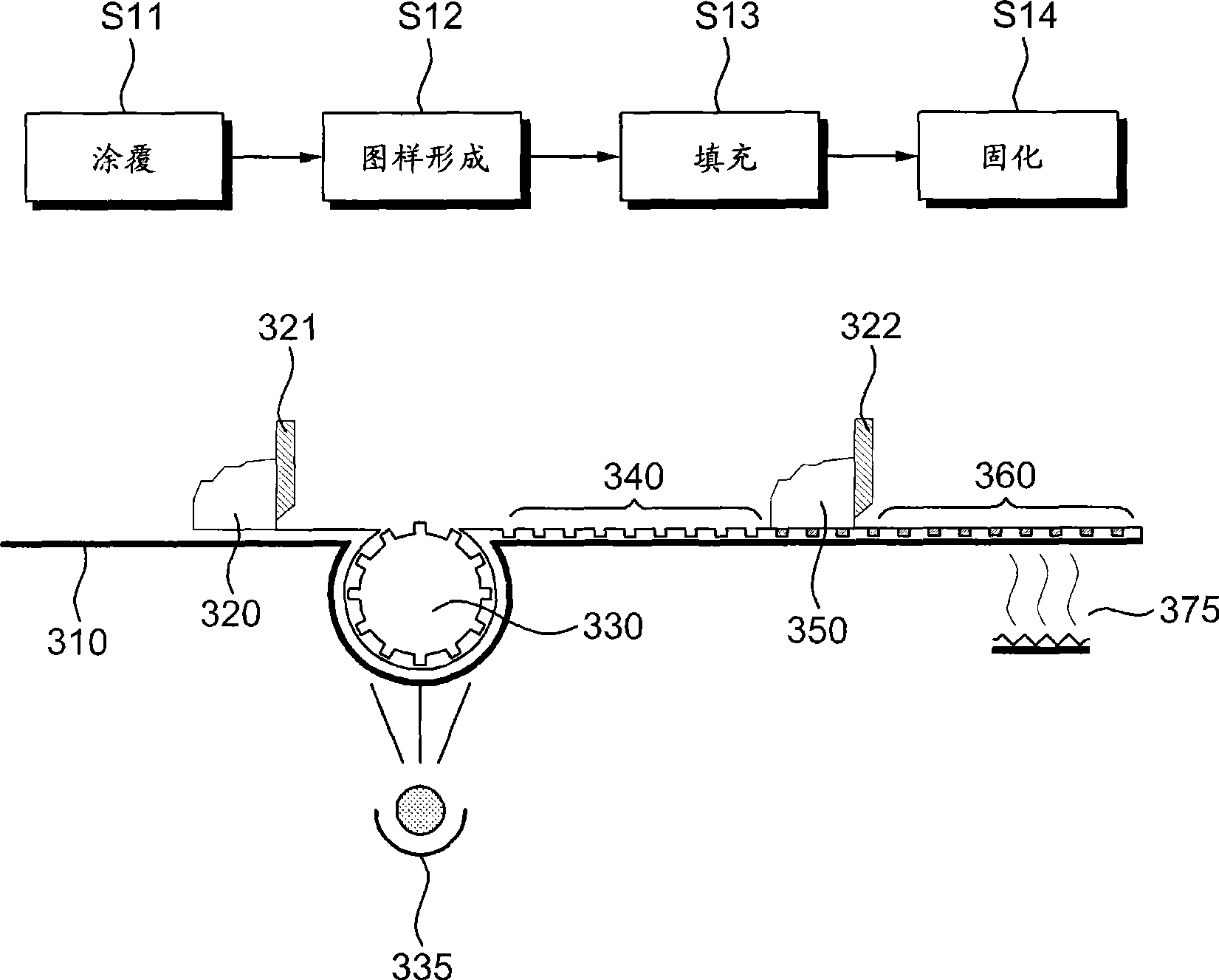

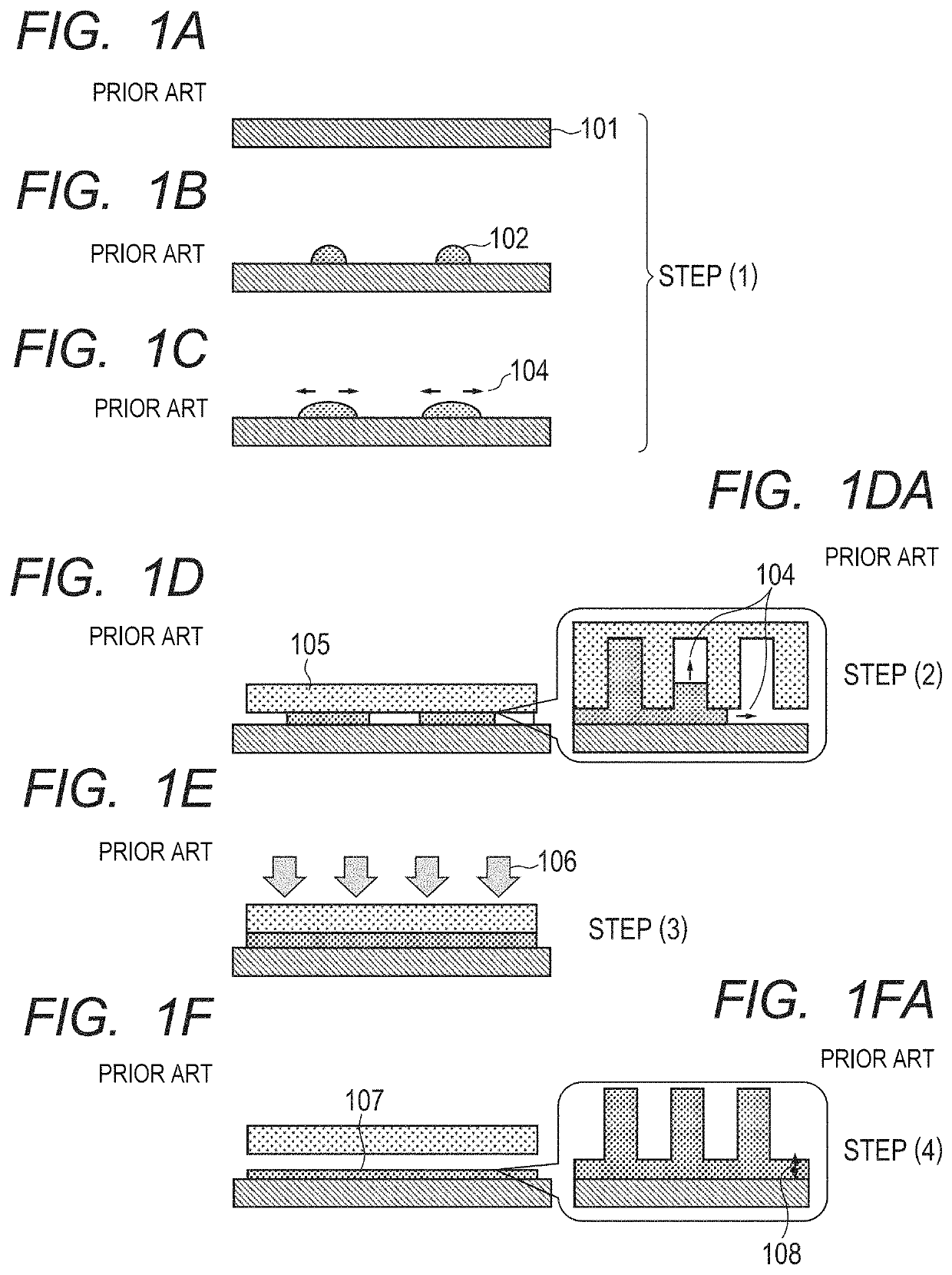

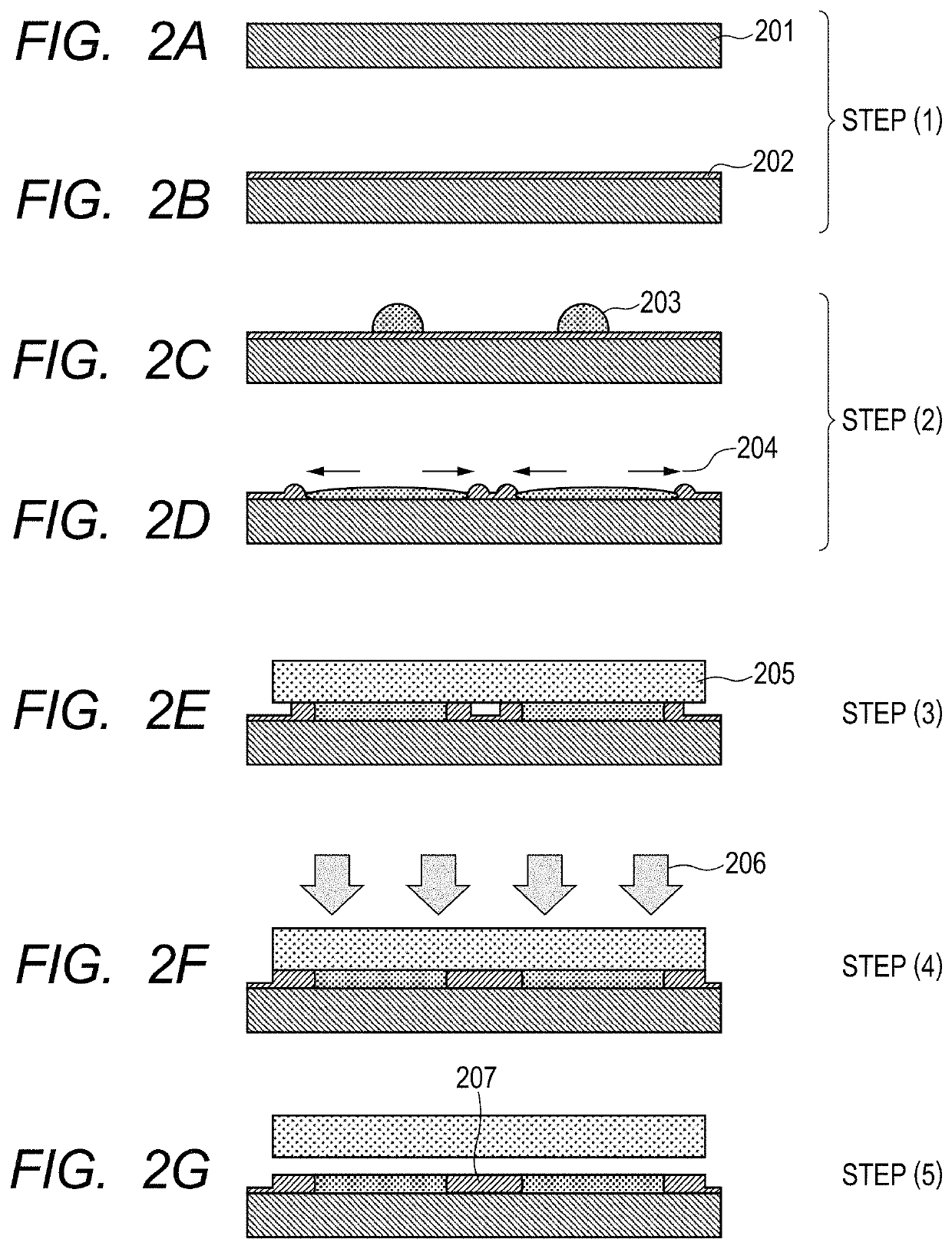

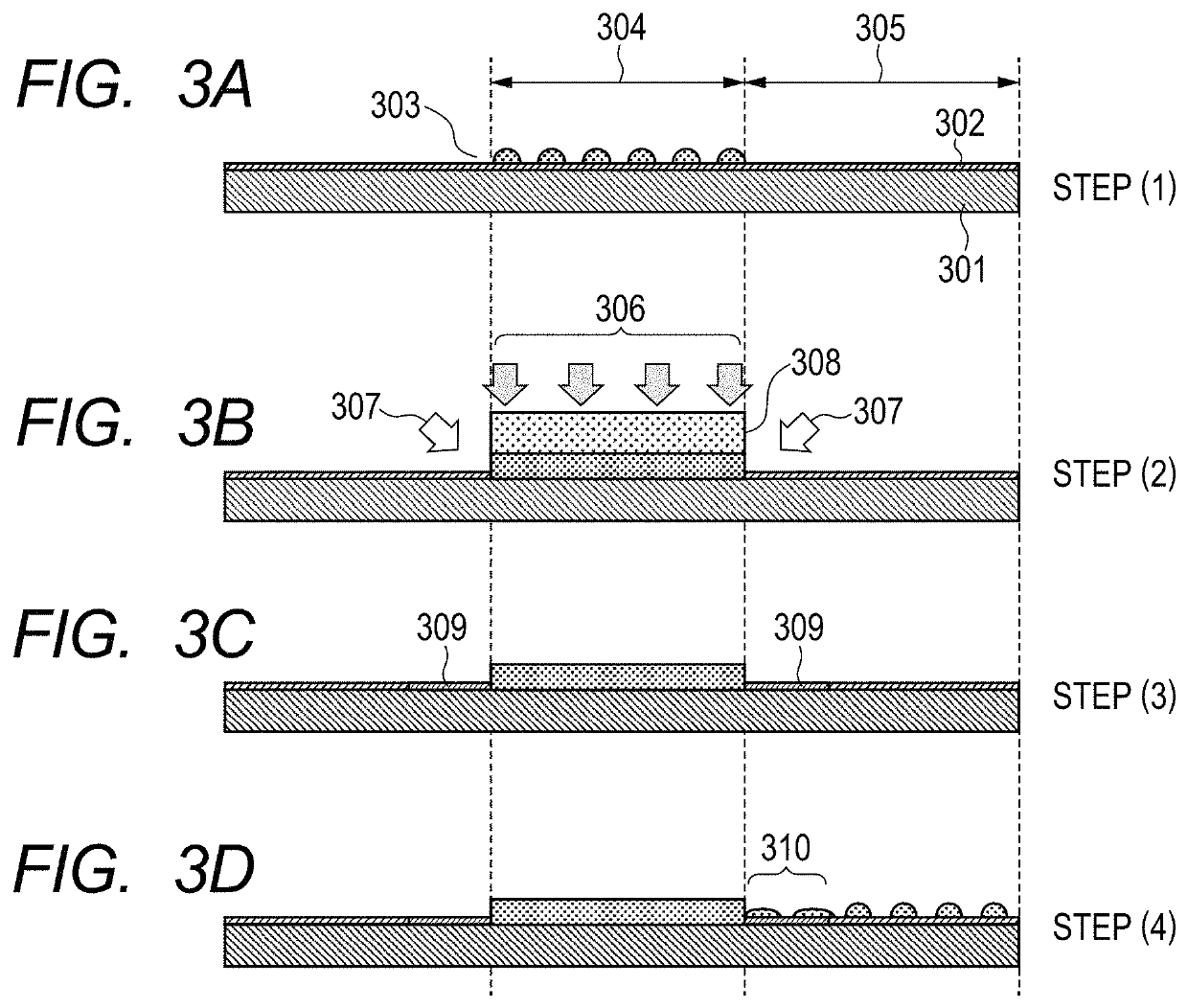

Pattern forming method as well as production methods for processed substrate, optical component, circuit board, electronic component and imprint mold

ActiveUS20170285464A1Improve throughputImprove uniformityPhotomechanical apparatusOptical articlesElectronic componentSolvent

A pattern is formed on a substrate with forming a layer of a curable composition (A1) containing a component (a1) serving as a polymerizable compound and a component (d1) serving as a solvent on a surface of the substrate, then dispensing droplets of a curable composition (A2) containing at least a component (a2) serving as a polymerizable compound dropwise discretely onto the layer of the curable composition, subsequently sandwiching a mixture layer of the curable composition (A1) and the curable composition (A2) between a mold and the substrate, then irradiating the mixture layer with light to cure the layer, and releasing the mold from the mixture layer after the curing.

