Patents

Literature

73results about How to "Beautiful pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

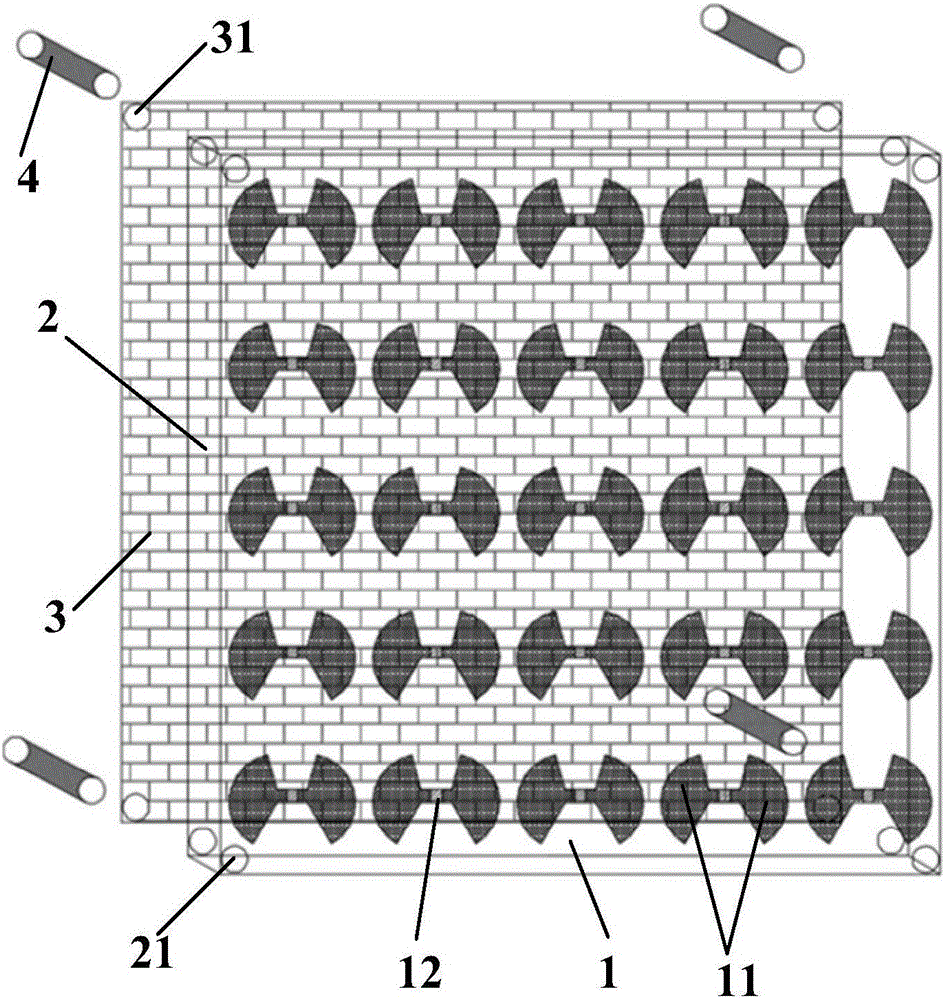

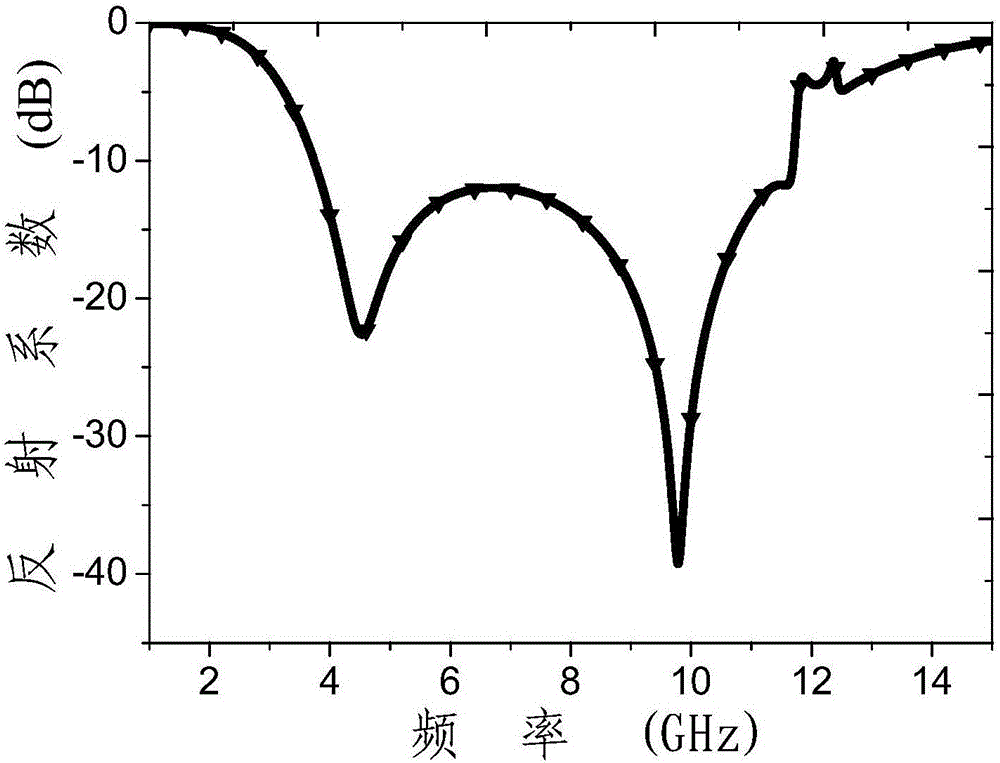

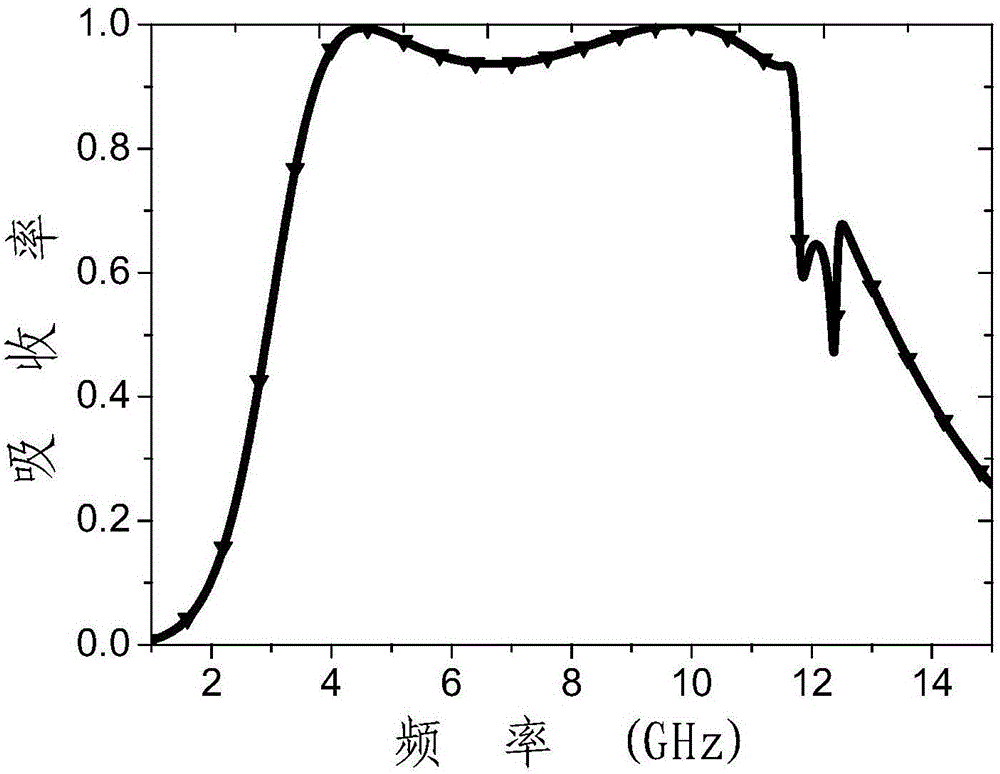

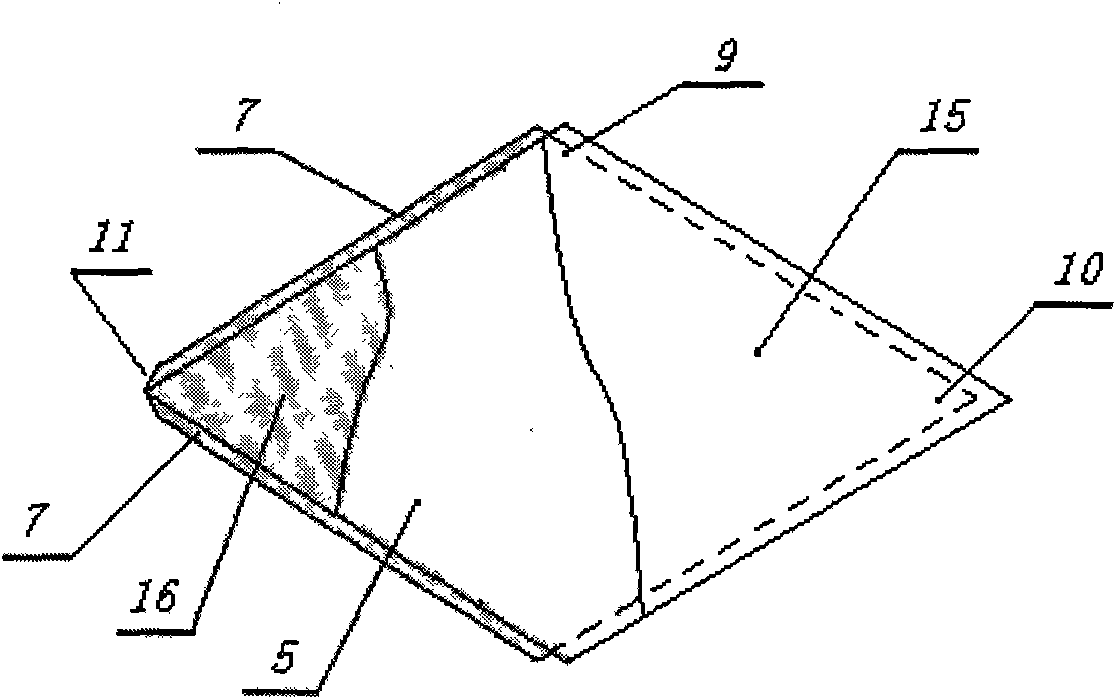

Ultra wideband wave absorber based on resistance loading

The invention discloses an ultra wideband wave absorber based on resistance loading. The ultra wideband wave absorber comprises a dipole array antenna, patch resistors, a metal floor and four plastic screws, wherein the four plastic screws are used for locating and fixing the dipole array antenna and the metal floor, the dipole array antenna is formed by periodically arranging a plurality of same dipoles similar to butterfly wings, two welding points of a single patch resistor are separately welded at the two ends of a dipole arm so as to further achieve perfect matching with a single dipole, and an electromagnetic wave can be absorbed by the dipole array antenna and is consumed by the patch resistors so as to achieve the purpose of wave absorption. The ultra wideband wave absorber can be applied to a microwave / millimeter-wave anti-interference system and has the advantages of simplicity in structure, light weight, low cost, unit miniaturization and short processing period; and moreover, the electromagnetic wave absorption within different frequency ranges can be achieved by designing dipole antennas in different frequency ranges.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

