Fresh and beautiful multifunctional fabric and manufacturing method thereof

A multi-functional, fabric technology, applied in yarn, textile and papermaking, fiber processing, etc., can solve problems such as inducing cancer, melanin and pigmentation, endangering human health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

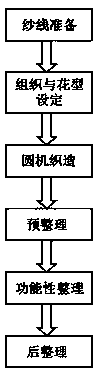

[0019] figure 1 It is a process step chart of the fresh and beautiful multifunctional fabric preparation method of the embodiment of the present invention; the multifunctional fabric is knitted from 22.4tex warp and weft yarns, and the warp and weft yarns are all intelligent temperature-regulating fiber / polyester / cotton fiber blended yarns , the preparation method includes the following steps: a) yarn preparation, b) weave and pattern setting, c) circular weaving, d) pre-finishing, e) functional finishing, f) post-finishing.

[0020] The fresh and beautiful multifunctional fabric mentioned in the present invention uses 22.4tex intelligent temperature-regulating fiber / polyester / cotton fiber blended yarn as the warp and weft yarn, and carefully sets the structure and pattern and optimizes the process parameters. 10cm, weft density 112 / 10cm knitted. Among them, the blending ratio of blended yarn is: intelligent temperature-regulating fiber 50%, polyester 20%, cotton fiber 30%....

Embodiment

[0022] The specific preparation method is as follows:

[0023] a) Yarn preparation, the yarn preparation process includes: spinning, winding, warping, and sizing. Among them, the spinning process parameters are: 4 channels and 8 drawing frames, the relative humidity of coarse sand is 75%, and the relative humidity of fine sand is 60%. Winding process parameters are: speed 900m / min, winding tension 7cN, short thick place 120%×2cm, long thick place 35%×35cm, long detail -35%×35cm. Warping process parameters are: speed 550m / min, tension scale 3.3, winding density 0.5g / cm 3 , workshop temperature 24 ℃, relative humidity 66%. The sizing process parameters are: size tank temperature 96°C, first squeeze roll pressure 9kN, second squeeze roll pressure 17kN, vehicle speed 50m / min, sizing rate 12%, moisture regain 10%, slurry pH 7.5.

[0024] b) Tissue and pattern setting, using black and white flower pattern and plain ground warp flowering tissue, with black tone as the base, white ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com