Owner:CANON KK

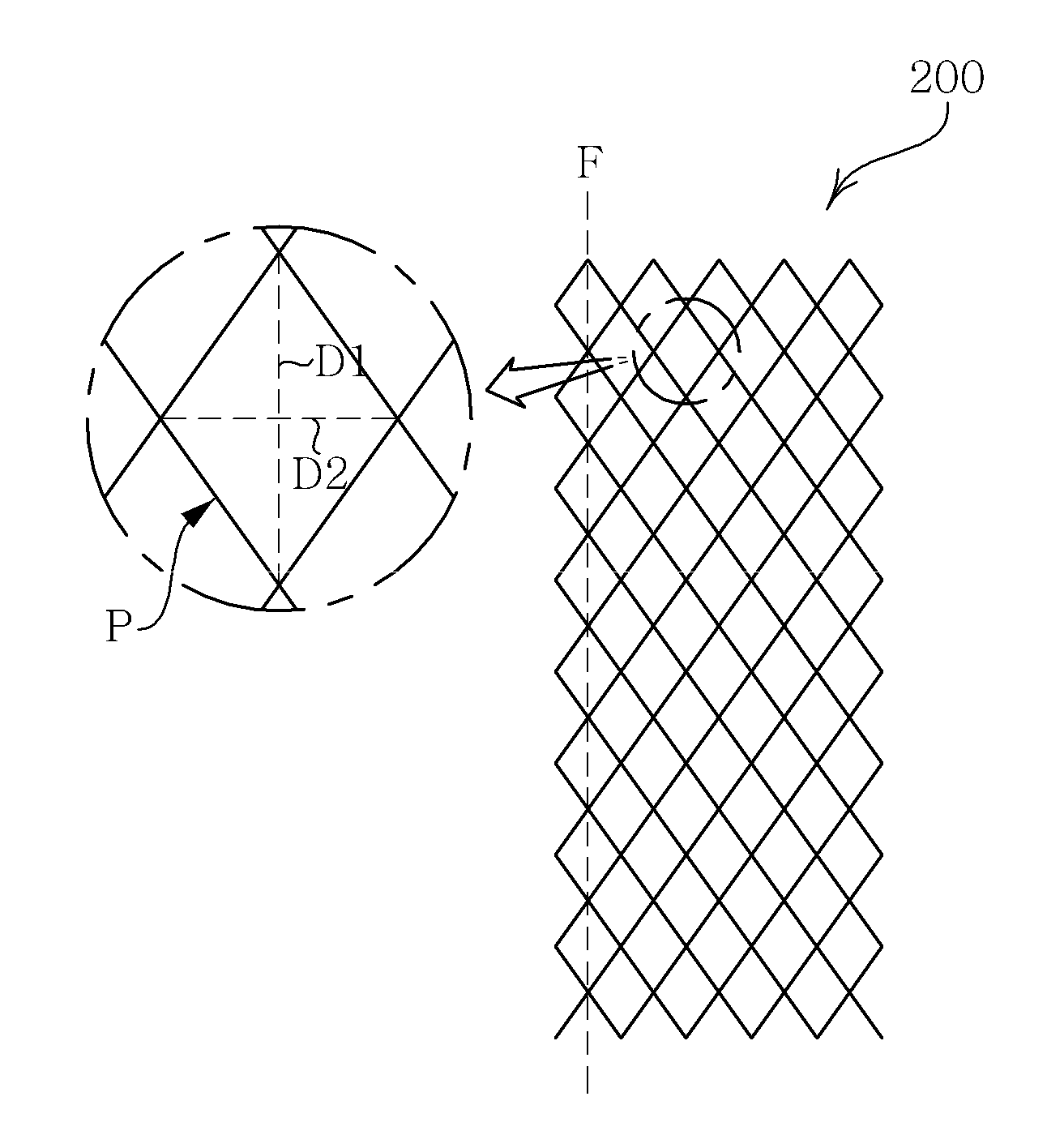

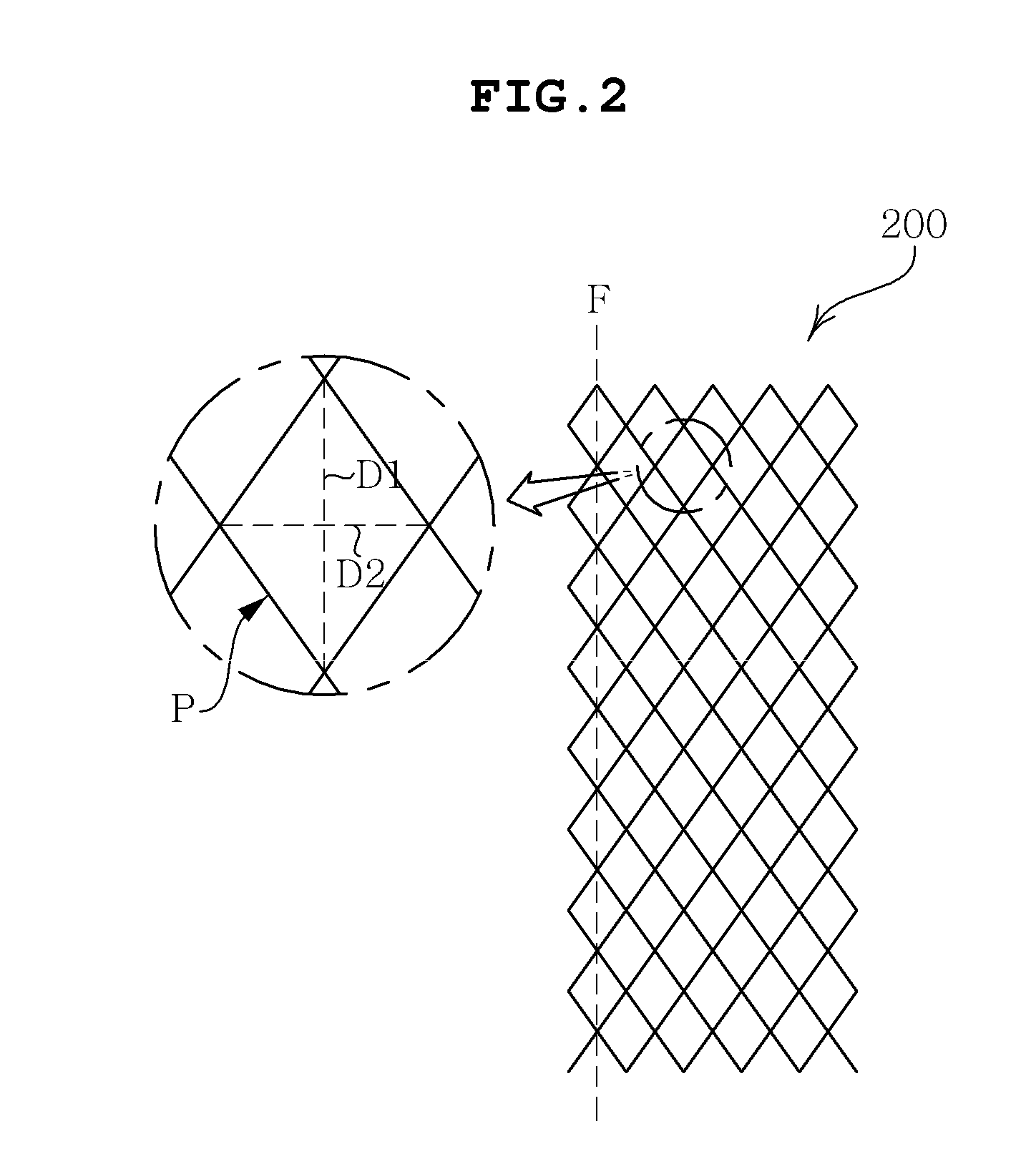

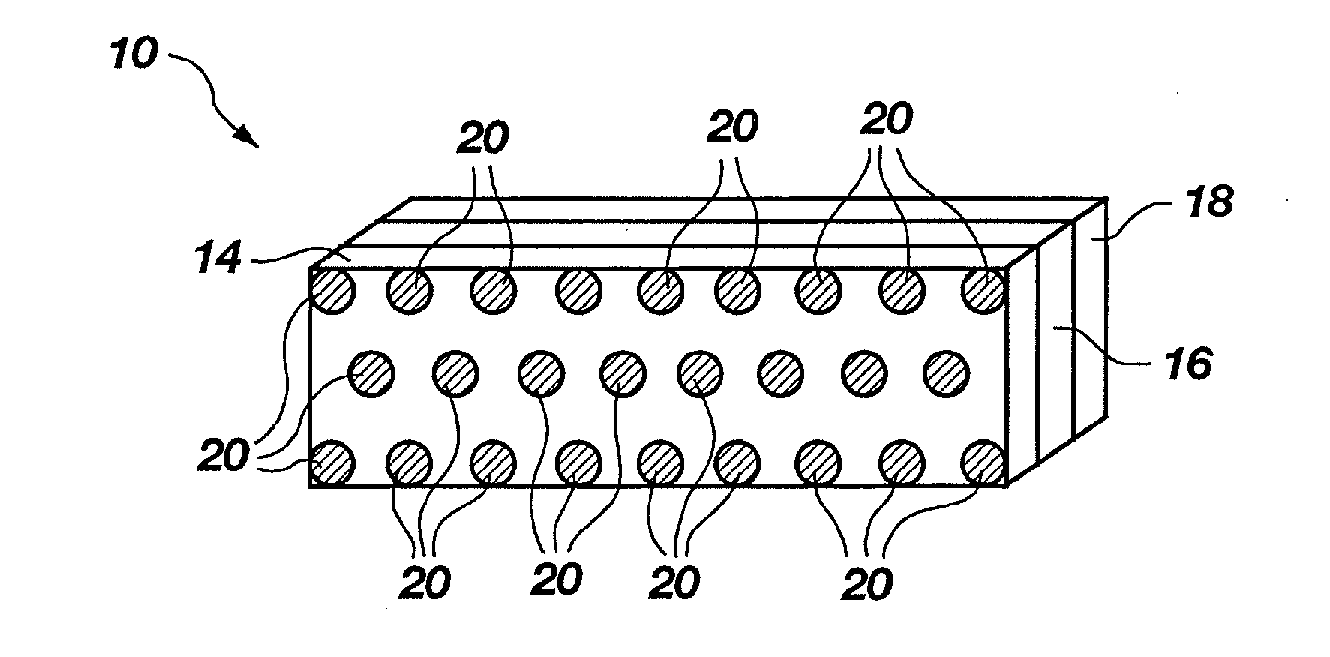

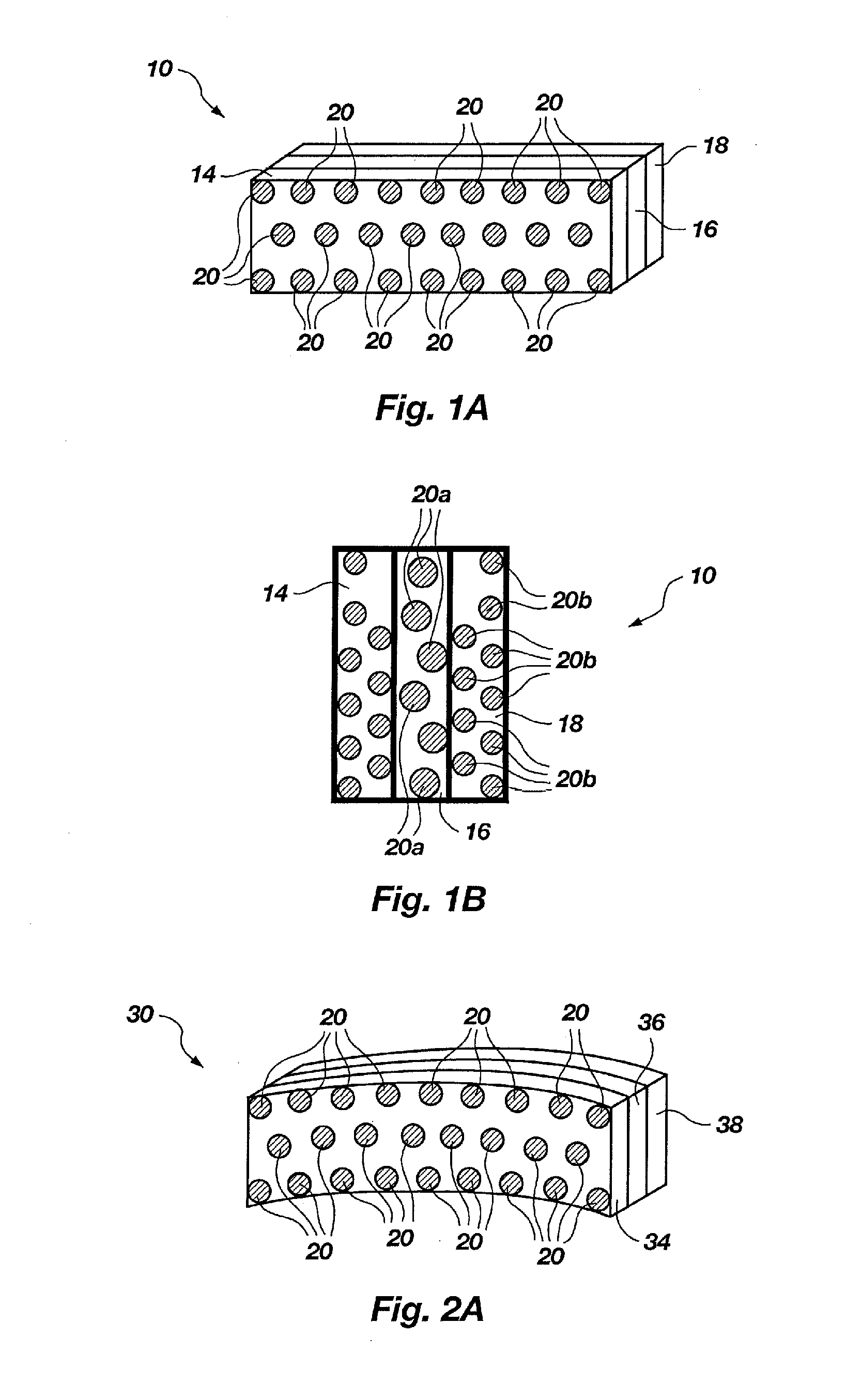

Superbrasvie Tools Containing Uniformly Leveled Superabrasive Particles and Associated Methods

InactiveUS20110293905A1Improve performanceImproved cutting, sawing, or grinding,Pigmenting treatmentPressurized chemical processMetalMaterials science

A superabrasive tools having uniformly leveled superabrasive particles and associated methods are provided. In one aspect, for example, a superabrasive can include a metal matrix configured for bonding superabrasive particles and a plurality superabrasive particles held in the metal matrix at specific positions according to a predetermined pattern, wherein tips of each of the plurality of the superabrasive particles protrude from the metal matrix to a uniform height.

Owner:KINIK

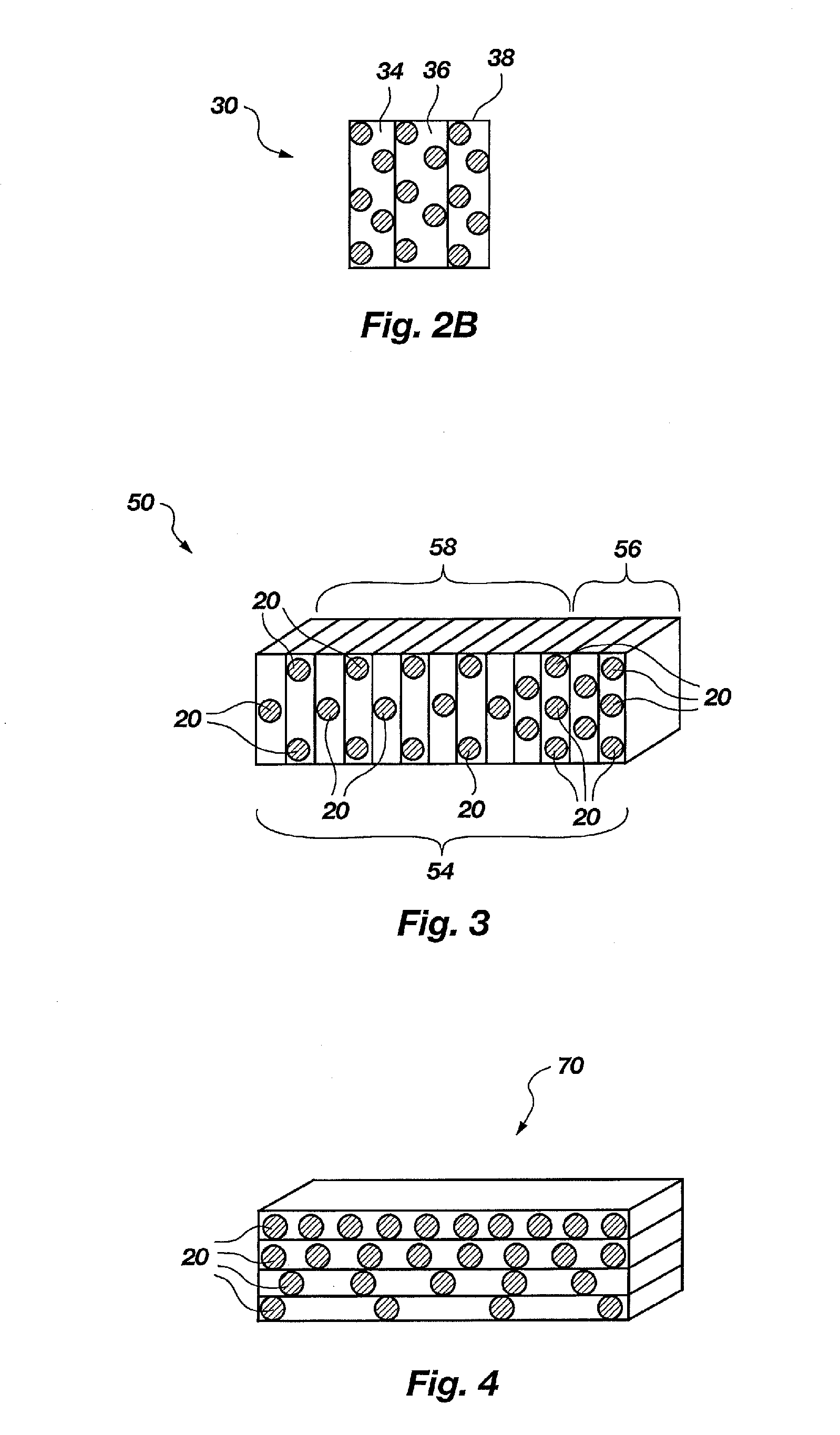

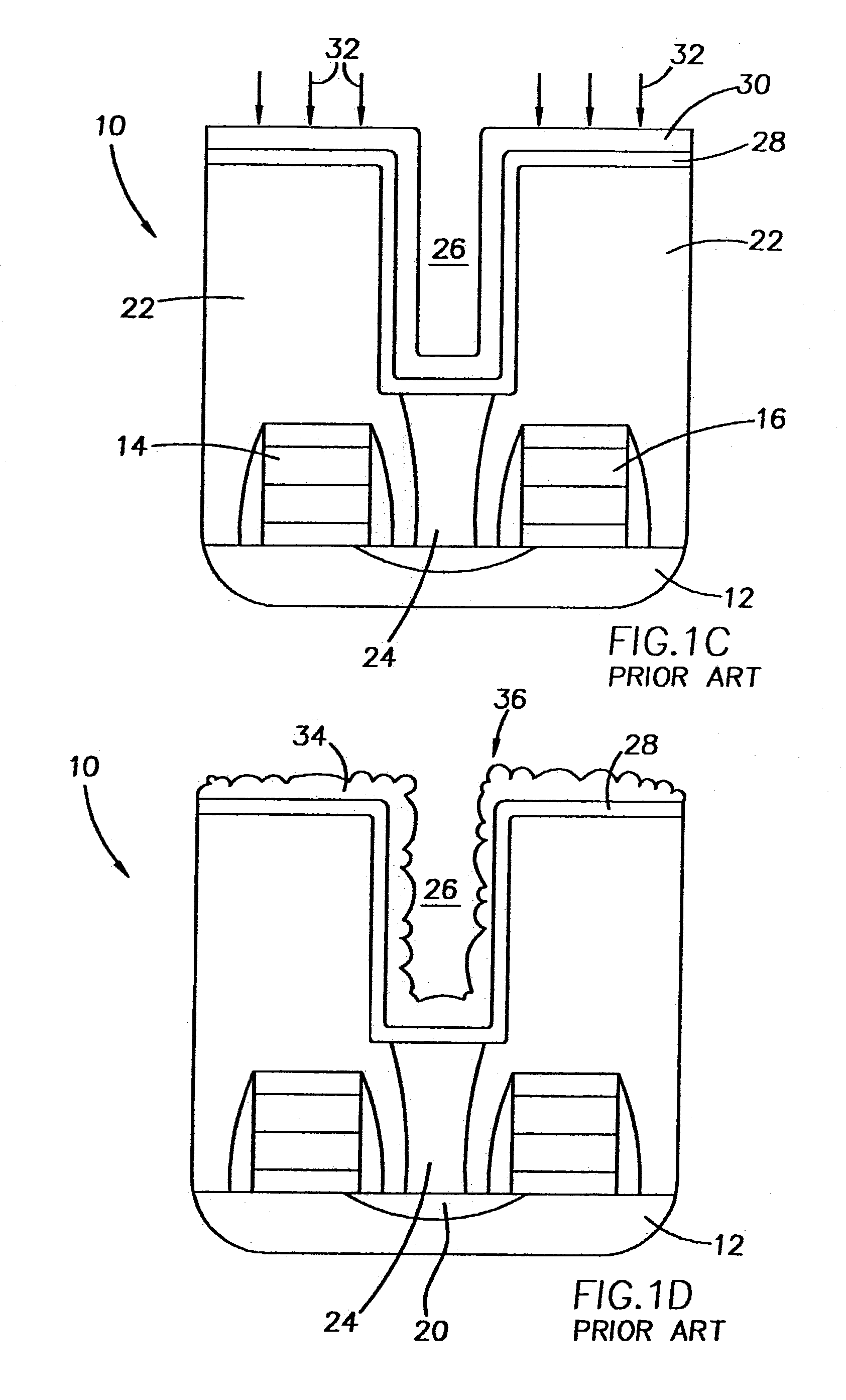

Method for enhancing electrode surface area in DRAM cell capacitors

InactiveUS7148555B2Facilitates fabricationGreat level of controlTransistorNanoinformaticsDislocationSemiconductor

