Method for manufacturing rhombic wood-bamboo composite floor board

A wood-bamboo composite and manufacturing method technology, applied in the direction of manufacturing tools, wood processing utensils, etc., can solve the problems of lack of change in composition, affecting sales, and single shape, and achieve the effect of simple and convenient splicing, guaranteeing use quality, and beautiful pattern shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

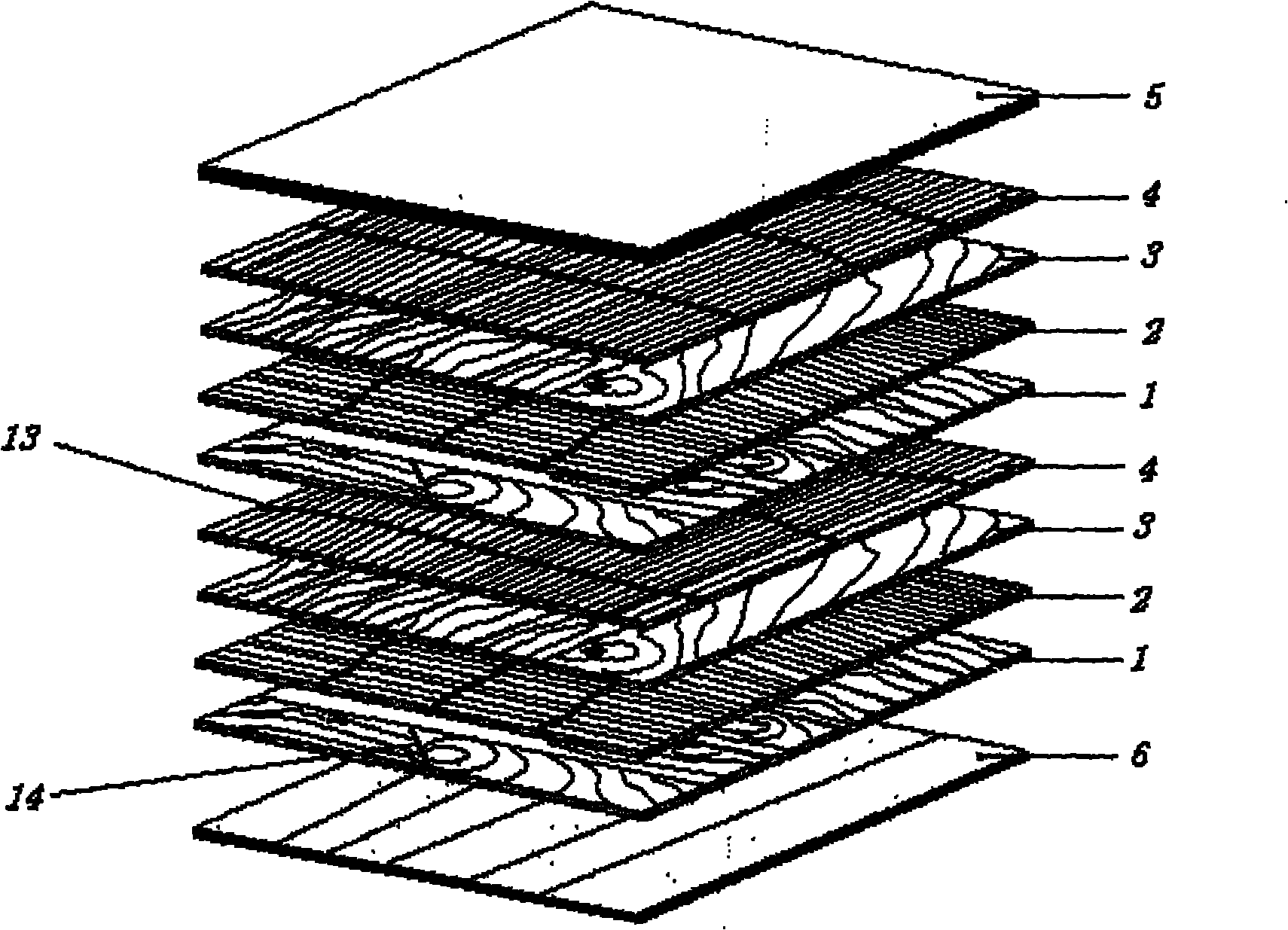

[0025] 1). Manufacture of wood-bamboo composite slab surface board and bottom board

