Lockstitch sewing machine capable of feeding automatically

A technology of automatic feeding and lockstitch machine, applied in the field of lockstitch machine, can solve the problems of not being able to cooperate well, affecting the sewing effect, different structures and functions between multi-needle machine and lockstitch machine, etc. Uniform, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

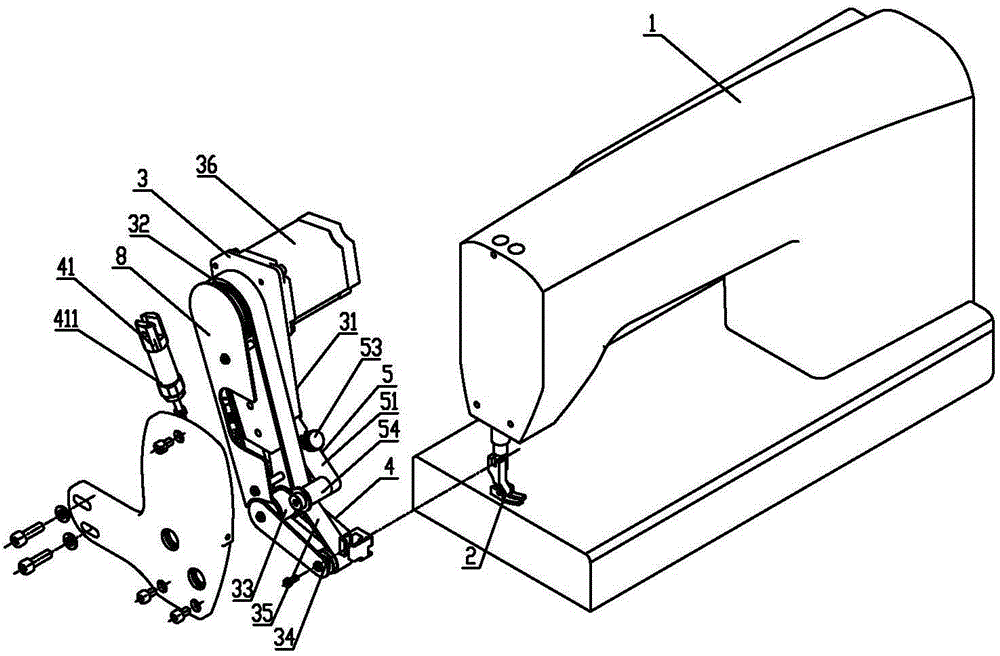

[0023] Specific embodiment one, refer to Figure 1 to Figure 3 As shown, an automatic feeding lockstitch sewing machine includes a lockstitch sewing machine body 1, a presser foot lifter 2, a material puller 3, a linkage mechanism 4 and a belt pressing device 5, wherein the presser foot lifter 2 is arranged on the lockstitch sewing machine body 1 ;