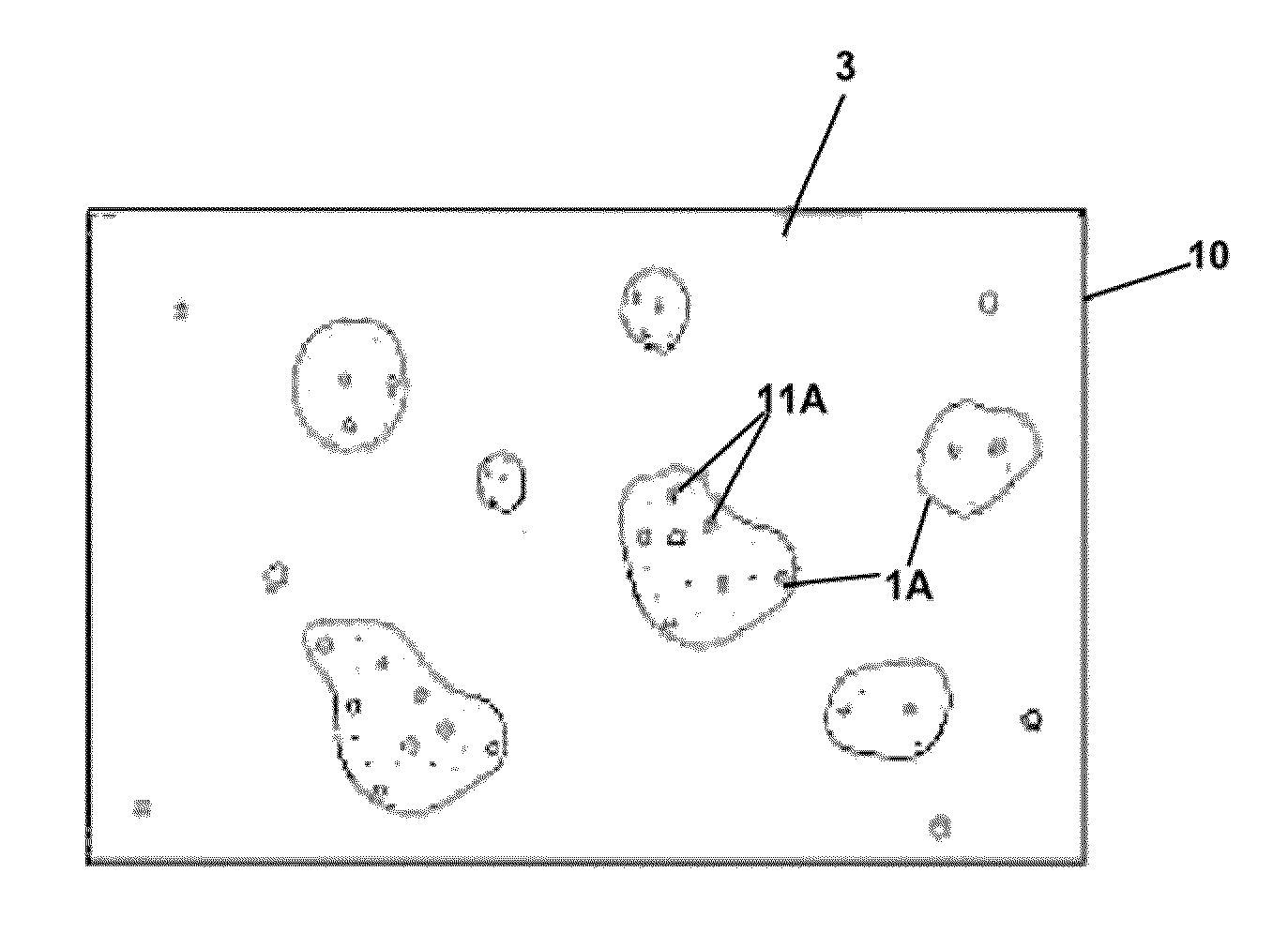

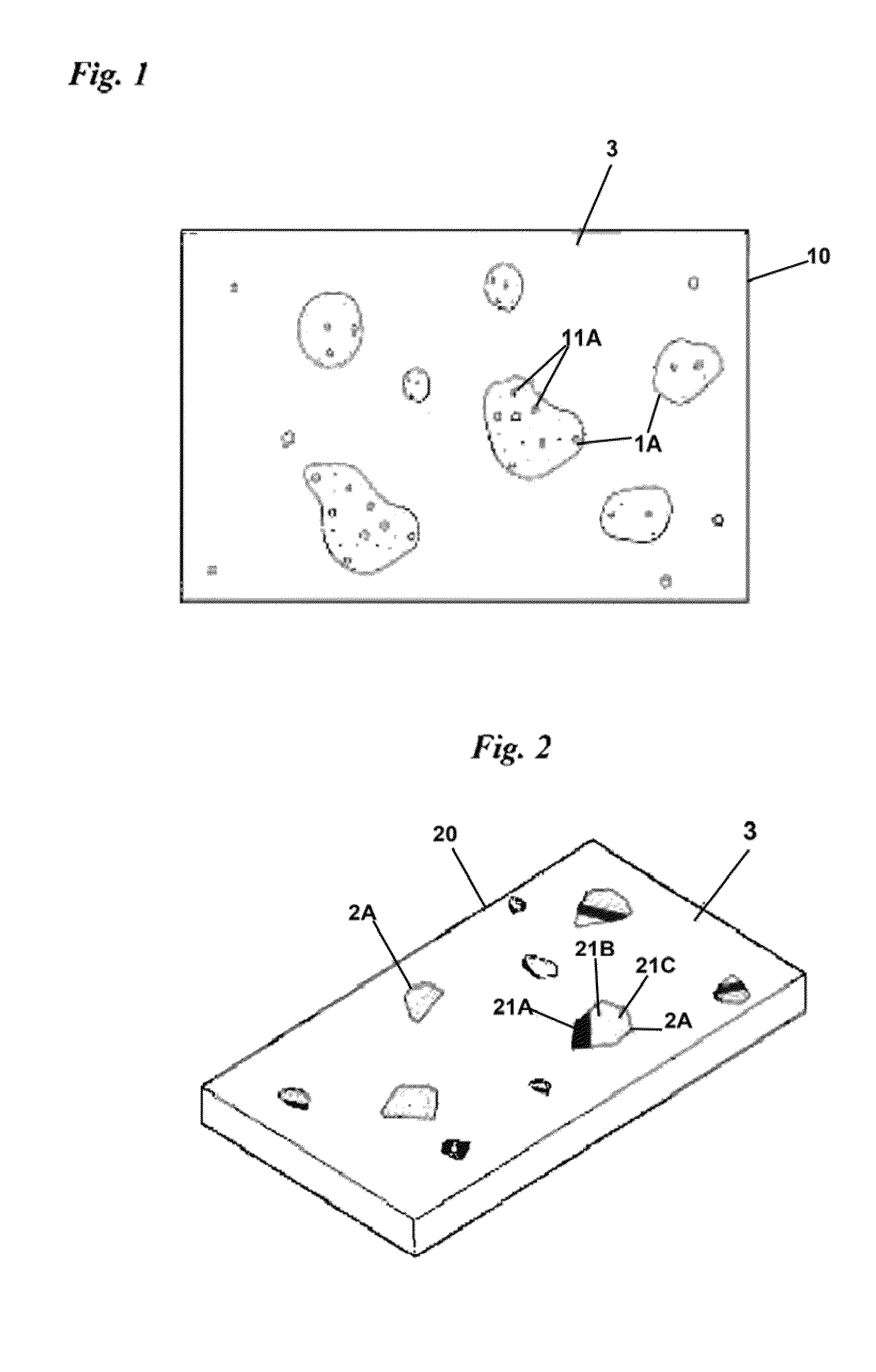

Methods for forming the lower electrode of a capacitor in a semiconductor circuit, and the capacitors formed by such methods are provided. The lower electrode is fabricated by forming a texturizing underlayer and then depositing a conductive material thereover. In one embodiment of a method of forming the lower electrode, the texturizing layer is formed by depositing a polymeric material comprising a hydrocarbon block and a silicon-containing block, over the insulative layer of a container, and then subsequently converting the polymeric film to relief or porous nanostructures by exposure to UV radiation and ozone, resulting in a textured porous or relief silicon oxycarbide film. A conductive material is then deposited over the texturizing layer resulting in a lower electrode have an upper roughened surface. In another embodiment of a method of forming the lower electrode, the texturizing underlayer is formed by depositing overlying first and second conductive metal layers and annealing the metal layers to form surface dislocations, preferably structured as a periodic network. A conductive metal is then deposited in gaseous phase, and agglomerates onto the surface dislocations of the texturizing layer, forming nanostructures in the form of island clusters. The capacitor is completed by depositing a dielectric layer over the formed lower electrode, and forming an upper capacitor electrode over the dielectric layer. The capacitors are particularly useful in fabricating DRAM cells.

Owner:MICRON TECH INC

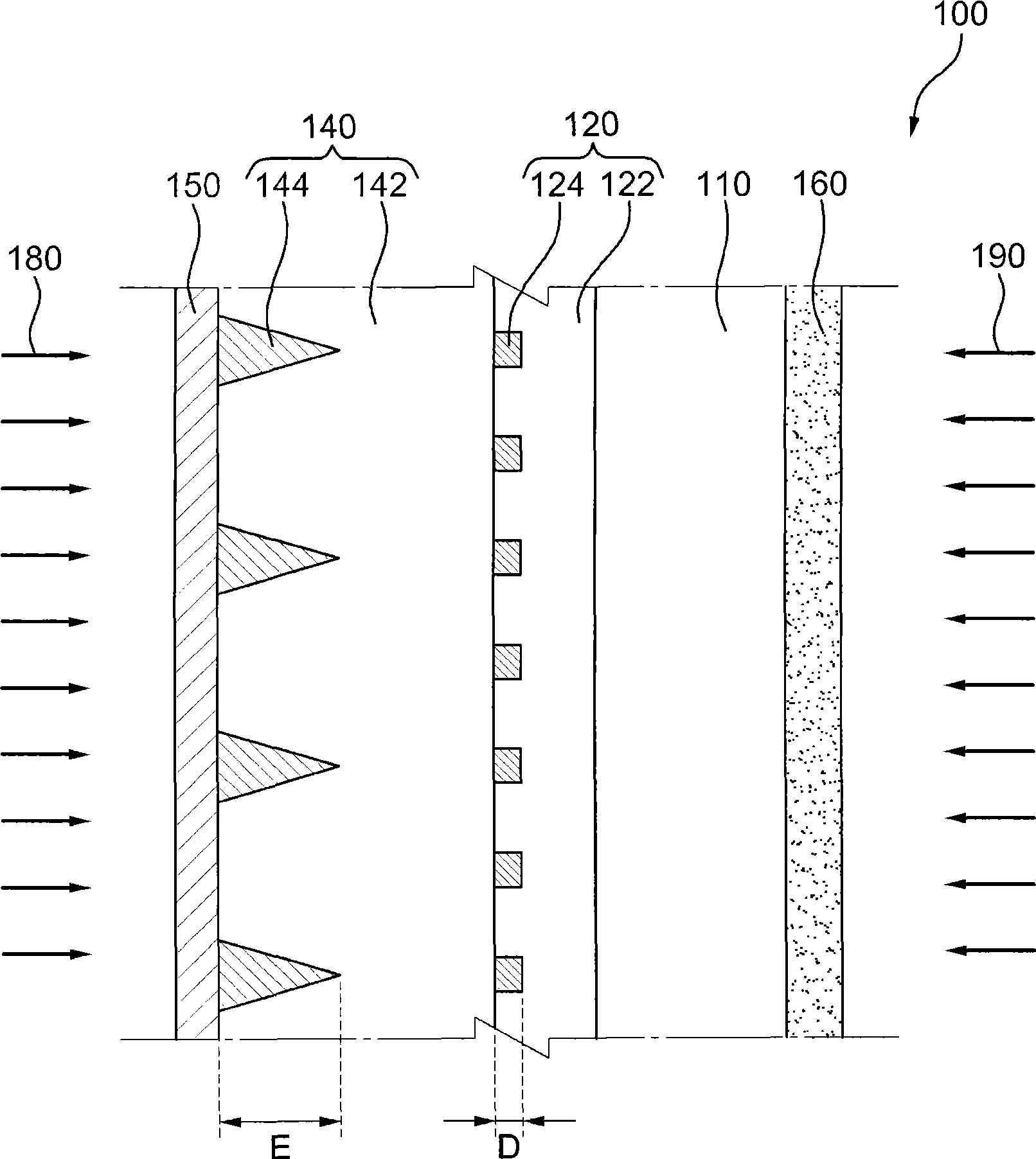

Electromagnetic shielding film for display device, filter having the same, and method of fabricating the same

InactiveCN101441290ARaise the ratioExcellent electromagnetic wave blocking abilityMagnetic/electric field screeningLayered productsDisplay deviceConductive materials

An electromagnetic shielding film for a display device includes a transparent, resinous first base, an intaglio pattern formed on at least one side of the first base, and an electromagnetic shielding pattern containing a conductive material with which the intaglio pattern is filled. A method of fabricating an electromagnetic shielding film for a display device, includes the steps of coating a first curable resin on one surface of a transparent backing, forming an intaglio pattern on the first curable resin using a patterning roll and curing the first curable resin, filling the intaglio pattern with a second curable resin containing a conductive material, and curing the second curable resin.

Owner:SAMSUNG CORNING CO LTD

Alcohol-acid type wrinkled resin and preparing method

InactiveCN101070376AIncrease productionPromote development and utilizationCoatingsPolymer scienceGlycerol

The present invention discloses a kind of alkyd wrinkles resin. The alkyd wrinkles resin comprises linolenic acid, 95% glycerine, phthalic anhydride, adduct, xylene, and diluted solvent. The present invention also discloses the preparation method of the said alkyd wrinkles resin. The present invention avoids the general existing process of high-temperature refining tung oil and many defects of winkles paint brought by adding tung oil, and makes the process of synthesizing winkles paint resin simply and easy to operate, and also saves energy. The resin-prepared winkles paint synthesized by using the present invention, has no necessary to be diluted with benzene before using, which makes it more secure and more environmentally friendly for the use of winkles paint, and meets the overall trend of current development of paints.

Owner:NANJING CHANGJIANG PAINT

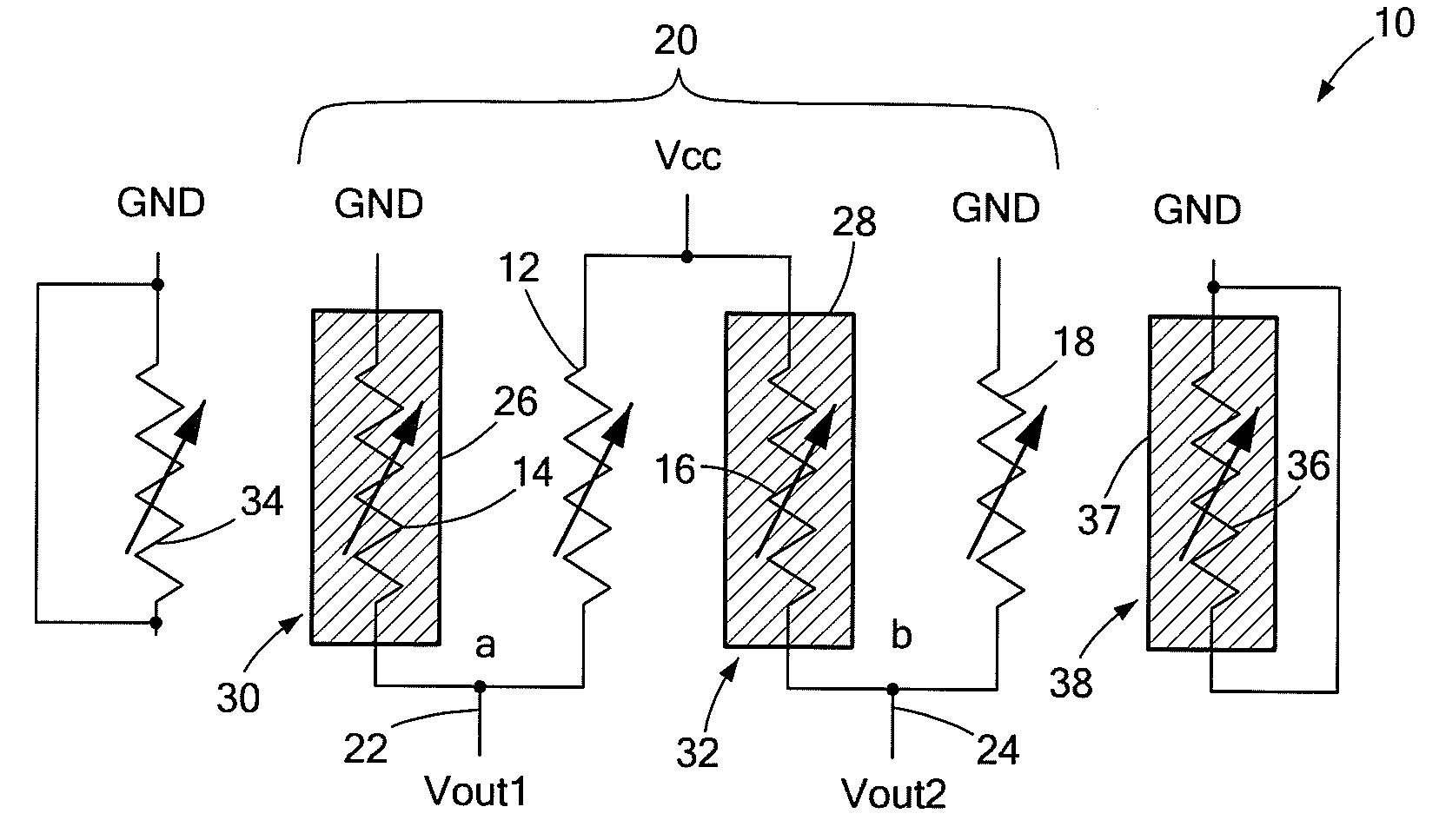

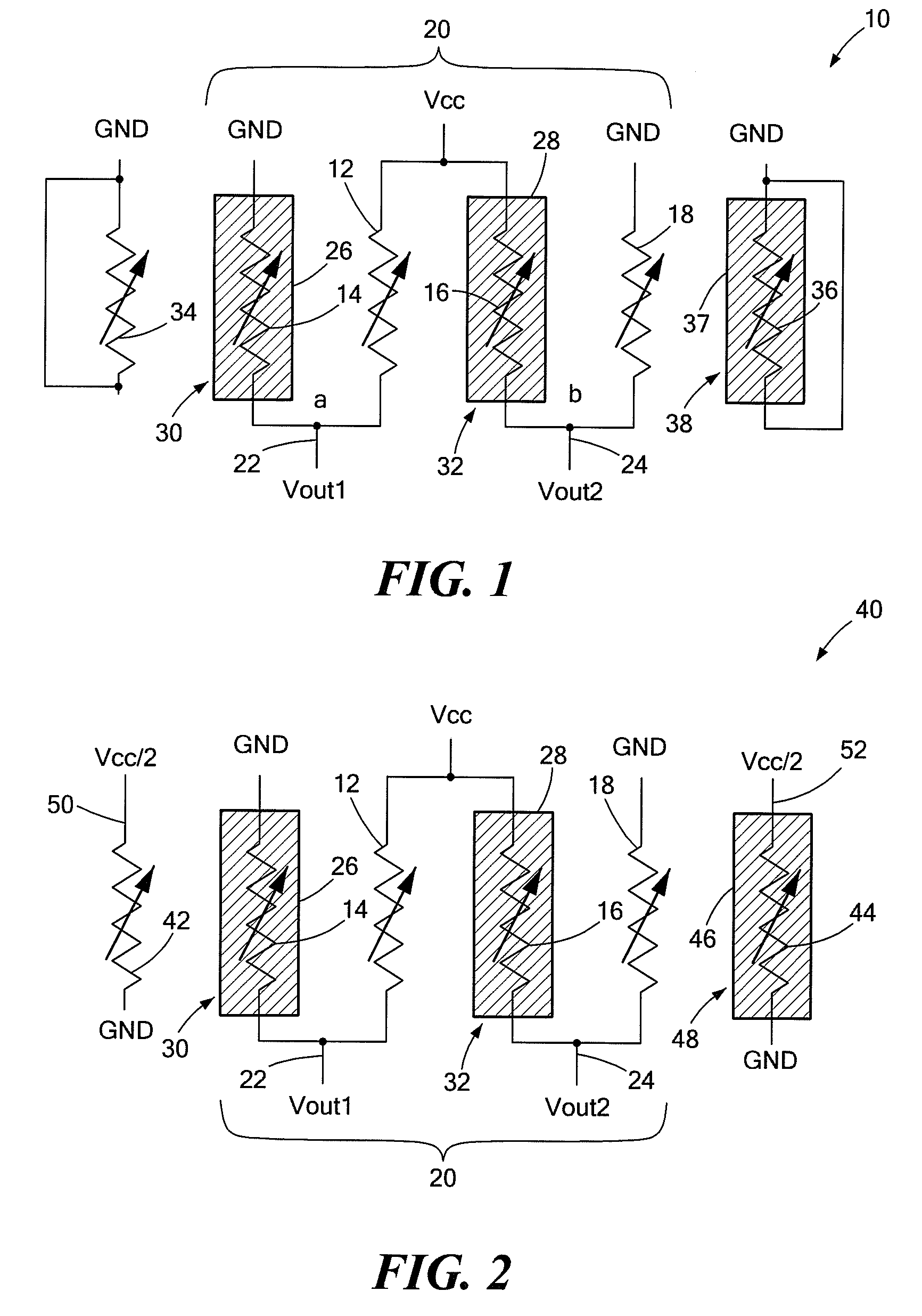

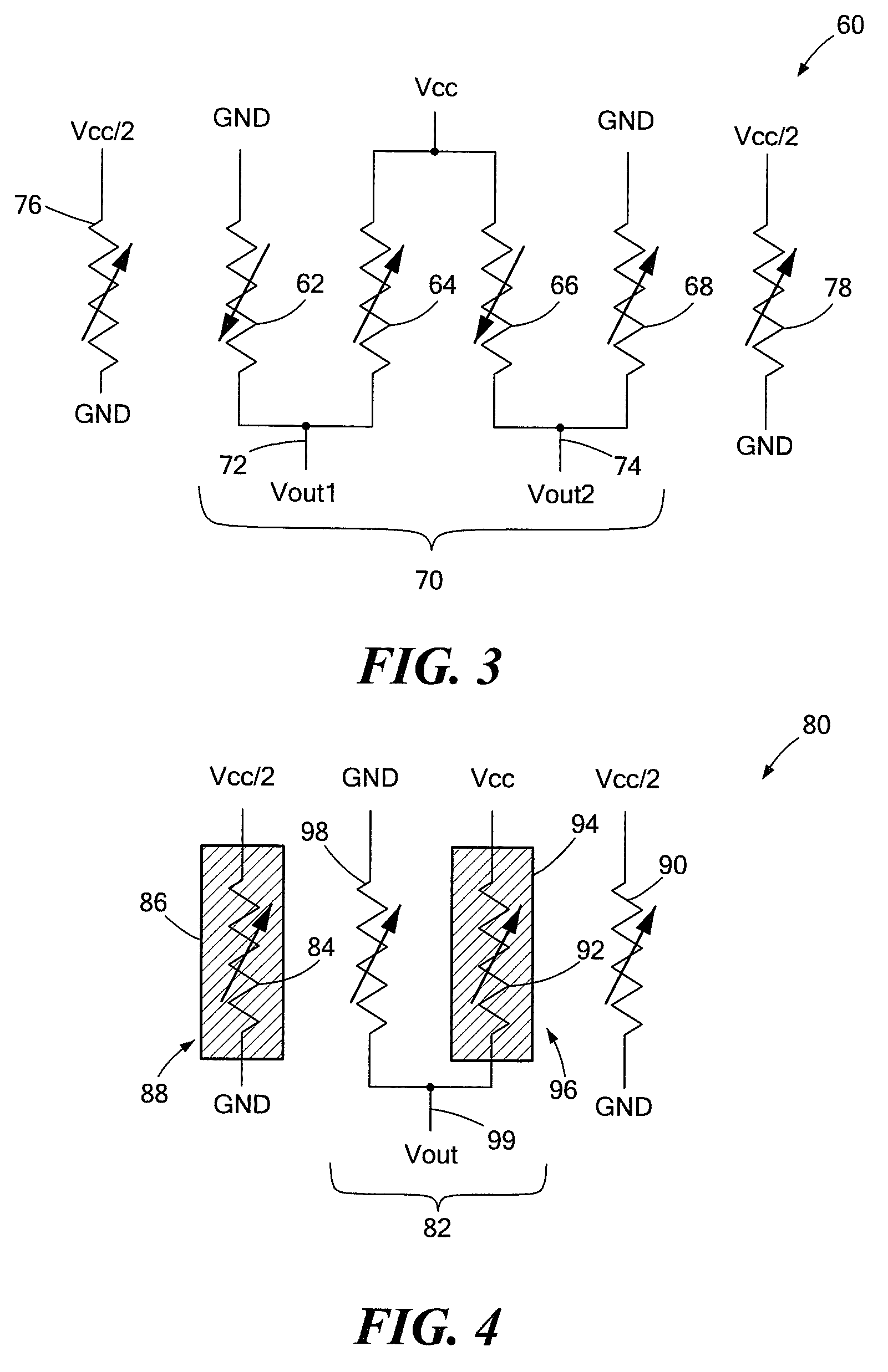

Matching of GMR sensors in a bridge

ActiveUS7795862B2Reduce variationUniform patternNanomagnetismMagnetic-field-controlled resistorsElectricityEngineering

A magnetoresistive (MR) sensing device includes MR elements electrically connected to form a bridge circuit and one or more non-functional (or “dummy”) MR elements for improved matching of the bridge circuit MR elements.

Owner:ALLEGRO MICROSYSTEMS INC

Preparation process for solving problem of polishing yellow edges of grey glazed bricks

ActiveCN110978221AGood sphericityFlat surfacePolishing machinesCeramic shaping apparatusBrickPolishing

The invention relates to a preparation process for solving the problem of polishing yellow edges of grey glazed bricks. The method comprises the following steps: (1) powder is prepared: the ball discharge slurry moisture is 34-36%, the fineness 325-mesh screen residue is 1.5-2.0%, the flow rate is 50-80S, the pressed powder moisture is 6.0-6.5%, and the volume weight of the powder is 0.95-1.0; (2)the powder is aged for 24 hours, pressed, molded and dried at the temperature of 210 DEG C for 2 hours, and is discharged from a kiln at the temperature of 70-90 DEG C; (3) grinding and polishing ofthe green body are carried out; (4) ground coat is sprayed on the surface of the green body; (5) ink-jet decoration is carried out: ink sorts: blue, brown, brown, bright red, orange, golden yellow, black, black and gray; (6) transparent glaze is sprayed on the surface of a brick body; (7) firing in a roller kiln at the temperature of 1168-1185 DEG C for 75-82 minutes is carried out; and (8) polishing is carried out, wherein polishing parameters comprise 20 groups of rough polishing grinding heads, 16 groups of medium polishing grinding heads and 20 groups of fine polishing grinding heads.

