Manufacturing method of 3D three-dimensional vertical bubble wrinkle weft elastic fabric

A production method and a wrinkle-weft elastic technology are applied in the production field of 3D vertical bubble wrinkle-weft elastic fabrics, which can solve the problems of low-grade fabrics, easy lint loss in flocking process, poor three-dimensional sense of fabrics, etc. Uniform pattern, excellent waterproof and windproof effect, good elasticity and recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The manufacturing method of the 3D three-dimensional vertical bubble wrinkled weft elastic fabric comprises the following steps:

[0034] Step 1, gray cloth weaving: fabric design:

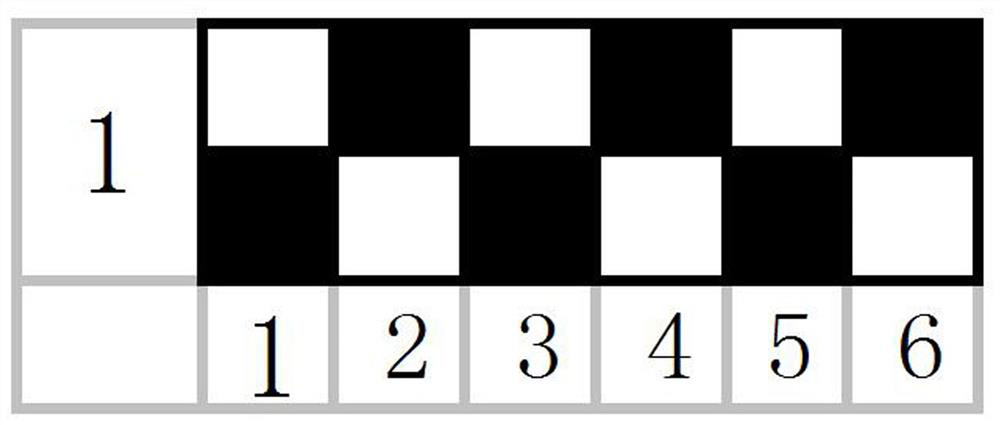

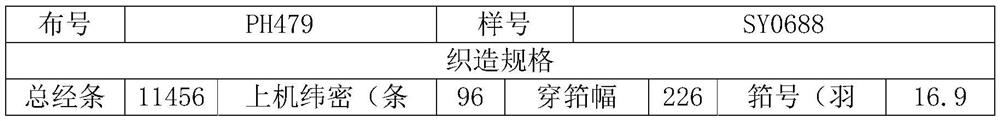

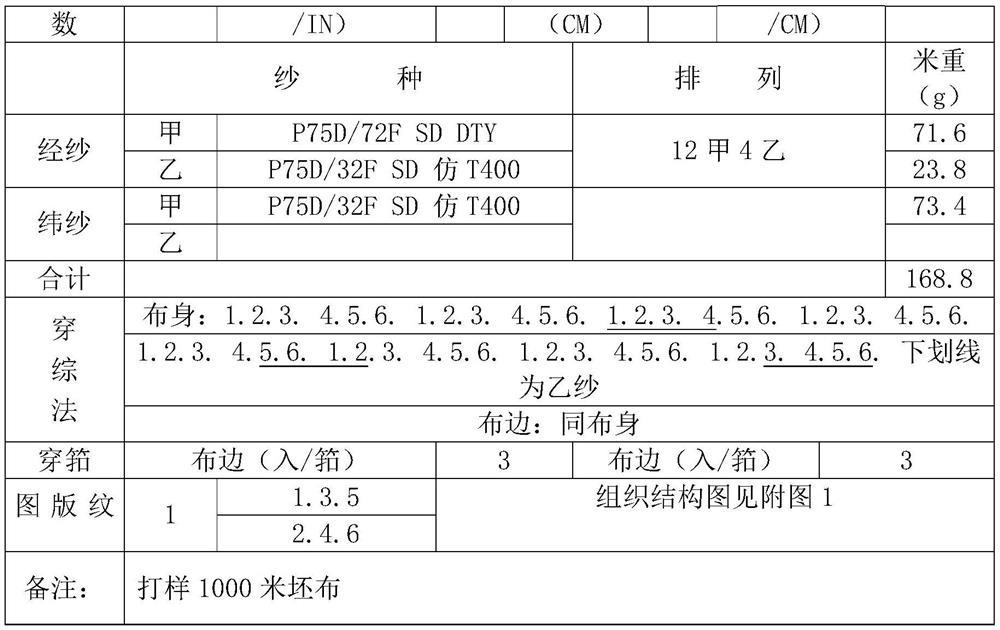

[0035] a. Fabric design: first design the craft form of 3D three-dimensional vertical bubble wrinkle weft elastic fabric, first calculate the total number of pan head 140×208÷2.54≈11456 (calculation formula warp density×full width÷2.54), and then Calculate the weft density of the upper machine is 99× (1-3%) ≈ 96 pieces (grain weft density × (1-weaving shrinkage)), if the width of the upper machine is 226CM, then the reed number is 11456÷226÷3=16.9 feathers , the gray fabric process is shown in Table 1, and the organizational structure diagram is shown in figure 1 shown.

[0036] b. Warping: first estimate the number of yarns and the amount of yarns needed to weave 1000 meters of gray cloth, then the required warping length is 1000 × (1+10% (loss)) = 1100 meters, each needing warping The ...

Embodiment 2

[0056] The manufacturing method of the 3D three-dimensional vertical bubble wrinkled weft elastic fabric comprises the following steps:

[0057] Step 1, gray cloth weaving: fabric design:

[0058] a. Fabric design: first design the craft form of 3D three-dimensional vertical bubble wrinkle weft elastic fabric, first calculate the total number of pan head 140×208÷2.54≈11456 (calculation formula warp density×full width÷2.54), and then Calculate the weft density of the upper machine is 99× (1-3%) ≈ 96 pieces (grain weft density × (1-weaving shrinkage)), if the width of the upper machine is 226CM, then the reed number is 11456÷226÷3=16.9 feathers , the gray fabric process is shown in Table 1, and the organizational structure diagram is shown in figure 1 shown.

[0059] b. Warping: first estimate the number of yarns and the amount of yarn needed to weave 1000 meters of gray cloth, then the required warping length is 1000 × (1+10% (loss)) = 1100 meters, each needing warping The n...

Embodiment 3

[0078] The manufacturing method of the 3D three-dimensional vertical bubble wrinkled weft elastic fabric comprises the following steps:

[0079] Step 1, gray cloth weaving: fabric design:

[0080] a. Fabric design: first design the craft form of 3D three-dimensional vertical bubble wrinkle weft elastic fabric, first calculate the total number of pan head 140×208÷2.54≈11456 (calculation formula warp density×full width÷2.54), and then Calculate the weft density of the upper machine is 99× (1-3%) ≈ 96 pieces (grain weft density × (1-weaving shrinkage)), if the width of the upper machine is 226CM, then the reed number is 11456÷226÷3=16.9 feathers , the gray fabric process is shown in Table 1, and the organizational structure diagram is shown in figure 1 shown.

[0081] b. Warping: first estimate the number of yarns and the amount of yarn needed to weave 1000 meters of gray cloth, then the required warping length is 1000 × (1+10% (loss)) = 1100 meters, each needing warping The n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com