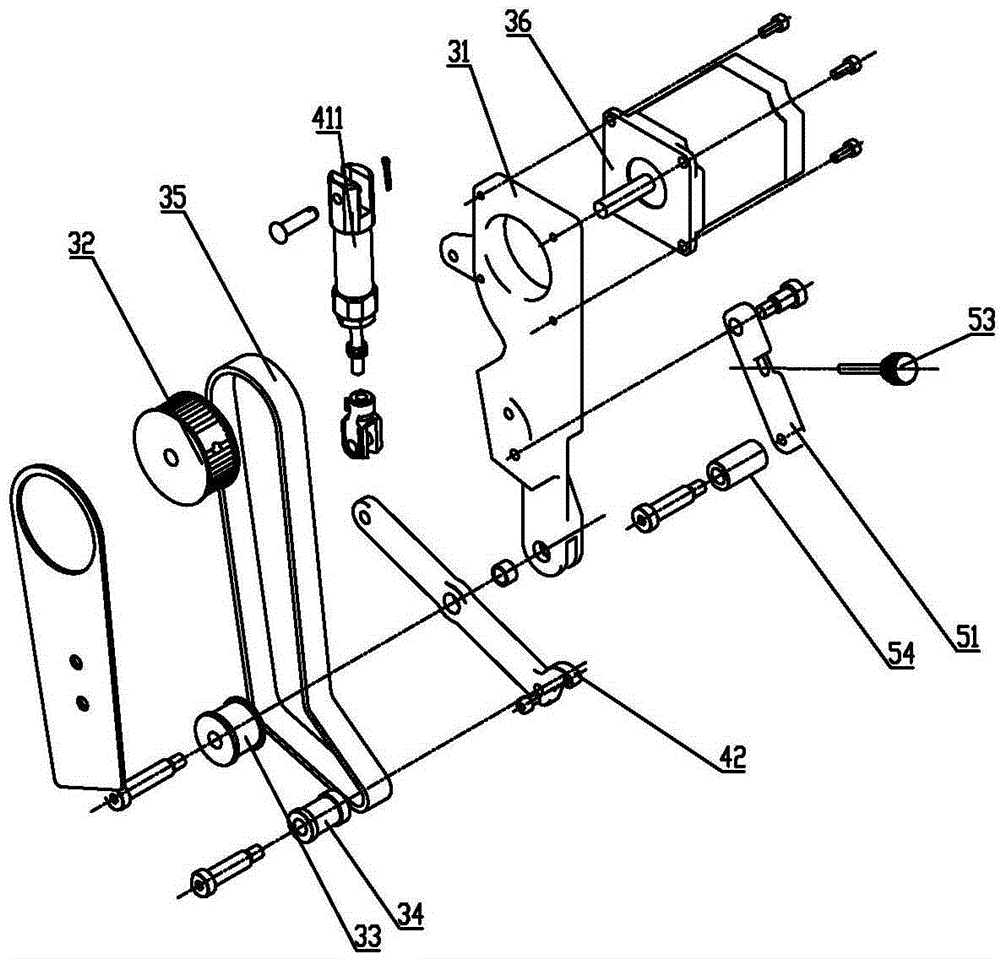

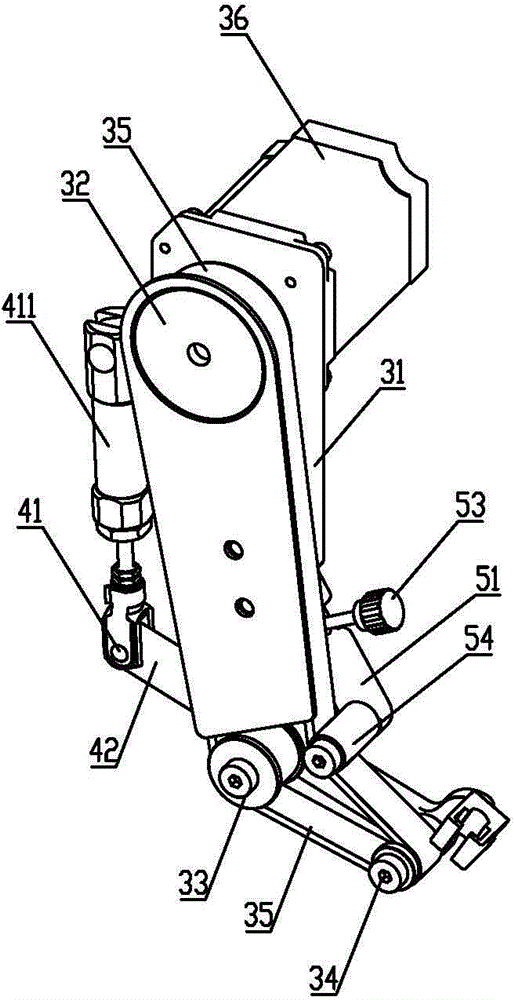

[0024] The puller 3 includes a mounting plate 31, a timing pulley 32, a belt roller 33, a pulling roller 34, a pulling belt 35 and a stepping motor 36, the mounting plate 31 is fixed on the lockstitch machine body 1, and the timing belt Wheel 32, tensioning roller 33 and pulling roller 34 are arranged on the mounting plate 31 in an "L" shape, and pulling roller 34 can rotate up and down around the tensioning roller 33, and pulling belt 35 is tensioned on the timing belt On the wheel 32, the stretching belt roller 33 and the pulling roller 34, the stepper motor 36 is connected with the synchronous pulley 32 and drives it to rotate...

specific Embodiment 2

[0031] Specific embodiment two: with reference to Figure 4 to Figure 6 As shown, an automatic feeding lockstitch sewing machine includes a lockstitch machine body 1, a presser foot lifter 2, a material puller 3, a linkage mechanism 4 and a belt pressing device 5, wherein the lockstitch machine body 1, the presser foot lifter 2, the puller The feeder 3 and the belt pressing device 5 are all the same as the specific embodiment one;

[0032] The linkage mechanism 4 includes a driving device 41a and a connecting arm 42a. The driving device 41a includes a presser foot lifter control device 411a and a presser foot lifter chuck 412a. The presser foot lifter control device 411a manually controls the presser foot lifter 2 Lifting or pressing down, there is a through groove 43a on the clamp 412a for the presser foot 2 to pass through, and a groove 44a matching the connecting arm 42a is opened on the side wall of the clamp 412a for the presser foot, During installation, the presser foo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com