Ornament attaching structure and method

A veneer and bonding technology, which is applied in the field of veneer bonding structure, can solve the problems of needing punching, easy falling off at the joint, and easy falling off, so as to improve the bonding firmness, the overall pattern is beautiful, and the design is scientific and reasonable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

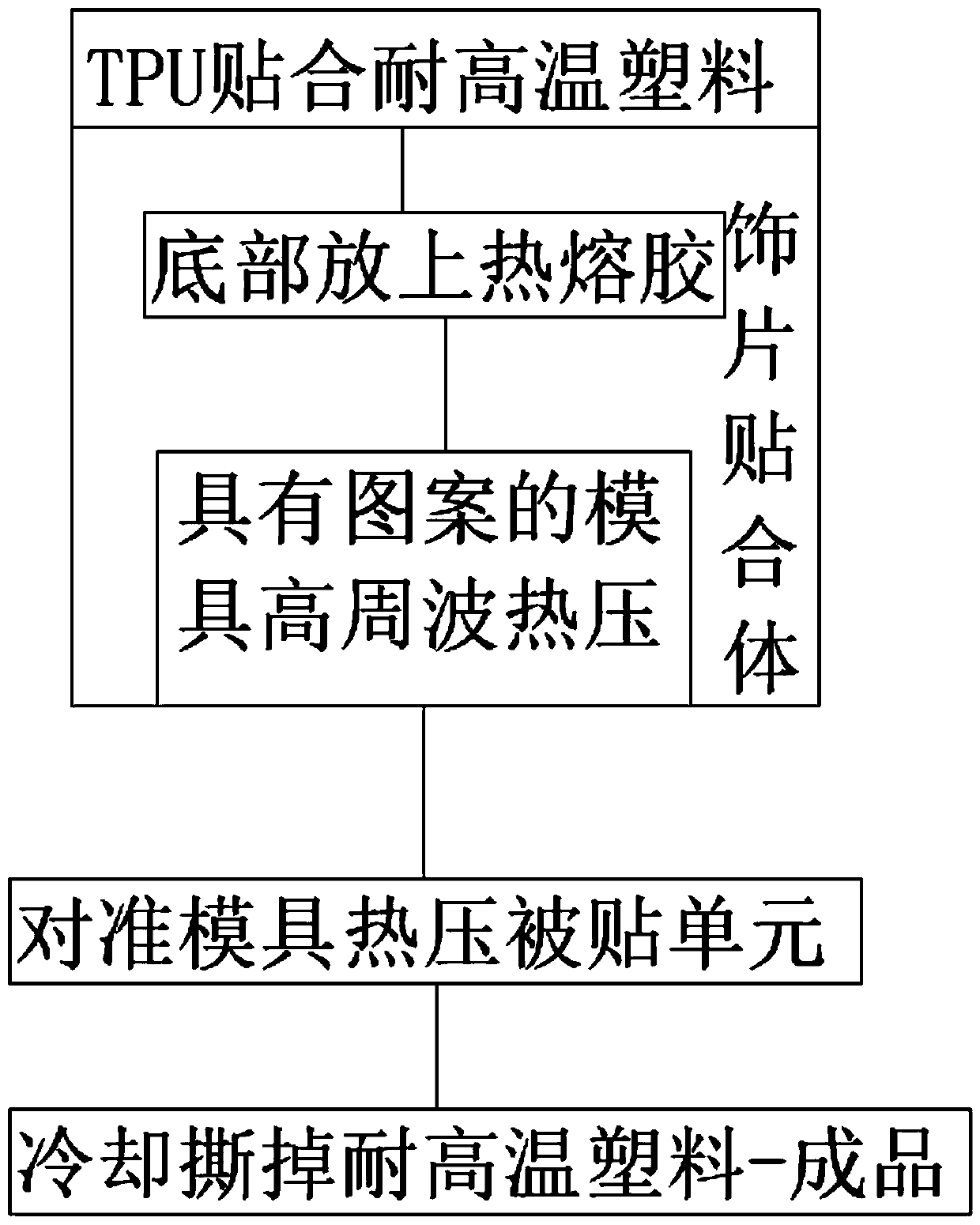

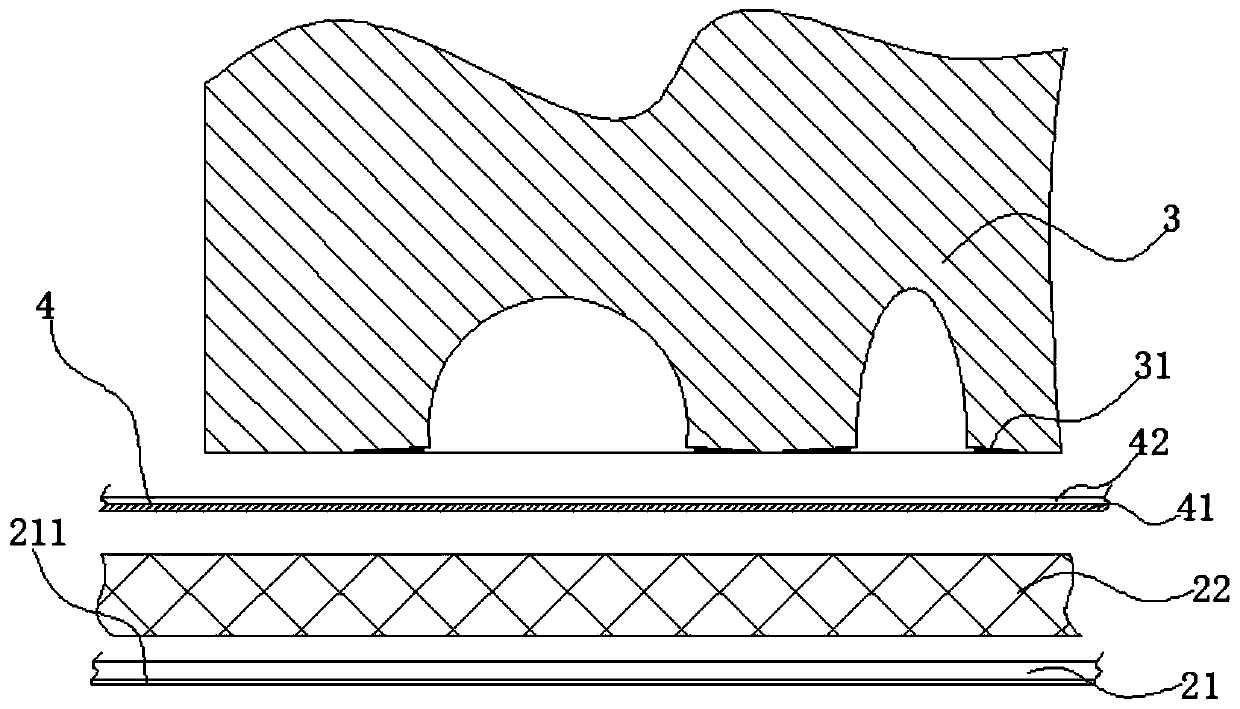

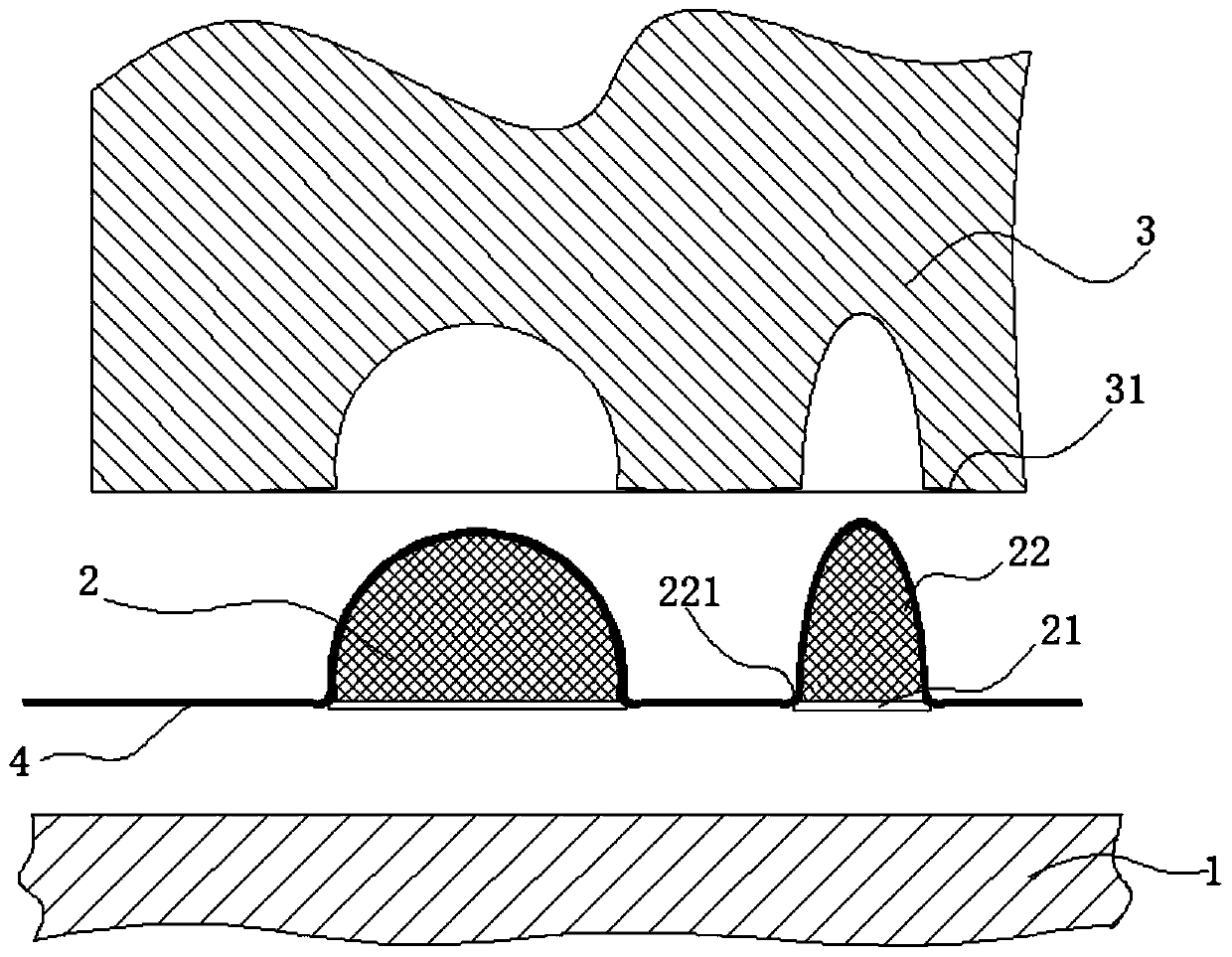

[0050] Such as Figure 1 to Figure 3 Shown, a kind of veneer bonding method, comprises the following steps:

[0051] 1) Paste high-temperature-resistant plastic on one side of TPU or PVC. When pasting high-temperature-resistant plastic, it is necessary to drive out the internal air bubbles; paste high-temperature hot-melt adhesive on the other side of TPU or PVC;

[0052] 2) Hot-pressing the high-temperature-resistant plastic in step 1) with a high-frequency wave on a mold with a pattern, and tearing off excess high-temperature hot-melt adhesive to obtain a patterned veneer body;

[0053] 3) Place the veneer fitting body on the pasted unit, align it with the patterned mold, he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com