Novel elastic fabric

A new type of elastic fabric technology, applied in textile, clothing, application and other directions, can solve the problems of short service life of latex silk, easy aging, slow production speed of spandex yarn, slow manufacturing speed, etc. The effect of leveling and improving the grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

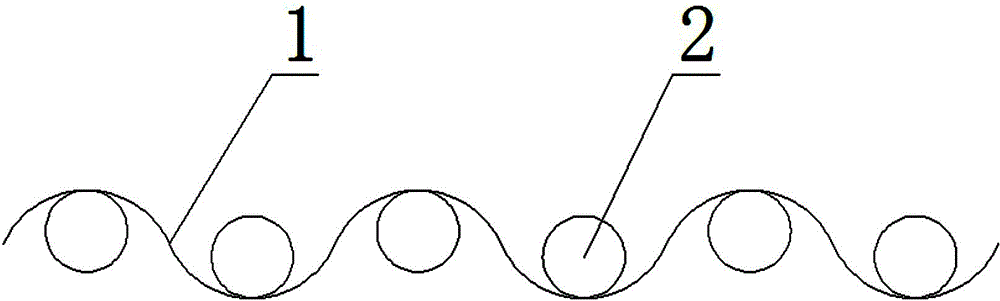

[0016] The new elastic fabric is composed of radial thread 1 and weft thread 2. The radial thread 1 is bi-component polyester filament PET / PTT, and the weft thread 2 is ordinary fiber containing low melting point fiber. The mass ratio of PTT to PET in the bicomponent polyester filament PET / PTT is 10%. The denier of the diameter line 1 is 30D. The mass ratio of low melting point fiber to polyester fiber is 60%. The count of weft 2 is 5 S . Diameter 1 and weft 2 interweave to form a plain weave structure.

[0017] The novel elastic fabric prepared in this example has a door width error of 0, a smooth surface, an elastic force of 220%, and an elastic loss of 1.7 cm. Elasticity loss refers to: when the finished product is pulled apart, after a certain point is pulled from 10cm to 20cm in length, the hand is released, and it rebounds to 11.7cm within 15 seconds.

Embodiment 2

[0019] The new elastic fabric is composed of radial thread 1 and weft thread 2. The radial thread 1 is bi-component polyester filament PET / PTT, and the weft thread 2 is ordinary fiber containing low melting point fiber. The mass ratio of PTT to PET in the bicomponent polyester filament PET / PTT is 30%. The fineness of diameter 1 is 150D. The mass ratio of the low-melting fiber to the polyester fiber, cotton fiber or polyester-cotton blended fiber is 45%. The count of weft 2 is 20 S . Diameter 1 and weft 2 interweave to form a twill structure.

[0020] The novel elastic fabric prepared in this example has a door width error of 0, a flat surface, an elastic force of 240%, and an elastic loss of 1.5 cm. Elasticity loss refers to: when the finished product is pulled apart, after a certain point is pulled from 10cm to 20cm in length, the hand is released, and it rebounds to 11.5cm within 15 seconds.

Embodiment 3

[0022] The new elastic fabric is composed of radial thread 1 and weft thread 2. The radial thread 1 is bi-component polyester filament PET / PTT, and the weft thread 2 is ordinary fiber containing low melting point fiber. The mass ratio of PTT to PET in the two-component polyester yarn PET / PTT is 50%. The fineness of diameter 1 is 250D. The mass ratio of the low-melting point fiber to the polyester fiber, cotton fiber or polyester-cotton blended fiber is 30%. The count of weft 2 is 40 S . Diameter 1 and weft 2 interweave to form a herringbone structure.

[0023] The novel elastic cloth prepared in this example has a door width error of 0, a smooth surface, an elastic force of 260%, and an elastic loss of 1.2 cm. Elasticity loss refers to: when the finished product is pulled apart, after a certain point is pulled from 10cm to 20cm in length, the hand is released, and it rebounds to 11.2cm within 15 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com