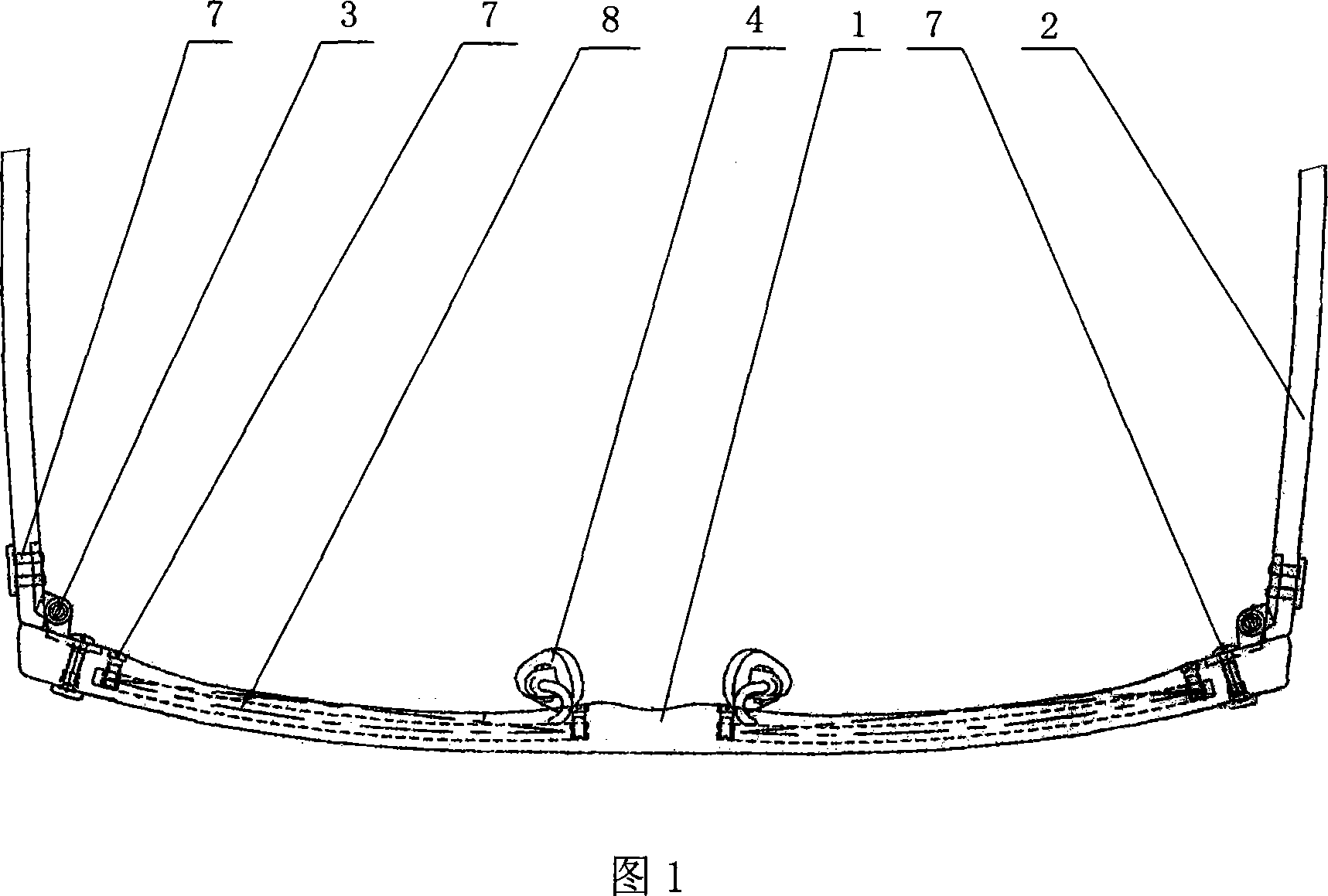

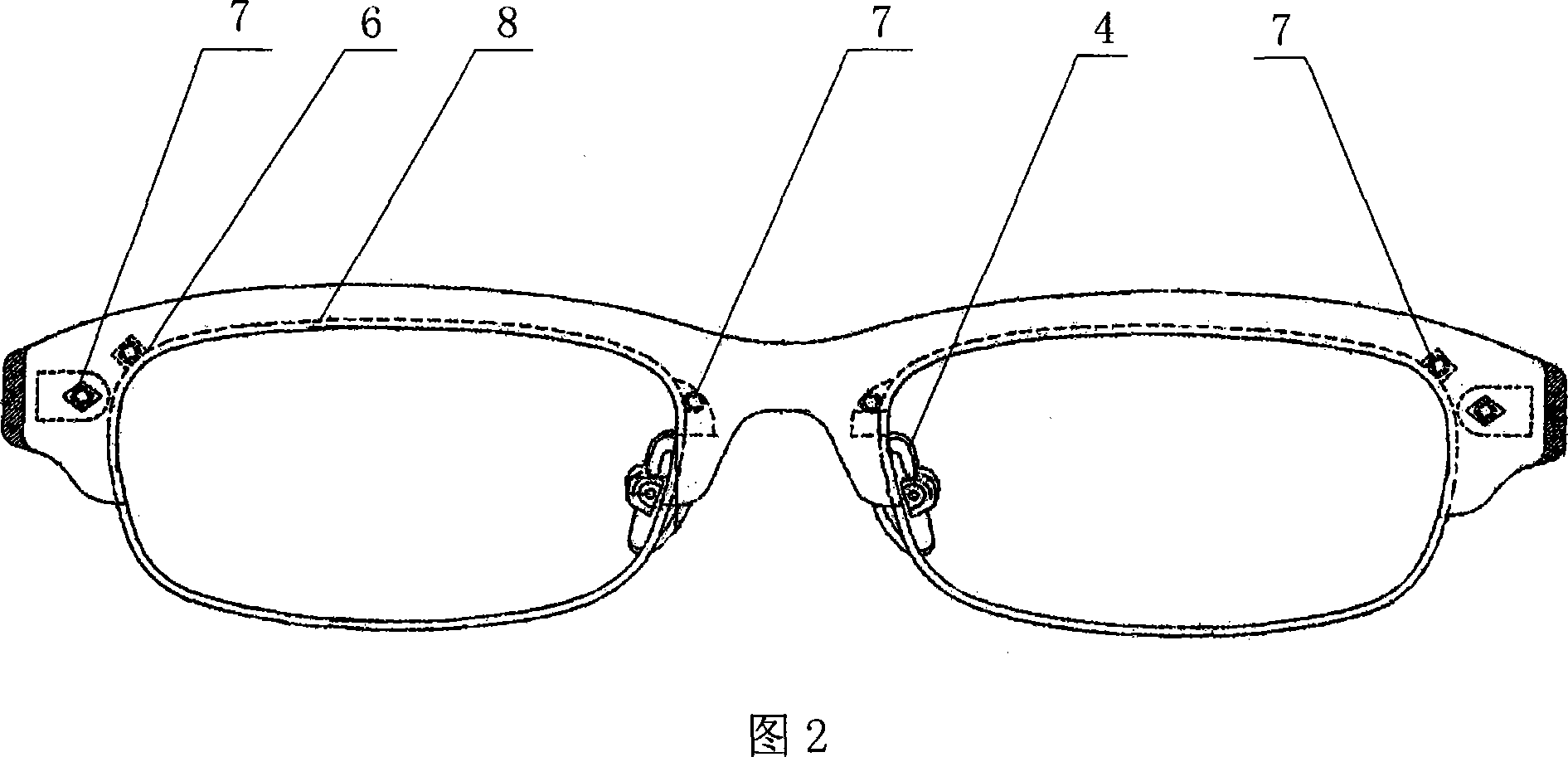

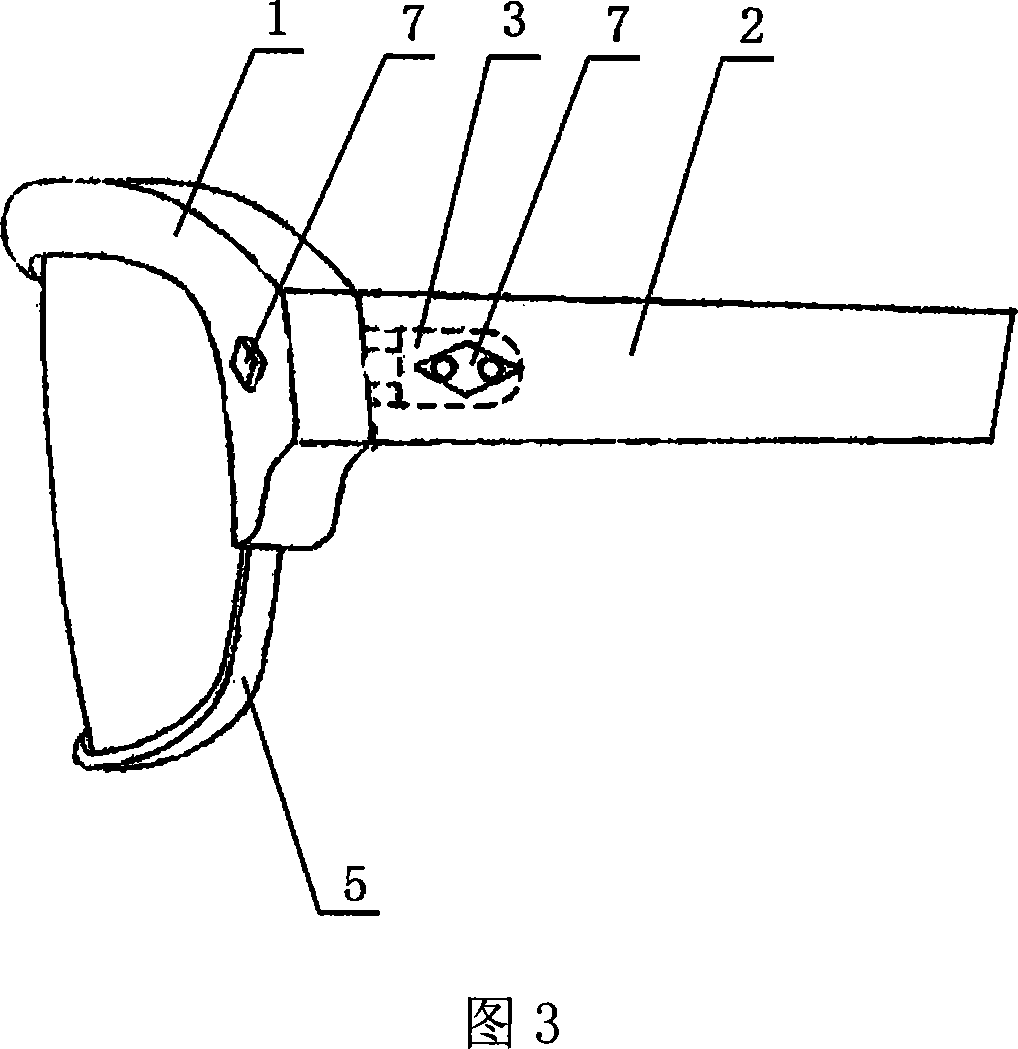

Process for producing glasses with wood or bamboo making glasses frame

InactiveCN101058205AFashionableEnvironmentally friendly materialsFramesWood working apparatusPulp and paper industryHinge angle

The invention relates to a wood or bamboo made glass frame with designing the frame and the fittings together with assembly drawing, selecting wood or bamboo to make the required small blocks of materials, manually making each block into glass frame and fittings or using robot to replace manual processing, polishing the frame and fitting surface, assembling the frame and glasses leg with hinges, then the installation of nose up, and finally the installation of glasses. It is novel in style, using environmental protective material, simple in making process.

Owner:袁权芬

Wooden veneered metal door

InactiveCN101769116AReduce energy consumptionImprove energy consumptionDoor leavesSolid woodSurface layer

The invention discloses a wooden veneered metal composite door and relates to a metal door. A metal plate is used as a base material; a layer of wooden veneer layer is adhered on the surface layer through an adhesive; the outermost layer is a lacquered layer and other protective materials; and a one-component or two-component adhesive is adopted to glue the wooden veneer on the base material of the metal door plate through cold pressing or hot pressing. Therefore, the wooden veneered metal composite door has various unique natural advantages of solid wood materials, has the characteristics of various colors, attractive decorative patterns, comfortable sense of touch, energy conservation and heat insulation, and the like, and has outstanding decorative performance and practicality.

