Large-particle rotational molding composite material with different flower color surface effects and preparation method of large-particle rotational molding composite material

A composite material and surface effect technology, applied in the field of rotomolding, can solve the problem that it is difficult to form large patterns with a diameter greater than 1mm, and achieve the effect of beautiful visual effect, good product performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

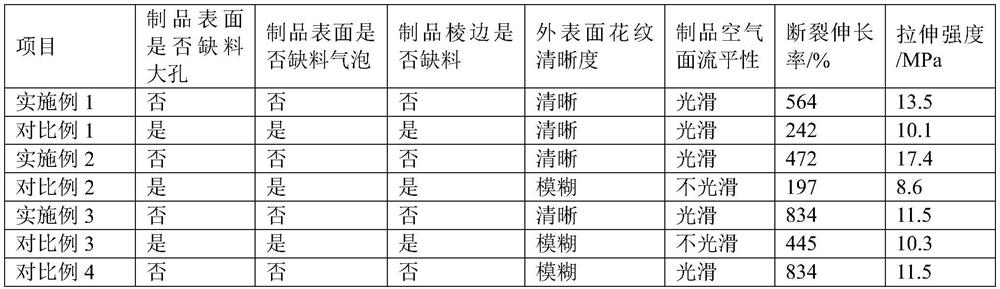

Examples

Embodiment 1

[0023] A large particle rotomoulding composite material with different surface effects, composed of A material powder, B material granule and C material granule, wherein the mucous membrane temperature from high to low is C material granule > B material granule > A material powder, The preparation method is:

[0024] (1) Preparation of material A powder: mix polyethylene (7042, Zhenhai Refining & Chemical) with a high-speed mixer for 4 minutes, set the temperature of each section of the extruder to 200°C, and the screw speed to 300rpm, and melt blend in a twin-screw extruder Granulate and dry to obtain material A granules; grind the material A granules with a plastic mill, and the milling process parameters: the temperature of the grinding disc is ≤ 70° C., and the rotational speed of the grinding disc is 3000 rpm to obtain the material A powder. The powder of material A is a natural powder with a particle size of D95=425μm, a powder fluidity of 25s / 100g, and a light transmitt...

Embodiment 2

[0035] A large particle rotomoulding composite material with different surface effects, composed of A material powder, B material granule and C material granule, wherein the mucous membrane temperature from high to low is C material granule > B material granule > A material powder, The preparation method is:

[0036] (1) Preparation of material A powder: Polyethylene (7149U, Qilu Petrochemical) was mixed for 3 minutes in a high-speed mixer, the temperature of each section of the extruder was set at 130 ° C, the screw speed was 100 rpm, and the twin-screw extruder was melt-blended to produce granules, dried to obtain material A granules; grind material A granules with a plastic mill, milling process parameters: milling disc temperature ≤ 70°C, milling disc rotating speed 2500rpm, to obtain material A powder. The powder of material A is a natural powder with a particle size of D95=485μm, a powder fluidity of 33s / 100g, and a light transmittance ≥ 60%.

[0037] (2) Preparation of...

Embodiment 3

[0044] A large-particle rotomolding composite material with different surface effects, in which the mucous film temperature from high to low is C material particles > B material particles > A material powder, composed of A material powder, B material granules and C material granules, The preparation method is:

[0045] (1) Preparation of material A powder: Mix polyolefin elastomer (C5070D, Sabic, Saudi Arabia) with a high-speed mixer for 3-5 minutes, set the temperature of each section of the extruder to 280°C, and the screw speed to 500rpm, twin-screw extruder Melting, blending, granulation, and drying to obtain material A granules; grind the material A granules with a plastic mill, and the milling process parameters: the temperature of the grinding disc is ≤ 70°C, and the rotational speed of the grinding disc is 3200rpm to obtain the material A powder. The powder of material A is a natural powder with a particle size of D95=465μm, a powder fluidity of 33s / 100g, and a light t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com