Owner:JIANGXI HEMEI CERAMICS +3

High-temperature-resistant artificial quartz stone plate and production process thereof

The invention discloses a high-temperature-resistant artificial quartz stone plate and a production process thereof. The high-temperature-resistant artificial quartz stone plate comprises, by weight, 40-50 parts of 20-40-mesh quartz sand, 20-30 parts of 400-600-mesh quartz powder, 30-40 parts of adhesives, 10-15 parts of blast furnace slag, 5-10 parts of ceramic fiber, 10-15 parts of attapulgite, 15-25 parts of nano wollastonite, 20-30 parts of sodium silicate, 15-20 parts of potassium feldspar powder, 0.5-1 part of double (pyrophosphate dioctyl oxygen radicals) ethylene ester titanate, and 0.2-0.3 part of pigments. The quartz stone plate is lightweight, even in density, bright in color, rich in pattern, high in strength, high-temperature-resistant, high in impact resistance, good in wear resistance, good in weather resistance, less prone to deformation, scratch-resistant, aging-resistant, less prone to dying, environment-friendly, pollution-free, durable and the like. In addition, the quartz stone plate is quite high in various organic solvent performance indexes such as acid-base resistance, salt-mist resistance and petroleum resistance, and the effect of high-simulation natural stone is completely achieved.

Owner:安徽瑞翔石英制品有限公司

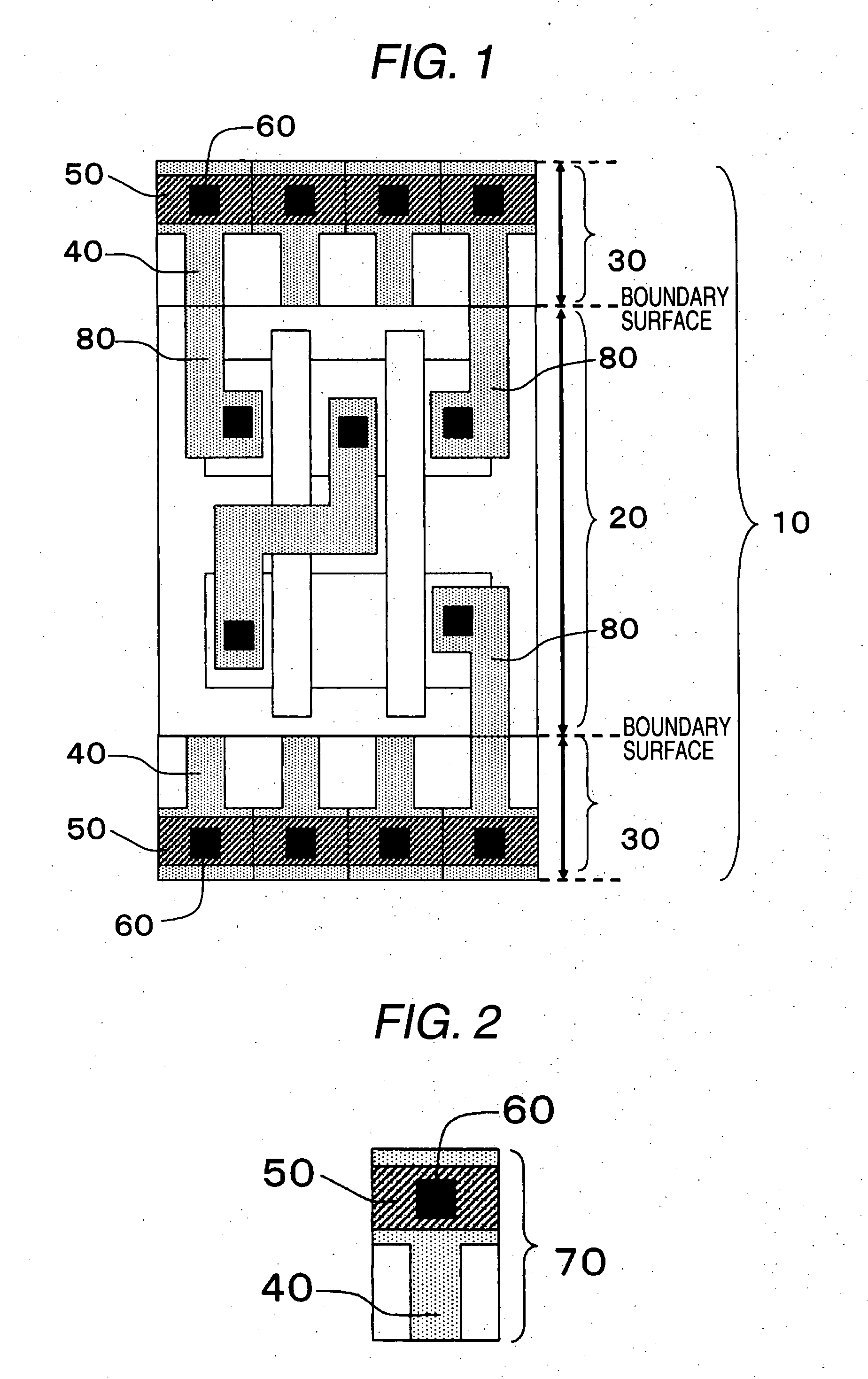

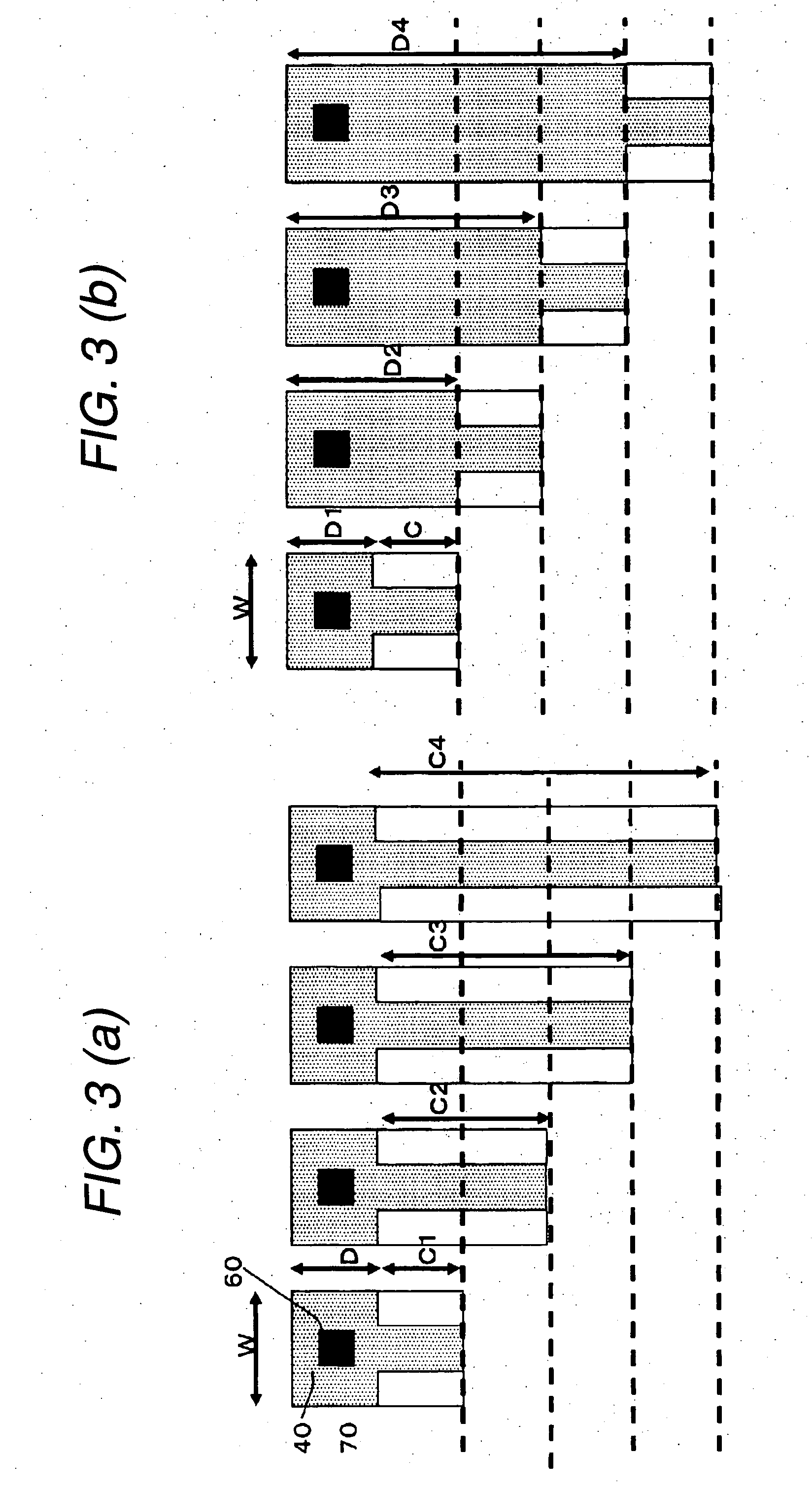

Semiconductor integrated circuit apparatus and method of designing the same

InactiveUS20070200238A1Maintain their area ratioHigh pattern accuracySemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitEngineering

In a semiconductor integrated circuit apparatus formed by a core cell constituting a circuit function and a power wiring cell including a power wiring, a metal of a power wiring unit cell constituting the power wiring cell is formed to take a shape of T, and the power wiring unit cell is disposed adjacently, thereby forming a serial power wiring. The core cell and the power wiring cell are connected to each other through a metal wiring in the core cell in which coordinates in a horizontal direction are preset, and a power signal is thus supplied.

Owner:PANASONIC CORP

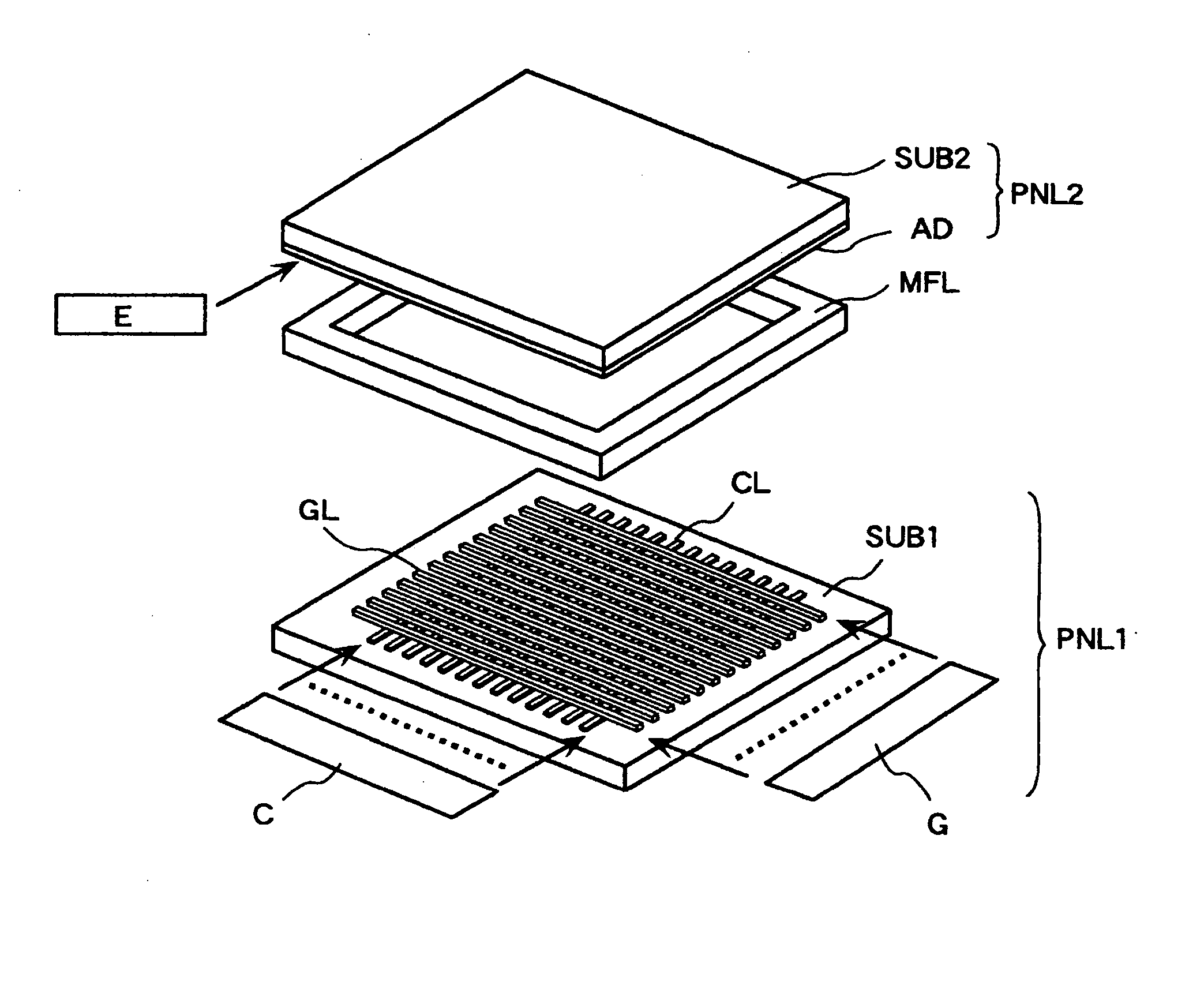

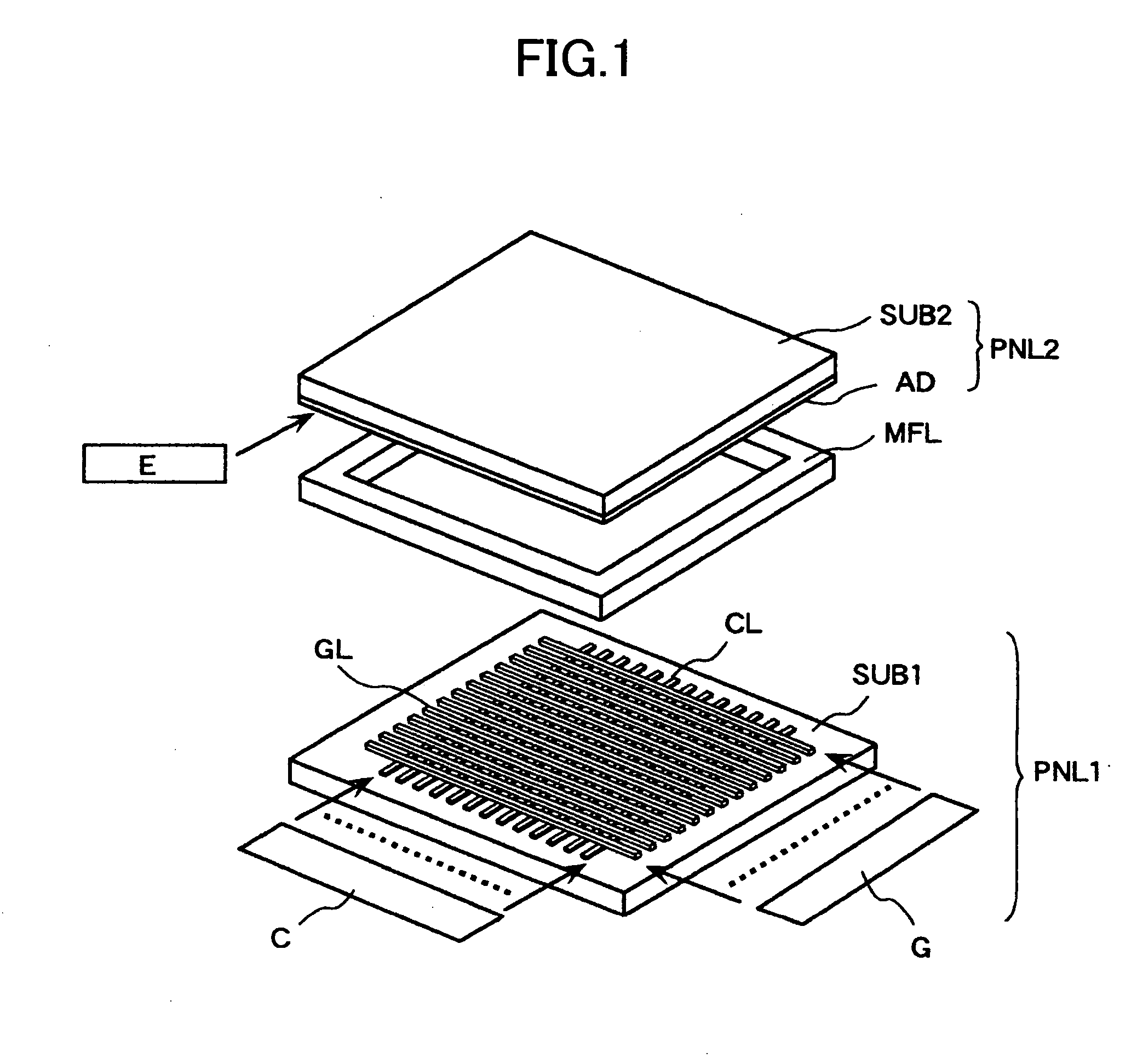

Self-luminous flat-panel display

InactiveUS20070018563A1Reduce wire resistanceUniform patternDischarge tube luminescnet screensCathode ray tubes/electron beam tubesCarbon nanotubeField electron emission

This invention relates to a field-emission-type flat-panel display apparatus that obtains an image by causing the electrons emitted from each of electron sources arranged in matrix form to impinge upon the phosphors formed on a phosphor screen. A carbon nanotube is used as an electron source material in this flat-panel display apparatus, and the electron sources are formed by printing. The vertical sizes of the depressions and projections on the surface of each electron source which has been formed by printing are suppressed to a value equal to or less than 1 μm, preferably, equal to or less than 0.5 μm. This makes it possible to obtain a flat-panel display apparatus of stable emission characteristics.