Owner:刘少来

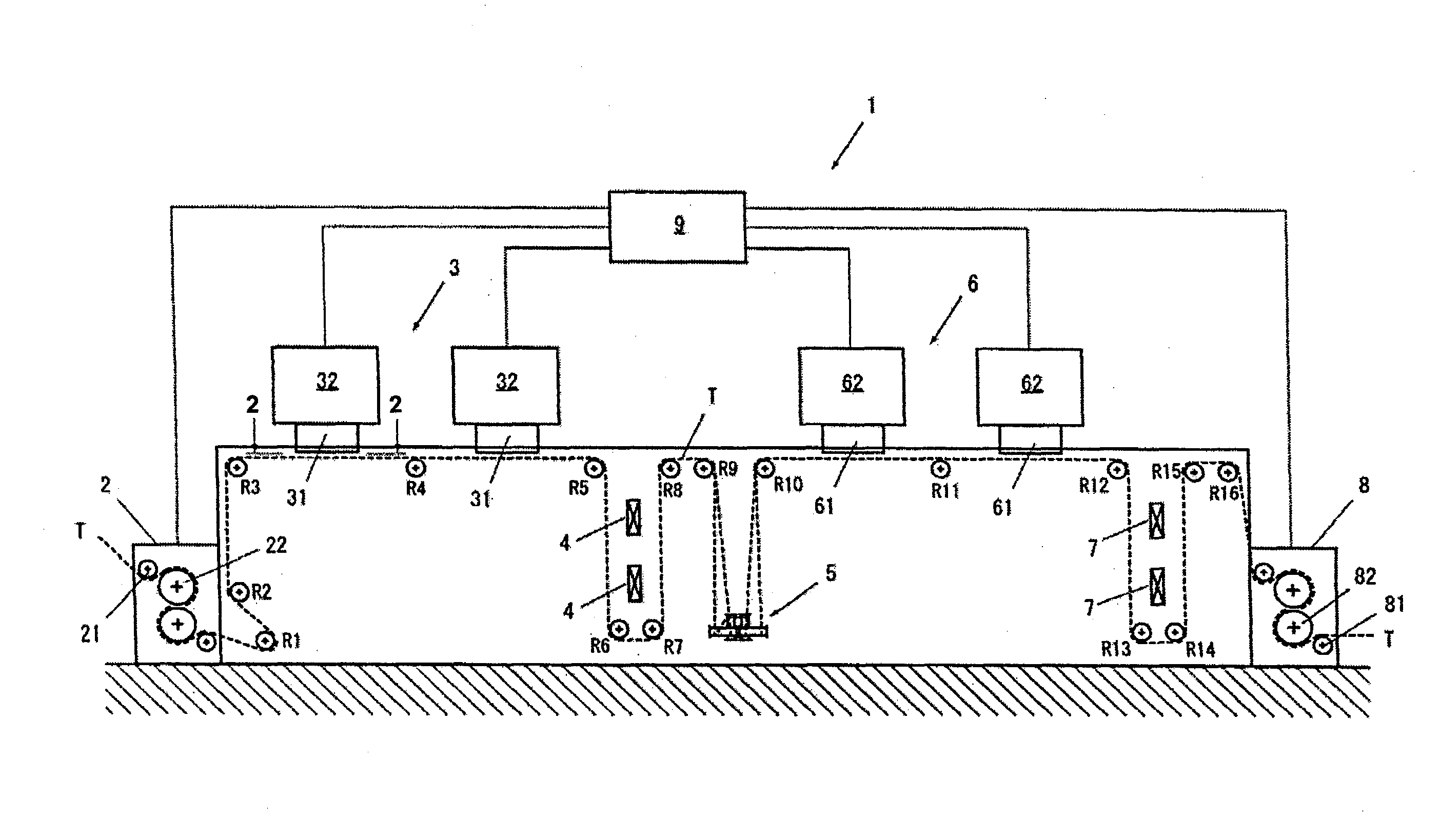

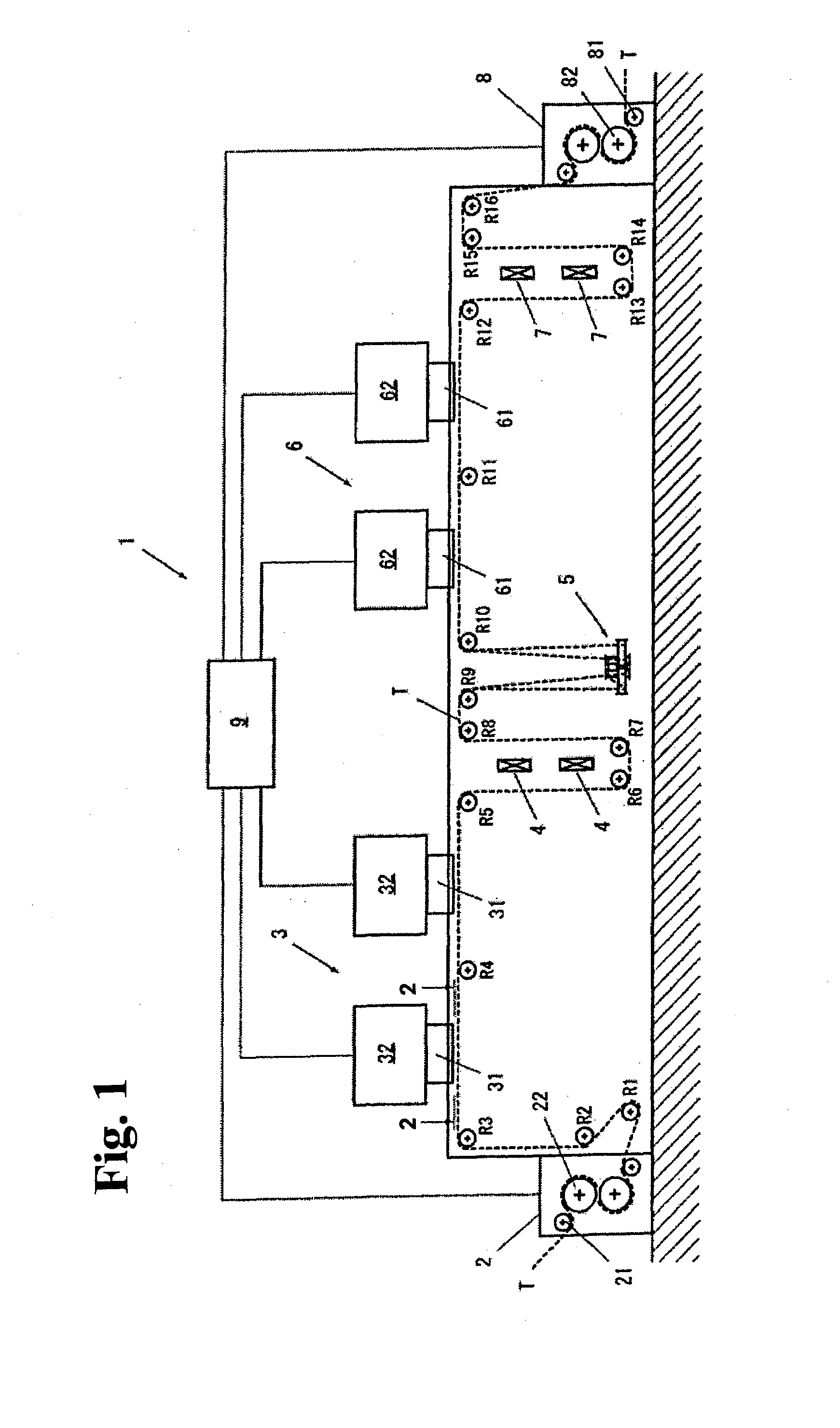

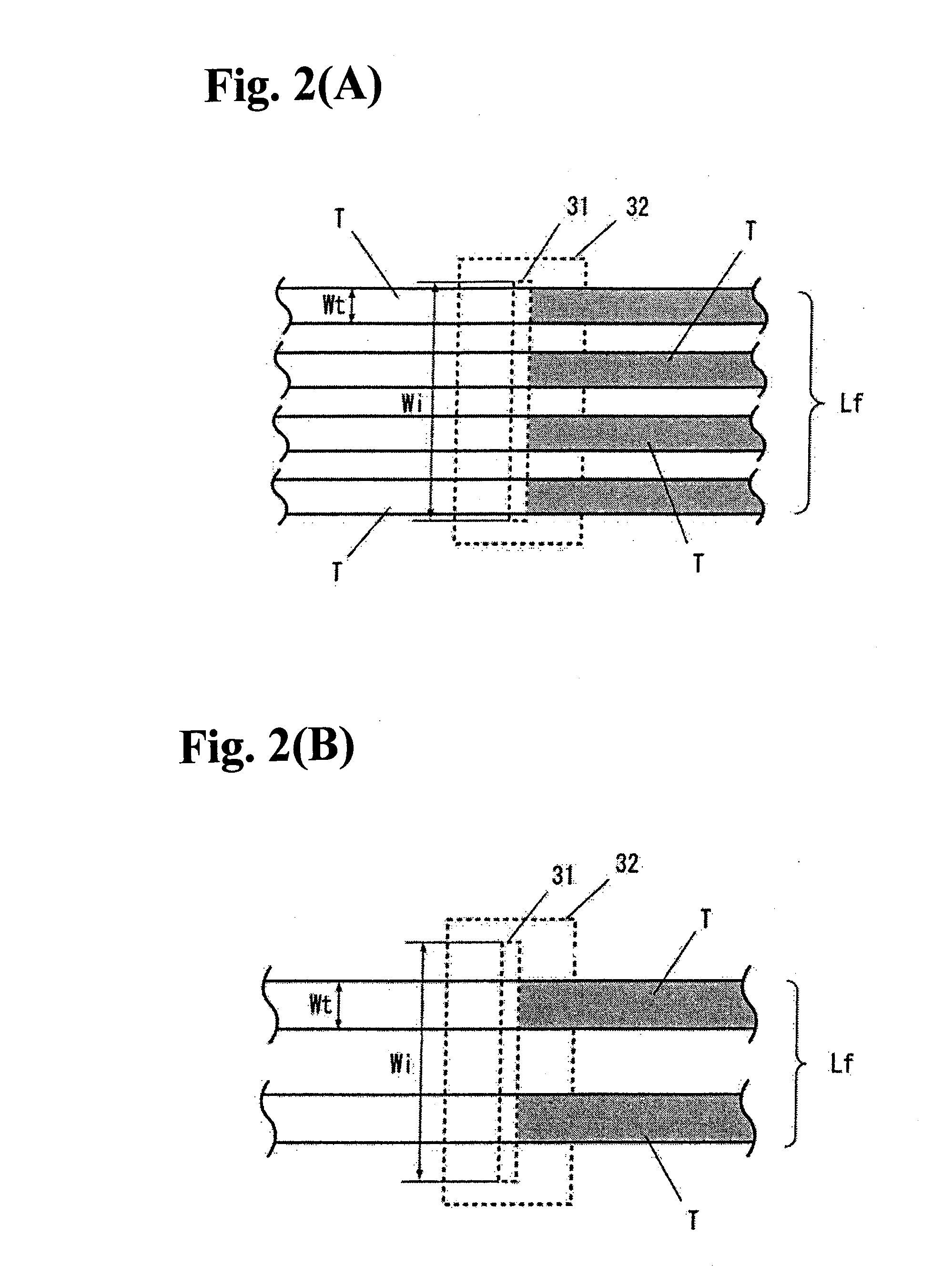

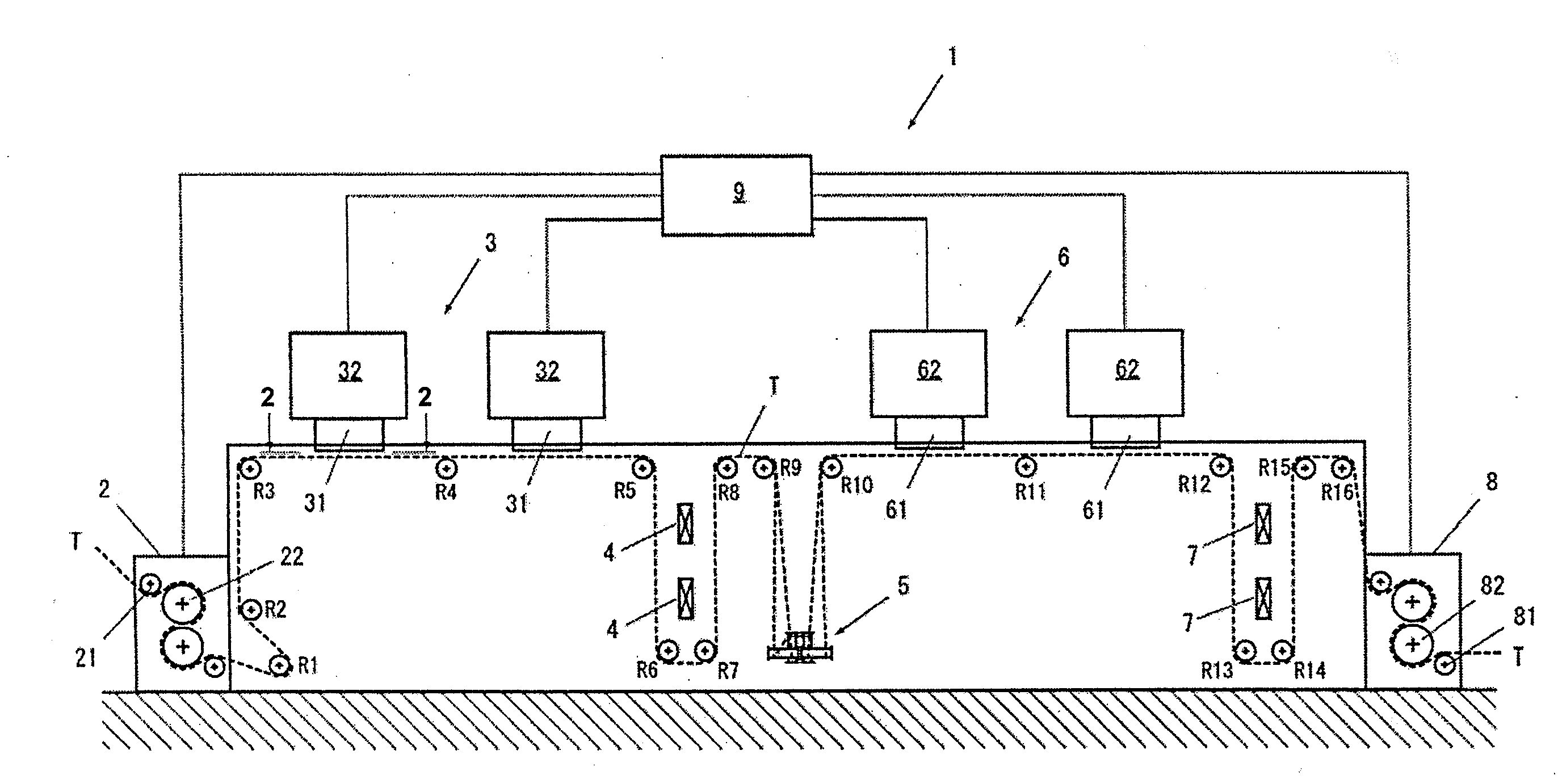

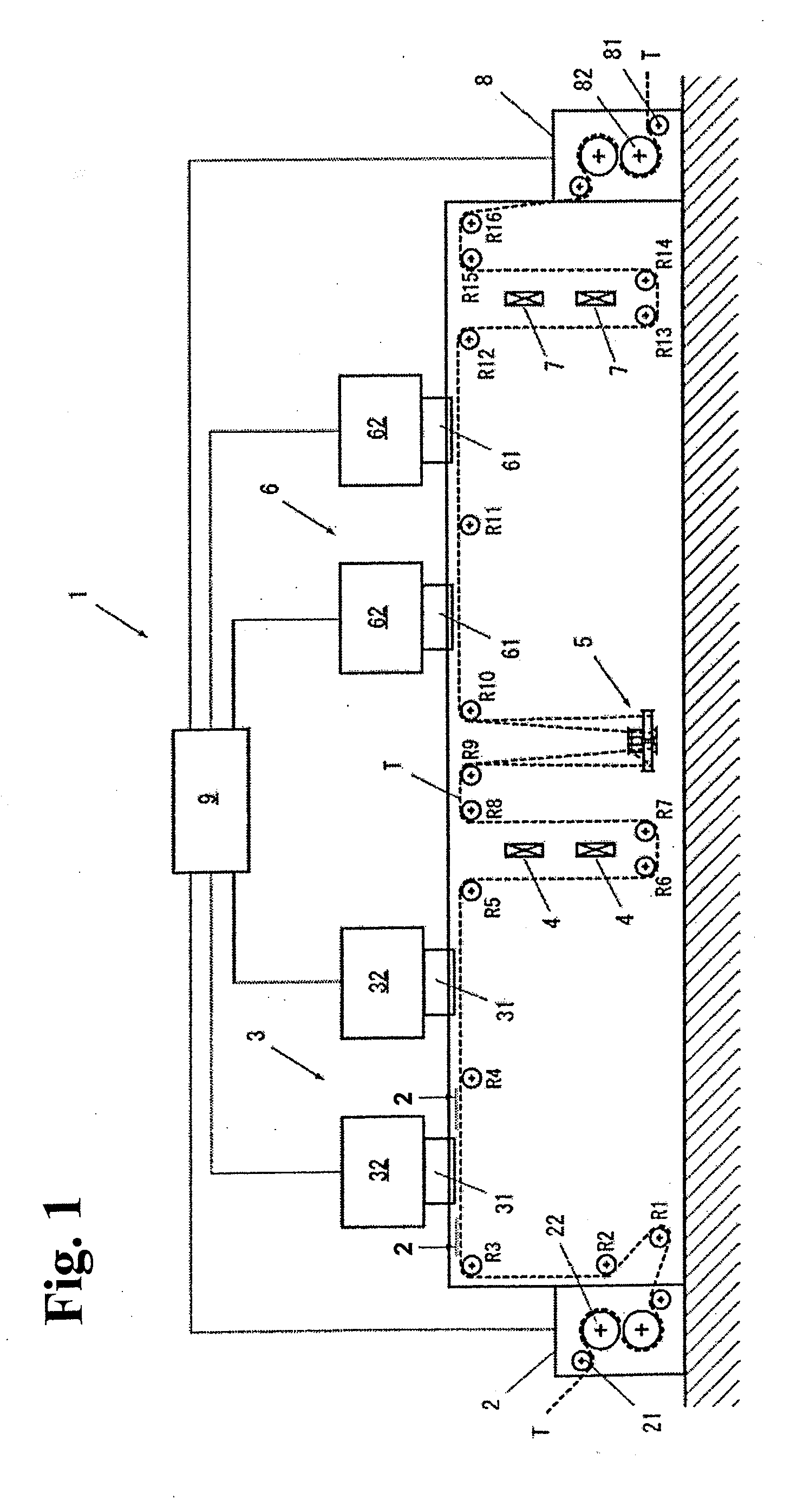

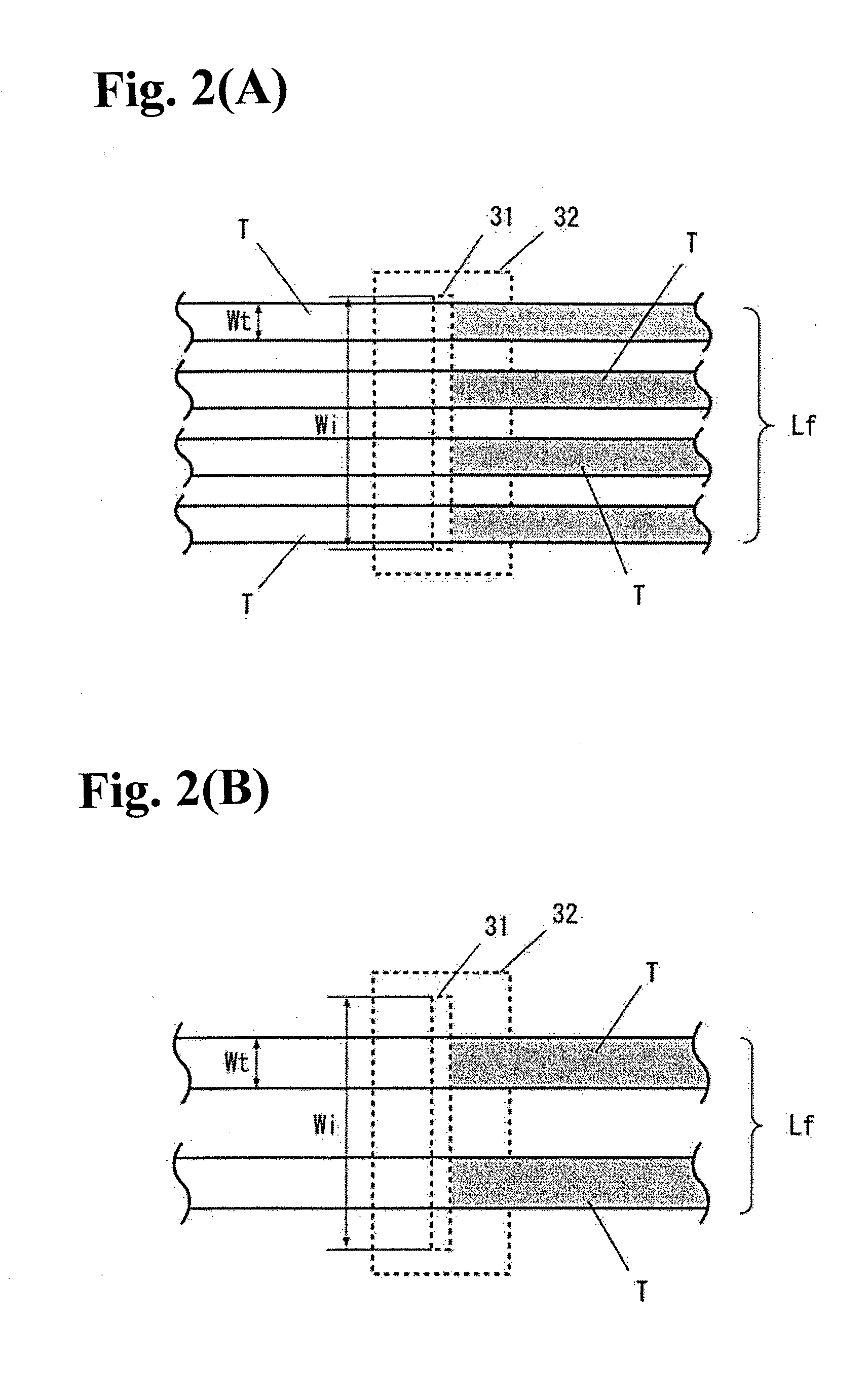

Inkjet dyeing method and apparatus

ActiveUS20100050347A1Easily subjected to continuous printingReduce the burden onControl devices for washing apparatusTypewritersEngineeringMechanical engineering

An inkjet dyeing apparatus for dyeing a belt-shape textile includes a feeding section for feeding the textile, a front surface printing section for dyeing a front surface of the textile by ink ejected thereon, a front surface drying section for drying the front surface of the textile, an inverting section for inverting and feeding the textile to a rear surface printing line, a rear surface printing section for dyeing the rear surface of the textile by ink ejected thereon, and a rear surface drying section for drying the rear surface of the textile. A transporting section is provided to transport the textile for further processing. A control unit controls ink ejection at the front and rear surface printing sections.

