Surface treatment method of medical metal material

A metal material and surface treatment technology, used in pharmaceutical formulations, medical science, prostheses, etc., can solve the problems of affecting the mechanical properties of the base material, harsh preparation conditions, falling off, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment relates to a surface texture and a preparation method for precisely regulating the surface tribological properties of medical metal materials, including the following steps:

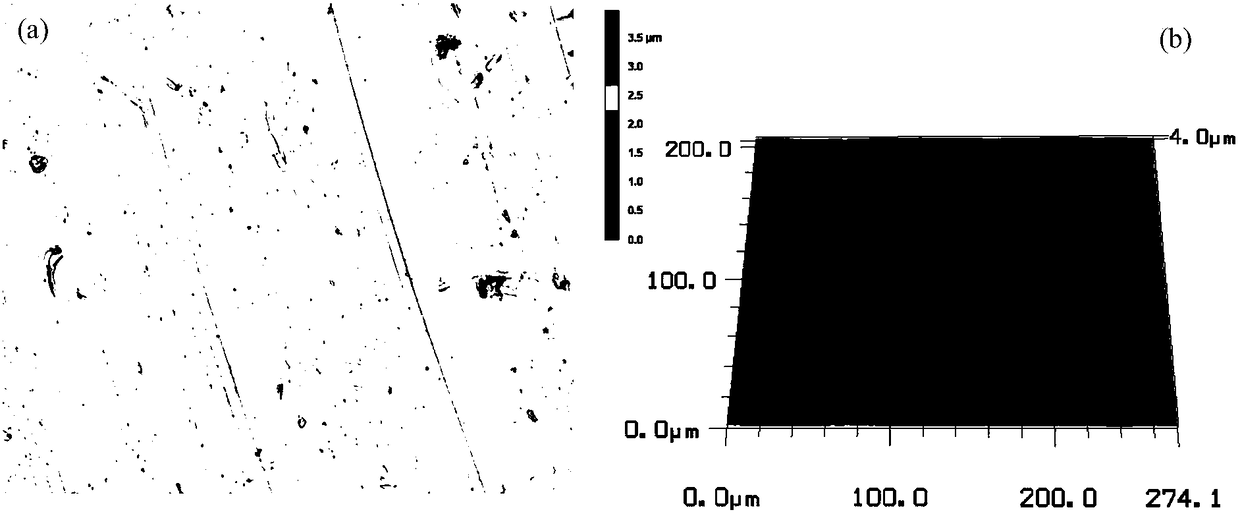

[0035] (1) Mechanically polish the surface of the titanium alloy, and ultrasonically clean it in acetone and alcohol solutions for 20 minutes respectively, and carry out degreasing treatment, refer to figure 1 ;

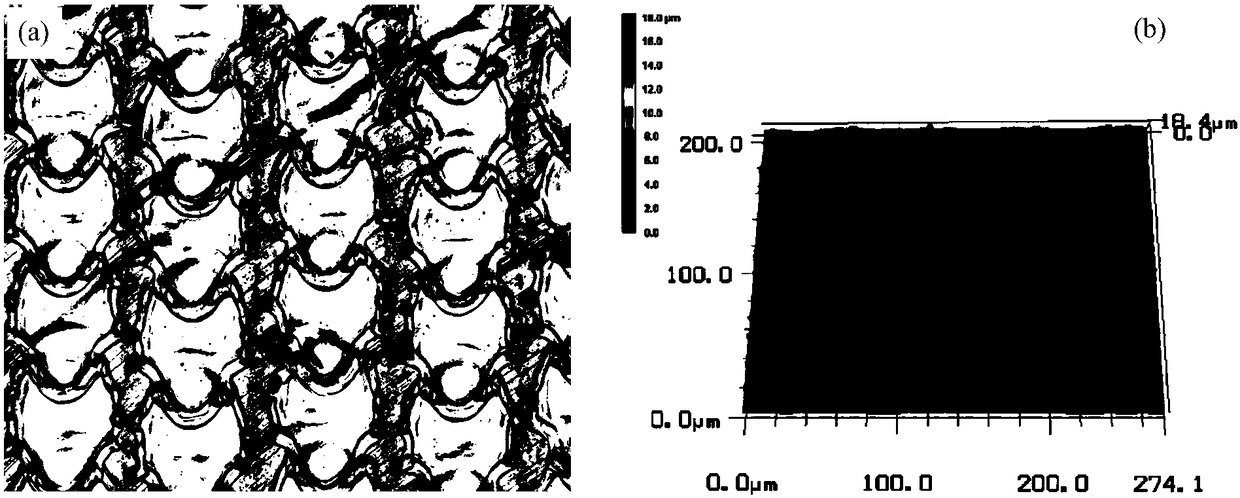

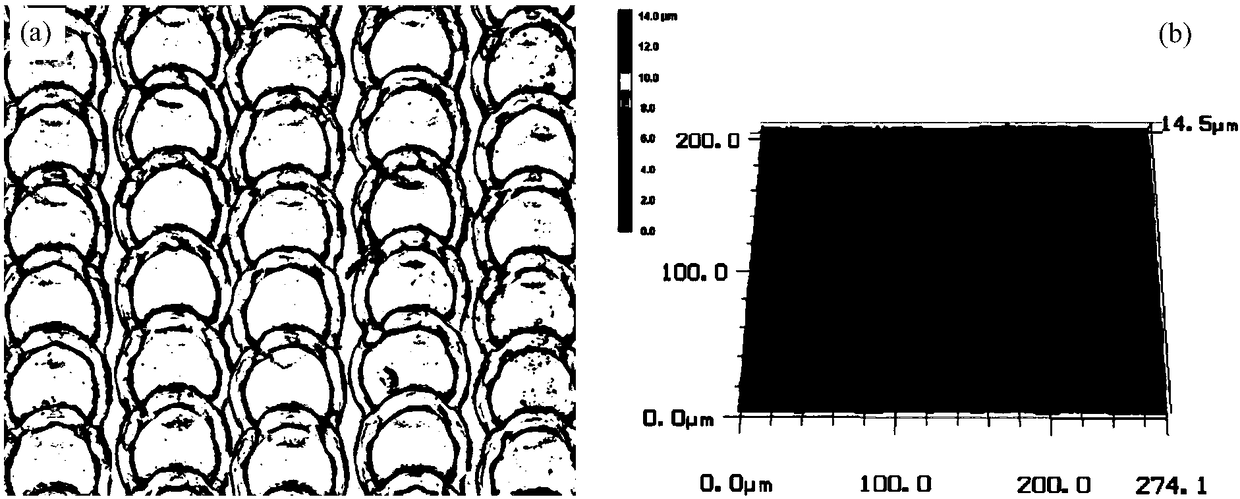

[0036] (2) Use a 20W ytterbium-doped fiber laser to texture the surface of the material, ablate or induce an artificial surface structure with micron or nanoscale, the basic parameters of the laser are: laser wavelength λ is 1064nm, pulse Frequency 1-100KHz, pulse width τ 1-1000ns; power 1-20W, laser speed 0.1-1.5m / s, lens focal length models: 160nm and 254nm, focal length and sample surface height 150-300mm.

[0037] (3) Use laser micromachining system to process micron-scale texture on the surface of titanium alloy. The diameter of the stacked ring is 10-60um, the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com