Owner:HITACHI DISPLAYS

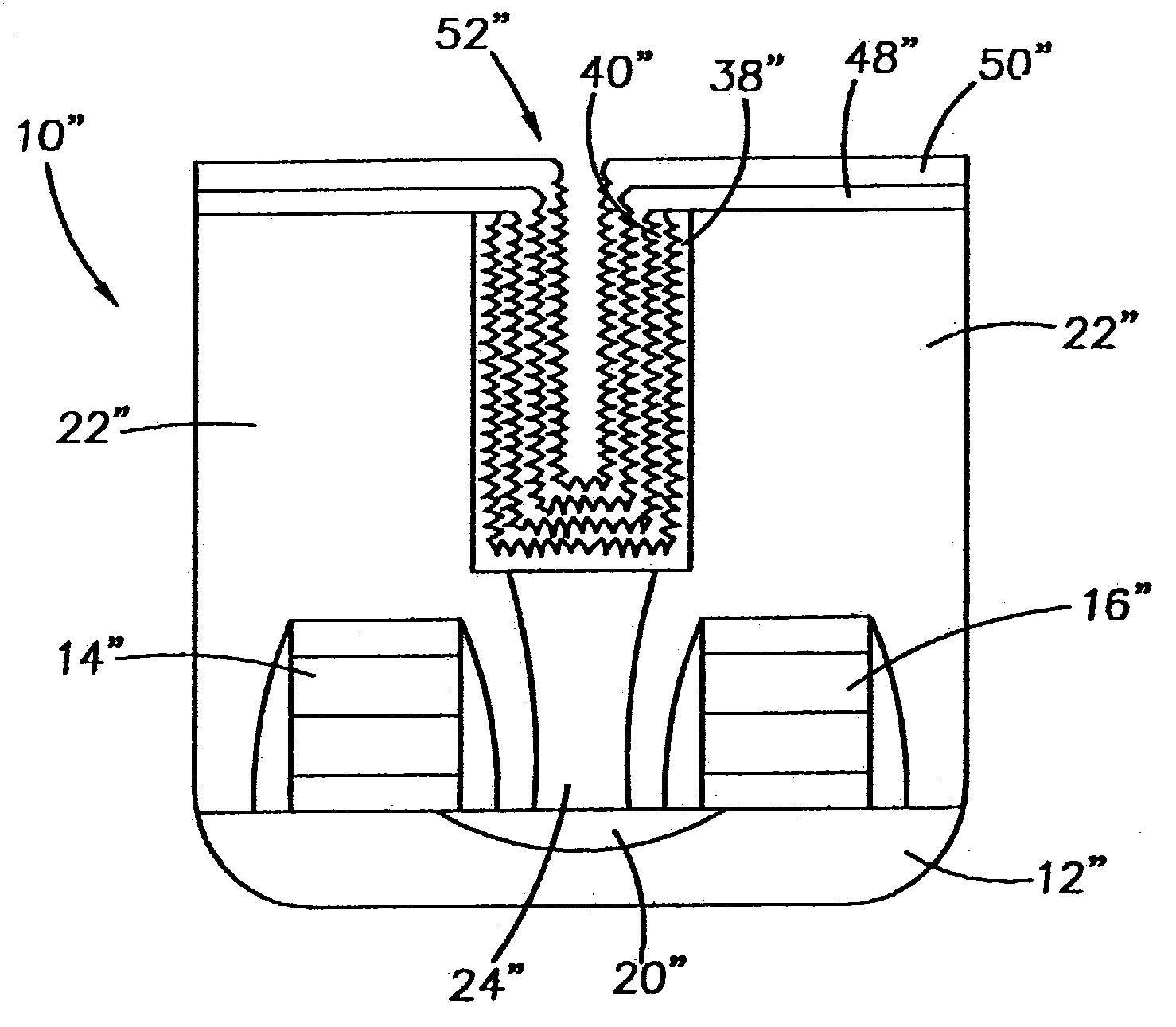

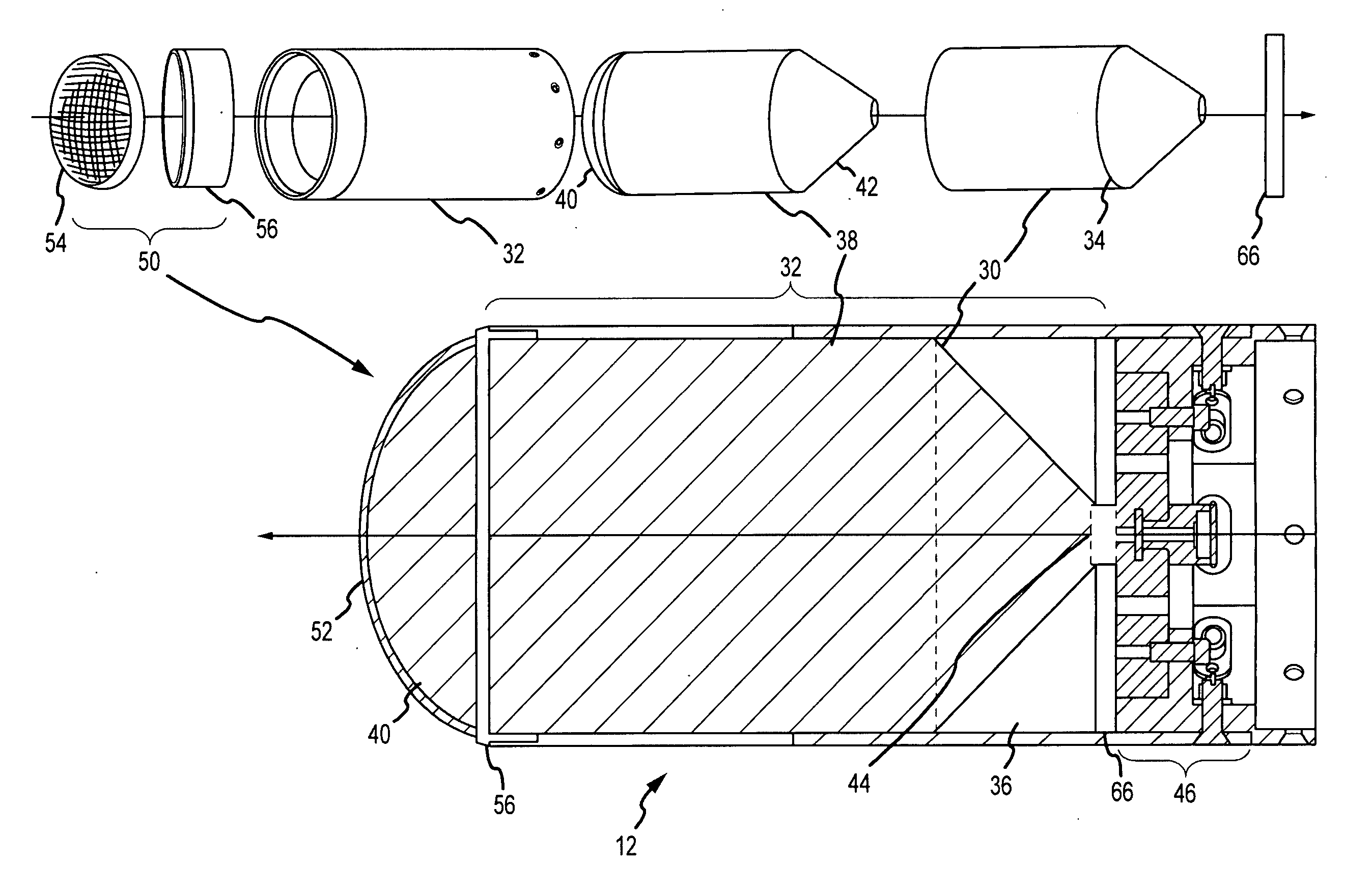

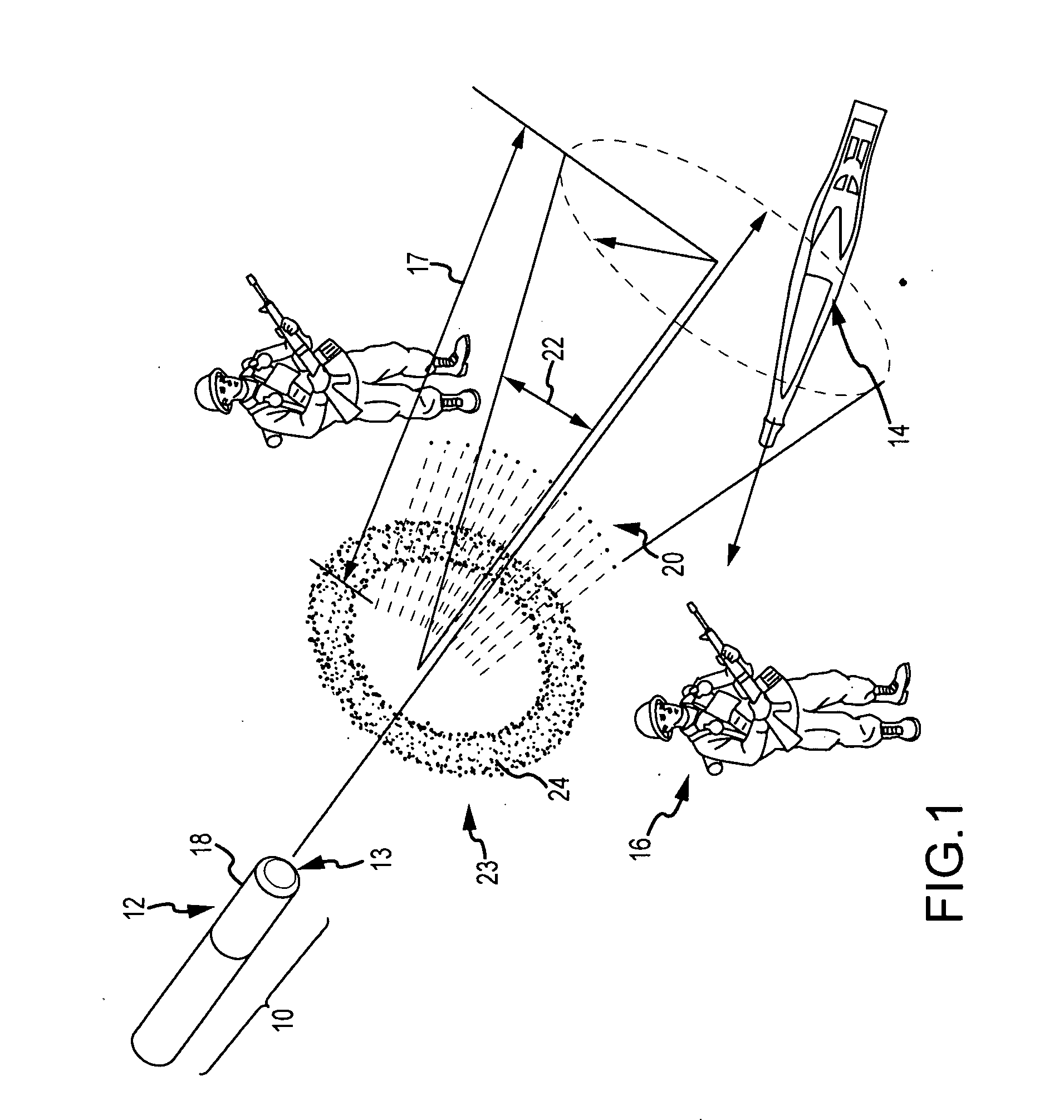

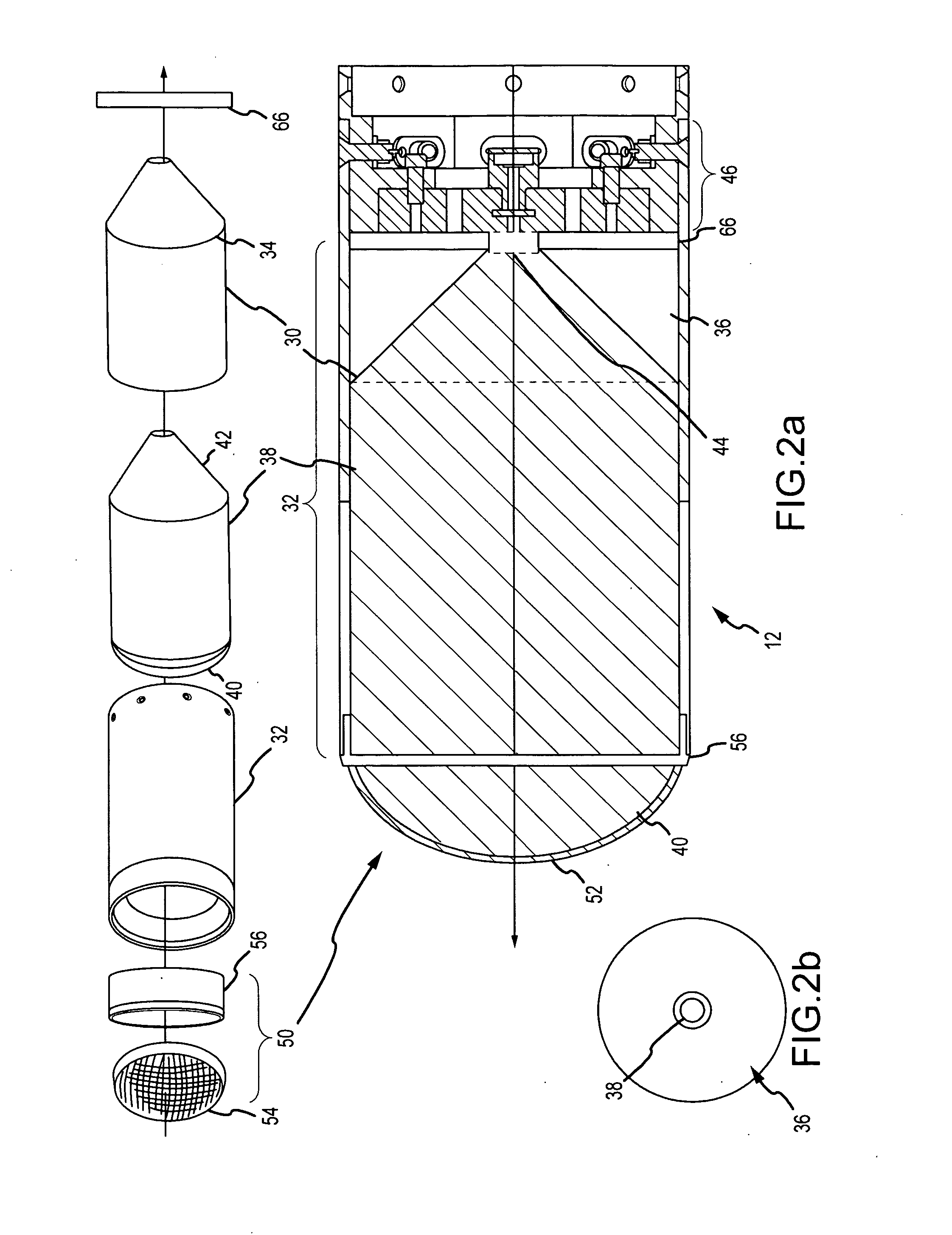

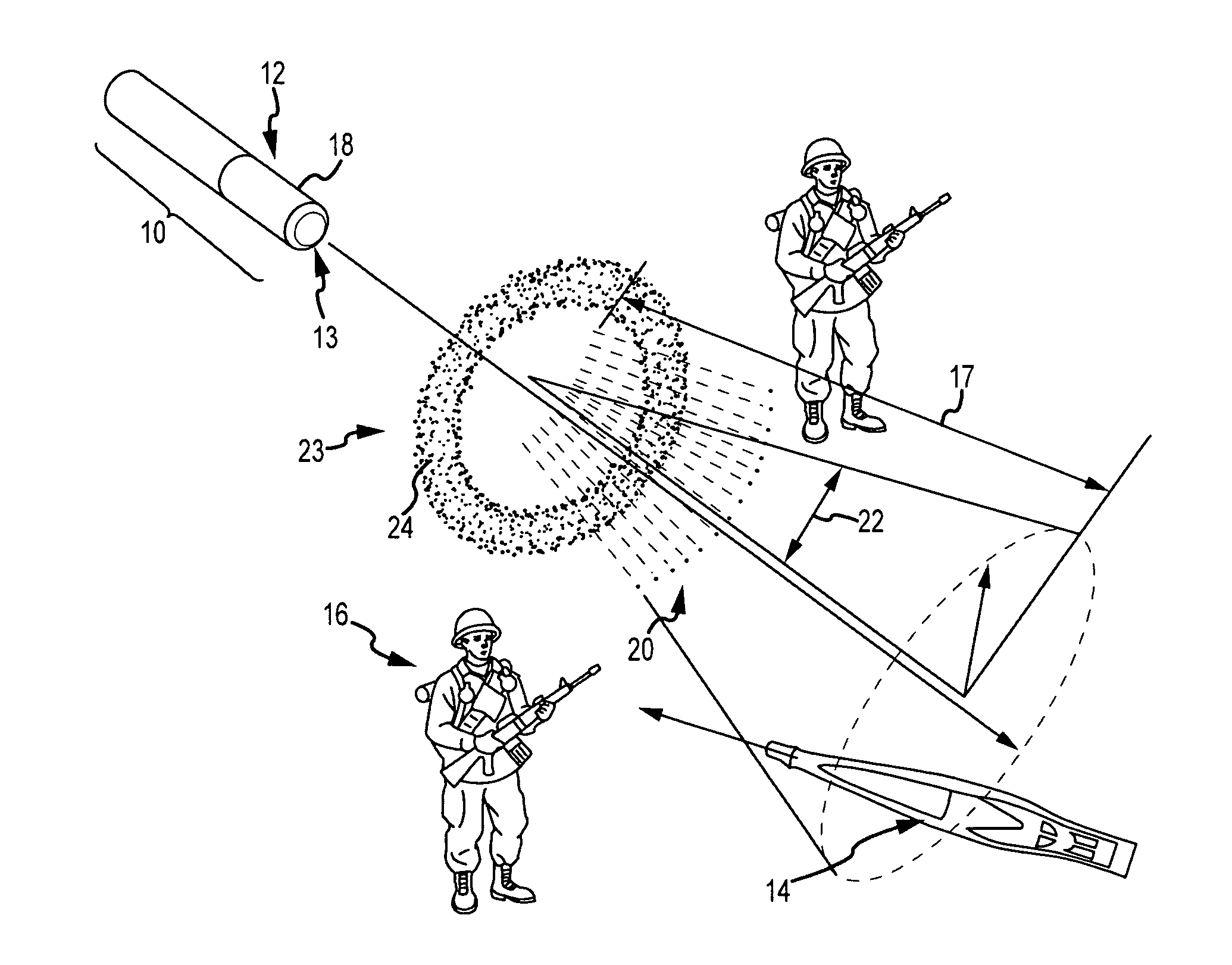

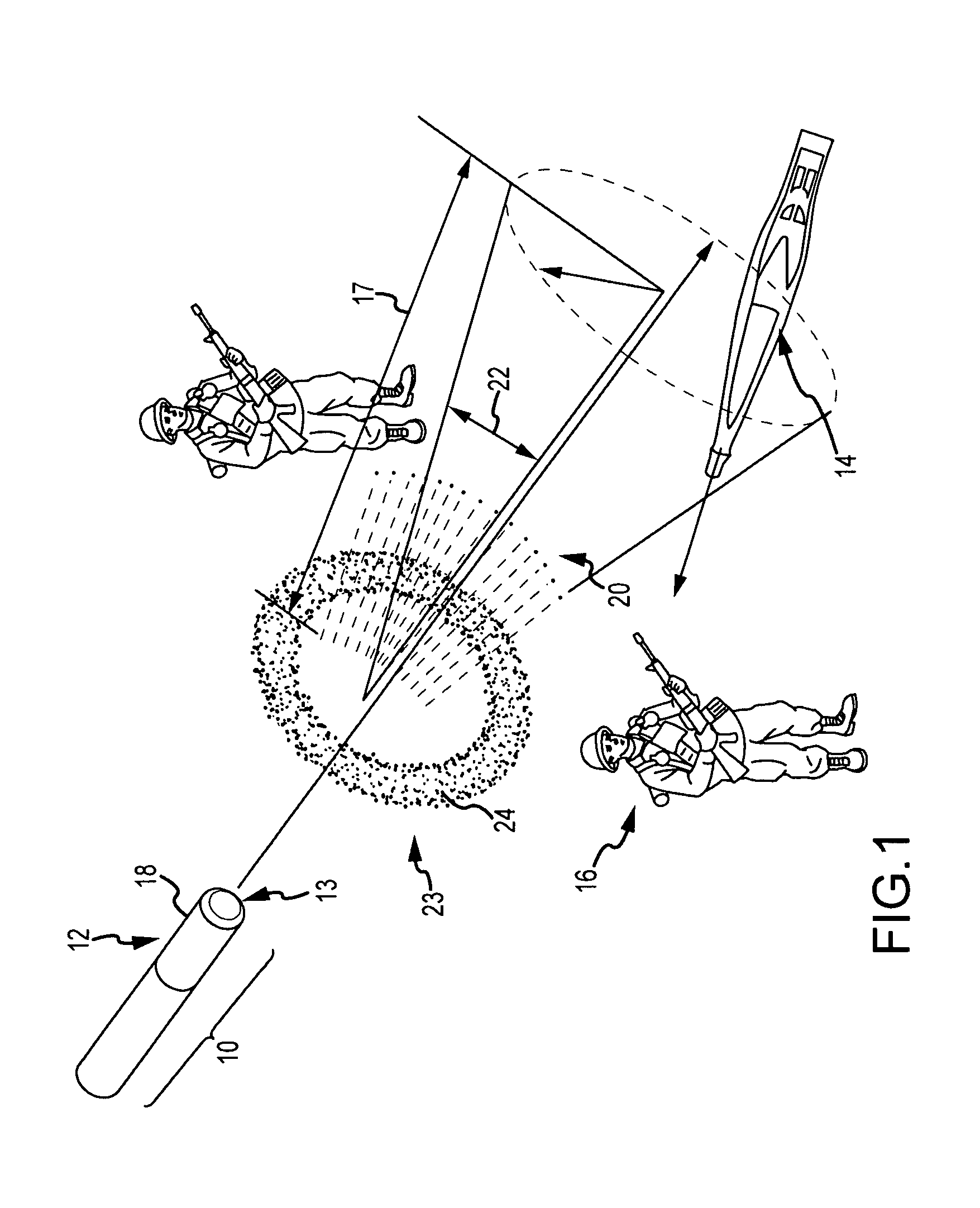

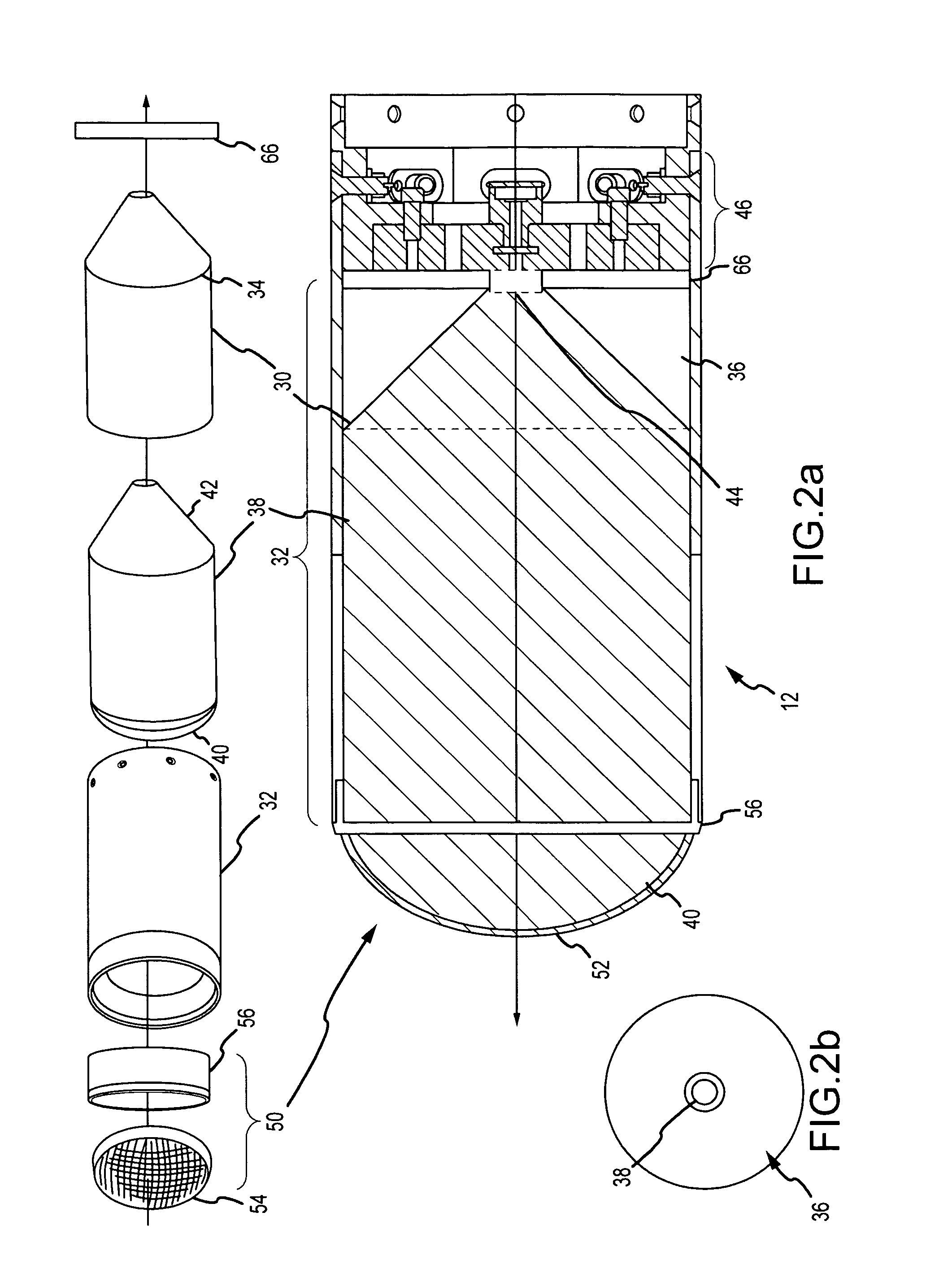

Forward firing fragmentation warhead

ActiveUS20110094408A1Threat lethalityReduced collateral damageExplosive chargesAmmunition projectilesVariable thicknessDetonation

A forward firing fragmentation warhead is constructed with casing materials that are pulverized upon detonation of the explosive. As a result, the lethality radius of the pulverized case fragments is no greater than that of the gas blast, thus reducing potential collateral damage. Warhead lethality may be improved by forming the fragmentation layer and explosive with dome-shapes that approximately match the shape of the advancing pressure wave. This increases fragment velocity and improves the uniformity of the fragment distribution over the forward-firing pattern. A variable-thickness pattern shaper may be placed between the fragmentation layer and explosive to provide additional shaping of the forward-firing pattern. Warhead weight and cost can be reduced by eliminating explosive at the aft end of the warhead that does not contribute to the total energy imparted to the fragments. More specifically, the aft section of the explosive and explosive containment structure may be tapered to approximately match the expansion of the pressure wave from the single-point aft detonation.