Owner:JOYSON SAFETY SYST JAPAN GK

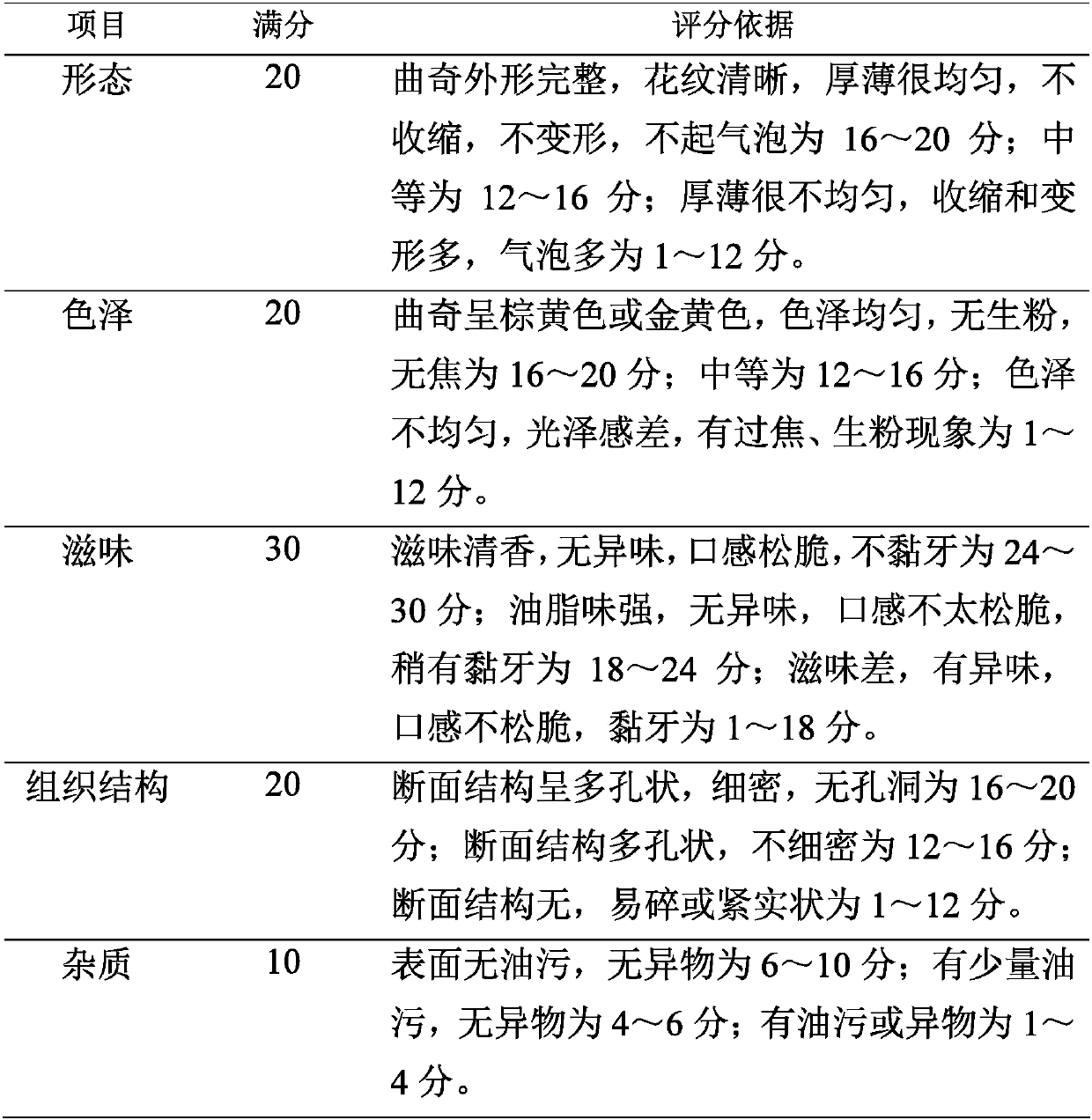

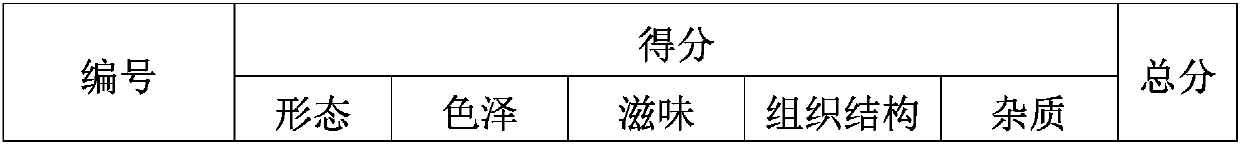

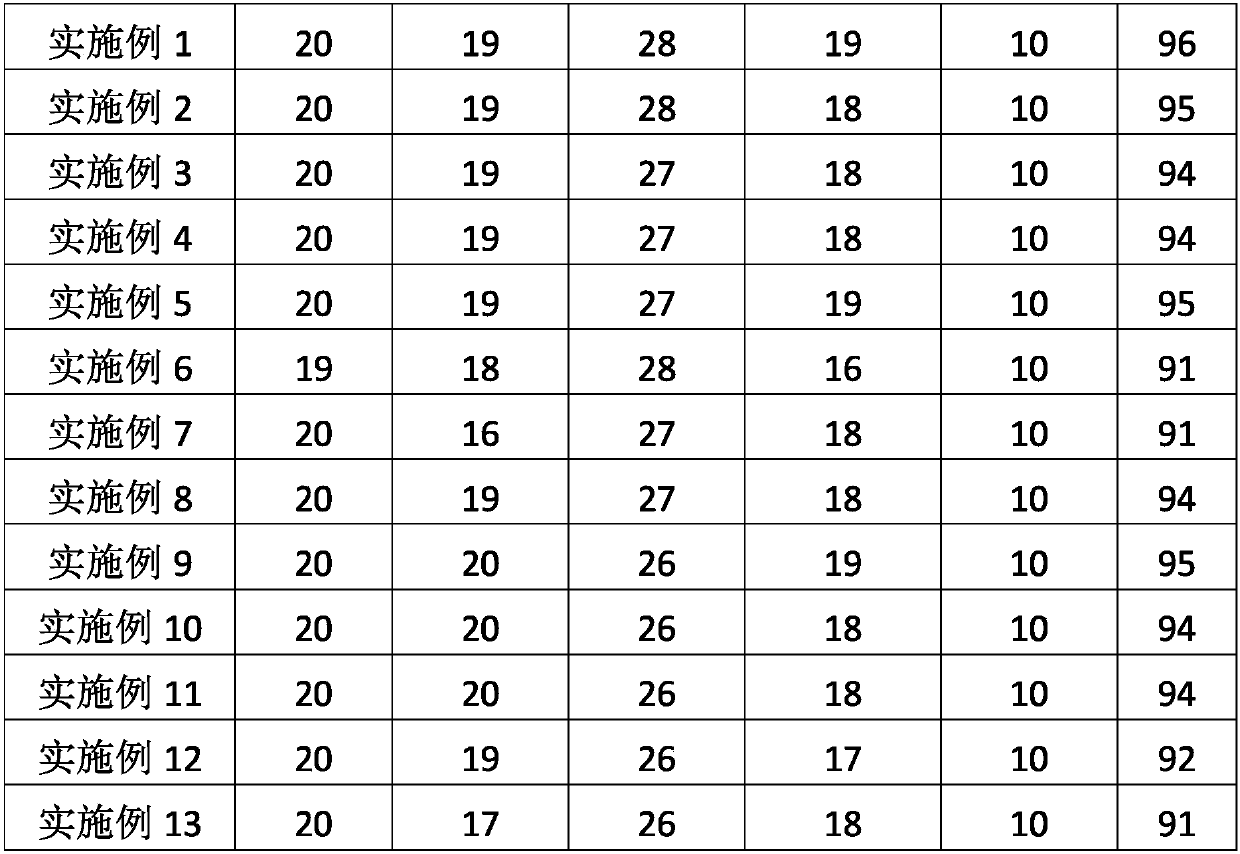

Coarse cereal cookie and preparation method thereof

The invention provides a coarse cereal cookie. The coarse cereal cookie is prepared from the following raw materials including, by weight, 30-50 parts of buckwheat flour, 30-50 parts of naked oat flour, 10-30 parts of corn flour, 50-70 parts of fat, 30-50 parts of powdered sugar, 40-60 parts of eggs and 0.1-1 part of baking soda. The fat is a combination of cream and milk or butter. The preparation method comprises the first step of mixing and sieving the buckwheat flour, the naked oat flour and the corn flour and sieving the powdered sugar, the second step of whisking the eggs and the powdered sugar into a creamy egg paste, the third step and the fourth step of mixing the fat and the creamy egg paste into a flocculent shape, the fifth step of pouring the buckwheat flour, the corn flour, the naked oat flour mixture into the paste and stirring the mixture to be uniform, the sixth step of extruding a semi-finished cookie, and the seventh step of baking. The coarse cereal cookie is rich in dietary fiber, protein and minerals, has golden color, oatmeal flavor, crisp texture and a simple formula, and is suitable for a cake shop, a snack food processing enterprise and home making.

Owner:BEIJING VOCATIONAL COLLEGE OF AGRI

Board made of tea seed shell

InactiveCN1485187ABeautiful patternEasy to processDomestic articlesFlat articlesEngineeringGreen tea

The invention relates to a construction material, in particular a plywood material by green tea seed shell for substituting wood and protecting cultivated land and method of production thereof, The invention provides a sheet making process using tea seed shells, the process by the invention not only is adaptive for sheet making in the tea seed production area, but also can prevent pollution to the environment and harm to the human body. íí

Owner:上海众望房地产经纪有限公司

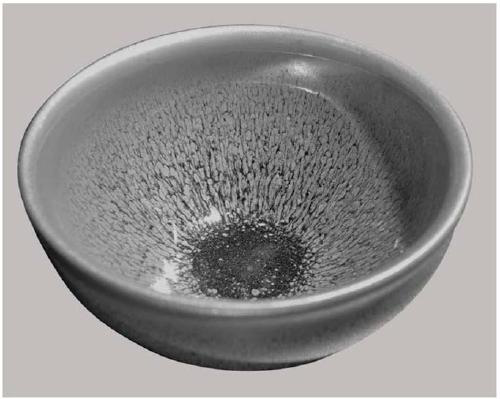

Jianzhan firing process

The invention discloses a Jianzhan firing process, comprising the steps of: providing green-body raw materials and a glaze slurry, conducting pugging on the green-body raw materials, conducting throwing shaping, and conducting trimming to obtain a green body; and putting the green body in an electric kiln for bisque firing, then conducting glazing, loading the glazed body in a sagger, sending thesagger into a chamber of a down draught kiln for sintering, conducting natural cooling, and taking the product out of the kiln. The formula, the firing atmosphere, the temperature curve and other technological flow are clear, easy to master and good in stability, the yield is high, the cost is low, prepared Jianzhan has less small pores, beautiful layered patterns, and a fine and moisture glaze surface, and can be favorably compared with Jianzhan produced through wood firing by a Dragon kiln.

Owner:南平市建阳区山石建盏陶瓷有限公司

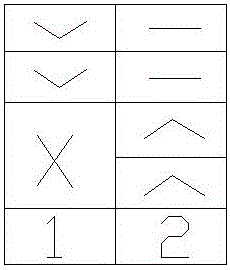

Digitized accurate cross-stitching pattern acquisition method

InactiveCN104700349AGo digitalAccurate collectionImage data processing detailsSpecial data processing applicationsComputer scienceColor scheme

The invention discloses a digitized accurate cross-stitching pattern acquisition method. The digitized accurate cross-stitching pattern acquisition method comprises the steps of setting grid parameters in software Photoshop, importing pattern pictures to be digitized into the software Photoshop and adjusting size, creating a picture layer, drawing patterns according to grids and the pattern pictures and paying attention to stitch number counting, setting an independent picture layer for each color, and saving a digitized accurate acquired pictures of the patterns. The digitized accurate cross-stitching pattern acquisition method adopts the professional software Photoshop to achieve digitization and performs layered management according to colors and positions of the patterns so as to facilitate follow-up color matching and design. Compared with existing general photographing, scanning and other digital means, the cross-stitching pattern detailed information can be accurately acquired, and accurate positioning is performed so as to facilitate re-production by using a scale plate marked with grid number. Stitches are separated by using the grids and are clear, and the patterns are attractive.

