Jianzhan firing process

A kind of technology and green body technology, which is applied in the field of Jianzhan firing technology, can solve the problems of low yield rate and achieve the effect of high yield rate, sufficient combustion and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

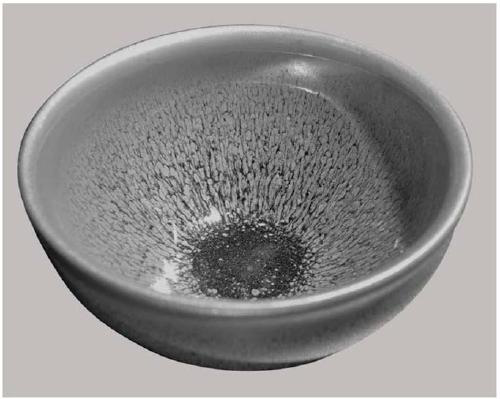

Image

Examples

Embodiment 1

[0032] Jianzhan firing process includes the following steps:

[0033] (1) Provide body raw materials and glaze slurry, among which,

[0034] The raw material of the green body is prepared by the following method: 3 parts by weight of white clay, 3 parts by weight of red clay and 3 parts by weight of red clay are mixed, crushed, washed, passed through an 80-mesh sieve, settled, bagged, filtered and stale , Get the raw material of the green body;

[0035] The glaze slurry is prepared by the following method: mixing 10 parts by weight of glaze ore and 10 parts by weight of water, grinding with a ball mill for 2 hours, and adding 0.225 parts by weight of talc, 0.275 parts by weight of limestone, 0.09 parts by weight of bovine ashes, and 0.06 parts by weight. Parts by weight of iron red, 0.225 parts by weight of potash feldspar, 0.3 parts by weight of clay and 0.10 parts by weight of plant ash, grind for another 2 hours, pass through an 80-mesh sieve to obtain a glaze slurry;

[0036] (2)...

Embodiment 2

[0048] Jianzhan firing process includes the following steps:

[0049] (1) Provide body raw materials and glaze slurry, among which,

[0050] The raw material of the green body is prepared by the following method: 4 parts by weight of white clay, 2.5 parts by weight of red clay and 3.6 parts by weight of red clay are mixed, crushed, elutriated, passed through an 85-mesh sieve, settled, bagged, filtered, and aged , Get the raw material of the green body;

[0051] The glaze slurry is prepared by the following method: mixing 11 parts by weight of glaze ore and 12 parts by weight of water, grinding by a ball mill for 2.3 hours, and then adding 0.25 parts by weight of talc, 0.25 parts by weight of limestone, 0.95 parts by weight of bovine ashes, 0.05 parts by weight of iron red, 0.25 parts by weight of potash feldspar, 0.28 parts by weight of clay, and 0.15 parts by weight of plant ash, then grind for 2.5 hours and pass through a 90-mesh sieve to obtain a glaze slurry;

[0052] (2) Refinin...

Embodiment 3

[0064] Jianzhan firing process includes the following steps:

[0065] (1) Provide body raw materials and glaze slurry, among which,

[0066] The raw material of the green body is prepared by the following method: mixing 3.5 parts by weight of white clay, 3.5 parts by weight of red clay and 2.8 parts by weight of red clay, mixing, pulverizing, elutriating, passing through an 80-mesh sieve, precipitating, bagging, filtering, and aging , Get the raw material of the blank;

[0067] The glaze slurry is prepared by the following method: mixing 12 parts by weight of glaze ore, 11 parts by weight of water, grinding by a ball mill for 2.5 hours, then adding 0.24 parts by weight of talc, 0.30 parts by weight of limestone, 0.10 parts by weight of bovine ashes, 0.07 parts by weight of iron red, 0.23 parts by weight of potash feldspar, 0.33 parts by weight of clay and 0.12 parts by weight of plant ash, and then grind for 2.2 hours, pass through a 100-mesh sieve to obtain a glaze slurry;

[0068] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com