Owner:RAYTHEON CO

Making process of green cigarette paper

InactiveCN101020393AIncrease coverageClear patternTobacco smoke filtersInksGranularityPulp and paper industry

The present invention relates to printing technology, and is especially making process of cigarette paper printed with water-thinned ink. The present invention features the printing plate cylinder with slots of 43-60 micron or 15-37 micron depth, the water-thinned ink with solid content of 36-55 wt%, pH 9-10, pigment granularity not greater than 15 micron and viscosity of 18-50 s, and paper for cigarette treated through brush printing, pre-stoving and stoving. Compared with available technology, the present invention has the advantages of high production safety, clear printed pattern, convenient ink compounding, etc.

Owner:张军生

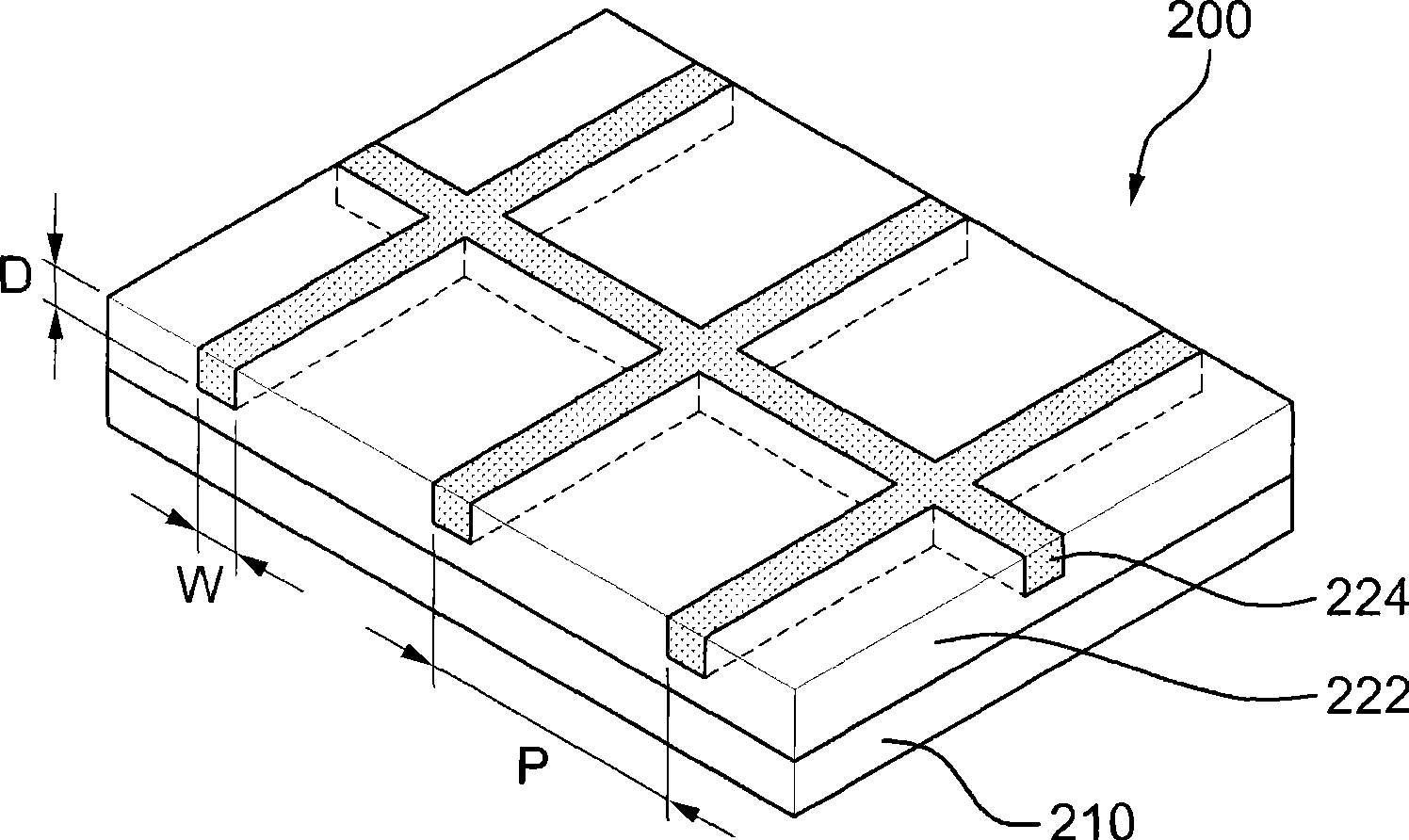

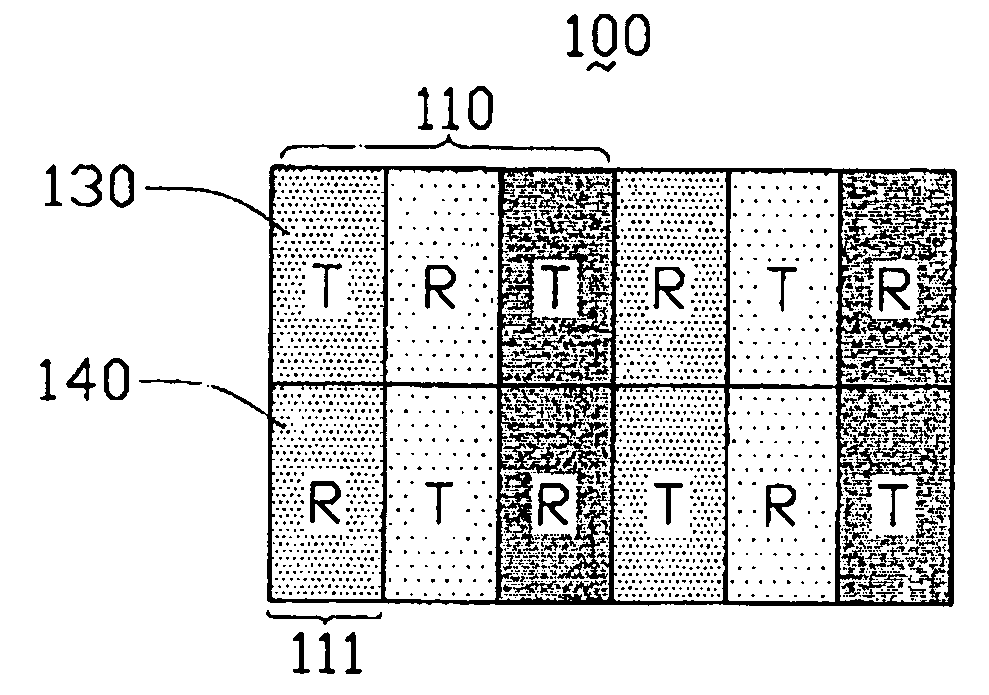

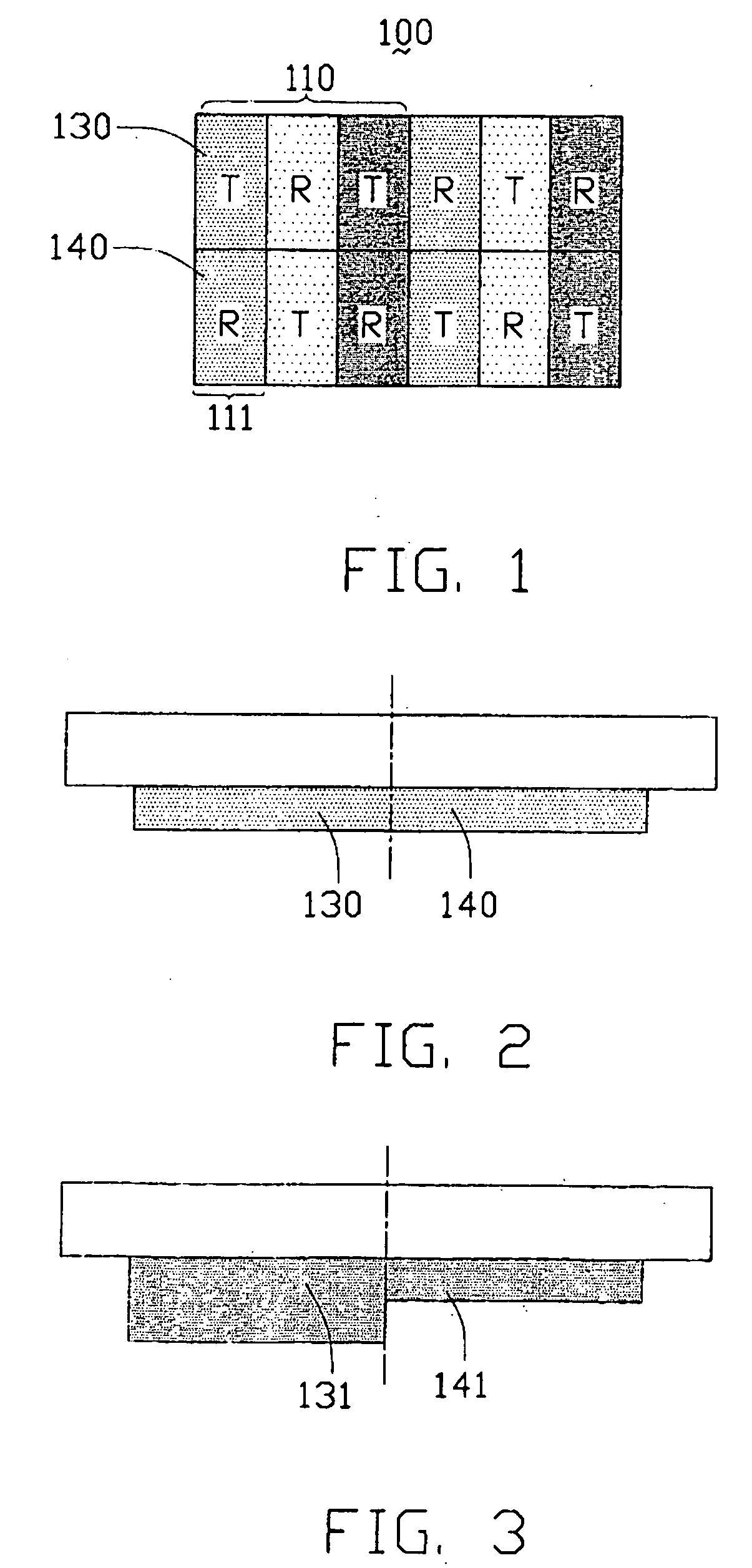

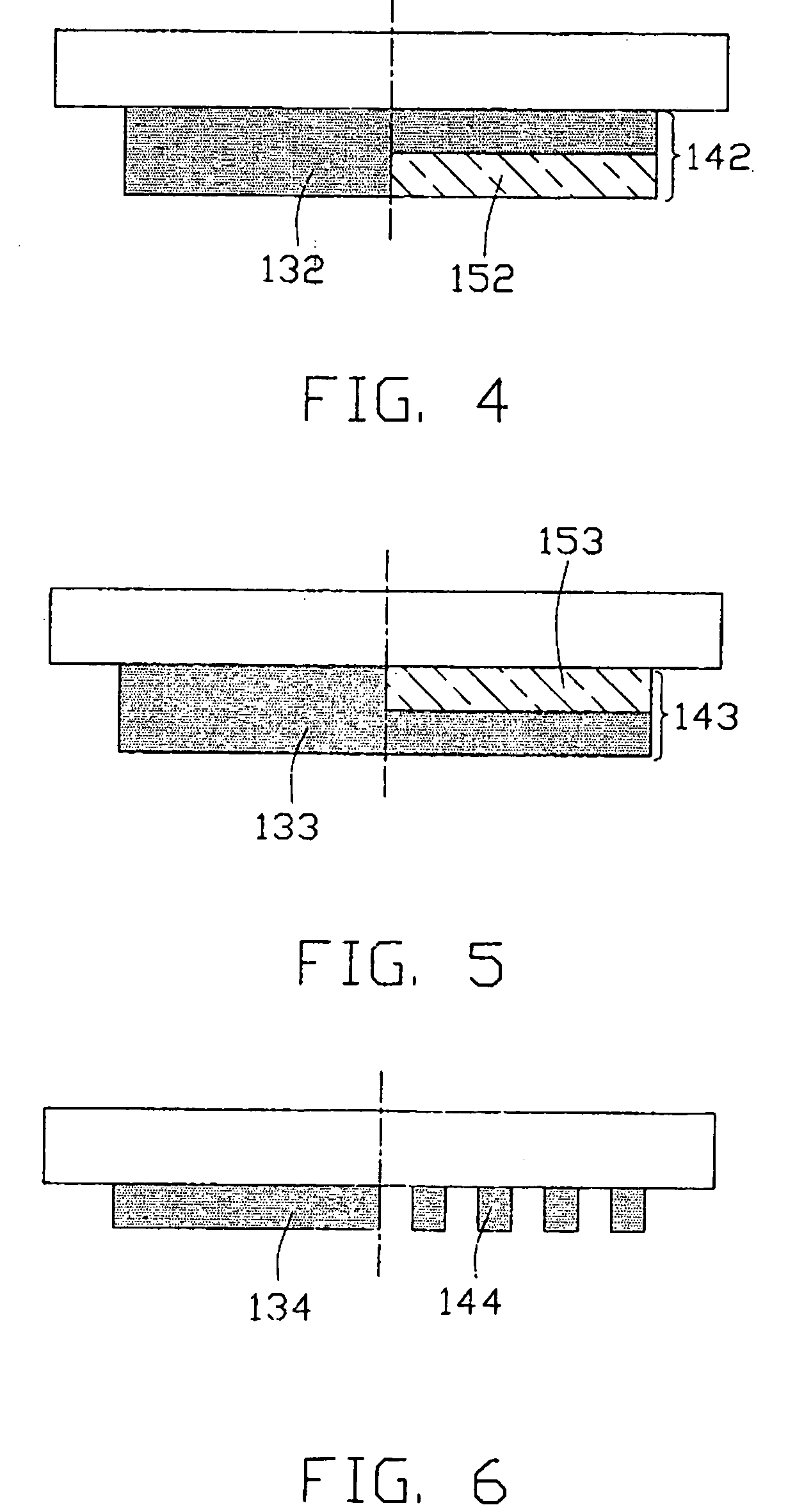

Color filter and liquid crystal display using the same

InactiveUS20050151897A1Reduced and no hue diversityUniform patternNon-linear opticsColor filter arrayLiquid-crystal display

A color filter (100) includes pixels (110), each pixel including three sub-pixels (111), and each sub-pixel including a reflection section (R) and a transmission section (T). In each pixel, the transmission sections and the reflection sections are alternately arranged along each row of the sections and along each column of the sections. The alternating arrangement of the transmission sections and the reflection sections of the pixels can provide a uniform pattern of hue balance over the whole display area. Furthermore, in various embodiments described, different optical thicknesses of the transmission sections and the reflection sections (or color layers of the reflection sections) can provide uniform hue over the whole display area.

Owner:INNOLUX CORP

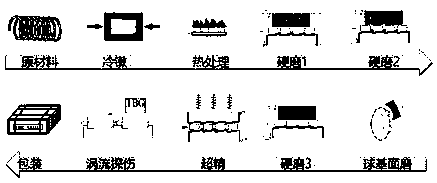

Production process for high-precision bearing roller for rail transit

The invention relates to a production process for a high-precision bearing roller for rail transit. The production process comprises the following steps of step 1, cold heading: after drawing steel byutilizing a four-station high-speed cold header, upsetting the drawn steel into a roller blank; 2, heat treatment which is a full-automatic mesh belt furnace heat treatment flow production line; 3, hard grinding 1; 4, hard grinding 2; 5, ball base surface processing; 6, hard grinding 3; 7, superfinishing, in which 8 oilstones are adopted to perform vibration back and forth to process a raceway surface of a roller; 8, eddy current inspection, in which eddy current inspection equipment produced by German IBG is adopted and is installed on a superfinishing machine to realize unfolding of the roller so as to perform 100 percent eddy current inspection which is mainly used for detecting defects on the surface of the roller and cracks of internal tissues of the roller; and 9, packaging. The production process has the advantages that through four-station multi-formation, the forming precision of a product can be guaranteed, a metal flow direction of a material can tend to be reasonable at the same time, and the service life of the product is prolonged.

Owner:JIANGSU LIXING GENERAL STEEL BALL +1

Forward firing fragmentation warhead

ActiveUS7930978B1Reduced collateral damageThreat lethalityAmmunition projectilesExplosive chargesVariable thicknessDetonation

A forward firing fragmentation warhead is constructed with casing materials that are pulverized upon detonation of the explosive. As a result, the lethality radius of the pulverized case fragments is no greater than that of the gas blast, thus reducing potential collateral damage. Warhead lethality may be improved by forming the fragmentation layer and explosive with dome-shapes that approximately match the shape of the advancing pressure wave. This increases fragment velocity and improves the uniformity of the fragment distribution over the forward-firing pattern. A variable-thickness pattern shaper may be placed between the fragmentation layer and explosive to provide additional shaping of the forward-firing pattern. Warhead weight and cost can be reduced by eliminating explosive at the aft end of the warhead that does not contribute to the total energy imparted to the fragments. More specifically, the aft section of the explosive and explosive containment structure may be tapered to approximately match the expansion of the pressure wave from the single-point aft detonation.