Owner:WUHAN UNIV

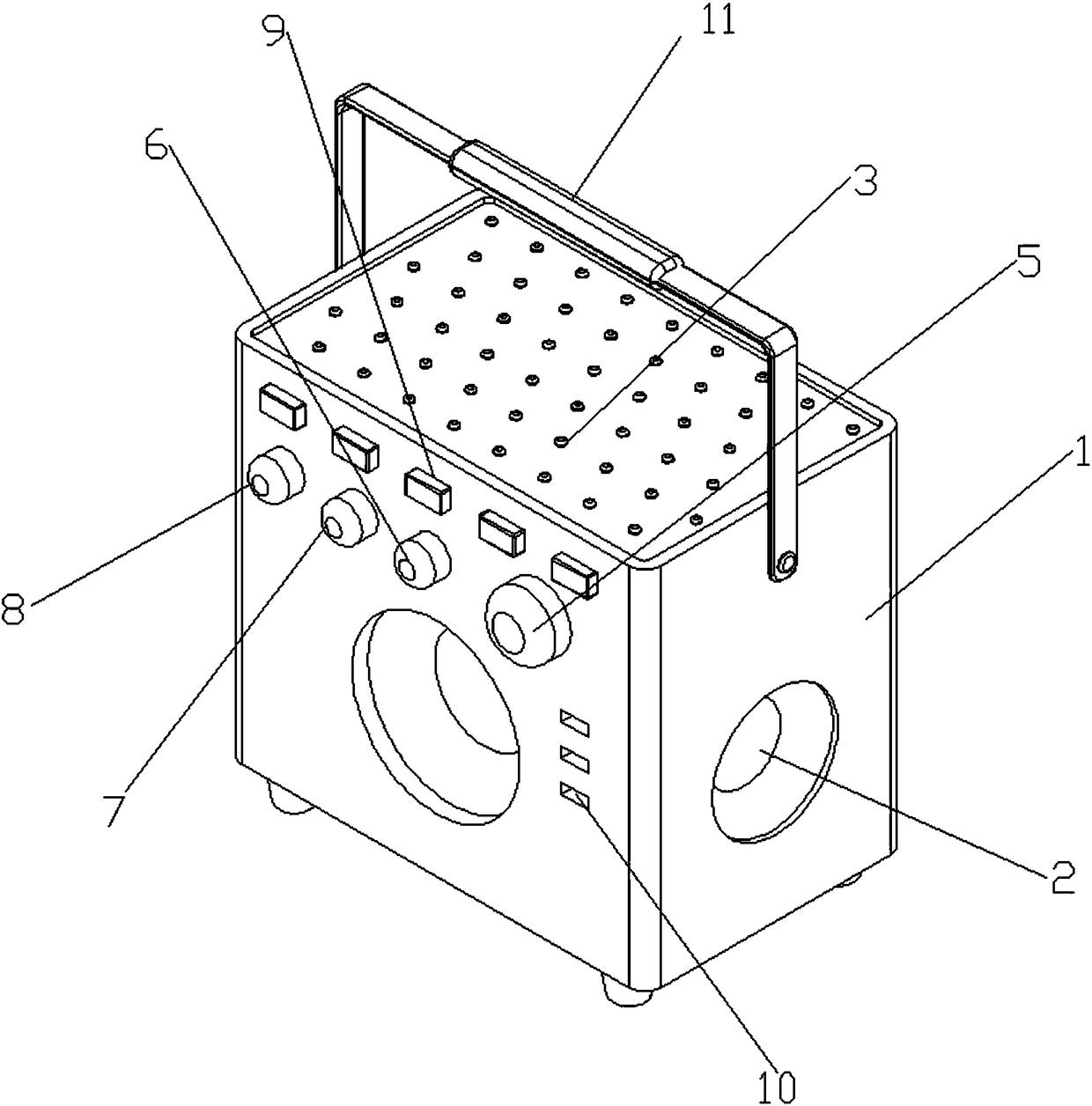

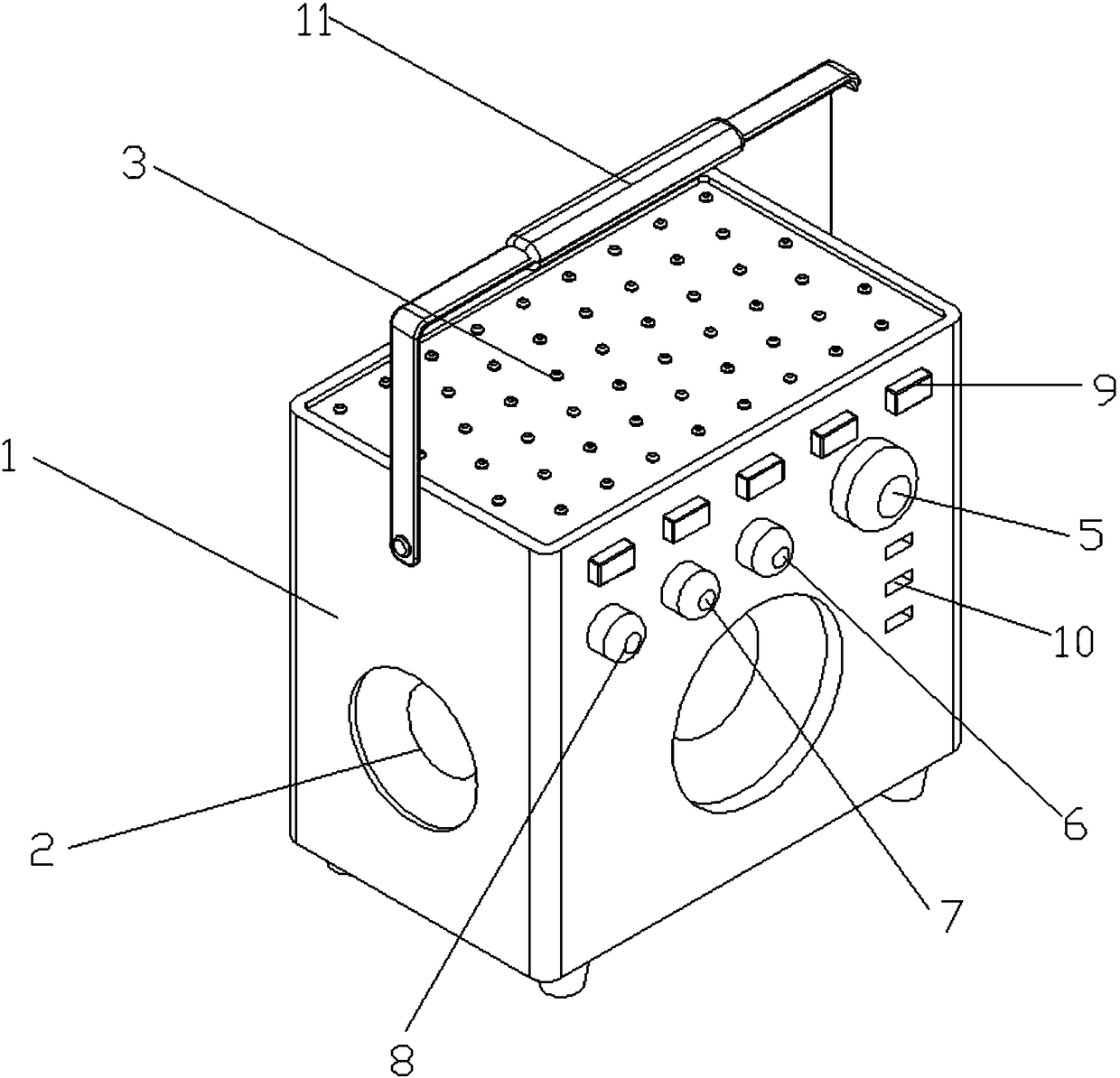

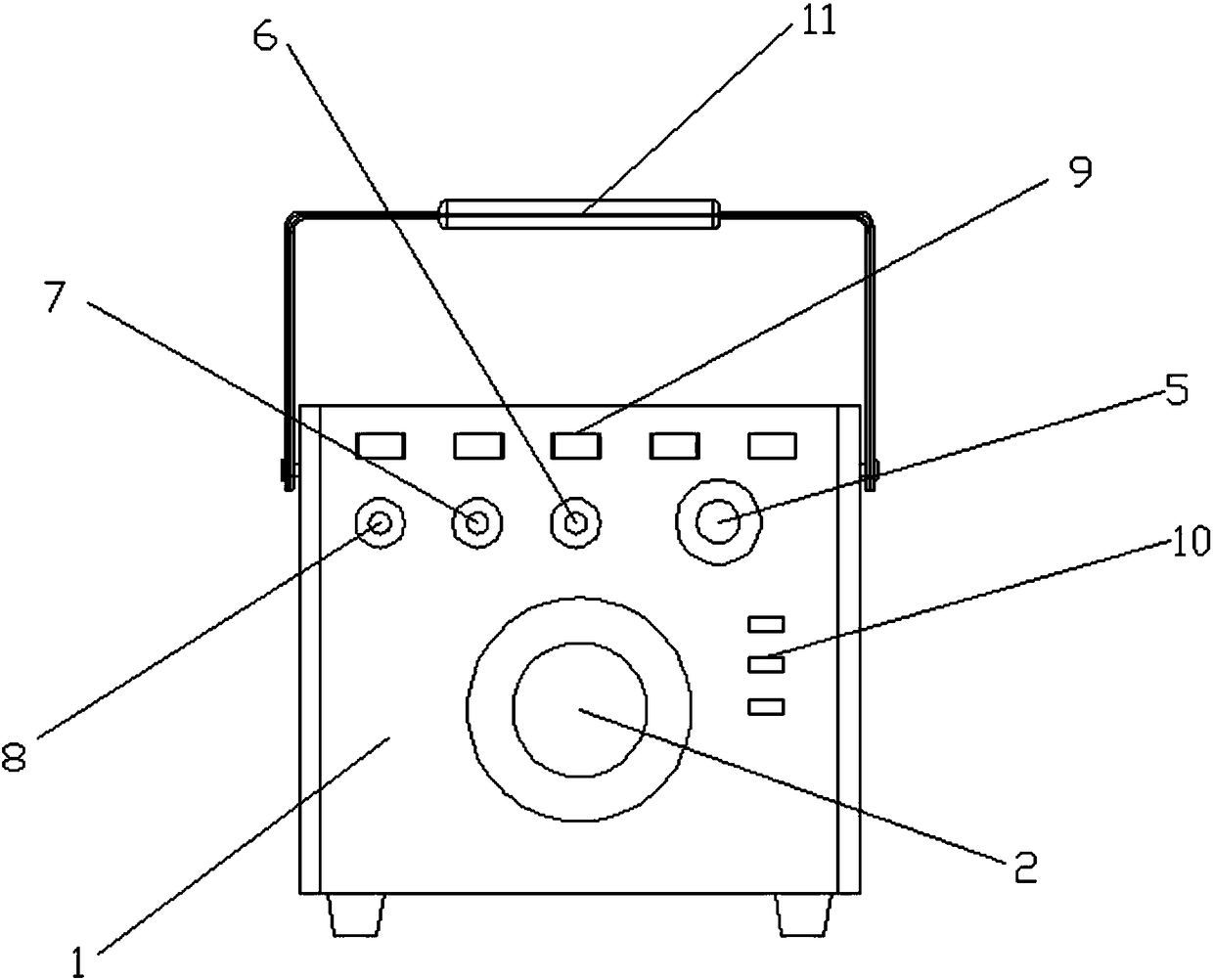

Laser photoelectric fireworks and crackers

InactiveCN108106502ABeautiful patternNo noise pollutionFirework simulationsLaser transmitterFireworks

The invention discloses laser photoelectric fireworks and crackers. The laser photoelectric fireworks and crackers comprise a body and is characterized in that loudspeakers are arranged on the periphery of the body, a plurality of laser emission heads are evenly arranged at the top of the body, and laser emitters are arranged inside the laser emission heads; a volume regulating button, a distanceregulating button, a color regulating button, a sound imitation regulating button and a color system selecting module are arranged on the body. The laser photoelectric fireworks and crackers have theadvantages that various different fireworks forms are written into a program, the program is used to control the laser emitters to emit laser of different colors, different heights and different positons to form different patterns, and the forms and sounds of various fireworks are simulated; the simulated electronic fireworks and crackers can increase festive atmosphere and do not generate smoke and gunpowder smell, and pollution and burden to atmosphere and environments are avoided; in addition, personal injury caused by fire caused by the fireworks is avoided.

Owner:中合国际知识产权股份有限公司

Orangefigured paint, preparation method and construction process thereof

InactiveCN102220078ABeautiful patternImprove the decorative effectPretreated surfacesPolyurea/polyurethane coatingsHigh resistanceAcrylic resin

The invention provides orangefigured paint, a preparation method and a construction process thereof. The orangefigured paint comprises the following components in percentage by weight: 30.0 to 40.0 percent of thermosetting acrylic resin, 5.0 to 15.0 percent of synthetic fatty acid resin, 0.01 to 0.05 percent of curing agent, 0 to 0.01 percent of defoaming agent, 0.3 to 1.2 percent of orangefiguring agent, 1.0 to 2.0 percent of antiflooding wetting dispersant, 0 to 10.0 percent of dimethylbenzene, 0 to 10.0 percent of trimethylbenzene, 0 to 5 percent of cyclohexanone and 20 to 50 percent of color paste. The orangefigured paint can form beautiful patterns, has high decorative performance, and has high weather resistance, high chemical resistance, high water resistance, high impact resistance and high wear resistance; the orangefigured paint also has high mechanical performance and high gasoline resistance, high engine oil resistant and high aging resistance; the cost of the paint is low, and the construction of the paint is convenient; and the paint can be widely used for indoor furniture decoration, indoor decoration and artwork surface decoration and can be used for machine tool, printing and dyeing machines, textile machines, plastic machines, safes, appliances and instruments, medical appliances, motors, electric tools, antitheft doors and other large machines.

Owner:周荣华 +1

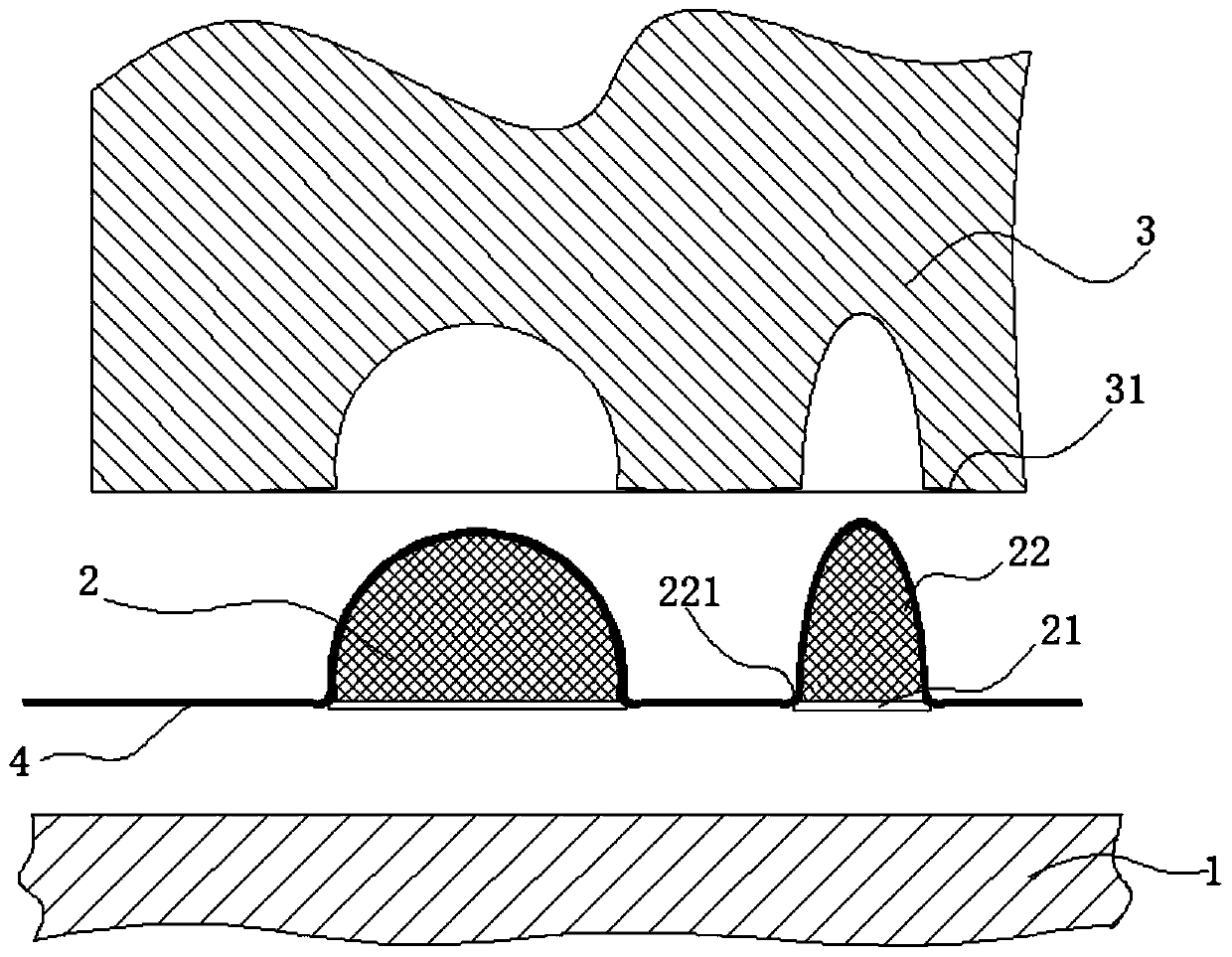

Production process of novel cobblestone prefabricated members

InactiveCN107662280ANo pollutionEasy constructionSingle unit pavingsMouldsSurface layerMaterials science

The invention discloses a production process of novel cobblestone prefabricated members. The production process comprises the technical process of the novel cobblestone prefabricated members. Different shapes and sizes of molds are made according to the demands of customers, patterns are firstly drawn or etched on the molds in advance, cobblestones are tightly arranged according to the patterns ofthe molds to make the molds full of the cobblestones, then the molds are fully filled with concrete grout or a colloidal material, the colloidal material concrete grout or colloidal material on the surface layers of the cobblestones are removed after the molds are turned over to make the middle-upper portions of the cobblestones exposed, the cobblestone prefabricated members to be parqueted are taken out of the molds and then are packaged and encased after complete drying and solidification. The parqueted cobblestone prefabricated members are spliced into a cobblestone path, the production process has the advantages of being simple and convenient to construct, high in construction speed, free of environmental pollution and the like, and the parqueted cobblestone prefabricated members hasthe lots of advantages that the prefabricated members are excellent in quality, high in artistry, good in flatness, high in ornamental value, capable of making water seep and friendly to the environment, damaged parts in the using process are convenient to replace and the like.

Owner:李博远

High-temperature fine Yangbuck resin for synthetic leather and preparation method thereof

The invention relates to a high-temperature fine Yangbuck resin for synthetic leather and a preparation method thereof. The high-temperature fine Yangbuck resin for synthetic leather comprises the following components: modified polyurethane, butanone, methylbenzene and high-temperature fine Yangbuck powder. The high-temperature fine Yangbuck resin for synthetic leather is used for the front-end process of the synthetic leather and belongs to the innovation-type front-end material, the Yangbuck leather made from the material is even in pores, is fine in velvet handfeeling, is clear in color and luster, has artistic patterns, is soft and nature in gloss, and is light, thin, soft and elastic.

