Production method of one-off directly filling seamless knitted down feather fabric

A technology of seamless knitting and down fabrics, applied in the field of textile fabrics, can solve the problems of increased labor intensity, unsightly appearance, and insufficient fluffiness, and achieve the effects of good windproof and waterproof performance, fluffy and warm-keeping performance, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

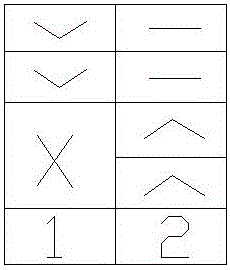

Image

Examples

Embodiment 1

[0019] A production method of one-time direct filling seamless knitted down fabric, firstly knitting with 50D / 72F polyester low elastic yarn on a knitting computer jacquard double-faced machine to obtain a gray cloth, and then washing the gray cloth with high temperature, dyeing, and shaping to obtain The semi-finished product is laminated with a waterproof, breathable and moisture-permeable polyurethane elastic film, cut into pieces, and then when the cut pieces are sewed, a down-filling tube is left to fill the down, and finally a direct-filled seamless knitted down fabric is obtained. The process of obtaining semi-finished products specifically includes the following steps:

[0020] 1) High-temperature water washing: put the gray cloth after opening into the dyeing vat for washing, add 1.5g / L soda ash and 1.5g / L detergent in the water, the bath ratio is 1:12, and the treatment temperature is 110°C. The treatment time is 25 minutes. The high-temperature washing is mainly to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com