Owner:RAYTHEON CO

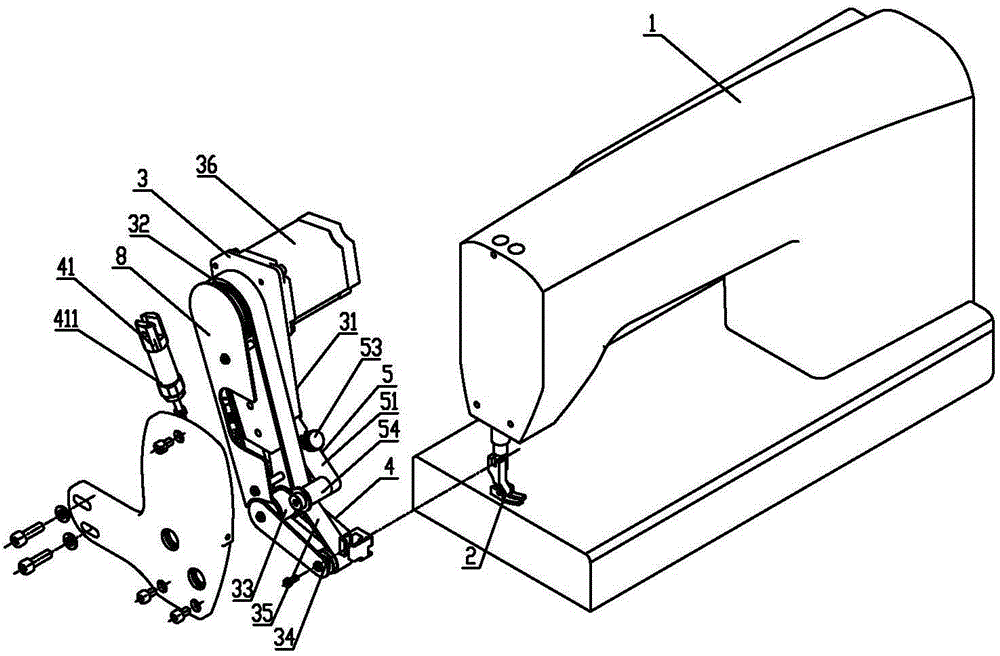

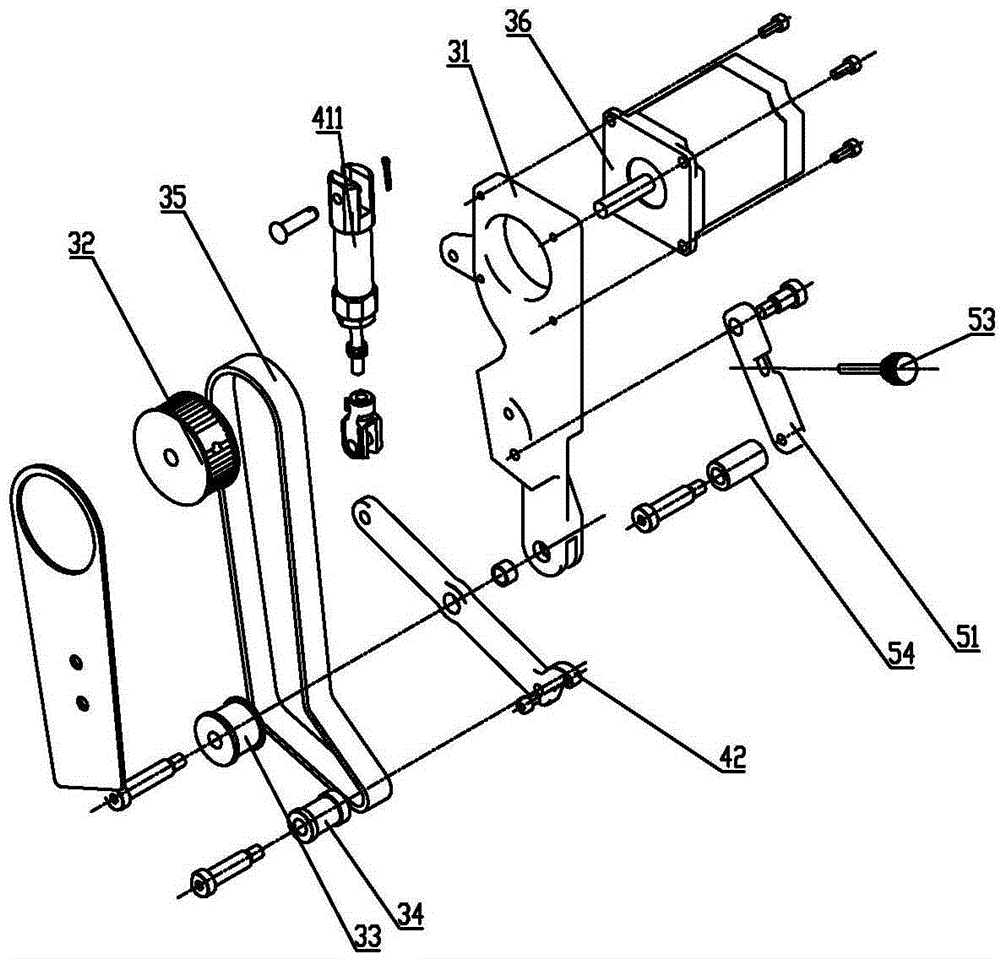

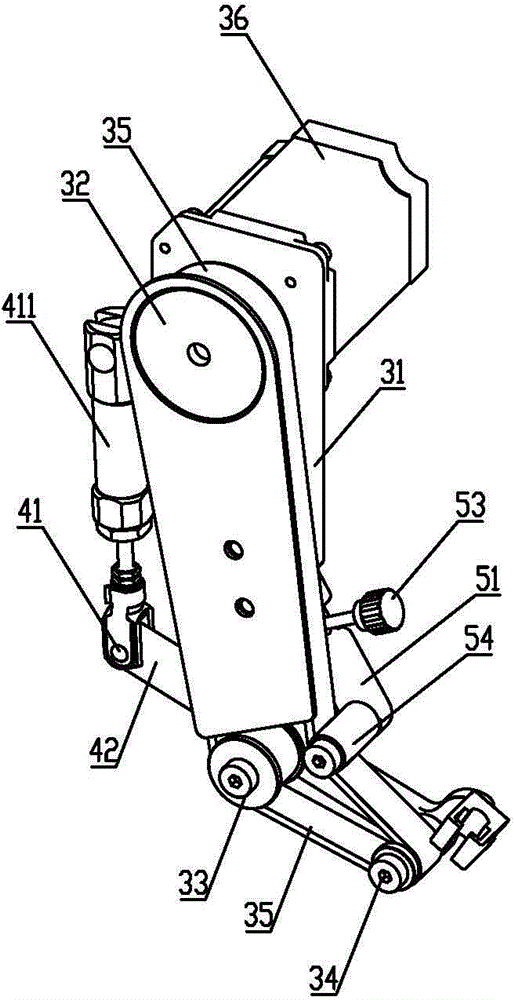

Lockstitch sewing machine capable of feeding automatically

The invention relates to the technical field of sewing machines, in particular to a lockstitch sewing machine capable of feeding automatically. The lockstitch sewing machine comprises a lockstitch sewing machine body, a presser foot arranged on the lockstitch sewing machine body, a material puller and a link gear, wherein the material puller comprises a mounting plate, a synchronous pulley, an tension roller, a material pulling roller, a material pulling belt and a stepping motor, the mounting plate is fixed on the lockstitch sewing machine body, the synchronous pulley, the tension roller and the material pulling roller are arranged on the mounting plate and can tension the material pulling belt, the material pulling roller is capable of rotating up and down around the tension roller, and the stepping motor is connected with the synchronous pulley and drives the same to rotate, and the link gear is connected with the presser foot and the material pulling roller so as to drive the material pulling roller to move up and down along with the presser foot. The lockstitch sewing machine is compact in structure and convenient to use, and via linkage matching of the material puller and the presser foot, patterns sewn by the lockstitch sewing machine are uniform and attractive in appearance.

Owner:QUANZHOU ZHONGFENGZHEN CAR CITY

Marble Chips for an Artificial Marble, Method of Making the Same, and Artificial Marble Including the Same

ActiveUS20110263783A1Readily surface treatHigh refractive indexEster polymer adhesivesFlotationOligomerArtificial stone

The present invention provides marble chips produced by hardening or molding a resin composition including a binder and a reactive monomer, wherein the binder comprises a halogenated alkoxylated diacrylate oligomer. The marble chips of the present invention can be formed into a uniform pattern, so that an artificial marble made using the marble chips of the present invention may have an outer appearance and texture similar to that of engineered stone.

Owner:LOTTE ADVANCED MATERIALS CO LTD

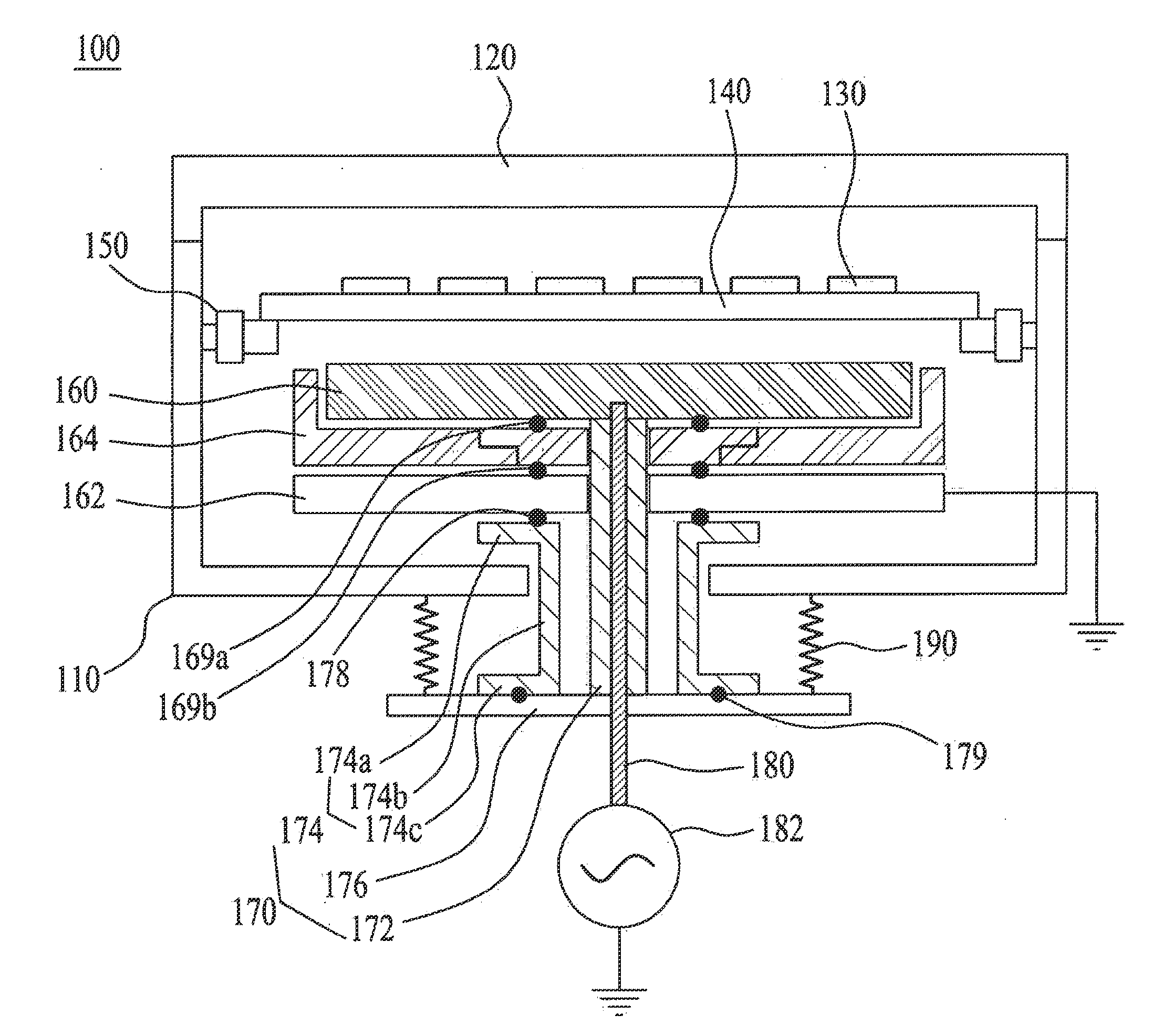

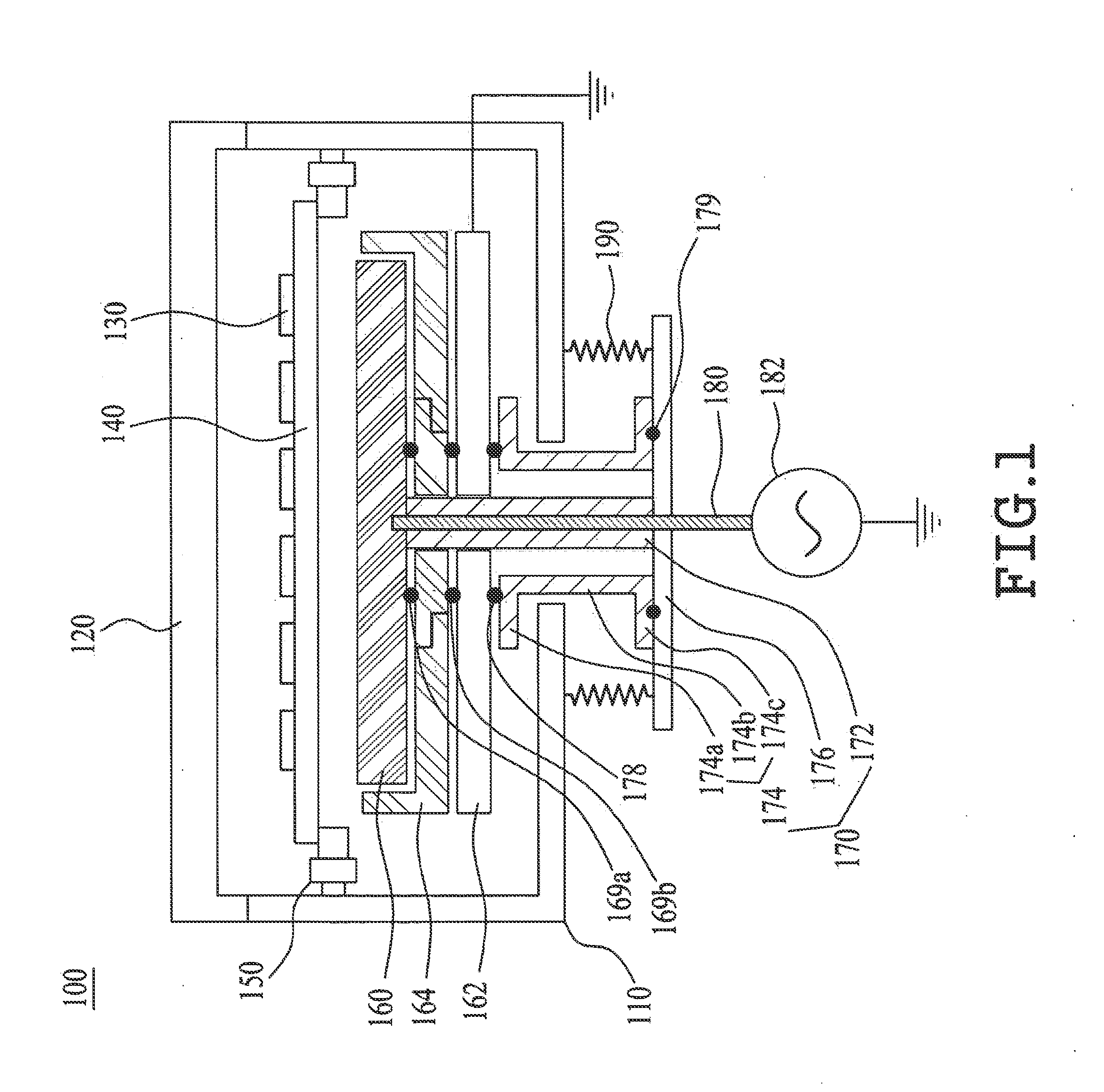

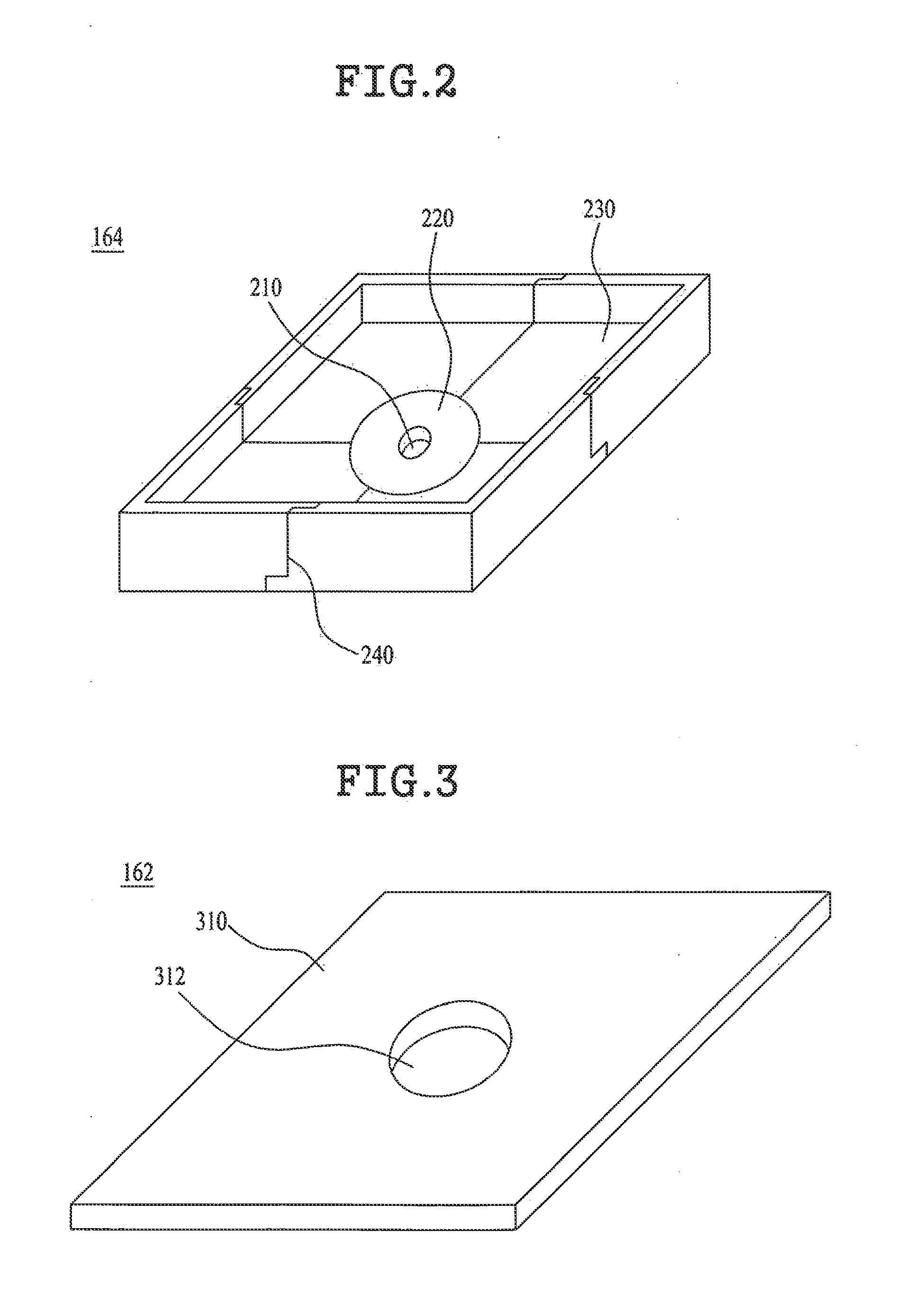

Dry etching apparatus

InactiveUS20130233491A1Uniform patternElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorHigh frequency power

A dry etching apparatus is disclosed, which is capable of forming a uniform pattern in a substrate surface, the dry etching apparatus for etching at least one substrate through the use of plasma, comprising the at least one substrate placed on a tray inside a chamber; a susceptor, provided inside the chamber while confronting with the at least one substrate, for supplying a high-frequency power to form the plasma; a grounding part provided beneath the susceptor while being untouchable to the susceptor; and an insulating part provided between the susceptor and the grounding part.

Owner:JUSUNG ENG

Pattern forming method as well as production methods for processed substrate, optical component, circuit board, electronic component and imprint mold

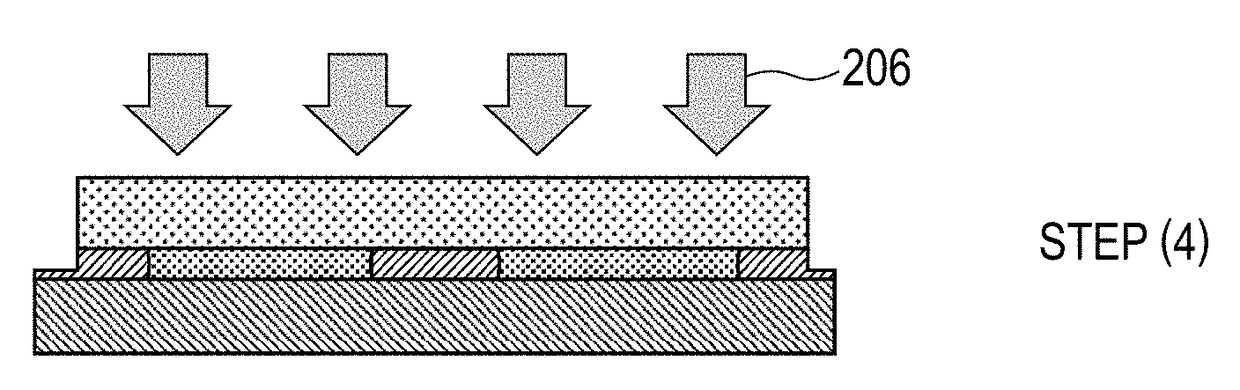

ActiveUS10754245B2Improve throughputUniform patternPhotomechanical apparatusOptical articlesPhoto irradiationElectronic component

A pattern is formed on a substrate with forming a layer of a curable composition (A1) containing a component (a1) serving as a polymerizable compound and a component (d1) serving as a solvent on a surface of the substrate, then dispensing droplets of a curable composition (A2) containing at least a component (a2) serving as a polymerizable compound dropwise discretely onto the layer of the curable composition, subsequently sandwiching a mixture layer of the curable composition (A1) and the curable composition (A2) between a mold and the substrate, then irradiating the mixture layer with light to cure the layer, and releasing the mold from the mixture layer after the curing.