Owner:JIANGSU BAOZE POLYMER MATERIAL

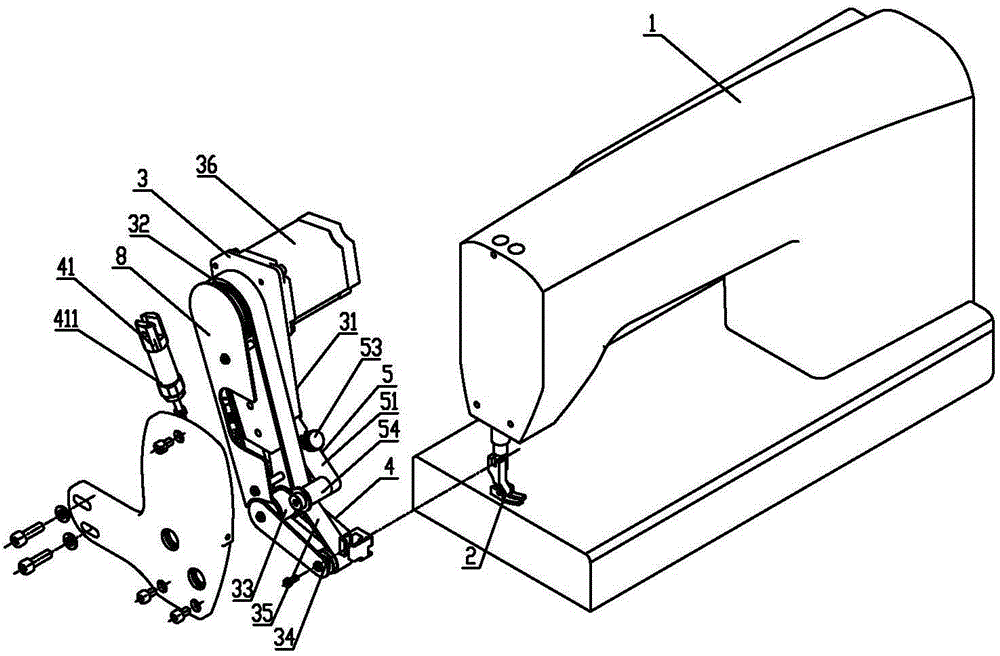

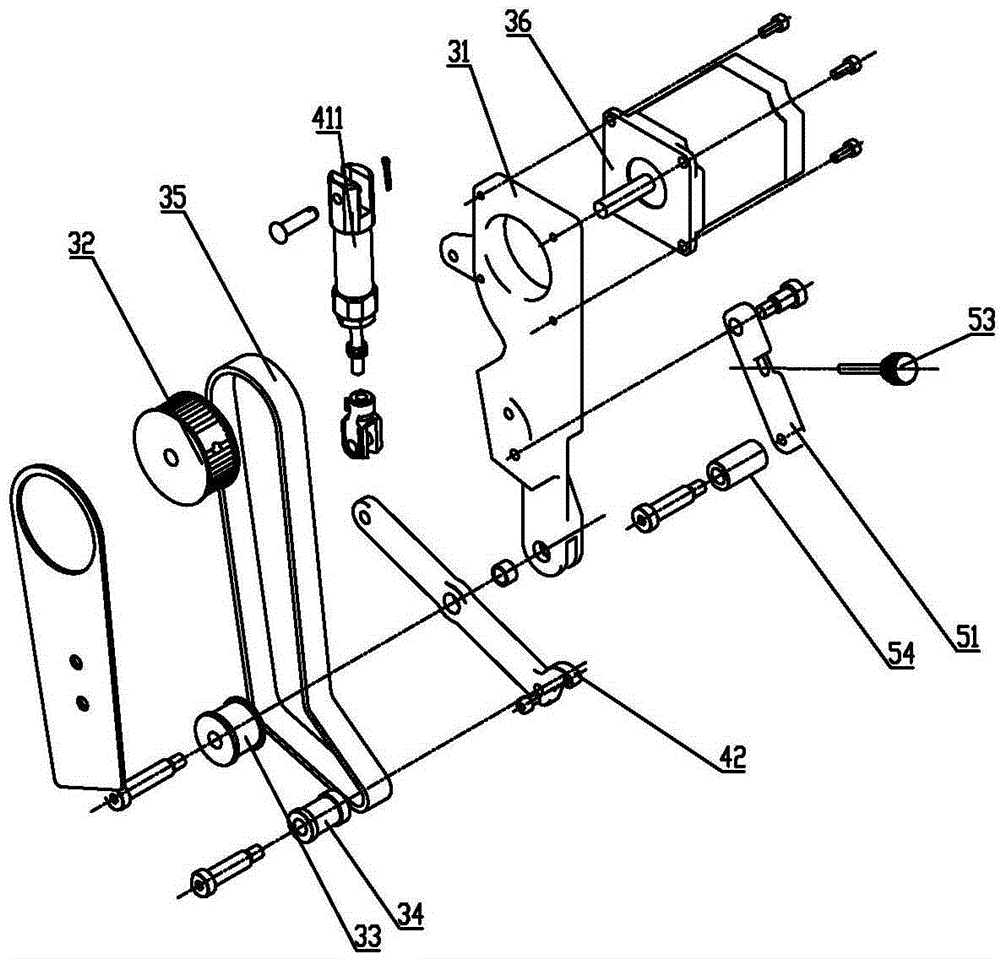

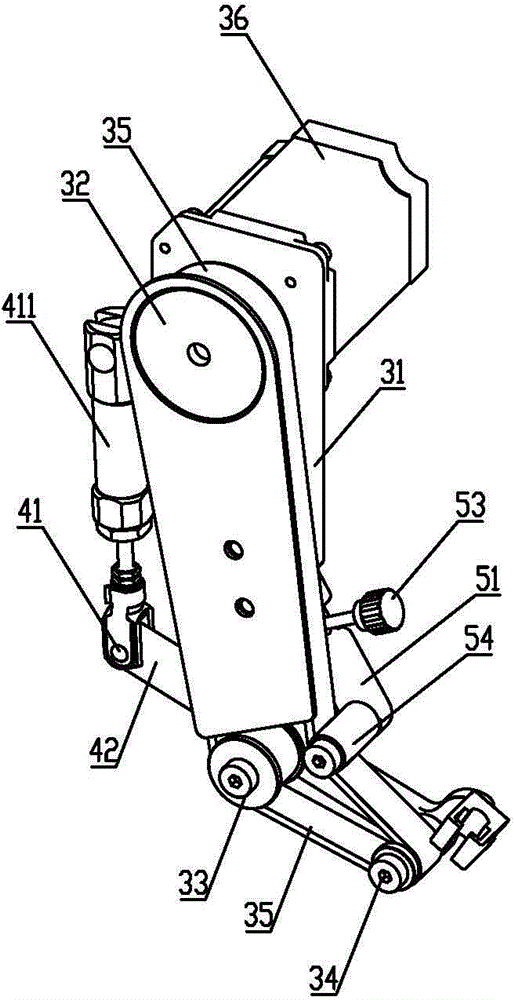

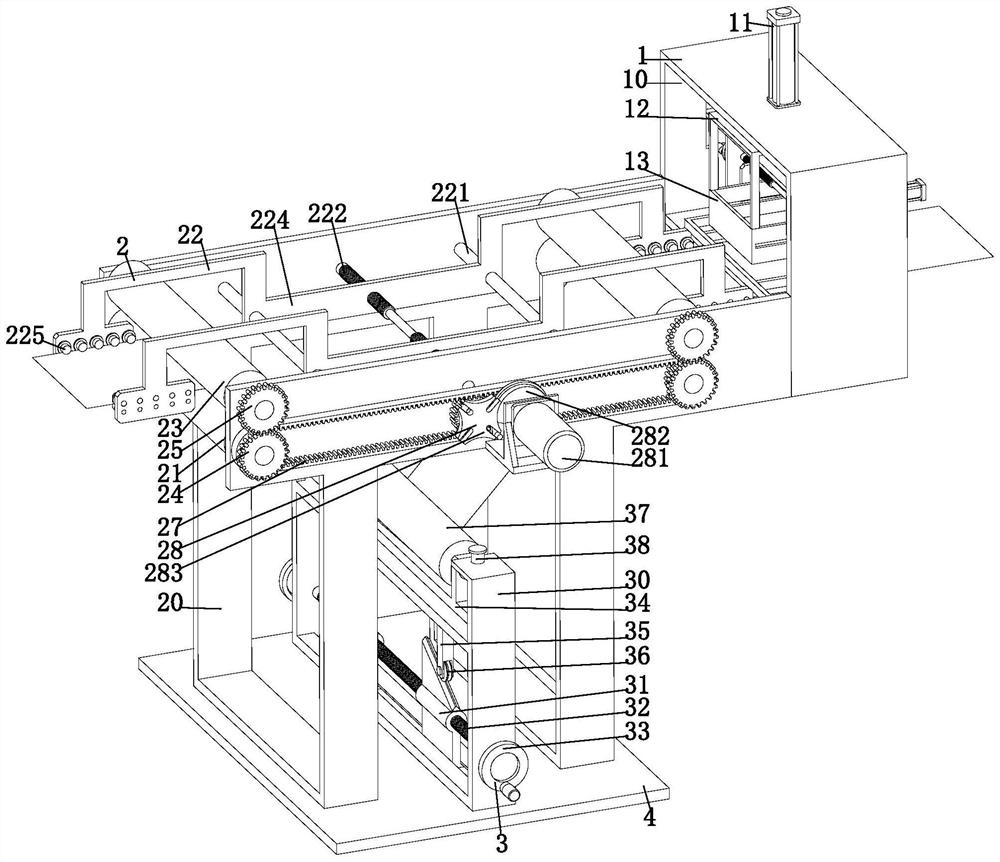

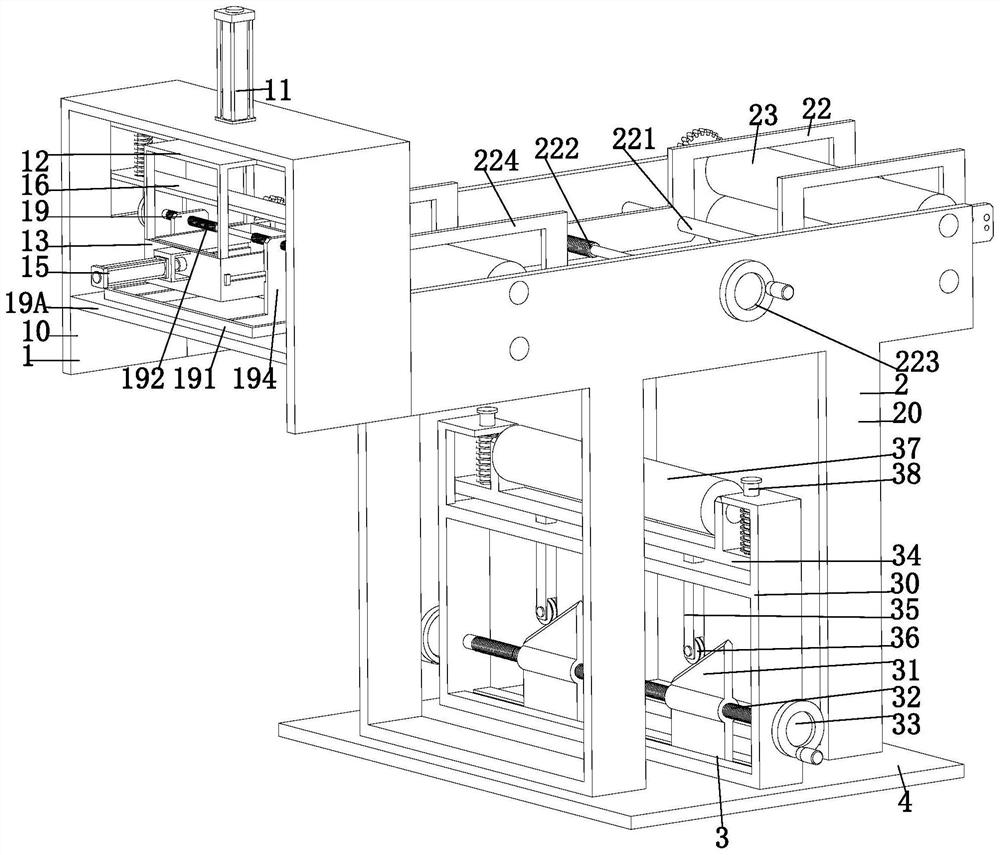

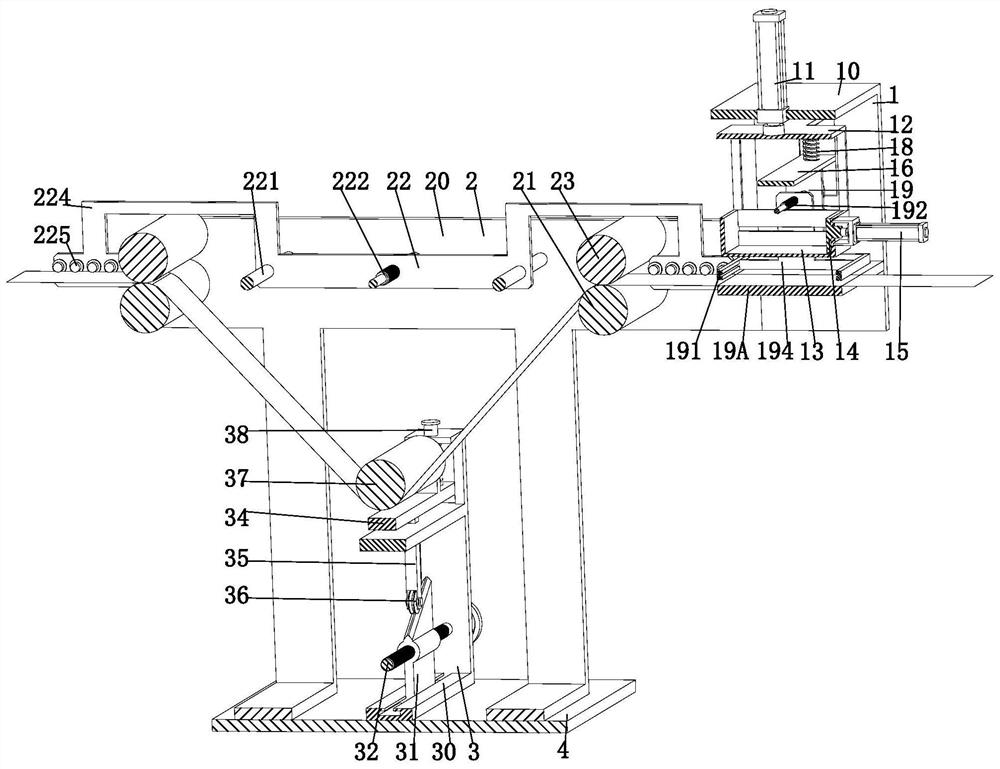

Lockstitch sewing machine capable of feeding automatically

The invention relates to the technical field of sewing machines, in particular to a lockstitch sewing machine capable of feeding automatically. The lockstitch sewing machine comprises a lockstitch sewing machine body, a presser foot arranged on the lockstitch sewing machine body, a material puller and a link gear, wherein the material puller comprises a mounting plate, a synchronous pulley, an tension roller, a material pulling roller, a material pulling belt and a stepping motor, the mounting plate is fixed on the lockstitch sewing machine body, the synchronous pulley, the tension roller and the material pulling roller are arranged on the mounting plate and can tension the material pulling belt, the material pulling roller is capable of rotating up and down around the tension roller, and the stepping motor is connected with the synchronous pulley and drives the same to rotate, and the link gear is connected with the presser foot and the material pulling roller so as to drive the material pulling roller to move up and down along with the presser foot. The lockstitch sewing machine is compact in structure and convenient to use, and via linkage matching of the material puller and the presser foot, patterns sewn by the lockstitch sewing machine are uniform and attractive in appearance.

Owner:QUANZHOU ZHONGFENGZHEN CAR CITY

Inkjet dyeing method

InactiveUS20120066843A1Easily subjected to continuous printingReduce the burden onMeasurement apparatus componentsTypewritersEngineeringDyeing

An inkjet dyeing method for dyeing a belt-shape textile by ejecting ink includes a feeding step of feeding the textile to an inkjet dyeing apparatus, a front surface printing step of dyeing the textile by ejecting the ink onto a front surface of the textile, a front surface drying step of drying the front surface of the textile, an inverting step of inverting the textile, a rear surface printing step of dyeing the textile by ejecting ink onto a rear surface of the textile, and a rear surface drying step of drying the rear surface of the textile.

Owner:JOYSON SAFETY SYST JAPAN KK

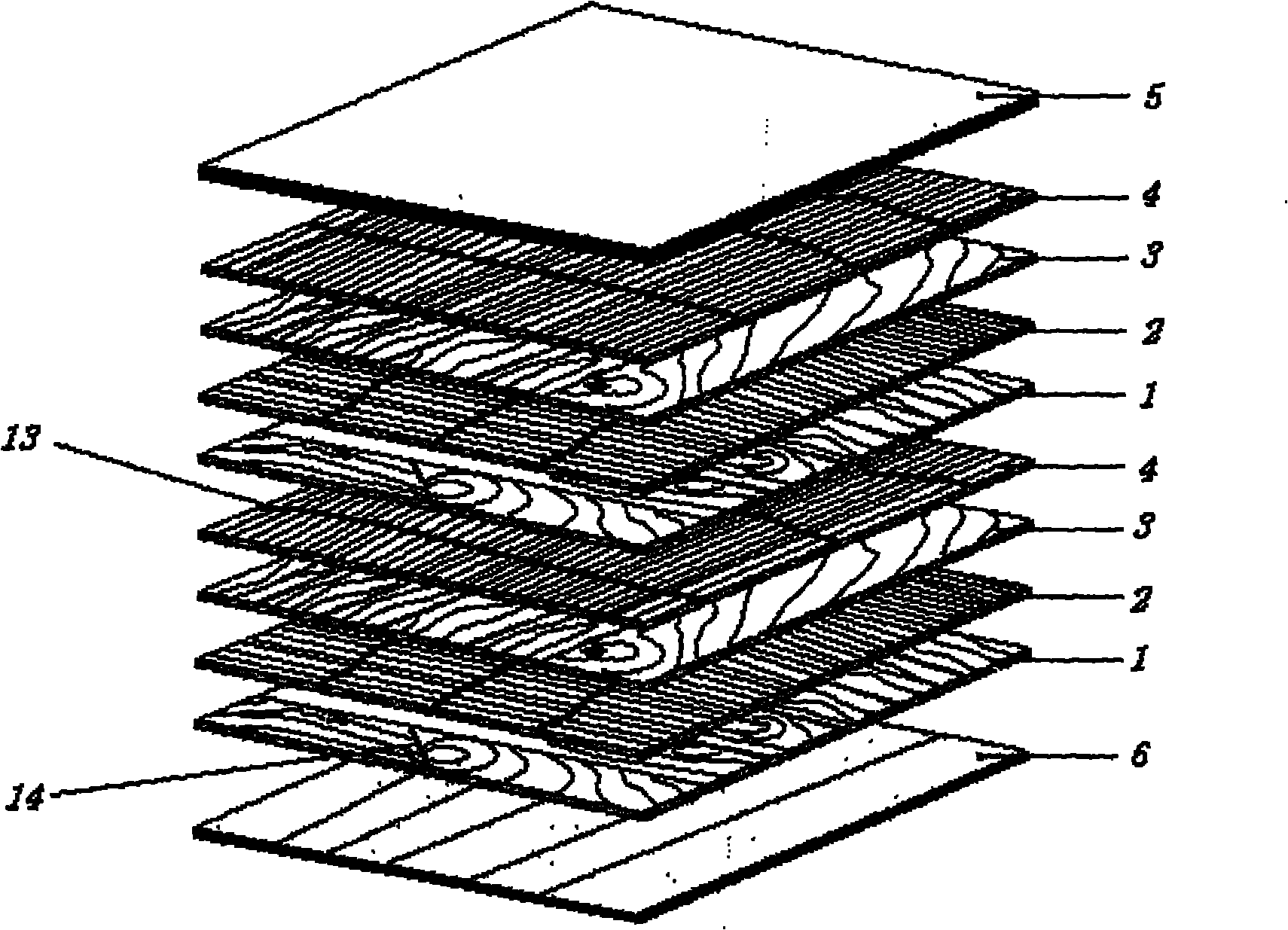

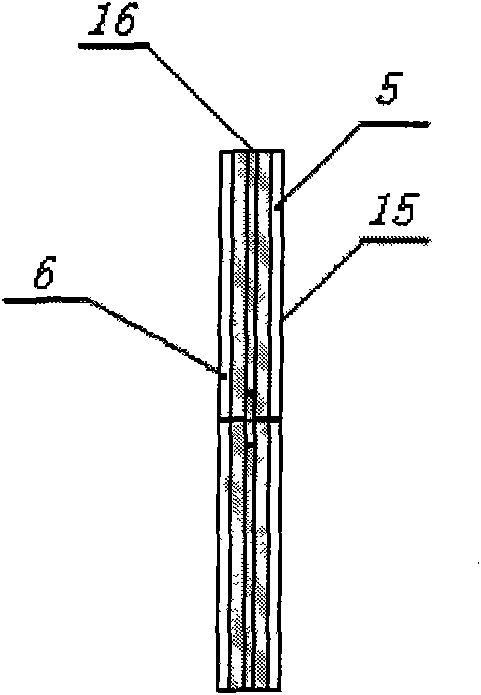

Method for manufacturing rhombic wood-bamboo composite floor board

InactiveCN102059729AGuarantee the quality of useStable structureWood working apparatusCompound aWood veneer

The invention provides a rhombic wood-bamboo composite floor board. The rhombic wood-bamboo composite floor board is manufactured by compounding purely natural wood and bamboo materials serving as raw materials, wherein the top surface of the floor board adopts a high-quality wood veneer; the bottom surface adopts a wood chips spliced veneer; the substrate of a pallet board of the floor board adopts an array structure which is formed by compounding a bamboo curtain (or a bamboo mat) with wood chips alternately and has criss-cross grain; the shape is characterized in that: a plane rhombus serves as a base unit; tenons and mortises are reserved on the four side surfaces; the total surface layer is coated by a moisture-proof wear-resistant paint; the floor board has uniform stress and small deformation; when the floor board is heated or moisturized, generated internal stress is diffused in all directions to be isotropic, so the deformation is very small; the moisture-proof size stability reaches 0.02 to 0.03 percent which is far lower than the national standard requirement of 0.30 percent; therefore, the rhombic wood-bamboo composite floor board cannot cause the phenomena of arch or crack; the use quality of the floor board is ensured; floor boards are simple and convenient to splice because of special shape; a large area of rich patterns can be spliced; and the patterns have attractive appearance, stereoscopic impression, toughness of bamboo and softness of wood, and particularly can achieve a warm sense effect in inhabitable rooms.