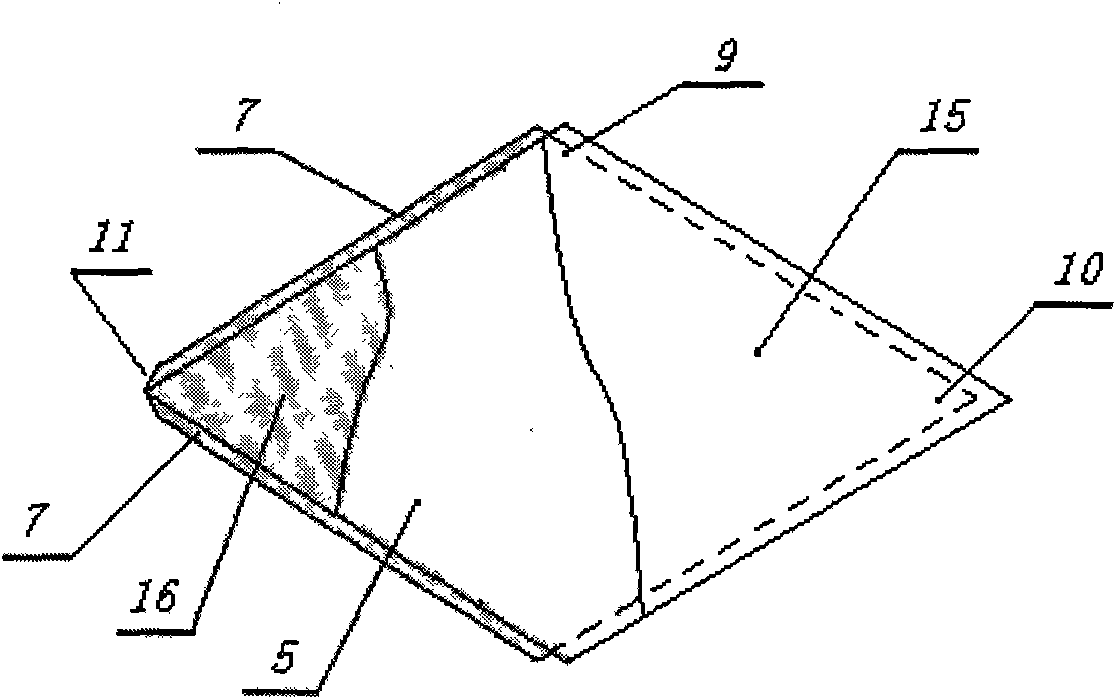

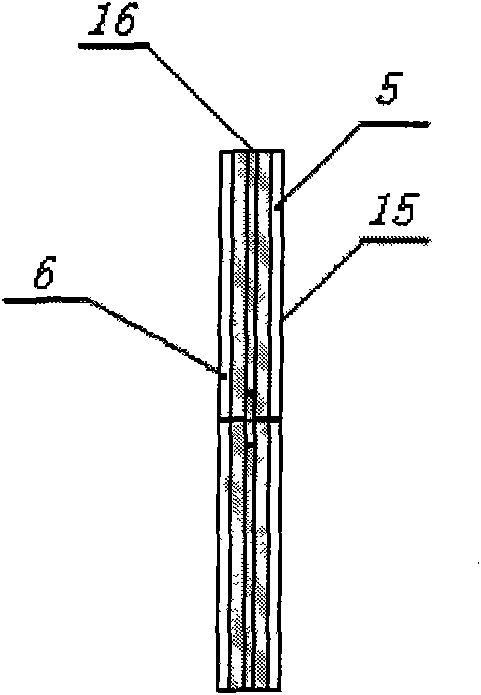

[0026] Logs (hardwood or basswood) are steamed at high temperature, processed into veneers with a thickness of 1.2-2.5 mm and a width of 1200-1500 mm with a rotary cutter, and after natural drying, they are used as wood-bamboo composite slabs (5) , its small fragmented boards are manually cut from the oblique direction of its natural texture, spliced with each other to grow 2.5 meters, 1.5 meters wide veneer, after natural drying, it is used as the wood-bamboo composite base board (6);

[0027] 2). Manufacture of wood and bamboo composite slab substrate

[0028] a. the mature bamboos with a bamboo age of more than five years are mechanically processed into bamboo strips (12) that remove the green bamboo, and cut to a length of 1.5-2.5 meters, sent to the distillation furnace for carbonization after natural drying, and then Use cotton thread (13) to connect them and weave a bamboo curtain w...

Embodiment 2

[0037] Present embodiment operation is described in b, d in 1), 3), 4) and 2) in embodiment 1, difference is in the manufacture 2) of a and c in the wood-bamboo composite slab substrate, As described in 2-a. and 2-c. below:

[0038] 2-a. Remove the bamboo green from the mature bamboos with a bamboo age of more than five years, and machine them into bamboo strips. The bamboo strips are 1.5-2.5 mm thick and 10-18 mm wide. After natural drying, send them to the distillation furnace for carbonization , and then criss-cross weave a bamboo mat with a length of 2.5 meters and a width of 1.5 meters;

[0039] 2-c. Dip the upper and lower planes of the above-mentioned bamboo mat and (b) single-layer wood chip slabs with resin glue, and take four layers of them to be laid alternately and stacked to form a blank, that is, each group is a single-layer wood chip arranged vertically from the lower layer to the upper layer. (1) Blank slabs, bamboo mats, horizontally arranged single-layer woo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com