Owner:CANON KK

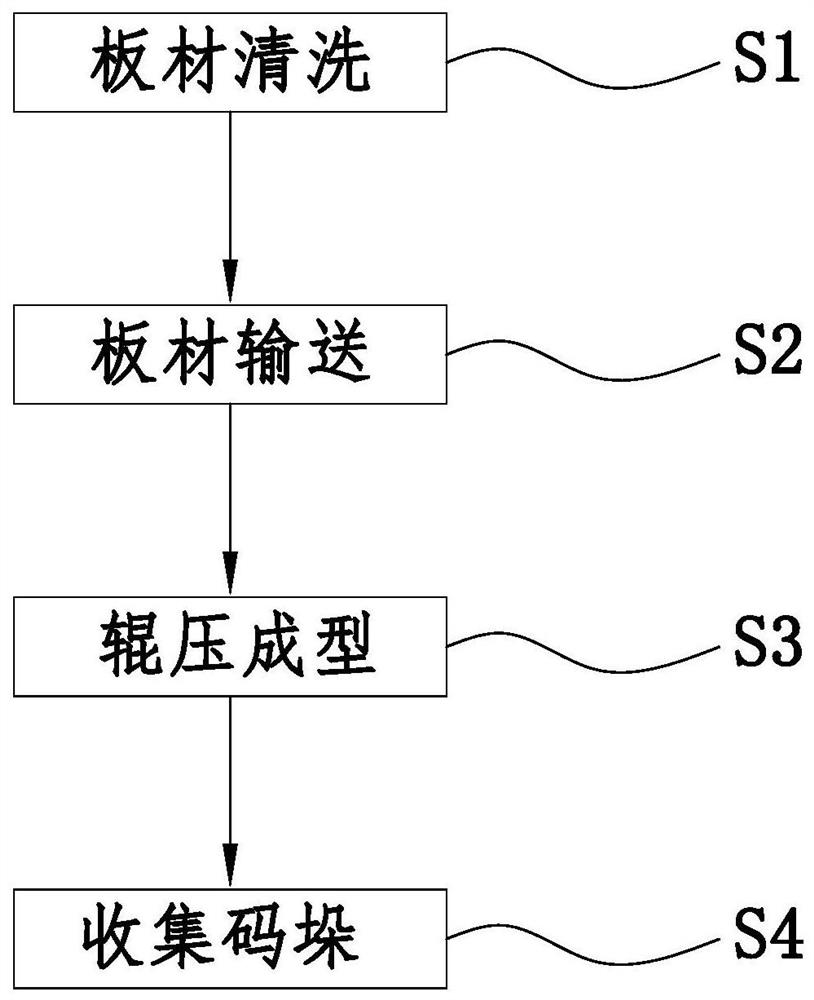

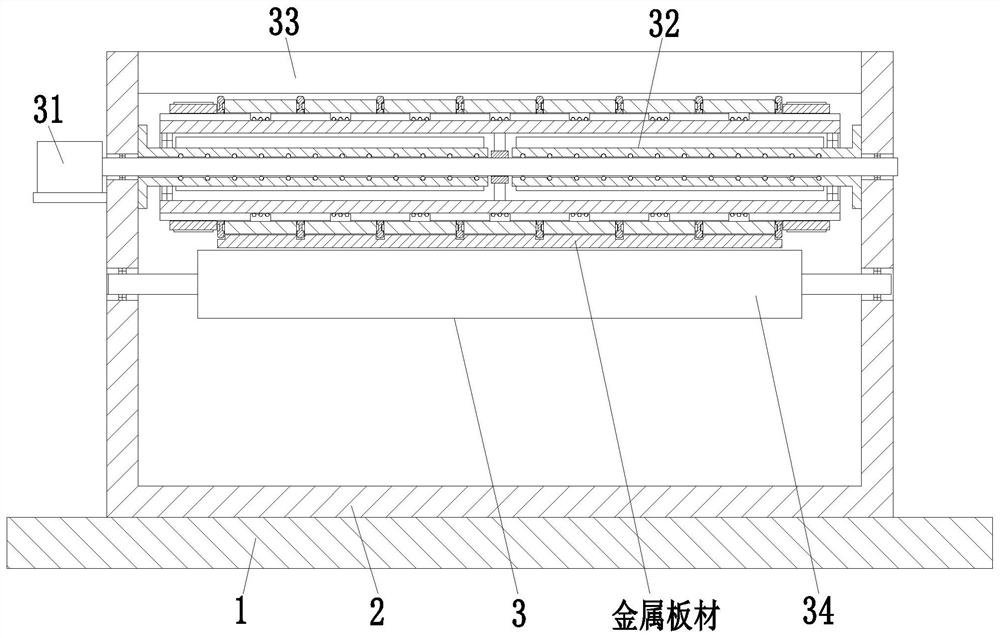

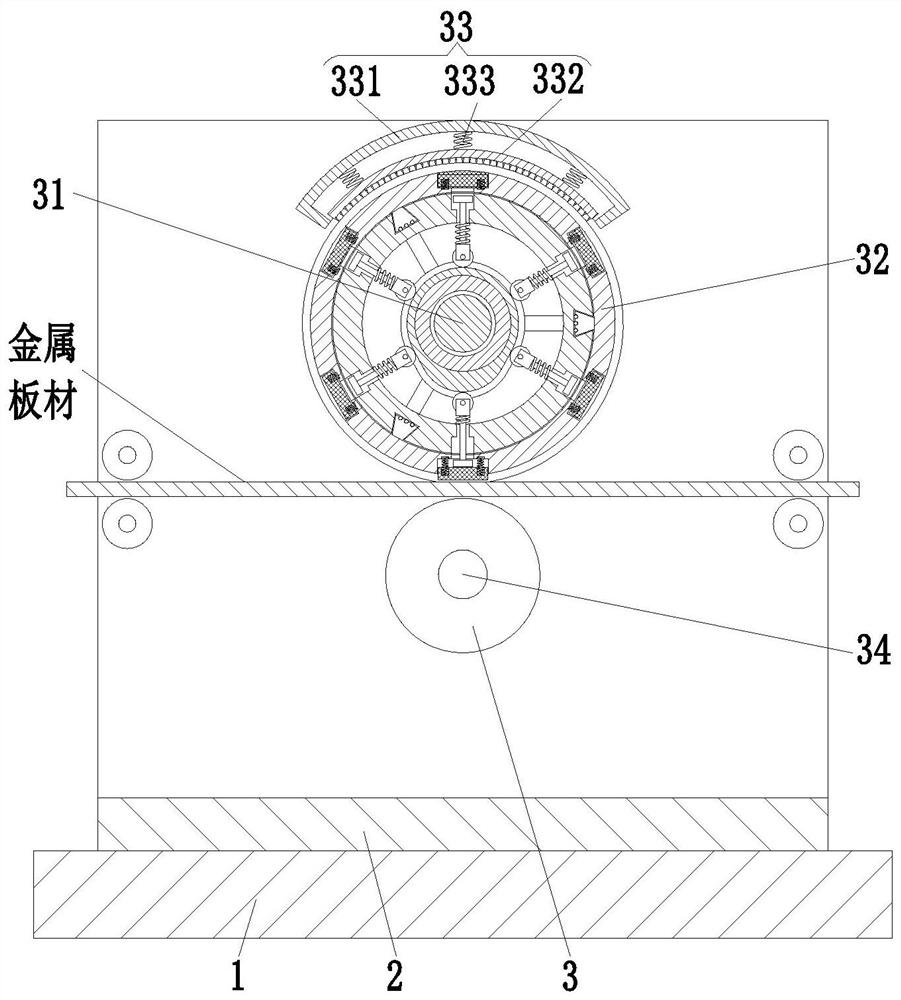

Metal embossed plate roll-forming method

PendingCN112455136AEffective rollingConvenience for subsequent useCleaning using toolsEmbossing decorationsMetallurgyMachining

The invention relates to a metal embossed plate roll-forming method which comprises a bottom plate, a mounting frame and a rolling device. The mounting frame is mounted in the middle of the upper endof the bottom plate; the mounting frame is of a U-shaped structure; conveying rollers are symmetrically mounted on the outer side of the interior of the mounting frame; and the rolling device is mounted in the middle of the interior of the mounting frame. The metal embossed plate roll-forming method provided by the invention can solve the problems that when existing equipment conducts rolling machining on a metal plate, the rolling effect is poor, the machining efficiency is low, embossing machining cannot be effectively conducted on a metal plate, meanwhile, adjustment cannot be conducted according to the width of the metal plate, the machining effect of the metal plate is affected, and when the existing equipment is used for conducting rolling machining on the metal plate, particle impurities adhering to the surface of a rolling mechanism cannot be effectively swept, so that the impurities easily scratch the surface of the metal plate, and subsequent use of the metal plate is not facilitated.

Owner:曹李

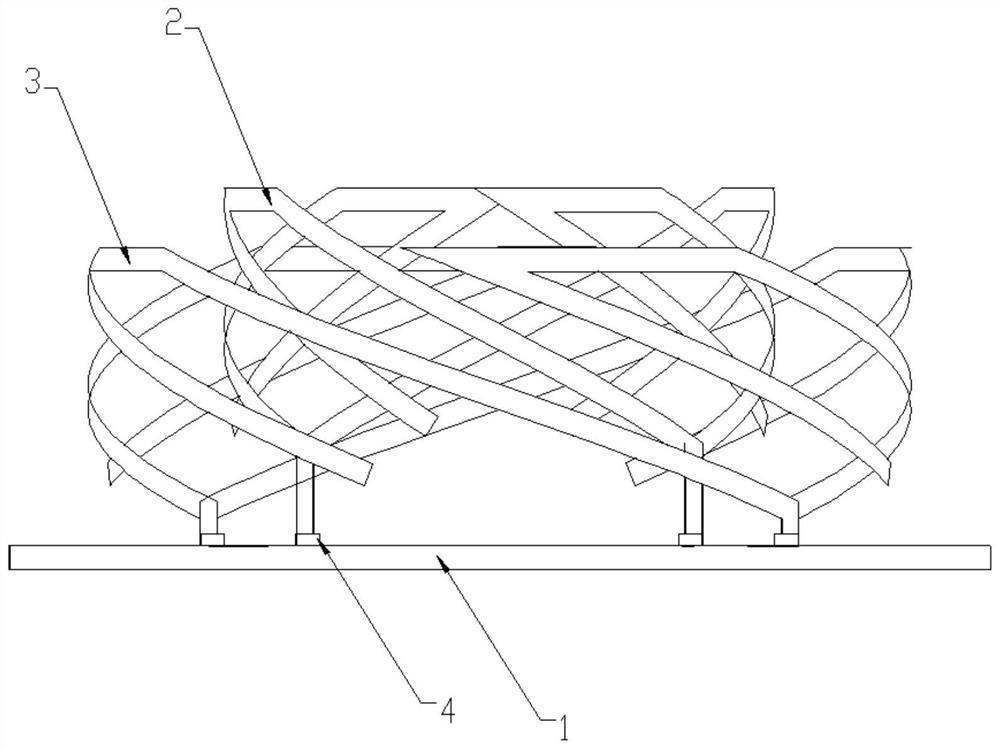

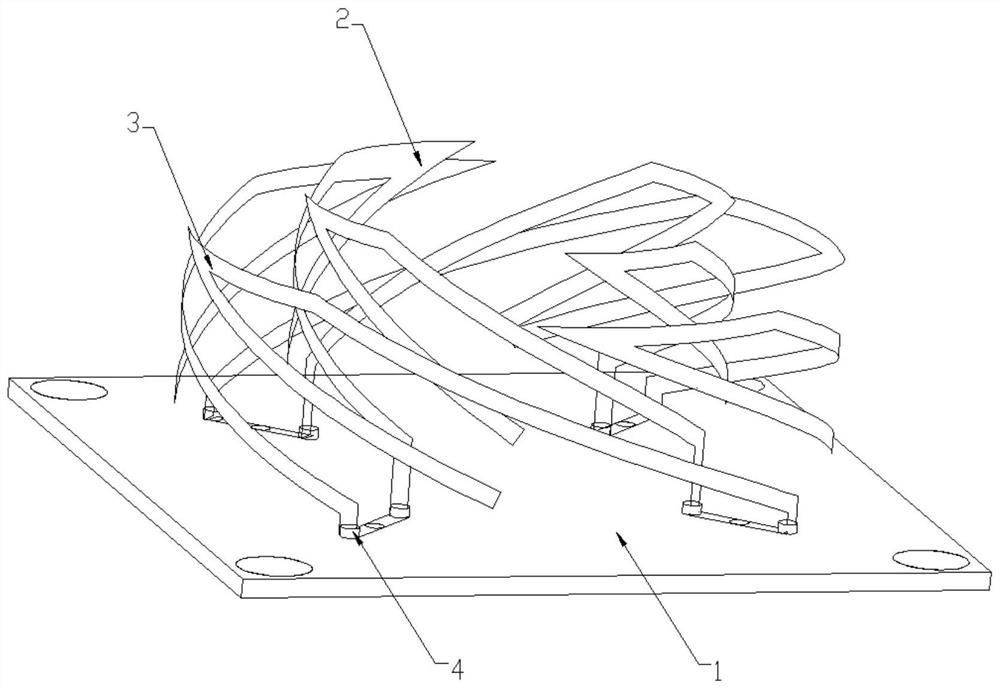

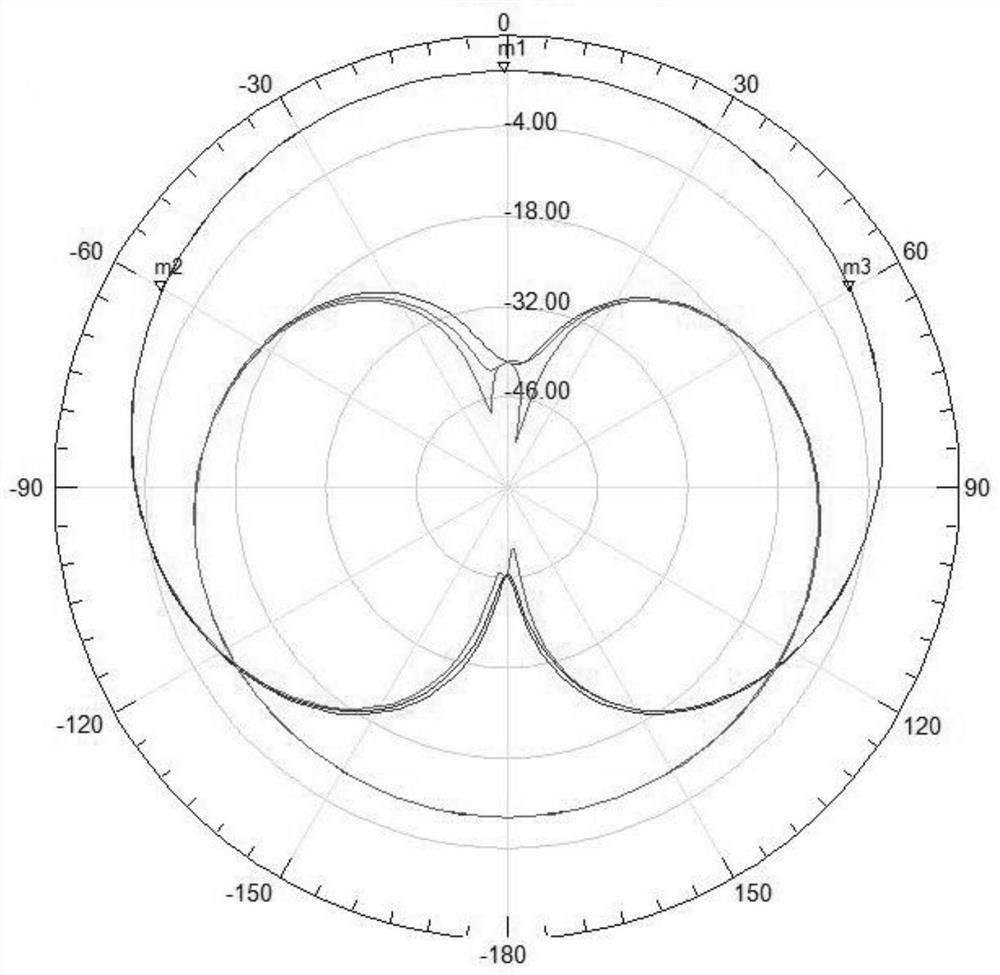

Novel high-precision positioning antenna

PendingCN112271435AUniform patternHigh precisionLogperiodic antennasSimultaneous aerial operationsEngineeringConcentric cylinder

The invention discloses a novel high-precision positioning antenna, and relates to the technical field of antennas. The antenna comprises a main board, a high-frequency helical antenna and a low-frequency helical antenna; the high-frequency helical antenna and the low-frequency helical antenna are arranged on the main board, the high-frequency helical antenna and the low-frequency helical antennaare arranged in a concentric cylinder, and the high-frequency helical antenna is arranged on the inner side of the concentric cylinder; the height of the high-frequency helical antenna is greater thanthat of the low-frequency helical antenna, the high-frequency helical antenna and the low-frequency helical antenna adopt 1 / 4 wavelength for radiation and feed through the same phase shift network, the feed network is provided with four ports, the ports are equal in amplitude, and the phases are 0 degree, 90 degrees, 180 degrees and 270 degrees in sequence. The spiral antenna is adopted, the manufacturing process is simple, and the cost is lower; the radiating surface of the antenna excites high-frequency and low-frequency gains through a high-frequency and low-frequency double-frequency helical antenna form, so that the directional diagram of the antenna is more uniform and the precision is higher.

Owner:SHENZHEN VLG WIRELESS TECH

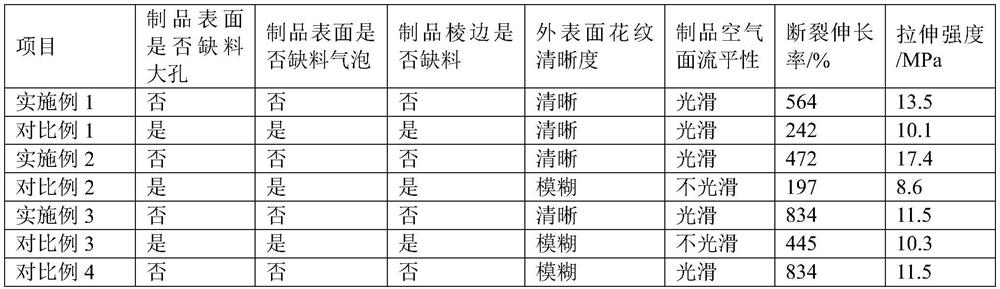

Large-particle rotational molding composite material with different flower color surface effects and preparation method of large-particle rotational molding composite material

The invention relates to the field of rotational molding, and provides a large-particle rotational molding composite material with different pattern surface effects aiming at the problem that large patterns with the diameter of more than 1mm are difficult to form by rotational molding, the large-particle rotational molding composite material is prepared from the following components in apparent volume fraction: 5-35 parts of A material powder, 30-90 parts of B material particles and 5-35 parts of C material particles, the base materials of the A material powder, the B material particles and the C material particles are resin, the mucosa temperature is that the material particles C are greater than the material particles B and greater than the material powder A in sequence from high to low, and the material particles B are granular materials with the diameter of 1-3mm and the length of 2-4mm and are a mixture of particles with a plurality of colors. The method can be used for manufacturing the large-pattern rotational molding product which is free of material shortage, clear and uniform in pattern and good in inner surface leveling property. The invention further provides a preparation method of the large-particle rotational molding composite material with the different color surface effects.

Owner:ZHEJIANG ROTOUN PLASTIC TECH

Three-dimensional patterned slip-proof gloves and preparation process thereof

InactiveCN108299688ABest dosageImprove gripDomestic articlesCoatingsLatex gloveCarboxymethyl cellulose

The invention discloses three-dimensional patterned slip-proof gloves, and belongs to the technical field of latex gloves. The three-dimensional patterned slip-proof gloves comprise the following components in parts by weight: 28 parts of pre-vulcanized natural latex, 5 parts of sodium carboxymethyl cellulose, 6 parts of colloidal calcium carbonate and 1 part of an emulsifier, and further comprisepotassium hydroxide, wherein the dosage of potassium hydroxide is 100-375 g based on a total amount of 200 kg of the raw materials. The invention further provides a preparation process of the three-dimensional patterned slip-proof gloves. According to the invention, the dosage of potassium hydroxide in the latex is controlled to realize coating pattern and three-dimensional effect on surfaces ofthe gloves; and a contrast experiment is performed on the pre-vulcanized latex without potassium hydroxide, and a wrinkling mechanism of patterns is discussed to obtain an optimal dosage of potassiumhydroxide, so that the surfaces of the gloves have balanced coating patterns and strong three-dimensional effect.

Owner:SHANDONG DENGSHENG SAFETY PROD

Method for preparing environment-friendly tipping paper for cigarettes

InactiveCN105269997AIncrease coverageClear patternPattern printingWater basedPulp and paper industry

The invention relates to printing technologies, in particular to a method for preparing environment-friendly tipping paper for cigarettes, and the method belongs to water-based ink printing. The manufacturing method is characterized in that the depth of a tank of a plate cylinder ranges from 43 [mu]m to 60 [mu]m or ranges from 15 [mu]m to 37 [mu]m; the solid content of water-based ink is controlled to range from 36% to 55%, the pH value is controlled to range from nine to ten or the scattering fineness of paint is smaller than or equal to 15 [mu]m, and the viscosity is controlled to range from 18 s to 50 s; after the raw tipping paper for cigarettes is printed and coated, the back of the raw tipping paper for cigarettes is pre-dried through a preheating device in a guide roller before the tipping paper enters a drying oven for drying. According to the method for preparing the environment-friendly tipping paper for cigarettes, water-based ink intaglio printing can be adopted. Compared with the prior art, the method has the advantages that the production safety is good, printed patterns are clear and uniform, the content of heavy metal such as arsenic and lead is lower, ink is convenient to prepare, and cost is reasonable.

Owner:赵强

Surface treatment method of medical metal material

ActiveCN108103428ANo pollution in the processNo noisePharmaceutical delivery mechanismProsthesisSurface structurePollution

The invention provides a surface treatment method of a medical metal material. The surface treatment method includes the steps of: performing mechanical polishing and oil dirt removal treatment to thesurface of a medical metal material and performing texturing to the surface of the medical metal material with laser so as to ablate or induce surface structures which are in micron / nano-scale and are formed by stacking a plurality of rings. Compared with the prior art, the method has the advantages as follows: 1) through the laser texturing on the surface of the medical metal material, the method can process the material directly in air environment without pollution and noise, the formed patterns being uniform and ordered; 2) friction performance of the medical metal material can be selectively reduced or enhanced, thus effectively broadening the application range of the medical metal material.

Owner:SHANGHAI JIAO TONG UNIV

Single-component acrylic acid modified wrinkle paint and resin preparation method

InactiveCN113637396AHigh molecular weightLess prone to agingPolyester coatingsBenzoic acidPolymer science

The invention discloses a single-component acrylic acid modified wrinkle paint and a resin preparation method, and relates to the technical field of coatings. The specific method comprises the steps of under the catalysis of a modified phosphazene base, initiating phenyl-substituted cyclopropene dimethyl ester and isobornyl acrylate to carry out anionic copolymerization by using a prepared short-chain silicon initiator so as to prepare carboxyl-terminated acrylic resin; sequentially adding n-butyl acetate, ethyl acetate, carboxyl-terminated acrylic resin, soya oil acid, linoleic acid, pentaerythritol, terephthalic acid, benzoic acid and dibutyltin dilaurate into a reactor for a heating reaction, and preparing acrylic acid modified wrinkle resin; and mixing the acrylic acid modified wrinkle resin with each auxiliary agent, and adjusting the viscosity to obtain the single-component acrylic acid modified wrinkle paint. The prepared single-component acrylic acid modified wrinkle paint is clear in pattern, simple to construct and good in weather resistance and mechanical strength.

Owner:宁夏星邦豹丰涂料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com