Owner:张世雄

Artificia dalbergia odorifera wood and preparation method thereof

ActiveCN107459828ABeautiful patternSoft colorCoating impregnationFlat articlesFragrant rosewoodMaterials science

The invention discloses artificial dalbergia odorifera wood and a preparation method thereof. The artificial dalbergia odorifera wood is prepared from the following five components by weight percent: 60-70% of fast-growing eucalyptus wood, 10-15% of loose knots, 10-15% of polylactic acid, 5-10% of rosewood heart wood and 3-5% of nano bismuth oxide. The preparation method comprises the six steps of carrying out wiredrawing on the fast-growing eucalyptus wood, pulping, starching eucalyptus wood filaments, paving, molding by hot pressing and modifying. The artificial dalbergia odorifera wood prepared by the method is attractive in patterns, soft in color and fragrant, is not rotten, is free from insects, does not fade, and can be used for replacing natural dalbergia odorifera wood for making furniture, handicraft articles, Buddhist prayer beads, hand strings, and the like.

Owner:吴仪

Film pasting vacuum electroplating method

InactiveCN102828148APrecise positioningNo blackening and yellowingVacuum evaporation coatingSputtering coatingUV curingFilm-coated tablet

The invention discloses a film pasting vacuum electroplating method, which comprises the following steps: a. processing incoming materials; b. pasting a film with a hollow pattern; c. removing an outer film and a middle film; d. coating a film, that is, performing sputtering coating processing of the product, taking out from a vacuum furnace, stripping away a bottom film to leave the electroplated pattern, performing primary examination, removing a hanging tool, detaching from a tool, performing secondary examination, covering the outer film; e. preparing before spraying; f. spraying, that is spraying UV paint with good glossiness on the product, then performing baking, UV curing, taking the product out, detaching from the spraying tool, and performing examination. The film pasting vacuum electroplating method of the invention does not form sawteeth at the pattern edge, and can be completed within a short period. In actual production, batch production of products with accurately-positioned pasted films is realized; the pasted film used in the invention does not release waste gas during vacuum coating, and has no blackening or yellowing phenomena of the film layer; and the method of the invention is a film-coating pattern-displaying scheme with rapid and mass production capability and beautiful patterns.

Owner:SHANGHAI TINGSHENG VACUUM MACHINERY TECH

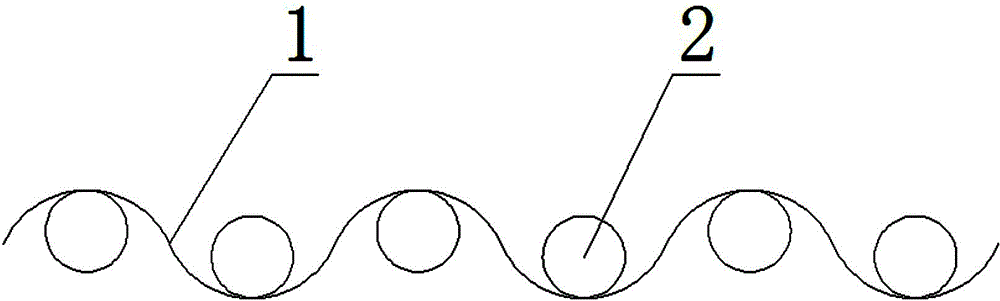

Novel elastic fabric

The invention relates to novel elastic fabric. The novel elastic fabric is formed by weaving of warps and wefts, wherein the warps are two-component polyester yarns PET / PTT, the wefts are ordinary fibers containing low-meting-point fibers, the mass of PTT in the two-component polyester yarns PET / PTT is 10-90% that of PET in the two-component polyester yarns PET / PTT, and the mass of low-meting-point fibers is 3-60% that of the ordinary fibers. A test conducted with a loom proves that the novel elastic fabric has the advantages that the cloth cover is thin and flat, lines are clear, the pattern is attractive, hand feel is good, and performance is higher than that of existing elastic fabric with spandex covering yarns or latex yarns serving as warps. The novel elastic fabric is suitable for full-size weaving, combination of the cloth cover and pattern is convenient, raw edges are avoided after cutting, cutting can be conducted freely as needed, using is convenient, cost is reduced, the grade is improved, and large-scale production is facilitated.

Owner:SHANDONG TOPTIDE HUABANG TEXTILE TECH

Colored crystal glass production process

InactiveCN108640529ASimple processHigh degree of automationGlass tempering apparatusColour fastnessPrinting ink

The invention provides a colored crystal glass production process which belongs to the technical field of colored crystal glass. The colored crystal glass production process comprises the steps of cutting, edging, cleaning, tempering, silk-screen through printing ink, drying, wiping and packaging, wherein during production, the tempering process and the drying process after silk-screen through theprinting ink are strictly controlled. The colored crystal glass production process provided by the invention is simple in process and suitable for large-scale production; the produced colored crystalglass is high in colour fastness, high in mechanical strength, not liable to break, and convenient to carry and store.

Owner:合肥金晋业实业有限公司

Production method of one-off directly filling seamless knitted down feather fabric

InactiveCN106637636AGood waterproof and windproof performanceSoft touchWeft knittingLaminationYarnPolyester

The invention discloses a production method of one-off directly filling seamless knitted down feather fabric. The production method includes the steps that 50D / 72F polyester drawn textured yarn is knitted through a knitting computerized jacquard double-faced machine to prepare gray fabric, then high-temperature washing, dyeing and setting are carried out on the gray fabric to obtain a semi-finished product, the semi-finished product is attached to a waterproof polyurethane elastic film with air and wet permeable functions, the compound is cut into pieces, when the peripheries of the pieces are sewn, a down feather filling orifice is reserved to fill down feather, and finally the one-off directly filling seamless knitted down feather fabric is obtained. The one-off directly filling seamless knitted down feather fabric is soft in handfeel, high in elasticity, attractive in pattern, uniform in fluffy and heat preserving performance, comfortable and light; the number of the working procedures is small, the process is simple, one-off down feather filling can be achieved, and labor and time are saved; the fabric is high in windproof and waterproof performance, the appearance, color and style can be realized by adjusting the polyurethane elastic film or changing used knitted raw material and the pattern according to needs, and the knitted down feather fabric allows wet and air to permeate and is high-end down feather fabric.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

Artificial exquisite crystal environmental-protection stone material craft calligraphy and painting plaque and preparing method thereof

InactiveCN102529556ABeautiful patternColorfulOrnamental structuresSpecial ornamental structuresRiver sandKetone

The invention discloses an artificial exquisite crystal environmental-protection stone material craft calligraphy and painting plaque and a preparing method thereof. The artificial exquisite crystal environmental-protection stone material craft calligraphy and painting plaque is prepared through a certain process with methyl ethyl ketone serving as a curing agent, naphthenic acid cobalt liquid serving as an accelerating agent, a 3388type, a 6688 type and 191 type or 196 type unsaturated polyester resin and talcum powder serving as adhesion agents and river sand serving as main raw materials. Different pigments are added according to different plaques so that patterns of the plaques are beautiful and bright in color. Therefore, the artificial exquisite crystal environmental-protection stone material craft calligraphy and painting plaque has the advantages of avoiding problems of aging, fading, breaking or delaminating, deformation and the like, and being clear and real in pattern, beautiful, bright in color, vivid and smooth in line, accurate and lifelike in modeling, high in breaking strength, durable, environment-friendly, high in quality and inexpensive. The preparing method of the artificial exquisite crystal environmental-protection stone material craft calligraphy and painting plaque can design out various patterns according to actual needs and is used for manufacturing various exquisite crystal environmental-protection stone material craft calligraphy and painting plaques (such as large longevity plaques, marriage commemoration plaques, large colorful gravestones, plaques with landscape, painting of flowers and birds, calligraphy and painting, various figures and animals).

Owner:江孟东

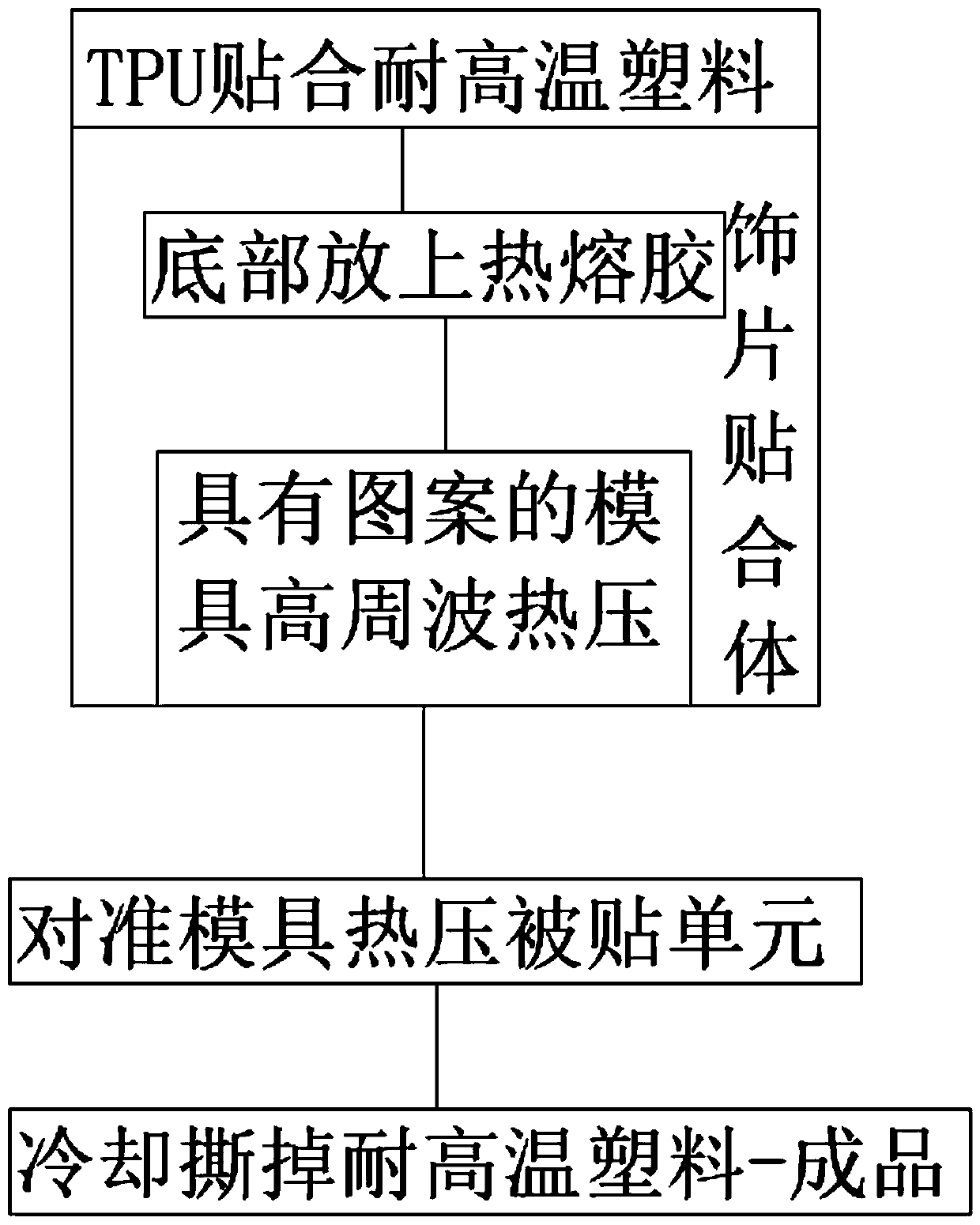

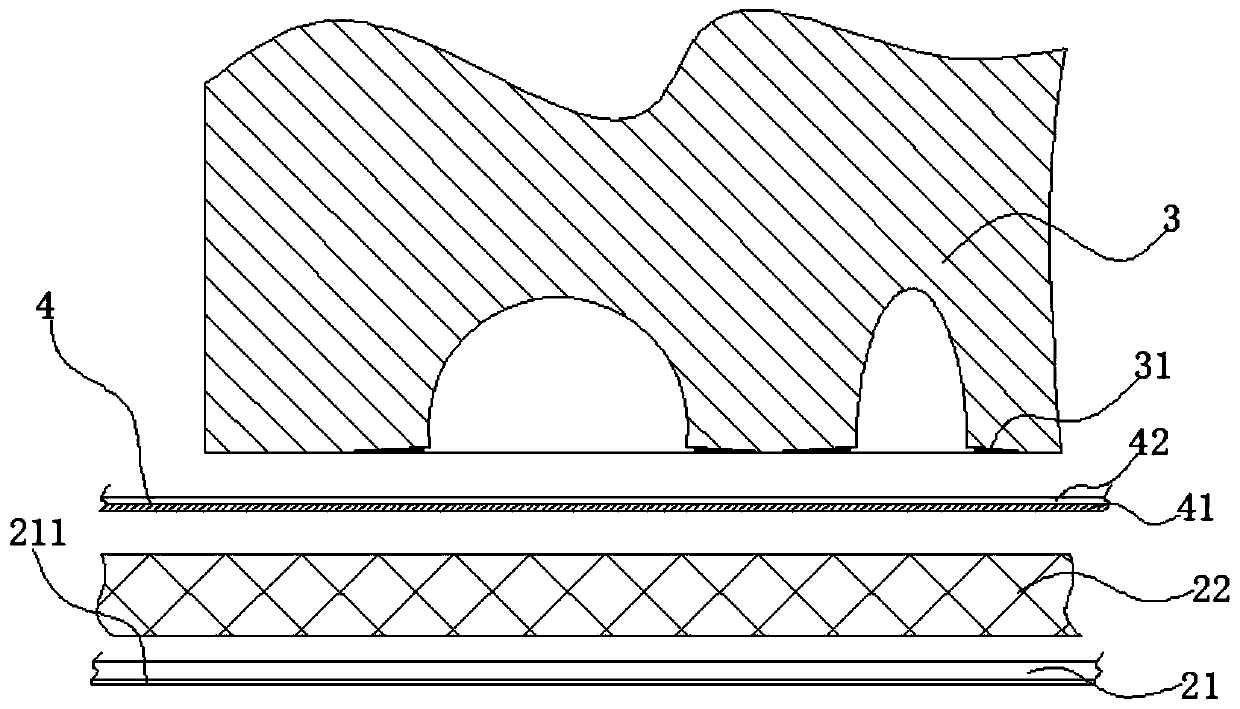

Ornament attaching structure and method

The invention discloses an ornament attaching method. The ornament attaching method comprises the following steps that high-temperature-resisting plastics are attached to one face of TPU or PVC, and high-temperature hot melting glue is attached to the other face of TPU or PVC; on a die, the high frequency is adopted for conducting hot pressing on the high-temperature-resisting plastics in the first step, the surplus high-temperature hot melting glue it torn off, and an ornament attached body with patterns is obtained; the ornament attached body is placed to the position above an attached unitand aligned with the die, high-frequency heating of the ornament attached body is conducted, and then the ornament attached body is subjected to hot pressing to the attached unit; and cooling is conducted to the room temperature, the surplus high-temperature-resisting plastics are torn off, and a firm ornament is pasted to the attached unit. According to the ornament attaching structure and method, design is scientific and reasonable, and the following effects that high-temperature-resisting film protection is adopted, integral patterns are attractive, the ornament attached body does not leavemarks on the die, and meanwhile the patterns with better third dimensions can be formed. Fusion with most of materials can be achieved, transition of adhesiveness of two different materials can be achieved, the bonding firmness is improved, and adaptability is wider.

Owner:彭体玲

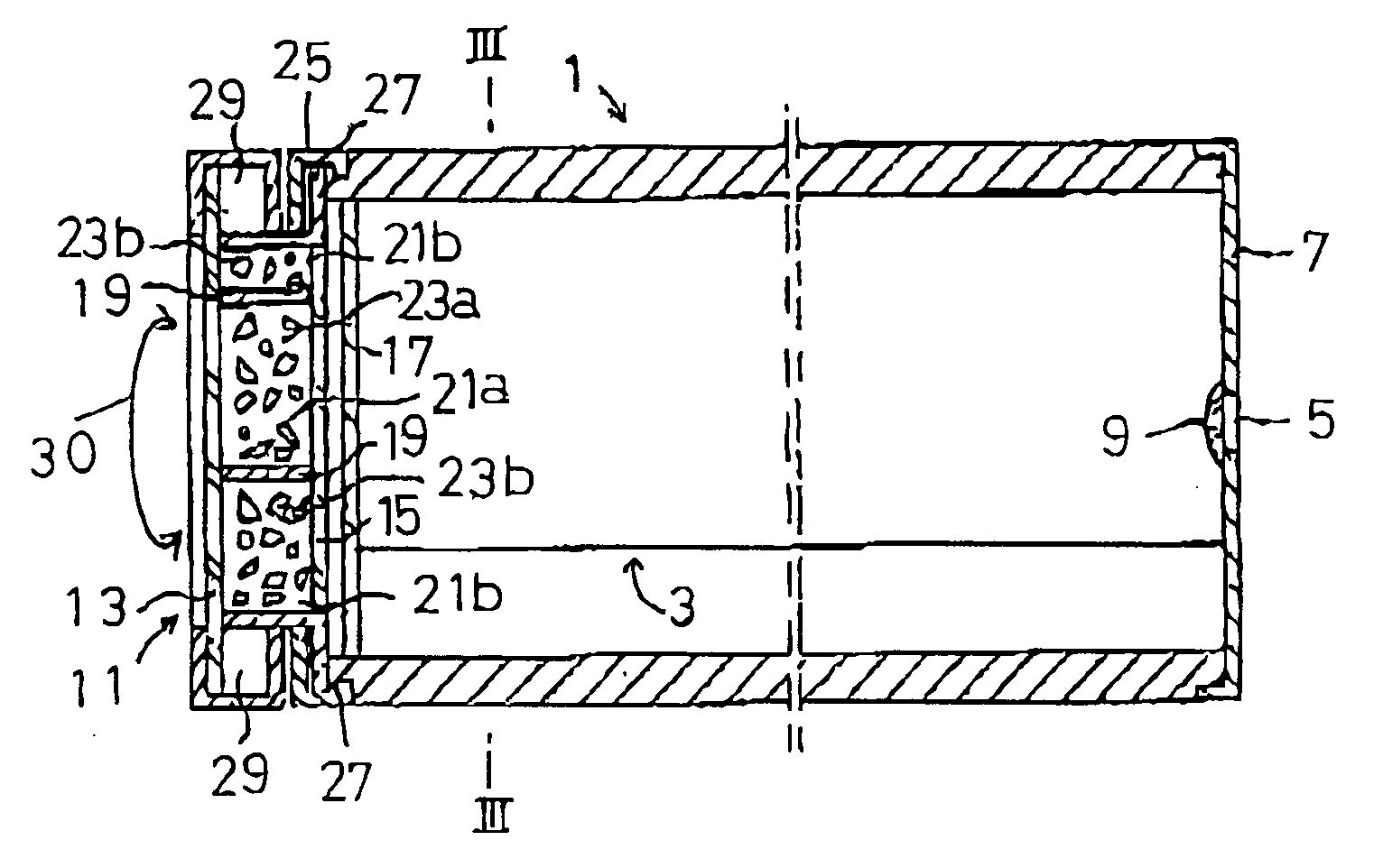

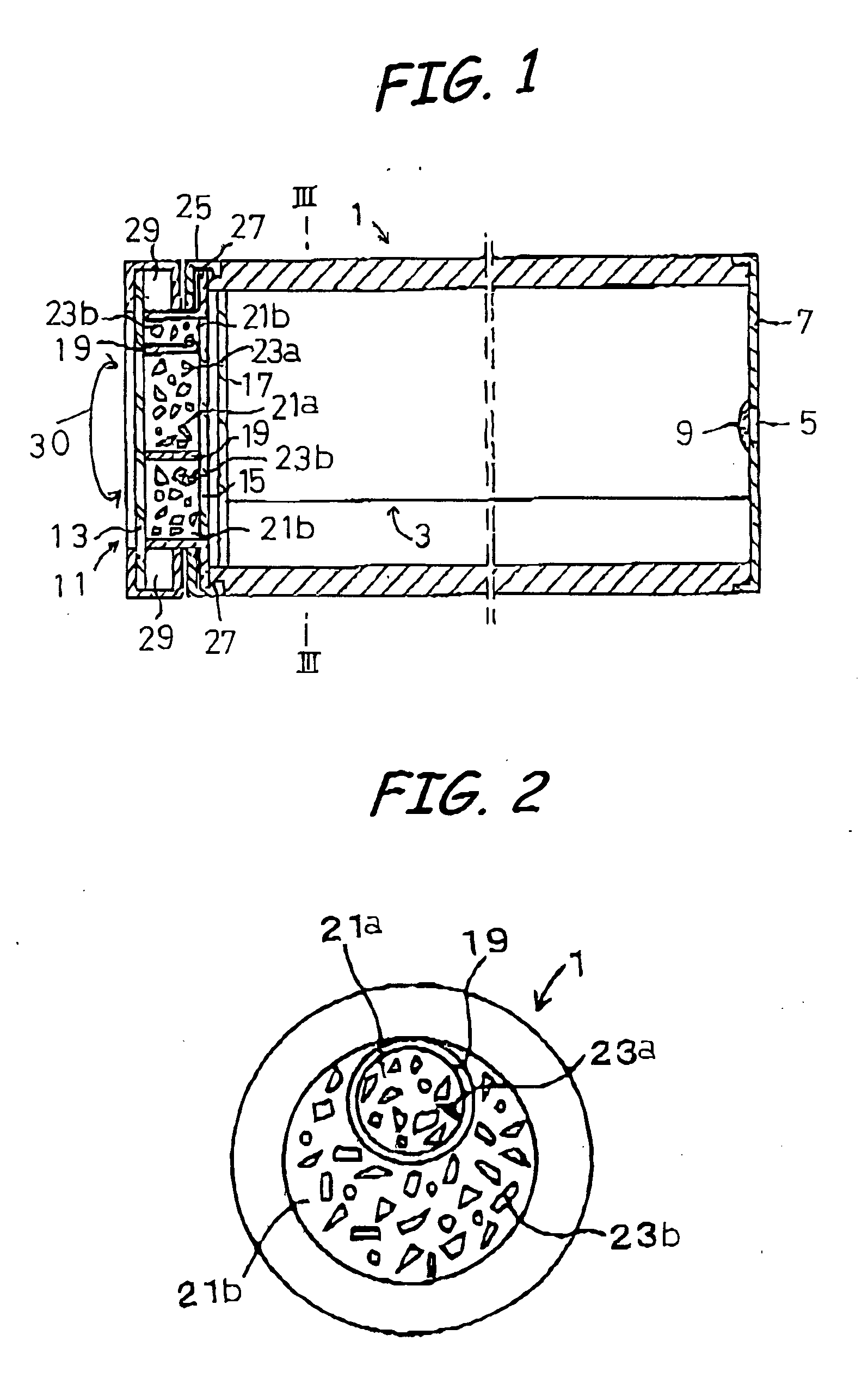

Kaleidoscope

A kaleidoscope is disclosed, which comprises a tubular casing extending longitudinally and having an observation window or peephole on its rear end, a closed box on its front end, and a mirror system inside it, wherein the closed box has its opposite ends closed by respective light transmitting elements, and contains lots objects or chips of colored glass or like that can be moving around inside the closed box. According to the present invention, the closed box is internally divided into several compartments that are delimited by partitions extending longitudinally of the closed box so that the compartments can be separated from each other and kept independent of each other. Each of the compartments contains lots of objects that can be moving around inside it.

Owner:OCHI INTERANTIONAL

Environment-friendly plastic bag surface image-text printing machine and printing method

PendingCN113954508AMeet the needs of press adjustmentImprove stabilityScreen printersScreen printingScreen printingEngineering

The invention provides an environment-friendly plastic bag outer surface image-text printing machine and a printing method. The environment-friendly plastic bag outer surface image-text printing machine comprises an image printing mechanism, a conveying mechanism, a tensioning mechanism and a bottom plate; solves the problems that when existing environment-friendly plastic bags are subjected to silk-screen printing, continuous manual feeding is needed, workers are required to manually hold scraping plates for scraping printing of the plastic bags, the printing efficiency is poor, and the labor intensity of workers is high; and solves the problems that when image-text printing is carried out on the surface of a plastic bag, the plastic bag is usually light in weight and cannot be flatly printed, wrinkles can occur, shaping is not facilitated when patterns are printed, printing errors are caused at the image-text positions on the surface of the plastic bag, the patterns are prone to being twisted and deformed, and the product quality is affected.

Owner:李伟

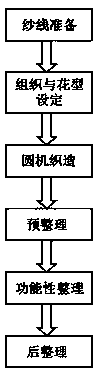

Fresh and beautiful multifunctional fabric and manufacturing method thereof

The invention provides a fresh and beautiful multifunctional fabric and a manufacturing method thereof. The multifunctional fabric is formed through knitting 22.4tex warp and weft yarns. The warp andweft yarns are intelligent temperature-regulating fiber / terylene / cotton fiber blended yarns. The manufacturing method comprises the following steps of a) yarn preparing; b) organization and pattern setting; c) circular machine weaving; d) preliminary finishing; e) functional finishing; and f) after finishing. The invention provides the fresh and beautiful multifunctional fabric and the manufacturing method thereof. A fabric pattern design is unique, the manufacturing method is simple and reasonable, and the manufactured fabric is beautiful in appearance and elegant in temperament, is with theflavor of the times, and has good wear resistance, soft comfort, an ultraviolet ray protection function and an intelligent temperature control function.

Owner:苏州吉佳鑫纺织科技有限公司

Preparation method of artware mold

The invention provides a preparation method of an artware mold. The preparation method is good in texture and capable of improving the work efficiency and includes the following steps that firstly, a mold blank and needed resin are prepared; secondly, a mold model is turned, wherein resin is poured into the mold blank, and the mold model is turned out through the mold blank; thirdly, the mold model is repaired, wherein the prepared mold model is simply repaired; fourthly, the mold is turned, wherein the prepared mold model is turned; fifthly, the mold is repaired, wherein the mold which is turned out is simply repaired; and sixthly, the mold is put into use, wherein the repaired mold is put into production. According to the preparation method of the artware mold, the mold model is made of resin materials, the made mold model is clear in texture and beautiful in pattern, and the retention cycle is long; the mold model repair time is short, and the work efficiency is improved; procedures are saved, the mold model can be repeatedly used, and the mold model does not need to be manufactured for secondary mold turning again; and the surface smoothness is high.

Owner:ZHUO DA NEW MATERIAL TECH GRP

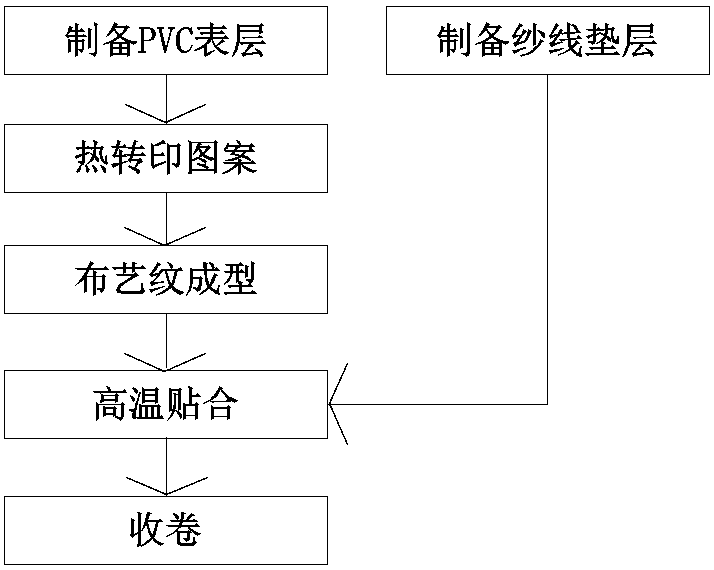

Production process of cloth-imitating PVC tablecloth

InactiveCN110754889AHighlight the concave-convex layeringExquisite, real, good effectLamination ancillary operationsLaminationYarnPolymer science

The invention relates to the field of home supplies, in particular to a production process of cloth-imitating PVC tablecloth. The production process of the cloth-imitating PVC tablecloth is characterized by comprising the steps that S1, a PVC surface layer is made; S2, a yarn cushion layer is woven; S3, a thermal transfer process is adopted to transfer a pattern on the PVC surface layer; S4, embossing is formed on the PVC surface layer through cloth line forming equipment, and the PVC surface layer and the yarn cushion layer are subjected to high-temperature attachment; and S5, rolling is performed. The tablecloth made through the process is soft, comfortable, good in wear resistance, waterproof, oil-proof, good in flatness, bright in surface pattern and beautiful in appearance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

3D stereo phantom coating

InactiveCN104449309ABeautiful patternDeep visual effectsPolyurea/polyurethane coatingsLow speedButyl acetate

The invention discloses a 3D stereo phantom coating. The 3D stereo phantom coating is prepared from the following components: a primer, a top finish, a curing agent and a diluent, wherein the primer is prepared by the following steps: firstly dispersing hydroxyl acrylic resin and a Texaphor anti-sedimentation agent by using toluene and butyl acetate, dispersing for 30min by a high-speed dispersing machine at high speed of 1500r / min until the fineness is not larger than 15 microns, then adding a flow agent and an adhesion promoter to carry out uniform high-speed dispersion, finally adding a 3D stereo apparition agent, and stirring for 3-5min at low speed; the top finish is prepared by the following steps: firstly dispersing a wetting dispersant and the flow agent by using a solvent, then adding the hydroxyl acrylic resin, 6# color carbon black and 6# extra dark, stirring for 30min at low speed, capping, standing for above 12h, grinding by an abrasing machine until the fineness is no larger than 15 microns, taking out from the machine, and filtering; the diluent is prepared from the following components in percentage by weight: 30.0 percent of toluene, 20.0 percent of xylene, 25.0 percent of butyl acetate, 20.0 percent of 100# heavy aromatics and 5.0 percent of a high boiling point solvent.

Owner:QINGDAO SHOUSHENG IND

Injection molded product

Owner:LG ELECTRONICS INC

Quail feed for improving laying rate and egg quality and preparation method thereof

InactiveCN112244172AImprove reproductive performanceImprove disease resistanceFood processingAnimal feeding stuffBiotechnologyAnimal science

The invention provides a quail feed for improving laying rate and egg quality and a preparation method thereof. The quail feed is prepared from the following raw materials in parts by weight: 40-65 parts of grains, 5-25 parts of bean pulp, 1-6 parts of sesame-seed cake, 1-2 parts of rapeseed cake, 2-6 parts of DDGS, 1-5 parts of corn gluten meal, 1-4 parts of bread crumbs, 1-3 parts of bean dregs,1-3 parts of instant noodle residues, 0.4-1.5 parts of grease, 0.1-0.3 part of salt, 0.1-0.5 part of amino acid, 2-5 parts of shell powder, 3-10 parts of mountain flour, 0.5-1 part of calcium hydrophosphate, 0.03-0.1 part of probiotics, 0.1-0.5 part of decavitamin, 0.1-0.5 part of compound trace elements, 0.05-0.1 part of a compound enzyme preparation, 0.05-0.15 part of choline chloride, 0.1-0.3part of baking soda, 0.01-0.04 part of high-temperature-resistant phytase, 0.01-0.03 part of glucose oxidase, 0.1-0.3 part of yeast culture and 0.03-0.05 part of butyrate. According to the quail feedprepared by the invention, various raw materials and functional additives are scientifically compounded, and the fertility, disease resistance and body health state of quails are obviously improved, so that the laying rate and egg quality of the quails are improved.

Owner:SHAANXI SHIYANG AGRI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com